Technical Contents

Engineering Guide: Professional 3D Printing Services

Engineering Insight: Precision as the Non-Negotiable Core of Professional Metal 3D Printing

In the realm of high-performance metal additive manufacturing, achieving dimensional accuracy and repeatability isn’t merely desirable—it is the absolute foundation of functional part integrity. Professional 3D printing services for critical aerospace, medical, and defense applications demand tolerances measured in microns, not millimeters. Sub-micron layer consistency, thermal management precision, and post-processing control directly dictate fatigue life, assembly fit, fluid dynamics, and ultimately, the safety and performance of the final component. Compromising on precision leads to scrap, costly rework, field failures, and eroded trust—risks no responsible engineer or procurement leader can accept when lives or mission success depend on the part.

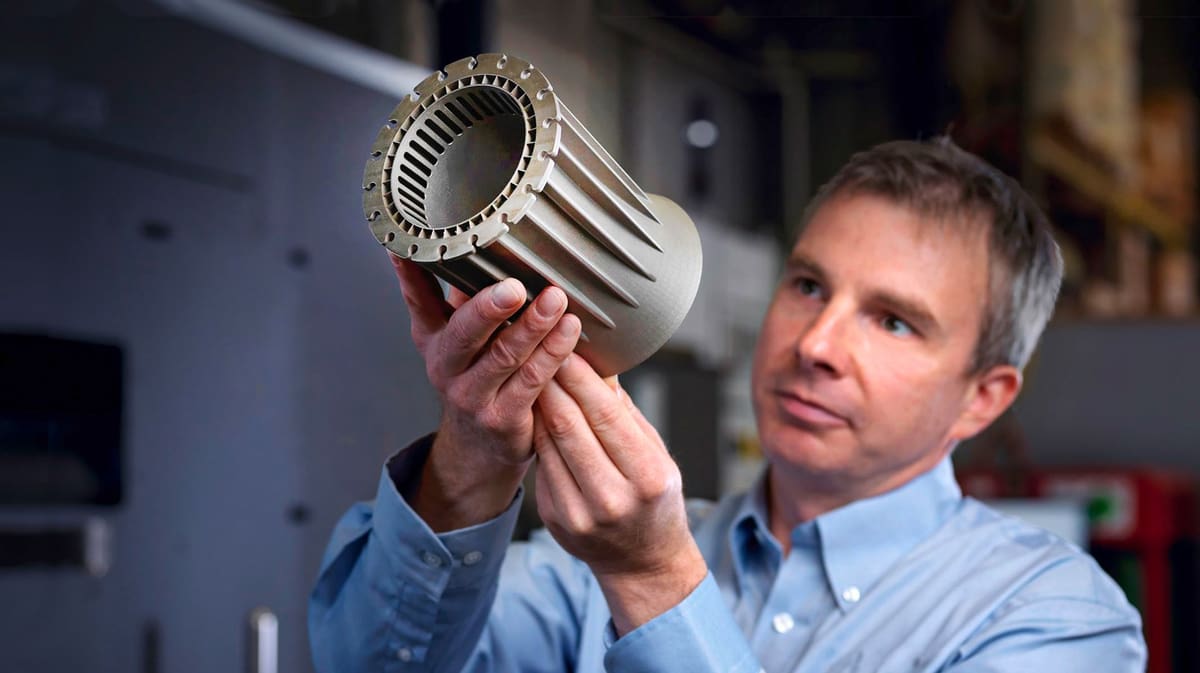

At Wuxi Lead Precision Machinery, our engineering philosophy treats precision as a non-negotiable parameter, rigorously controlled from digital design through final inspection. Our decade-long specialization in custom metal manufacturing, particularly for sectors where failure is not an option, has forged our approach. We integrate advanced in-situ monitoring systems within our industrial-grade metal printers, continuously tracking melt pool dynamics and environmental conditions. This data feeds directly into adaptive control algorithms, dynamically correcting for thermal distortion in real-time—a capability essential for producing complex geometries like conformal cooling channels or thin-walled aerospace brackets without warpage. Crucially, printing is only the first step; our vertically integrated facility ensures precision continues through mandatory CNC post-processing and metrology. Every critical feature undergoes verification on calibrated CMMs and optical comparators, guaranteeing adherence to ISO 2768-mK or customer-specified geometric tolerances before shipment.

