Technical Contents

Engineering Guide: Cnc Machining Services Georgia

Engineering Insight: Precision as the Foundation of CNC Machining Services in Georgia

Georgia’s manufacturing landscape demands uncompromising precision. From aerospace components in Savannah to medical device production in Atlanta and defense systems across the state, the margin for error is vanishingly small. Sub-micron tolerances and flawless surface finishes aren’t merely desirable; they are non-negotiable requirements dictated by safety regulations, performance specifications, and the relentless drive for innovation. In this high-stakes environment, the choice of CNC machining partner directly impacts product reliability, time-to-market, and ultimately, a manufacturer’s competitive standing. Precision engineering transcends basic part production; it is the critical enabler of complex assemblies, advanced material utilization, and the integration of cutting-edge technologies like additive manufacturing hybrids.

Wuxi Lead Precision Machinery understands this imperative at its core. Our engineering philosophy is forged through direct experience delivering mission-critical components where failure is not an option. We have provided ultra-precision machined parts for Olympic timing systems, demanding tolerances measured in millionths of an inch to ensure absolute accuracy in global sporting events. Furthermore, our facility holds stringent certifications required for machining components destined for classified defense systems, adhering to protocols that exceed standard industry practices. This heritage instills a discipline and quality consciousness that permeates every project, regardless of scale or industry sector. We bring this same level of rigor to supporting Georgia’s manufacturers, ensuring parts meet or exceed the exacting standards demanded by AS9100, ISO 13485, and ITAR-compliant programs.

Our capability to consistently achieve exceptional precision stems from a foundation of advanced technology, rigorous process control, and deep material science expertise. We invest continuously in state-of-the-art multi-axis CNC machining centers, coordinate measuring machines (CMMs) with nanometer-level resolution, and environmental controls to mitigate thermal drift. Combined with our engineers’ decades of experience in optimizing toolpaths, selecting optimal cutting parameters for exotic alloys and composites, and implementing real-time in-process inspection, we deliver dimensional accuracy and repeatability that Georgia’s advanced industries require. Partnering with Lead Precision means accessing a global supply chain node engineered for precision, offering Georgia manufacturers resilience without compromise.

Critical Precision Capabilities for Advanced Manufacturing

| Specification Category | Lead Precision Standard | Industry Relevance for Georgia |

|---|---|---|

| Positional Accuracy | ±0.0001″ (2.5 µm) | Essential for aerospace flight control surfaces and medical implants |

| Surface Finish (Ra) | As low as 2 µin (0.05 µm) | Critical for hydraulic components and optical mounting surfaces |

| Material Expertise | Titanium, Inconel, PEEK, 7075-T7351 Aluminum | Matches Georgia’s aerospace and defense material requirements |

| Quality Certifications | ISO 9001:2015, AS9100D, ITAR Registered | Mandatory for defense contractors and Tier 1 aerospace suppliers |

| In-Process Inspection | On-machine probing, CMM verification per ASME Y14.5 | Ensures compliance with complex GD&T on first-article submissions |

Precision machining in Georgia is not a commodity service; it is a strategic capability. Wuxi Lead Precision Machinery leverages its proven experience in the world’s most demanding applications to become a trusted extension of your engineering team, delivering the exacting quality Georgia manufacturers need to succeed globally. We provide the precision foundation upon which innovation and reliability are built.

