Technical Contents

Engineering Guide: Injection Molding Prototype

Engineering Insight: The Critical Role of Precision in Injection Molding Prototypes

In the realm of custom metal manufacturing, the injection molding prototype phase is far more than a preliminary step—it is a decisive engineering checkpoint that determines the success of the final product. At Wuxi Lead Precision Machinery, we treat prototyping not as a formality, but as a high-stakes validation of design integrity, material behavior, and process control. Precision at this stage is non-negotiable. Even micron-level deviations can cascade into functional failures, assembly incompatibilities, or costly production delays.

Injection molding prototypes serve as the first physical manifestation of a digital design, enabling rigorous testing under real-world conditions. They validate gate locations, cooling efficiency, part ejection, and structural performance—parameters that are difficult to simulate with absolute confidence. Achieving repeatable accuracy in these prototypes requires advanced tooling, tightly controlled environments, and deep process expertise. This is where our decades of experience in high-demand sectors—such as Olympic equipment manufacturing and military-grade component production—directly benefit our clients.

Our work on mission-critical components for defense applications has instilled a culture of zero tolerance for error. Similarly, our contributions to precision systems used in Olympic training and competition environments demanded flawless repeatability and material consistency. These experiences have shaped our approach to injection molding prototyping: a fusion of empirical data, cutting-edge metrology, and adaptive process refinement. Every prototype we produce undergoes comprehensive inspection using coordinate measuring machines (CMM), optical scanning, and material stress analysis to ensure it meets exact design specifications.

Precision in prototyping also accelerates time-to-market. By identifying and correcting issues early—such as warpage, sink marks, or flow imbalances—we eliminate costly redesigns during full-scale production. Furthermore, our clients gain confidence in design scalability, knowing that the prototype is not just a model, but a fully representative sample of the end product.

