Technical Contents

Engineering Guide: Short Run Injection Moulding

Engineering Insight Precision Imperatives in Short Run Injection Moulding

Short run injection moulding demands exceptional precision engineering, far exceeding the tolerances often acceptable in high-volume production. When producing limited quantities, typically under 10,000 units, the cost and time impact of tooling errors or part inconsistencies become critically magnified. Each component must meet exact specifications on the first iteration; there is no economic buffer for iterative corrections across thousands of cycles. Precision directly dictates scrap rates, secondary operation requirements, and ultimately, the project’s viability. Achieving micron-level accuracy in cavity design, core alignment, cooling channel placement, and ejection systems is non-negotiable for functional integrity and assembly compatibility, especially for complex geometries or multi-material components common in advanced applications. Neglecting this precision foundation inevitably leads to costly delays, compromised part performance, and failed qualification testing.

At Wuxi Lead Precision Machinery, our engineering discipline is forged in environments where zero-defect performance is mandatory. Our precision manufacturing heritage, validated through critical projects for Olympic sporting equipment and stringent military specifications, directly informs our approach to short run injection moulding. These sectors demand absolute reliability under extreme conditions, requiring tolerances often tighter than ISO Class 5 standards and flawless material consistency. This experience translates directly to our short run clients: we apply the same rigorous metrology protocols, advanced simulation for mould flow and stress analysis, and uncompromising process validation used in aerospace and defense supply chains. Our engineers understand that a tolerance stack-up error of mere microns can render a high-value, low-volume component unusable, wasting irreplaceable tooling investment and critical time.

Our precision capability ensures short runs deliver maximum value from the outset. The table below outlines key precision parameters achievable within our short run injection moulding process:

| Parameter | Standard Capability | Enhanced Capability (Olympic/Military Grade) |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm (±0.002 in) | ±0.01 mm (±0.0004 in) |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) |

| Warpage Control | < 0.5% of linear dimension | < 0.1% of linear dimension |

| Material Consistency | ISO 9001 Compliant | MIL-STD-883 / ASTM F624 Compliant |

| First Article Approval | 95% Pass Rate | 99.5% Pass Rate |

This precision focus eliminates the hidden costs of short runs. Clients avoid expensive rework, achieve faster time-to-market with production-ready parts from the initial batch, and gain confidence that every component meets the exacting demands of integration and performance. For low-volume, high-value applications where failure is not an option, partnering with an engineering team proven in the most demanding precision environments is not just advantageous—it is essential. Wuxi Lead Precision Machinery delivers this assurance, transforming short run challenges into opportunities for rapid, reliable component realization.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in short run injection moulding for high-precision industrial applications. Our integrated production ecosystem combines state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every component meets exacting engineering standards. Designed for clients requiring rapid prototyping, low-volume production, and complex geometries, our short run injection moulding services are optimized for performance, repeatability, and dimensional accuracy.

At the core of our machining capability is a fleet of advanced 5-axis CNC machines, enabling multi-directional cutting with unparalleled precision. This technology allows us to machine intricate metal components from a single setup, reducing cycle times and minimizing human error. The simultaneous movement across five axes ensures superior surface finishes and tight tolerances, even on highly complex parts such as mould cores, cavities, and inserts used in injection moulding systems. Materials commonly processed include tool steels, stainless steels, aluminum alloys, and high-temperature resistant metals, all machined to net shape or near-net shape specifications.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of critical dimensions, form, and positional accuracy. Our CMM systems operate with sub-micron resolution, ensuring compliance with international standards such as ISO 2768 and GD&T specifications. In addition to first-article inspection reports, we provide full traceability, material certifications, and in-process quality checks to support consistent output and client confidence.