Precision Specs & Tolerances

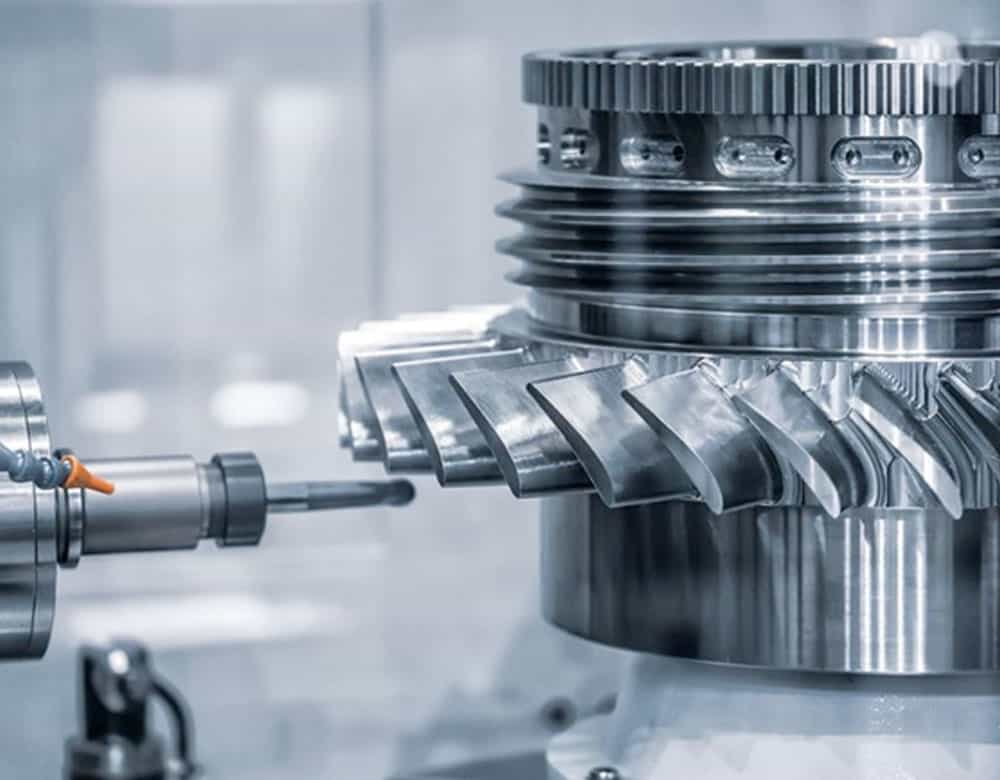

Advanced 5-Axis CNC Machining Capabilities for Demanding Industrial Applications

Wuxi Lead Precision Machinery delivers elite-level CNC machining services engineered to meet the rigorous demands of aerospace, medical, energy, and advanced industrial sectors. Our core technical strength lies in high-precision 5-axis CNC machining, enabling the production of complex geometries with superior accuracy, surface finish, and part consolidation. Unlike conventional 3-axis systems, our 5-axis platforms allow simultaneous movement across X, Y, Z, and two rotational axes (A and B), significantly reducing setup cycles and enhancing dimensional consistency. This capability supports the efficient manufacturing of intricate components such as turbine blades, hydraulic manifolds, and surgical instrument housings—parts where precision and repeatability are non-negotiable.

Our machining centers are equipped with state-of-the-art controls, high-speed spindles, and automated tool changers, ensuring optimal performance across a broad spectrum of materials. We routinely machine aluminum alloys, stainless steels, titanium, Inconel, and engineered plastics with consistent throughput and micron-level control. In-process probing and tool monitoring systems further enhance process reliability, minimizing human intervention and reducing the risk of errors during extended production runs.

To guarantee compliance with international quality standards, every critical dimension is validated through comprehensive post-machining inspection. Our quality control protocol centers on Coordinate Measuring Machine (CMM) verification, utilizing both tactile and optical probing systems for full 3D geometric validation. This metrology-backed approach ensures that every component conforms to specified GD&T requirements and customer-defined inspection criteria. All inspection reports are documented and archived, providing full traceability for regulated industries.

The following table outlines our standard and advanced machining tolerances, reflecting our commitment to precision and consistency across production volumes:

| Feature | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.005 mm | Up to 300 mm length |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed or honed finishes |

| Positional Tolerance | ±0.020 mm | ±0.005 mm | Per GD&T, relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined; 0.4 µm achievable via polishing |

| Angular Tolerance | ±0.05° | ±0.02° | Between features |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Verified via CMM and optical flat |

Our technical capabilities are reinforced by a quality management system compliant with ISO 9001:2015 standards, ensuring consistent process control from raw material to final shipment. With a focus on precision, scalability, and full inspection traceability, Wuxi Lead Precision Machinery stands as a trusted partner for OEMs requiring mission-critical components manufactured to the highest global benchmarks.