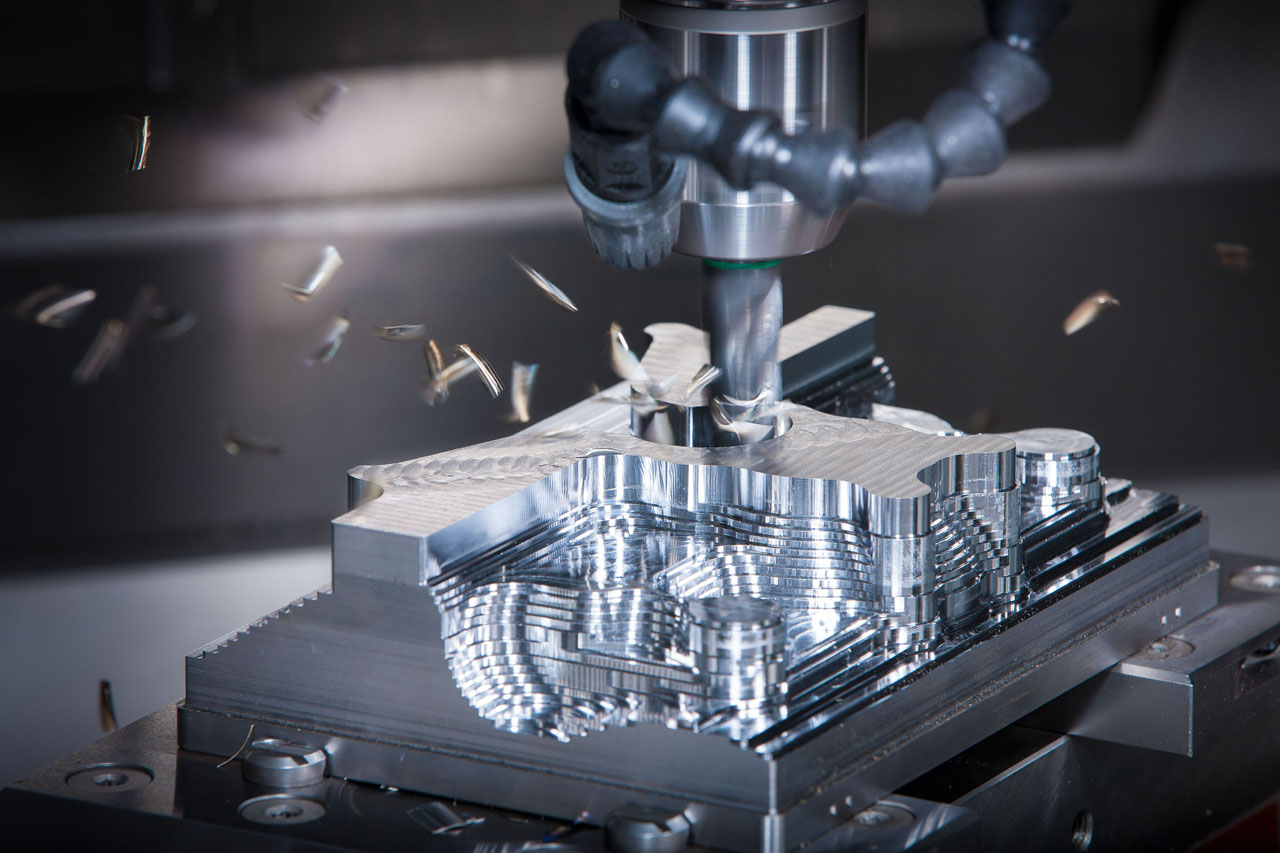

At Wuxi Lead Precision Machinery, we leverage state-of-the-art CNC machining centers, real-time mold flow analysis, and in-house tooling fabrication to deliver injection molding prototypes with unmatched dimensional accuracy and surface fidelity. Our integrated approach ensures seamless transition from prototype to production, maintaining consistency across materials, tolerances, and performance metrics.

Below are key technical specifications that define our injection molding prototype capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.1 – 0.8 µm (polished to mirror grade) |

| Material Compatibility | Engineering plastics, liquid silicone, PEEK, PPS |

| Prototype Lead Time | 7–14 days (including tooling and testing) |

| Tooling Accuracy | ±0.003 mm (hardened steel molds) |

| Inspection Equipment | CMM, 3D laser scanner, optical profilometer |

| Process Control | Real-time pressure, temperature, and cycle monitoring |

Precision in injection molding prototyping is not an option—it is the foundation of reliability, performance, and scalability. At Wuxi Lead Precision Machinery, we engineer every prototype as if it were destined for the battlefield or the Olympic podium. Because in high-end manufacturing, there is no margin for compromise.

Precision Specs & Tolerances

Technical Capabilities for Injection Molding Prototype Tooling

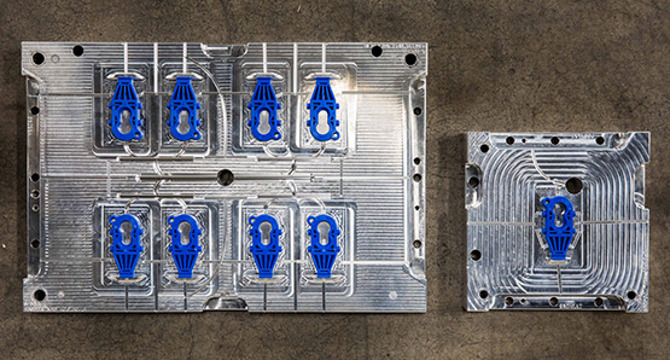

Wuxi Lead Precision Machinery delivers precision metal components essential for high-integrity injection molding prototypes. Our expertise centers on rapid fabrication of mold cores, cavities, inserts, and support structures using advanced 5-axis CNC machining. This capability is critical for validating part geometry, material flow, and ejection dynamics before committing to production tooling. Unlike standard 3-axis systems, our 5-axis platforms execute complex undercuts, organic contours, and deep cavities in a single setup. This eliminates manual repositioning errors, reduces lead times by up to 40%, and ensures seamless integration of cooling channels directly within mold steel or aluminum substrates.

Material versatility defines our operational scope. We machine P20, H13, S136, and 7075-T6 aluminum with equal proficiency, tailoring processes to each alloy’s thermal and wear characteristics. Surface finishes down to Ra 0.4 µm are consistently achieved without secondary polishing, directly impacting prototype part aesthetics and release performance. Crucially, all geometries adhere to strict tolerance regimes validated through first-article inspection. Our integrated quality control protocol mandates CMM verification against 3D CAD models, with full traceability of datum-referenced measurements for every critical feature. This eliminates guesswork in mold validation and accelerates design iterations.