The following table outlines the standard technical tolerances achievable across our short run injection moulding and precision machining processes:

| Feature | Standard Tolerance | High-Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | Up to 500 mm length |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or honed features |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm surface |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined finish; polish optional |

| Angular Tolerance | ±0.1° | ±0.05° | Between features |

| Mold Cavity Matching | ±0.02 mm | ±0.01 mm | Core-to-cavity alignment |

These capabilities are supported by a fully integrated design-to-delivery process, where engineering collaboration begins at the concept stage. Our team works closely with clients to optimize part design for manufacturability, reduce assembly complexity, and accelerate time-to-market. Whether producing a single prototype or a limited production run, Wuxi Lead Precision Machinery ensures every component reflects the highest standard of precision metalworking excellence.

Material & Finish Options

Material Selection for Short Run Injection Moulding Excellence

Material choice critically impacts mould longevity, part quality, production speed, and total cost for short run injection moulding projects. At Wuxi Lead Precision Machinery, our engineering team prioritizes matching the optimal base metal and surface treatment to your specific application demands, balancing performance requirements with the economic realities of low-volume production. Selecting wisely ensures rapid iteration capability without sacrificing the dimensional stability or surface finish required for functional prototypes or limited commercial batches.

Aluminum alloys, particularly 7075-T6 and 6061-T6, are the preferred foundation for rapid tooling in short runs. Their superior machinability significantly reduces lead times compared to steel, enabling faster time-to-market for prototypes and bridge tooling. Aluminum’s high thermal conductivity promotes efficient cooling cycles, improving part consistency during production. While not suited for millions of cycles, modern hard-coated aluminum moulds reliably produce thousands of high-quality parts. This makes aluminum ideal for design validation, pilot production, and low-volume commercial runs where speed and cost efficiency are paramount.

Tool steels like P20, H13, and S136 remain essential for applications demanding maximum wear resistance, thermal stability, or production of highly abrasive materials. These steels offer exceptional hardness and longevity, justifying their higher initial machining cost for medium-short runs requiring superior surface replication or extended tool life beyond aluminum’s capability. Steel moulds are the standard for production volumes exceeding several thousand parts or when processing engineering resins that accelerate wear.

Titanium alloys present a specialized solution for extreme conditions, such as moulds exposed to highly corrosive materials or requiring exceptional strength-to-weight ratios in complex core designs. While significantly more expensive and challenging to machine, titanium’s unparalleled corrosion resistance and durability in niche applications can provide a compelling return on investment where conventional materials fail prematurely.

Anodizing is the definitive surface enhancement for aluminum moulds, directly addressing their primary limitation: susceptibility to wear and corrosion. Hard anodizing (Type III) creates a dense, abrasion-resistant ceramic layer integral to the aluminum substrate. This treatment dramatically extends mould life in short runs, improves release characteristics for complex geometries, and provides excellent resistance to chemical attack from many plastics and release agents. The controlled thickness and hardness of the anodized layer are precisely specified by Wuxi Lead engineers based on resin type and part complexity to maximize performance.

Key material properties guide optimal selection as summarized below:

| Material | Hardness Range (HRC) | Thermal Conductivity (W/mK) | Typical Applications | Key Advantages for Short Runs |

|---|---|---|---|---|

| Aluminum 7075 | 150 HB (Base) | 130 | Prototypes, Bridge Tooling, Low Volume | Fast machining, Rapid cooling, Low cost |

| P20 Steel | 28-32 | 28-36 | Medium Volume Production, Complex Parts | High wear resistance, Dimensional stability |

| H13 Steel | 48-52 | 25-30 | High Temp Resins, Longevity Critical | Thermal fatigue resistance, Toughness |

| Titanium | 32-36 | 7-10 | Extreme Corrosion, Specialized Cores | Unmatched corrosion resistance, Strength |

Partner with Wuxi Lead Precision Machinery to leverage our deep materials science expertise. We analyze your resin, part geometry, volume, and quality targets to prescribe the precise metal substrate and anodizing specification, ensuring your short run injection moulding project achieves peak efficiency and part integrity from the first shot.

