Technical Contents

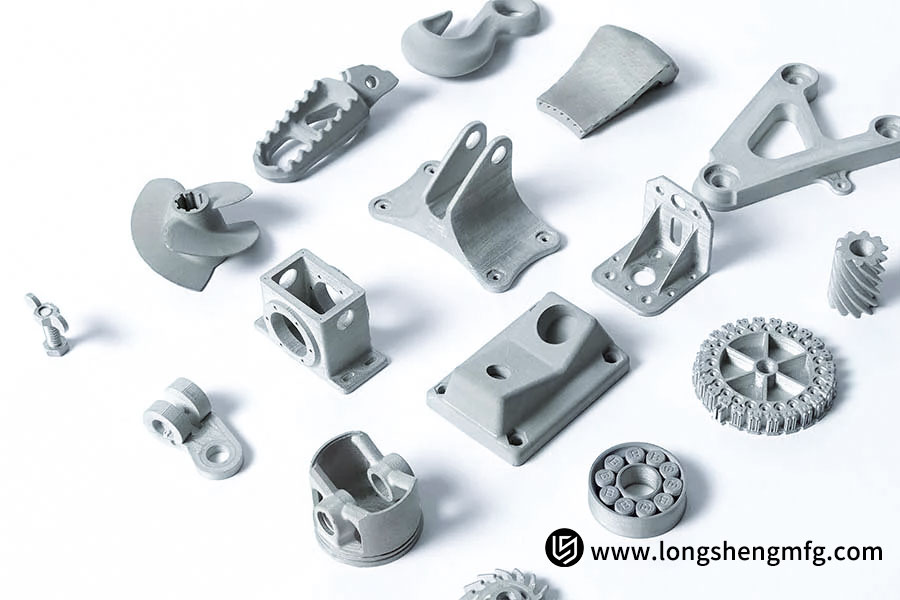

Engineering Guide: Fast 3D Printing Service

Engineering Insight: Precision as the Non-Negotiable Core of Fast Metal 3D Printing

Speed in metal additive manufacturing delivers undeniable supply chain advantages, but velocity without uncompromising precision is a costly illusion for critical applications. In high-stakes sectors like aerospace, defense, and advanced medical devices, dimensional accuracy, material integrity, and repeatability are paramount. A component printed rapidly but failing to meet micron-level tolerances or exhibiting inconsistent mechanical properties introduces risk far exceeding any time savings. True value in fast 3D printing service lies not merely in rapid layer deposition, but in the rigorous engineering discipline ensuring every part meets exacting specifications on the first build. At Wuxi Lead Precision Machinery, we define speed through the lens of reliable throughput – delivering certified, mission-ready components predictably, without sacrificing the precision demanded by our most exacting clients.

Achieving this balance requires deep integration of process science, advanced metrology, and material expertise across the entire workflow. It begins with validated parameter sets for each alloy, meticulously developed through thousands of builds and destructive testing. Inert gas purification systems maintain oxygen levels below 25 ppm during printing to prevent oxidation and ensure material homogeneity. Real-time melt pool monitoring with high-speed thermal imaging detects anomalies instantly, triggering automatic corrections. Crucially, precision extends beyond the build chamber. Our proprietary post-processing protocols, including stress-relief annealing in vacuum furnaces and multi-axis precision machining, are calibrated to hold tolerances often tighter than the as-printed state. Statistical process control (SPC) is embedded at every stage, with full traceability from raw powder lot to finished part certification.

The necessity of this precision-first approach is proven in applications where failure is not an option. Wuxi Lead has successfully delivered components for the Beijing Winter Olympics infrastructure, requiring sub-10μm surface finishes and perfect geometric conformity under extreme cold. Similarly, our work supporting Chinese military programs demands adherence to stringent MIL-STD-810 specifications for vibration resistance and dimensional stability in harsh environments. These projects underscore that speed only matters when the output is guaranteed to perform. Below is a comparison of critical precision parameters achievable through our integrated process versus typical industry benchmarks:

| Parameter | Industry Standard (Fast Track) | Wuxi Lead Precision Standard | Validation Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.02 mm | CMM (ISO 10360-2 Certified) |

| Surface Roughness (Ra) | 10-15 μm | 1.6-3.2 μm (As-Built) | Profilometer (ISO 4287) |

| Material Density | 98-99.5% | >99.95% | Archimedes, Micro-CT |

| Mechanical Property CV | 8-12% | <4% | Tensile Testing (ASTM E8) |

| Geometric Deviation | ±0.2% of feature size | ±0.05% | GD&T Analysis (ASME Y14.5) |