Our commitment to uncompromising precision is validated by the most demanding applications. We engineered and delivered titanium lattice structures for the aerodynamic components of China’s official bobsled team at the Beijing 2022 Winter Olympics, where aerodynamic efficiency down to 0.01mm deviations directly impacted medal contention. Simultaneously, our facility consistently produces mission-critical components for defense systems, where adherence to MIL-STD specifications underpins operational reliability. This dual validation—Olympic podium performance and military-grade dependability—proves our process control transcends standard industry benchmarks.

The following table outlines the precision capabilities achievable within our professional metal 3D printing service framework, reflecting our engineering standards for high-value applications:

| Parameter | Standard Capability | High-Precision Capability | Key Enablers |

|---|---|---|---|

| Layer Thickness | 20-50 µm | 15-30 µm | Dual 700W fiber lasers, closed-loop monitoring |

| Dimensional Tolerance | ±0.1 mm | ±0.02 mm | Inert gas control, thermal compensation algo |

| Surface Roughness (as-built) | Ra 12-25 µm | Ra 6-10 µm | Optimized scan strategies, powder management |

| Critical Feature Accuracy | ±0.05 mm | ±0.01 mm | Integrated CNC finishing, CMM verification |

| Supported Materials | Ti-6Al-4V, AlSi10Mg, 316L, Inconel 718 | Same + CoCr, Maraging Steel | Vacuum sieving, certified material batches |

Precision in professional metal 3D printing is not an incremental advantage; it is the threshold for entry into mission-critical manufacturing. Wuxi Lead Precision Machinery’s engineering discipline, proven under Olympic and military scrutiny, ensures your complex metal components meet the exacting standards required for real-world performance and reliability. When microns define success, partner with a manufacturer where precision is engineered, not estimated.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Precision Metal Components