Manufacturing Process & QC

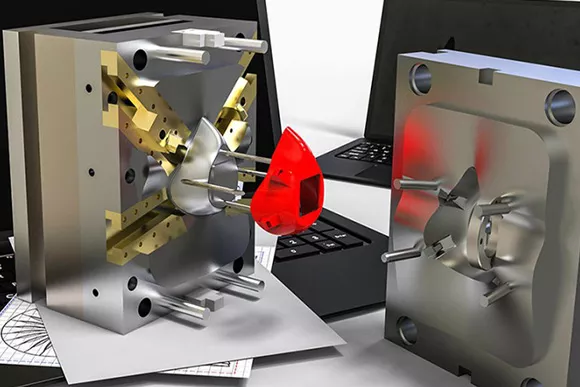

Design Phase: Precision Engineering for Zero Defects

The foundation of successful short run injection moulding begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a collaborative design review, integrating customer specifications with our in-house expertise in material science, thermal dynamics, and tooling longevity. Our engineering team employs advanced 3D CAD software and finite element analysis (FEA) to simulate mold flow, identify potential stress points, and optimize gate locations. This proactive approach ensures that part geometry, wall thickness, and draft angles are engineered for manufacturability, minimizing warpage, sink marks, and voids before any metal is cut. Design for manufacturability (DFM) feedback is delivered within 48 hours, enabling rapid iteration and alignment with zero-defect objectives.

Prototyping: Validating Performance at Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined aluminum or pre-hardened steel molds. These prototype tools replicate the conditions of full-scale production, allowing functional testing of parts under real injection parameters. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy within ±0.005 mm. We conduct material compatibility tests, cycle time analysis, and first-article inspections per ISO 9001 standards. This phase not only confirms design integrity but also fine-tunes process parameters such as melt temperature, injection speed, and cooling time—critical for achieving repeatable quality in subsequent production runs.

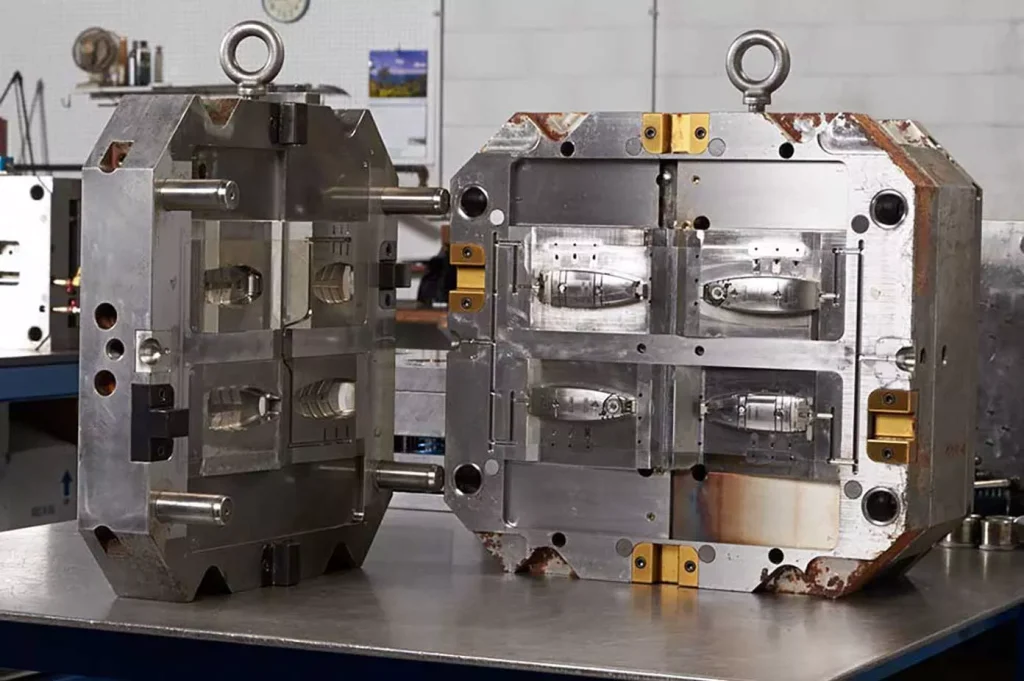

Mass Production: Consistency Through Automation and Control

With prototype validation complete, we transition to short-run mass production using hardened steel molds built for durability and precision. Our automated molding cells operate under strict environmental controls, with real-time monitoring of pressure, temperature, and clamp force. Each production batch is supported by Statistical Process Control (SPC) systems that track critical dimensions and detect deviations before they result in non-conformance. In-line vision systems and automated part ejection ensure consistent quality and eliminate human error. Every component is traceable through our digital manufacturing execution system (MES), providing full documentation from raw material to final inspection.