For engineering teams evaluating fast 3D printing partners, prioritize providers whose speed is demonstrably anchored in metrology and process control, not just machine uptime. Wuxi Lead Precision Machinery’s decade of experience delivering for Olympic and defense projects provides the proven framework to transform rapid prototyping into reliable, high-integrity production. Contact our engineering team to discuss how our precision-driven fast printing service ensures your critical metal components arrive on time – and perform flawlessly.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for industries demanding precision, reliability, and rapid turnaround. At the core of our technical capabilities is a fully integrated suite of 5-axis CNC machining centers, enabling us to produce highly complex geometries with exceptional accuracy. These state-of-the-art machines allow simultaneous multi-axis movement, minimizing setup requirements and ensuring superior surface finishes on intricate components. Our 5-axis technology supports a wide range of metals, including aluminum alloys, stainless steel, titanium, and high-performance superalloys, making it ideal for aerospace, medical, automotive, and energy sector applications.

Precision is non-negotiable in high-end manufacturing, which is why every component undergoes rigorous quality control using coordinate measuring machine (CMM) inspection. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceable and repeatable measurement results. This closed-loop inspection process verifies dimensional accuracy across critical features, confirming that each part conforms precisely to engineering specifications. Full inspection reports are provided upon request, offering clients complete transparency and compliance with ISO and AS standards.

Our manufacturing workflow is optimized for speed without compromising quality. Leveraging digital twin simulation and adaptive machining strategies, we reduce cycle times and eliminate potential errors before cutting metal. This enables us to offer fast 3D printing service alternatives through high-speed CNC machining—ideal for functional prototypes, bridge production, and low-volume custom runs. Unlike additive methods that may introduce porosity or anisotropic material behavior, our subtractive process ensures full-density, structurally sound components with certified mechanical properties.

Material selection, toolpath optimization, and in-process probing are all managed within a unified digital environment, allowing seamless transition from CAD model to finished part. We support tight tolerance machining, fine surface finishes, and complex feature integration such as cooling channels, thin walls, and undercuts—all within a single setup when possible. Our facility operates under strict environmental and process controls to maintain consistency across batches, whether producing one-off prototypes or scaled production runs.

The following table outlines our standard technical specifications and achievable tolerances:

| Feature | Specification |

|---|---|

| Maximum Work Envelope (5-axis) | 1,200 mm × 800 mm × 600 mm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (milled features) | ±0.010 mm |

| Tight Tolerance Capability | ±0.005 mm (with inspection) |

| Surface Roughness (Ra) | As low as 0.4 µm (polished to 0.1 µm available) |

| Minimum Wall Thickness | 0.5 mm (aluminum), 0.8 mm (steel/titanium) |

| Supported Materials | Aluminum 6061, 7075; Stainless Steel 304, 316, 17-4 PH; Titanium Ti-6Al-4V; Inconel 718, 625; Tool Steels |

| Inspection Equipment | Zeiss and Hexagon CMMs, 3D scanning, optical comparators |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade verification to deliver custom metal parts that meet the most stringent engineering demands. Our fast, precision-driven approach ensures clients receive high-performance components on schedule, every time.

Material & Finish Options

Material Selection for High-Speed Metal Additive Manufacturing

Material choice directly impacts part performance, production speed, and total cost in metal additive manufacturing. At Wuxi Lead Precision Machinery, we prioritize materials that balance rapid build rates with stringent industrial requirements. Aluminum alloys, stainless steels, and titanium dominate aerospace, medical, and automotive applications due to their distinct mechanical properties and compatibility with laser powder bed fusion (LPBF) processes. Selecting the optimal material requires evaluating strength-to-weight ratio, thermal stability, corrosion resistance, and post-processing needs. Misalignment here risks extended lead times or part failure—our engineering team validates every selection against your functional specifications to ensure first-time-right production.