Material & Finish Options

Material Selection for Precision CNC Machining in Georgia’s Industrial Sector

Selecting optimal materials is critical for CNC machining success in Georgia’s demanding aerospace, medical, and energy sectors. Wuxi Lead Precision Machinery leverages decades of expertise to guide clients through material choices that balance performance, cost, and manufacturability. Aluminum, steel, and titanium dominate high-precision applications, each offering distinct advantages for Georgia-based projects requiring tight tolerances and durability.

Aluminum remains the premier choice for lightweight structural components. Its excellent machinability reduces cycle times and tool wear, directly lowering production costs for high-volume Georgia orders. Grade 6061-T6 provides superior weldability and corrosion resistance for marine or outdoor equipment, while 7075-T6 delivers exceptional strength for aerospace brackets and defense hardware. Aluminum’s thermal conductivity also benefits heat-sensitive applications like semiconductor tooling.

Carbon and alloy steels are indispensable for high-stress mechanical systems. 4140 chrome-moly steel offers outstanding toughness for oilfield valves and shafts operating under extreme pressure, common in Georgia’s energy infrastructure. Stainless steel 304/316 provides essential corrosion resistance for medical devices and food processing machinery, meeting stringent FDA requirements. Steel’s higher density demands precise toolpath strategies to minimize vibration, a capability Wuxi Lead engineers implement through adaptive CNC programming.

Titanium alloys address the most severe operational environments. Grade 5 (Ti-6Al-4V) dominates aerospace landing gear and medical implants due to its unmatched strength-to-weight ratio and biocompatibility. While challenging to machine, our specialized tooling and coolant systems ensure dimensional accuracy for Georgia clients in critical applications where failure is not an option.

Anodizing is the preferred surface treatment for aluminum components, enhancing wear resistance and enabling color-coding for assembly. Type II sulfuric acid anodizing provides economical corrosion protection for industrial enclosures, while Type III hardcoat anodizing delivers 50-70 μm thickness for hydraulic pistons subjected to abrasive wear. All finishes comply with ASTM B580 standards, ensuring consistency for Georgia manufacturers requiring traceable quality documentation.

Material properties directly impact machining efficiency and final part performance. The table below summarizes critical selection criteria:

| Material | Key Grades | Machinability (Relative) | Primary Applications | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Excellent (90-100%) | Aerospace frames, heat sinks | Good (anodized) |

| Steel | 4140, 304/316 SS | Moderate (50-70%) | Valves, surgical instruments | Varies (SS excellent) |

| Titanium | Ti-6Al-4V | Poor (20-30%) | Aircraft fittings, implants | Excellent |

Wuxi Lead Precision Machinery collaborates with Georgia engineering teams to validate material suitability against operational loads, environmental exposure, and regulatory frameworks. Our in-house metallurgical lab verifies raw material certifications, while CNC process simulations prevent costly prototyping iterations. For projects requiring rapid turnaround, we maintain strategic aluminum and steel inventory in China to offset trans-Pacific logistics, ensuring on-time delivery for Atlanta-area manufacturers. Partner with us to transform material specifications into precision-machined reality.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect delivery in every CNC machining project. Serving global clients in high-performance industries such as aerospace, medical, and advanced automation, our workflow integrates rigorous design validation, rapid prototyping, and scalable mass production—all anchored in a disciplined quality management system.

Design begins with comprehensive client collaboration. Engineers analyze 3D CAD models and technical drawings to assess manufacturability, material suitability, and geometric tolerances. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to preempt potential issues. This phase ensures that every component can be produced within specified tolerances while optimizing tool paths, minimizing waste, and reducing cycle times. Our engineering team maintains direct communication with clients to resolve ambiguities and refine designs before any metal is cut.