Process Specifications

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.02 mm |

| Material Compatibility | ABS, PC, POM, Nylon, PP, PBT, LCP, and filled grades |

| Mold Material | NAK80, S136, 2738H, 718H (customizable) |

| Tool Life | 100,000+ cycles (hardened steel) |

| Production Volume | 100 – 10,000 units per run |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Production) | 15–25 days after approval |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC |

Through integrated design validation, precision prototyping, and tightly controlled production, Wuxi Lead ensures zero-defect delivery for every short run injection moulding project. Our process is engineered not just for speed, but for uncompromised quality in custom metal manufacturing.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Short Run Injection Moulding

Short run injection moulding demands more than standard tooling—it requires precision engineering, rapid adaptability, and unwavering quality control to transform complex designs into flawless production-ready components. Generic suppliers often compromise on tolerances or material integrity, leading to costly iterations and delayed time-to-market. At Wuxi Lead Precision Machinery, we bridge this gap with 20+ years of expertise in custom metal manufacturing, specifically engineered for high-stakes short-run applications. Our integrated approach combines advanced CNC machining, rigorous metallurgical analysis, and real-time process validation to deliver moulds that consistently achieve ±0.005mm tolerances—critical for aerospace, medical, and automotive sectors where failure is not an option.

We specialize in transforming your technical specifications into production reality without the overhead of mass-production tooling. Our facility leverages HAAS and DMG MORI 5-axis CNC systems, coupled with in-house EDM and surface treatment capabilities, ensuring every mould cavity meets exact material and thermal requirements. Unlike competitors who outsource critical stages, we maintain full control from steel selection to final validation, eliminating supply chain vulnerabilities and guaranteeing repeatability across runs as small as 50 units. This vertical integration reduces lead times by 30% while adhering to ISO 9001 and IATF 16949 standards.

Key technical capabilities driving your short-run success include:

| Specification | Capability | Industry Impact |

|---|---|---|

| Tolerance Range | ±0.005mm to ±0.02mm | Ensures part consistency in tight-clearance assemblies |

| Material Expertise | P20, H13, S136, Stainless 420, Beryllium Copper | Optimizes thermal conductivity and wear resistance |

| Lead Time (Mould) | 15–25 days (avg.) | Accelerates prototyping to production cycles |

| Max Mould Size | 800 x 600 x 500 mm | Supports medium-complexity components |

| Surface Finish | SPI-A1 to N8 (Ra 0.05µm) | Meets medical-grade cosmetic standards |

Our process begins with a no-cost DFM (Design for Manufacturability) review, where our engineers identify potential defects before machining commences. We then deploy real-time cavity pressure monitoring during trial runs, adjusting parameters to eliminate sinks, warpage, or knit lines—common pitfalls in short runs. This proactive methodology has delivered 99.2% first-pass yield rates for clients transitioning from prototyping to low-volume production.

When your project demands precision that scales without compromise, partner with the team that treats every short run as a mission-critical deliverable. Submit your technical package—including 3D models, material specs, and volume requirements—to [email protected]. Reference “Short Run Precision Guide” in your subject line to trigger immediate engineering review. Our technical sales team will respond within 4 business hours with a validated timeline and DFM report, no generic quotes. With limited capacity reserved for high-complexity short runs, initiate your project today to secure priority scheduling. Wuxi Lead Precision Machinery: Where precision metal craftsmanship meets agile manufacturing execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.