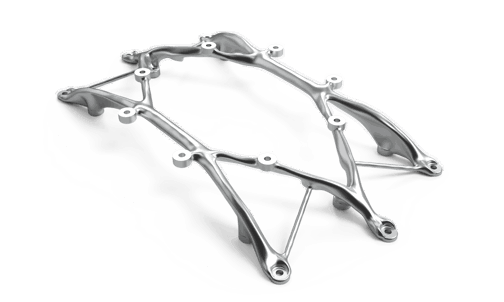

Aluminum AlSi10Mg delivers exceptional thermal conductivity and low density, making it ideal for lightweight heat exchangers, drone components, and rapid prototyping. Its fast solidification rate accelerates build speeds by 15–20% compared to denser metals, though it requires T6 heat treatment for structural applications. Stainless Steel 17-4 PH offers superior hardness and wear resistance for hydraulic manifolds, tooling inserts, and marine hardware. With high yield strength and machinability post-build, it withstands aggressive environments but necessitates stress-relief annealing to prevent distortion. Titanium Ti6Al4V provides the highest strength-to-weight ratio and biocompatibility for critical aerospace brackets and medical implants. While its reactive nature slows build speeds slightly, its fatigue resistance in cyclic loads justifies the investment for mission-critical parts.

Anodizing remains exclusive to aluminum components in metal AM workflows. This electrochemical finish enhances surface hardness by 300% and corrosion resistance in saline or acidic environments. Unlike decorative anodizing, our industrial-grade Type III (hardcoat) process achieves 50–75 µm thickness with tight pore sealing—essential for hydraulic sealing surfaces or wear-prone fixtures. Note that anodizing cannot be applied to steel or titanium; these require alternative treatments like passivation or HVOF coating.

The table below summarizes critical material properties influencing production velocity and application suitability:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Typical Build Speed (cm³/h) | Primary Industrial Use Cases |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 290–360 | 2.67 | 28–35 | Thermal management, lightweight structures |

| Stainless Steel 17-4 PH | 1000–1300 | 7.80 | 20–25 | High-pressure fluid systems, tooling |

| Titanium Ti6Al4V | 880–950 | 4.43 | 18–22 | Aerospace structural, biomedical implants |

Material decisions must align with your timeline and performance thresholds. Aluminum enables the fastest throughput for non-structural parts, while titanium demands meticulous parameter control but delivers unmatched durability. Wuxi Lead’s engineers leverage in-house material databases and real-time build monitoring to optimize your selection—reducing lead times without compromising integrity. Contact our applications team to review your project’s mechanical loads, environmental exposure, and delivery window for a precision-tailored recommendation.

Manufacturing Process & QC

From Concept to Consistency: The Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we engineer certainty into every phase of custom metal manufacturing. Our fast 3D printing service is not defined by speed alone—it is defined by precision, repeatability, and a zero-defect philosophy that spans from initial design through to full-scale production. This integrated workflow ensures that clients receive components that meet exact functional and dimensional requirements, every time.

The process begins with collaborative design engineering. Our team works directly with client CAD models, performing comprehensive design for additive manufacturing (DfAM) analysis. This includes evaluating part geometry, optimizing support structures, adjusting wall thicknesses, and ensuring thermal stability during build. We identify potential stress concentrations and recommend material-specific modifications to enhance performance and manufacturability. This phase is critical to eliminating downstream defects and ensuring first-time-right outcomes.

Once the design is finalized, we proceed to rapid prototyping using our high-precision metal additive systems. Utilizing laser powder bed fusion (LPBF) technology, we produce functional prototypes in materials such as stainless steel 316L, titanium Ti6Al4V, Inconel 718, and aluminum AlSi10Mg. These prototypes are not merely visual aids—they are fully tested under real-world conditions for fit, function, and durability. Dimensional inspection is performed using coordinate measuring machines (CMM), and metallurgical analysis verifies microstructure integrity. Feedback from this stage is used to refine the build strategy, ensuring the final production run is optimized for quality and consistency.