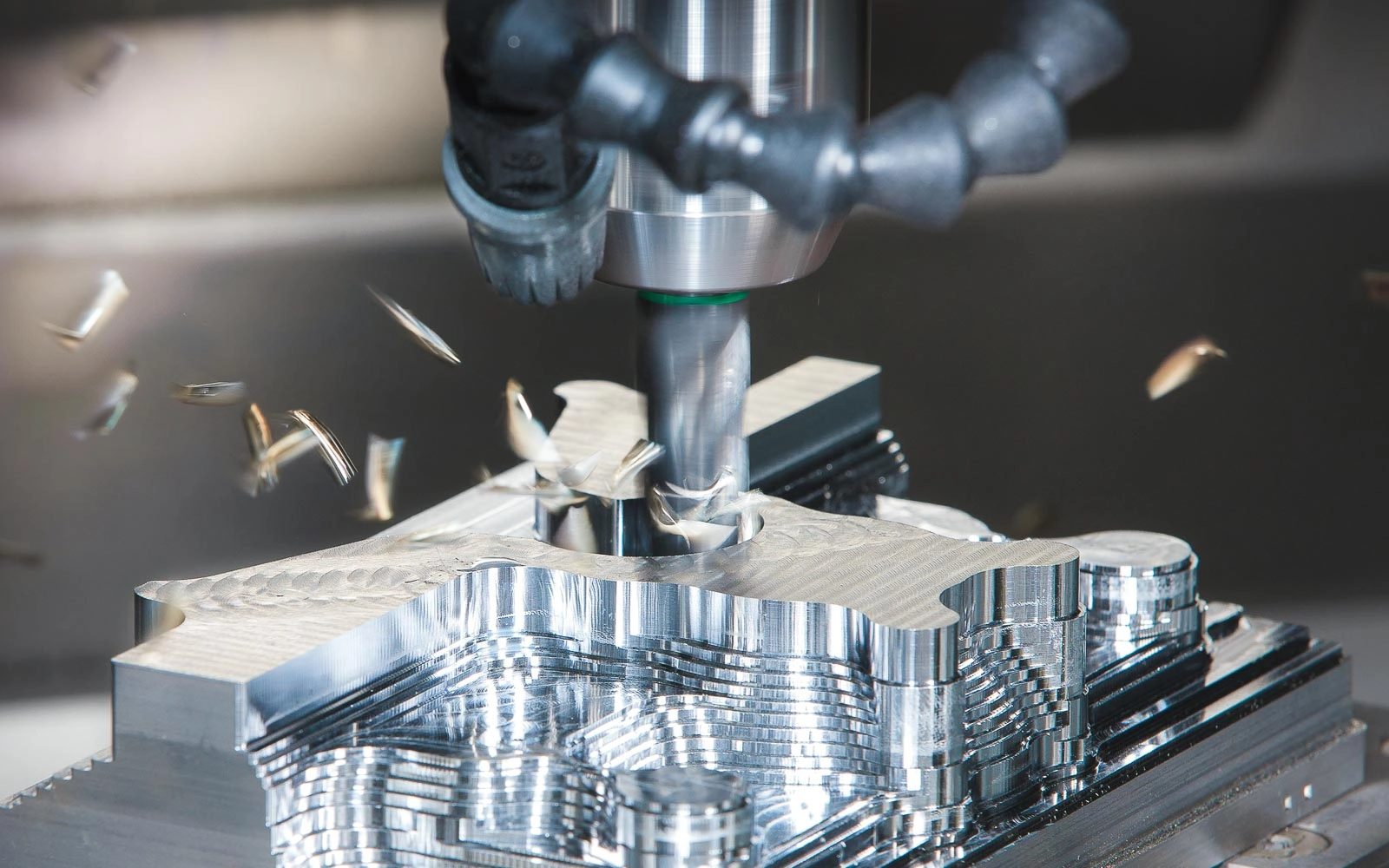

At Wuxi Lead Precision Machinery, our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to deliver complex, high-precision metal components for mission-critical industries such as aerospace, medical, energy, and advanced automation. Our 5-axis machining centers provide simultaneous multi-directional cutting, allowing for intricate geometries and tight-tolerance features that are unattainable with conventional 3-axis systems. This level of precision reduces the need for multiple setups, minimizes human error, and ensures superior surface finishes and part consistency across both prototyping and high-volume production runs.

Our machines are equipped with high-speed spindles, advanced tool management systems, and real-time monitoring software, ensuring optimal performance and material removal rates across a wide range of metals—including titanium, Inconel, stainless steel, aluminum alloys, and tool steels. The integration of CAD/CAM programming with digital twin simulation allows us to validate toolpaths and detect potential collisions before any material is cut, significantly reducing lead times and enhancing process reliability.

To maintain the highest standards of quality, every component undergoes rigorous inspection using our Coordinate Measuring Machine (CMM) system. This metrology-grade equipment provides micron-level accuracy in verifying dimensional conformity, geometric tolerances, and surface integrity. Our CMM inspection process is fully automated and aligned with ISO 10360 standards, ensuring traceability and compliance with international quality requirements. Inspection reports are provided with each batch, offering full transparency and documentation for customer audits and regulatory submissions.

Our technical team consists of certified CNC programmers, tooling engineers, and quality control specialists with extensive experience in high-precision manufacturing. They work collaboratively to optimize part design for manufacturability, select appropriate materials and cutting strategies, and ensure that every component meets or exceeds customer specifications.

The following table outlines our standard machining capabilities and achievable tolerances:

| Specification | Capability |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Work Envelope (Max) | 1200 mm × 800 mm × 750 mm |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances (Machined) | ±0.01 mm |

| Tight Tolerances (Precision) | ±0.005 mm |

| Surface Roughness (Typical) | Ra 0.8 µm |

| Surface Roughness (Fine Finish) | Ra 0.4 µm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Tool Steel, Brass |

| Quality Assurance | CMM Inspection, First Article Inspection, PPAP, FAI Reports |

With integrated digital workflows, precision equipment, and a disciplined quality management system, Wuxi Lead Precision Machinery ensures that every custom metal part is manufactured to the highest technical standards, delivering performance, reliability, and consistency for the most demanding applications.

Material & Finish Options

Material Selection for Professional Metal 3D Printing

Selecting the optimal material is paramount for achieving functional success and economic efficiency in metal additive manufacturing. At Wuxi Lead Precision Machinery, our engineering expertise ensures your application requirements drive the material choice, balancing mechanical properties, environmental resistance, manufacturability, and post-processing needs. Aluminum, steel, and titanium alloys dominate industrial applications, each offering distinct advantages for specific use cases. Understanding their core characteristics is essential for design validation and part performance.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components requiring good thermal conductivity and moderate strength. They excel in aerospace brackets, heat exchangers, and automotive housings where weight reduction is critical. While offering less ultimate strength than steel or titanium, aluminum provides excellent castability in the AM process and is highly responsive to anodizing for enhanced surface protection and aesthetics. Steel alloys, especially maraging steel (18Ni300) and 316L stainless steel, deliver superior strength, hardness, and wear resistance. Maraging steel is the go-to for high-stress tooling, injection molds, and aerospace fixtures demanding exceptional fatigue life. 316L stainless steel provides excellent corrosion resistance, making it ideal for marine components, chemical processing parts, and medical devices requiring biocompatibility. Titanium alloys, primarily Ti6Al4V (Grade 5), offer the highest strength-to-weight ratio and outstanding corrosion resistance, particularly in saline or high-temperature environments. This makes them indispensable for critical aerospace components, biomedical implants, and high-performance automotive parts where failure is not an option.