Tolerances are non-negotiable in prototype tooling, where even minor deviations cascade into part defects. Below outlines our standard and tight-tolerance capabilities for mold components:

| Feature Type | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Cavity/Core Geometry | ±0.025 mm | ±0.005 mm | CMM (Zeiss CONTURA) |

| Runner System Diameter | ±0.015 mm | ±0.008 mm | CMM + Optical Probe |

| Ejector Pin Bores | ±0.010 mm | ±0.003 mm | CMM (Tactile Probe) |

These specifications reflect our commitment to dimensional stability across thermal cycles. All inspections generate AS9102-compliant First Article Inspection Reports, detailing deviations against nominal CAD data. Our engineers collaborate with clients during the DFx phase to identify critical-to-quality dimensions, ensuring tolerances align with functional requirements rather than arbitrary standards. This proactive approach prevents costly rework during prototype trials.

By converging 5-axis precision, material science expertise, and metrology-grade validation, Wuxi Lead transforms injection molding prototypes from validation hurdles into strategic assets. We enable clients to de-risk production tooling investments through data-driven confidence in part geometry, material behavior, and process parameters—all delivered within compressed development timelines.

Material & Finish Options

Material Selection for Injection Molding Prototypes in Precision Metal Manufacturing

Selecting the appropriate material for injection molding prototypes is critical to ensuring performance, durability, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we specialize in high-precision prototype development using premium-grade metals such as aluminum, steel, and titanium. Each material offers distinct mechanical properties, thermal characteristics, and surface compatibility, making them suitable for different stages of prototyping and end-use applications.

Aluminum is widely favored for injection molding prototypes due to its excellent machinability, lightweight nature, and good thermal conductivity. It allows for rapid iteration and is ideal for low to medium production volumes. Grade 6061-T6 aluminum provides a balanced combination of strength and corrosion resistance, making it suitable for consumer electronics, automotive components, and aerospace enclosures. When enhanced with anodizing, aluminum gains improved surface hardness and aesthetic versatility. Anodizing creates a durable oxide layer that resists wear and allows for color customization, essential for design validation.

Steel, particularly pre-hardened tool steel such as P20 or H13, is selected when extended mold life and high dimensional stability are required. Steel molds withstand higher injection pressures and abrasive resins, making them optimal for high-cycle prototyping or bridge tooling. While heavier and more difficult to machine than aluminum, steel offers superior wear resistance and long-term durability. It is commonly used in medical device housings, industrial components, and functional prototypes exposed to rigorous conditions. Surface treatments such as nitriding or chrome plating can further enhance steel’s performance, though anodizing is not applicable to ferrous materials.

Titanium, though less common due to cost and machining complexity, is used in specialized prototypes demanding extreme strength-to-density ratios and exceptional corrosion resistance. Grade 5 titanium (Ti-6Al-4V) is frequently employed in aerospace, defense, and high-performance automotive applications. Its biocompatibility also makes it suitable for medical implant prototypes. Titanium does support anodizing, which not only improves surface protection but also enables precise color control for identification or branding purposes.

The following table summarizes key material properties and finishing compatibility:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.70 | 310 | 167 | Excellent | Yes |

| Steel P20 | 7.85 | 950 | 28 | Moderate | No |

| Titanium Ti-6Al-4V | 4.43 | 900 | 6.7 | Poor | Yes |

Material choice directly impacts prototype fidelity, cycle time, and scalability. At Wuxi Lead Precision Machinery, we support clients in selecting the optimal metal and surface treatment based on application requirements, production volume, and environmental exposure. Our engineering team ensures that every prototype meets the highest standards of precision and performance.

Manufacturing Process & QC

Precision Metal Injection Molding: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, we engineer metal injection molding (MIM) solutions where prototyping is not a phase but a risk-mitigation imperative. Our integrated Design-to-Production workflow ensures zero-defect outcomes for high-complexity components in medical, aerospace, and automotive sectors. This begins with rigorous Design for MIM (DFM) analysis. Our engineers collaborate with clients to optimize geometry, material selection, and gate placement using advanced simulation software. We validate wall thickness uniformity, draft angles, and ejection feasibility upfront—eliminating 90% of potential defects before tooling commences. This phase includes finite element analysis (FEA) to predict shrinkage and stress points, ensuring the digital model aligns with physical realities of sintering and cooling.