With validation complete, we transition seamlessly into mass production. Our automated build platforms and in-process monitoring systems maintain tight control over every layer. Each build is supported by real-time melt pool monitoring, oxygen level control, and powder quality management. Post-processing follows standardized procedures including stress relieving, support removal, surface finishing, and optional heat treatments. Every component undergoes 100% inspection using non-destructive testing (NDT) methods such as industrial CT scanning or ultrasonic testing, where applicable.

Our zero-defect mandate is enforced through full traceability. Each batch is documented with build logs, material certifications, and inspection reports, ensuring complete audit readiness. This structured progression—design validation, prototype verification, and controlled production—eliminates variability and delivers parts that meet the most stringent industry standards.

Key Process Specifications

| Parameter | Capability |

|---|---|

| Build Volume | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm (can be reduced to Ra 1–2 μm post-processed) |

| Supported Materials | 316L, Ti6Al4V, Inconel 718, AlSi10Mg, Tool Steel |

| Lead Time (Prototype) | 5–7 days from approved design |

| Lead Time (Production) | 10–15 days for batches up to 500 units |

| Quality Standards | ISO 9001, ASTM F75, ISO/TS 16949 compliant |

This end-to-end control ensures that speed never compromises quality—delivering high-performance metal components with unmatched reliability.

Why Choose Wuxi Lead Precision

Accelerate Your Metal Innovation with Lead Precision Engineering

In high-stakes industrial manufacturing, time-to-market separates industry leaders from competitors. Wuxi Lead Precision Machinery delivers certified metal additive solutions engineered for speed without compromise. Our industrial-grade DMLS and SLM systems operate under stringent ISO 9001 and AS9100 frameworks, transforming complex digital models into flight-certified aerospace components, medical implants, and energy sector tooling within 72-hour production cycles. Unlike conventional prototyping services, we integrate full metallurgical validation and in-process monitoring to ensure every part meets ASTM F75 or ISO 22068 standards upon delivery. For global OEMs facing supply chain volatility, our Shenzhen and Wuxi facilities provide scalable capacity with 98.7% on-time shipment reliability across 47 countries.

Technical Capabilities Driving Your Competitive Edge

| Specification | Performance Metric | Industrial Application Impact |

|---|---|---|

| Build Volume | Ø250 x 325 mm (EOS M 400-4) | Full-scale turbine blades in single print |

| Layer Thickness | 20–50 μm | Micro-channel heat exchangers with ≤0.1mm tolerance |

| Material Range | Ti-6Al-4V, Inconel 718, 17-4PH, AlSi10Mg | Aerospace brackets with 1,250 MPa UTS |

| Surface Finish | As-built Ra 8–12 μm (post-processed to Ra 0.8 μm) | Hydraulic manifold internal flow paths |

| Geometric Accuracy | ±0.02 mm repeatability | Multi-part assemblies requiring zero shimming |

Our engineering team collaborates from initial design feasibility analysis through DFAM optimization and first-article inspection. By leveraging generative design tools and topology optimization software, we routinely reduce component weight by 35% while maintaining structural integrity—critical for electric vehicle and drone manufacturers. Recent partnerships with Tier-1 defense contractors demonstrate our capacity to deliver 500+ certified parts monthly under ITAR-controlled environments, with full traceability from powder lot to finished component.

Your Path to Precision Execution

Initiate your precision project with a technical consultation tailored to your production timeline and quality requirements. Our application engineers will conduct a complimentary design-for-additive assessment within 24 hours of receiving your CAD file, identifying opportunities to consolidate assemblies or enhance thermal performance. For urgent requirements, our express validation protocol delivers material test coupons and dimensional reports alongside first articles—eliminating weeks of traditional qualification delays.

Contact [email protected] with your project specifications and target delivery window. Include “FAST TRACK REQUEST” in the subject line to activate our priority engineering review. Within 4 business hours, you will receive a formal quotation with build orientation analysis, material certification path, and logistics planning. Wuxi Lead Precision Machinery operates 24/7 production cells with dedicated project managers ensuring seamless integration into your manufacturing workflow. Trust our 15-year heritage in mission-critical metal additive systems to transform your innovation timeline from concept to certified production.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.