Material performance must be evaluated against specific project demands. The following table summarizes key comparative specifications for common industrial AM metals:

| Material | Key Properties | Common Grades | Typical Applications |

|---|---|---|---|

| Aluminum | Lightweight, Good thermal conductivity, Moderate strength, Excellent machinability | AlSi10Mg | Aerospace brackets, Heat sinks, Enclosures |

| Steel | High strength, Excellent hardness, Good wear resistance | 18Ni300, 316L | Tooling, Molds, High-stress fixtures |

| Titanium | Highest strength-to-weight ratio, Exceptional corrosion resistance, Biocompatible | Ti6Al4V (Grade 5) | Aerospace components, Medical implants |

Surface finishing, particularly anodizing, significantly enhances aluminum parts. Type II (sulfuric acid) anodizing provides good corrosion resistance and dye acceptance for identification or branding. For demanding applications requiring maximum wear resistance and electrical insulation, Type III (hard coat) anodizing is essential. Our integrated finishing capabilities ensure precise control over coating thickness, hardness, and appearance, meeting stringent aerospace and medical standards. Wuxi Lead Precision Machinery leverages deep material science knowledge and advanced AM systems to select, process, and finish your chosen alloy optimally. Contact our engineering team to discuss how precise material and finish selection can elevate your next metal 3D printing project from prototype to high-performance production reality.

Manufacturing Process & QC

Design Phase: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process for professional 3D printing services begins with a rigorously validated design phase. Our engineering team collaborates directly with clients to analyze CAD models, ensuring geometric feasibility, material compatibility, and structural integrity under operational loads. Finite Element Analysis (FEA) and thermal simulation tools are employed to predict performance and identify potential stress concentrations or deformation risks. This stage incorporates Design for Additive Manufacturing (DfAM) principles, optimizing part topology to reduce weight, eliminate unnecessary material, and enhance functional performance—all while maintaining dimensional accuracy and manufacturability. Every design is reviewed against ISO 13485 and AS9100 standards where applicable, ensuring compliance with aerospace, medical, and industrial requirements.

Prototyping: Validating Performance Before Scale

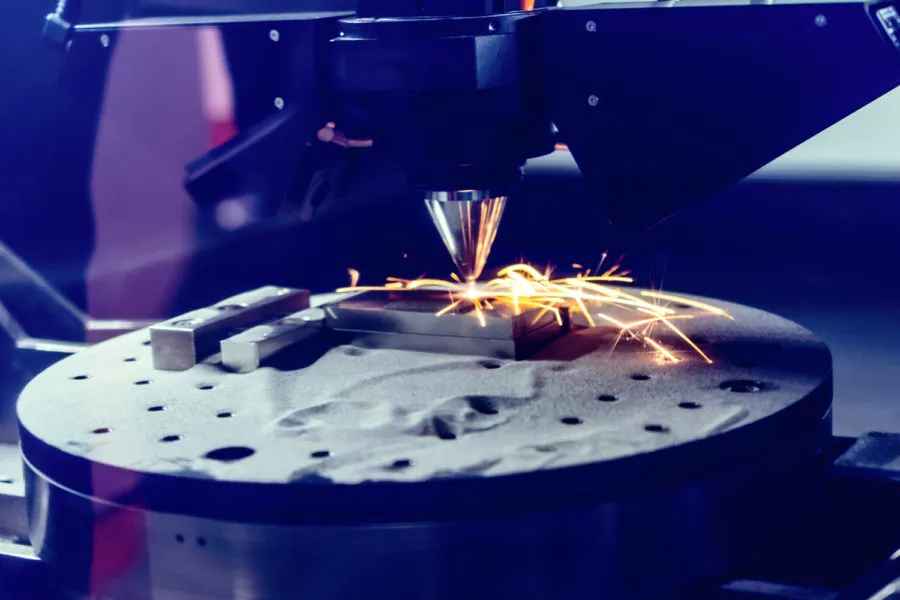

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art metal additive systems, including SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering). Prototypes are produced in the same material intended for mass production—ensuring accurate representation of mechanical properties, surface finish, and thermal behavior. Each prototype undergoes comprehensive metrology inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional conformance within ±0.02 mm. Functional testing, including pressure cycling, fatigue analysis, and non-destructive testing (NDT), confirms real-world performance. Iterations are swiftly implemented based on test data, minimizing time-to-refinement and ensuring the final design is production-ready with zero compromise on quality.