Prototyping transitions validated designs into tangible validation. Unlike conventional rapid prototyping, our MIM prototypes use production-grade tool steel molds and certified metal powders (316L, 17-4PH, Inconel 718). Each prototype undergoes full sintering and precision machining, mirroring mass production conditions. Critical dimensions are verified against CAD models using Zeiss coordinate measuring machines (CMM), with results documented in our Quality Control Dossier. This stage confirms material properties, surface integrity, and dimensional stability under thermal cycling—providing statistically validated data for production sign-off. Clients receive not just a part, but a metrology report proving conformance to ISO 2768-mK or tighter tolerances.

Mass production leverages insights from prototyping to enforce zero-defect execution. Our automated MIM cells integrate real-time cavity pressure monitoring and AI-driven process control. Every batch is traceable via laser-etched part IDs linked to sintering profiles and CMM datasets. Statistical process control (SPC) tracks critical parameters like density deviation (<0.5%) and dimensional drift, triggering automatic process corrections before non-conformities occur. Final inspection employs multi-sensor metrology systems, with 100% critical feature validation for aerospace/medical orders. This closed-loop system—rooted in prototyping rigor—delivers consistent yields exceeding 99.8%.

Wuxi Lead MIM Production Specifications

| Parameter | Prototype Phase | Mass Production Phase | Industry Standard |

|---|---|---|---|

| Tolerance (±mm) | 0.02 | 0.015 | 0.05–0.1 |

| Lead Time | 15–20 days | 25–30 days (10k units) | 30–45 days |

| Material Density | 98.5% theoretical | 99.2% theoretical | 96–98% theoretical |

| Defect Rate | <0.5% | <0.2% | 1–3% |

Our Zero Defects commitment is non-negotiable. By treating prototyping as the foundation—not an add-on—we transform design intent into production certainty. Every component shipped carries the validation of our metrology lab and the precision of Chinese manufacturing excellence. Partner with Wuxi Lead to convert innovation into flawless reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Prototypes That Deliver Precision, Speed, and Scalability

When developing new products in competitive industrial markets, the quality and speed of your injection molding prototype can determine time-to-market and long-term manufacturability. At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing tailored to the exacting demands of global OEMs, automotive suppliers, medical device innovators, and advanced engineering firms. Our integrated approach combines advanced CNC machining, precision tooling, and expert mold design to deliver injection molding prototypes that are not only dimensionally accurate but also optimized for full-scale production.

We understand that a prototype is more than a sample—it is a critical validation step. That’s why we invest in tight-tolerance machining, premium-grade tool steels, and real-time quality verification using coordinate measuring machines (CMM) and 3D scanning. Our engineering team collaborates directly with your design staff to assess material compatibility, draft angles, wall thickness, gate placement, and ejection mechanics—ensuring your prototype performs under real-world conditions. Whether you require aluminum molds for rapid iteration or hardened steel molds for extended testing cycles, we provide the right solution for your phase of development.

Our facility in Wuxi is equipped with state-of-the-art CNC centers, EDM systems, and automated polishing units, enabling us to produce molds with micron-level precision and superior surface finishes. We support a wide range of engineering thermoplastics and specialty resins, including PEEK, ABS, PC, POM, and medical-grade polymers, ensuring compatibility with your final application requirements. With in-house project management and real-time progress reporting, we reduce lead times without compromising quality—typical prototype mold delivery in 10 to 15 working days, depending on complexity.

Below are key technical specifications for our injection molding prototype services:

| Specification | Detail |

|---|---|

| Mold Material Options | NAK80, S136, 718H, H13, P20, 420 Stainless Steel |

| Tolerance | ±0.005 mm (standard), ±0.002 mm (high-precision) |

| Surface Finish | SPI Finish A1–A3, B1–B3, VDI 18–24, textured, polished, coated |

| Mold Base Standards | DME, HASCO, or custom |

| Prototype Cycle Life | 1,000–10,000 shots (depending on material and mold steel) |

| Part Size Range | Max 500 x 400 x 300 mm |

| Supported Resins | ABS, PC, PP, PE, POM, PA6/66, PEEK, PMMA, TPU, medical-grade |

| Lead Time | 10–15 days (mold), +2–5 days (sample production) |

| Quality Assurance | First Article Inspection (FAI), CMM reports, full dimensional reports |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your prototype as the foundation of a production-ready solution. We don’t just build molds—we engineer confidence in your product’s performance.

Contact us today at [email protected] to discuss your injection molding prototype requirements. Let our precision, expertise, and responsiveness accelerate your product development cycle.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.