Prototyping follows design validation and serves as a critical verification stage. Using high-precision 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes that mirror final production quality. These prototypes undergo full dimensional inspection using coordinate measuring machines (CMM), surface roughness testing, and, when required, non-destructive testing (NDT). Clients receive detailed inspection reports and sample parts for form, fit, and function testing. Any required design adjustments are implemented at this stage, ensuring the final product meets all performance criteria before scaling.

Mass production is executed on automated, high-efficiency CNC lines with real-time process monitoring. Each workpiece is traced through our manufacturing execution system (MES), enabling full batch traceability from raw material to shipment. In-process inspections occur at predefined intervals, and final inspection includes 100% critical dimension checks. Our ISO 9001 and IATF 16949-certified quality system enforces zero-defect protocols, supported by statistical process control (SPC) and root cause analysis for any non-conformance.

All stages are backed by advanced metrology and a culture of continuous improvement. Whether producing 10 prototypes or 100,000 units, Wuxi Lead ensures every part meets the same exacting standards.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Maximum Work Envelope (XYZ) | 2000 x 1000 x 800 mm |

| Axis Capabilities | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Surface Finish | Ra 0.4 µm standard, down to Ra 0.1 µm with polishing |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAI, SPC |

| Production Capacity | Prototype to high-volume serial production |

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Capabilities with Wuxi Lead Precision Machinery

Georgia’s advanced manufacturing sector demands partners who deliver uncompromising precision, scalability, and technical agility. As a strategic extension of your engineering team, Wuxi Lead Precision Machinery bridges the gap between ambitious design requirements and flawless execution. Our ISO 9001:2015-certified facility in China specializes in complex, high-tolerance CNC machining for aerospace, medical, and industrial clients across North America. We understand Georgia manufacturers face unique pressures: compressed timelines, stringent quality mandates, and volatile supply chains. Partnering with Lead Precision mitigates these risks through proactive engineering collaboration, real-time production transparency, and a relentless focus on your end-to-end success.

Our technical capabilities are engineered for the most demanding applications. The table below outlines core specifications ensuring your components meet exacting standards:

| Specification | Detail |

|---|---|

| Material Expertise | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, PEEK, Stainless Steel 316L |

| Tolerance Capability | ±0.0002″ (5µm) for critical features |

| Max Work Envelope | 800 x 600 x 500 mm (3-axis milling) |

| Equipment Fleet | 42 CNC centers (Mazak, DMG MORI), 5-axis milling, Swiss turning, wire EDM |

| Lead Time Efficiency | Prototype: 7–10 days; Production: 15–25 days (including surface finishing) |

Beyond machining, we integrate secondary operations—precision grinding, anodizing, passivation, and metrology—under one roof. Our engineers collaborate during your design phase to optimize manufacturability, reducing costs without sacrificing performance. Real-time CNC process monitoring and AI-driven quality analytics ensure zero-defect delivery, while dedicated project managers provide daily production updates aligned with your time zone. Unlike transactional suppliers, we invest in understanding your application’s functional requirements, transforming blueprints into mission-critical components that exceed industry benchmarks.

Wuxi Lead Precision Machinery operates with the accountability expected by Georgia’s top-tier manufacturers. We enforce strict IP protection protocols, adhere to AS9100 aerospace standards where required, and maintain traceable material certifications for every batch. Our logistics network guarantees seamless delivery to Atlanta, Savannah, or any U.S. destination via DDP terms, eliminating customs delays. When your project demands a partner who treats your deadlines as non-negotiable and your quality as sacred, Lead Precision delivers certainty in an uncertain market.

Initiate a strategic partnership that redefines precision manufacturing outcomes. Contact our Georgia-focused engineering team directly at [email protected] to discuss your next project. Include your component drawings and target timeline for a guaranteed response within 4 business hours. We do not rely on automated forms—your inquiry receives immediate human analysis from CNC specialists fluent in both technical rigor and your operational realities. Transform supply chain vulnerability into competitive advantage with a partner built for excellence. Your precision journey starts with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.