Mass Production: Industrial-Grade Consistency with Zero Defects

Our transition to mass production is governed by a Zero Defects Manufacturing (ZDM) framework. Each build is executed on calibrated industrial 3D printers operating in controlled environments with real-time atmosphere monitoring (oxygen levels < 100 ppm). In-process monitoring via melt pool sensors and layer-wise imaging enables immediate anomaly detection and corrective action. Post-build, components undergo stress relief,热处理 (heat treatment), and precision machining as required. Surface finishing options—including shot peening, polishing, and coating—are applied to meet functional or regulatory needs.

All parts are 100% inspected using automated optical inspection (AOI) and industrial CT scanning where needed. Final quality documentation includes full traceability of material lot, build parameters, and inspection reports, ensuring compliance with ISO 9001 and IATF 16949 standards.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Materials | Stainless Steel 316L, Inconel 718, Ti-6Al-4V, AlSi10Mg, Tool Steel (Maraging), Cobalt-Chrome |

| Layer Thickness | 20–60 μm |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 8–12 μm; down to Ra 0.8 μm post-finishing |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Passivation, Coating |

| Quality Standards | ISO 9001, IATF 16949, ISO 13485 (on request) |

Through disciplined execution across design, prototyping, and production, Wuxi Lead ensures every component meets the highest standards of precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Metal Manufacturing with Precision Engineering

Wuxi Lead Precision Machinery delivers industrial-grade metal 3D printing solutions engineered for mission-critical applications. Our additive manufacturing services bridge the gap between complex design intent and functional reality, serving aerospace, medical, energy, and defense sectors where tolerances are non-negotiable. We transform digital models into high-integrity metal components using certified materials and rigorously validated processes, eliminating traditional constraints of casting or machining. Partner with us to solve challenges in topology-optimized structures, lightweighting, and rapid prototyping of end-use parts—without compromising on repeatability or material performance.

Our technical capabilities are anchored in state-of-the-art equipment and metallurgical expertise. The table below outlines core specifications for our metal additive production:

| Parameter | Specification Detail |

|---|---|

| Materials | Inconel 718/625, Titanium Ti-6Al-4V, Stainless Steel 316L/17-4PH, Aluminum AlSi10Mg, Cobalt Chrome |

| Build Volume | Up to Ø250 x 325 mm (EOS M 400-4) / Ø300 x 400 mm (SLM Solutions NXG XII) |

| Layer Thickness | 20–60 μm (adjustable by application) |

| Dimensional Accuracy | ±0.05 mm for features < 50 mm; ±0.1% for larger geometries |

| Surface Finish | As-built: Ra 12–25 μm; Post-processed: Ra 0.8–3.2 μm |

| Post-Processing | Stress relief, HIP, CNC machining, precision polishing, metrology (CT scanning, CMM) |

| Lead Time | Prototypes: 7–10 days; Production batches: 15–25 days |

What distinguishes Lead Precision is our integrated engineering workflow. We begin with design-for-additive manufacturing (DfAM) consultation to optimize part geometry for strength, weight, and manufacturability. Every build undergoes in-process monitoring via melt pool analysis and thermal imaging, ensuring defect-free layer consolidation. Post-build, components progress through our NADCAP-accredited finishing suite, where proprietary heat treatments and precision machining achieve aerospace-grade surface integrity. Our quality management system adheres to ISO 9001:2015 and AS9100D standards, with full material traceability and first-article inspection reports provided for every order.

Global OEMs trust us to de-risk their supply chains through responsive engineering collaboration. Our team of metallurgists and CNC specialists works alongside your engineers from concept validation through serial production, offering iterative feedback to accelerate time-to-market. Whether you require low-volume complex assemblies or high-reliability spare parts, we provide scalable capacity without outsourcing dependencies—backed by 15 years of precision manufacturing heritage in Wuxi’s advanced industrial corridor.

Initiate your next breakthrough project with a partner committed to engineering excellence. Contact our technical sales team to discuss material certifications, process validation protocols, or request a confidential design review. Send your requirements to [email protected] for a tailored proposal within 24 business hours. Let Lead Precision become your strategic extension in metal additive innovation—where precision is non-negotiable and performance is guaranteed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.