Technical Contents

Engineering Guide: B And B Mold

Engineering Insight: The Role of Precision in b and b Mold Manufacturing

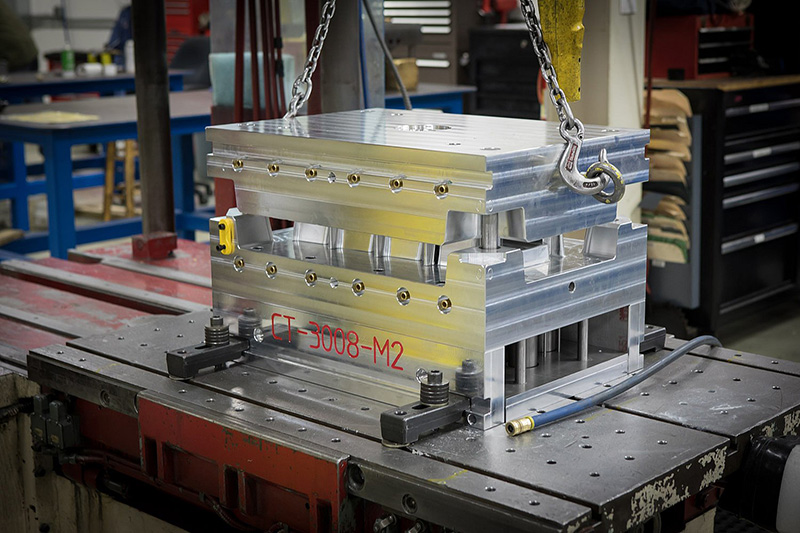

In the realm of custom metal manufacturing, the integrity and performance of tooling systems are directly tied to the precision of their engineering. This is particularly critical in the development of b and b mold systems—complex, high-tolerance assemblies used in advanced injection and compression molding applications. At Wuxi Lead Precision Machinery, we understand that the success of such molds hinges on micron-level accuracy, material consistency, and long-term repeatability under demanding production cycles.

b and b molds are not standard tooling solutions. They are engineered to deliver consistent part quality across thousands of cycles, often in sectors where failure is not an option—such as aerospace, defense, and high-performance automotive. The “b” in b and b mold typically refers to the core and cavity configuration, where both halves of the mold must align with extreme precision to prevent flash, ensure dimensional stability, and maintain surface finish integrity. Any deviation, even at the micron scale, can result in part rejection, increased downtime, or systemic manufacturing delays.

Our experience at Wuxi Lead Precision Machinery extends beyond commercial applications. We have contributed to projects requiring the highest standards of quality, including components used in Olympic-grade equipment and military-grade systems. These engagements demanded not only flawless execution but also rigorous documentation, traceability, and compliance with international standards such as ISO 9001 and AS9100. This background informs our approach to b and b mold engineering: every design is treated as mission-critical.

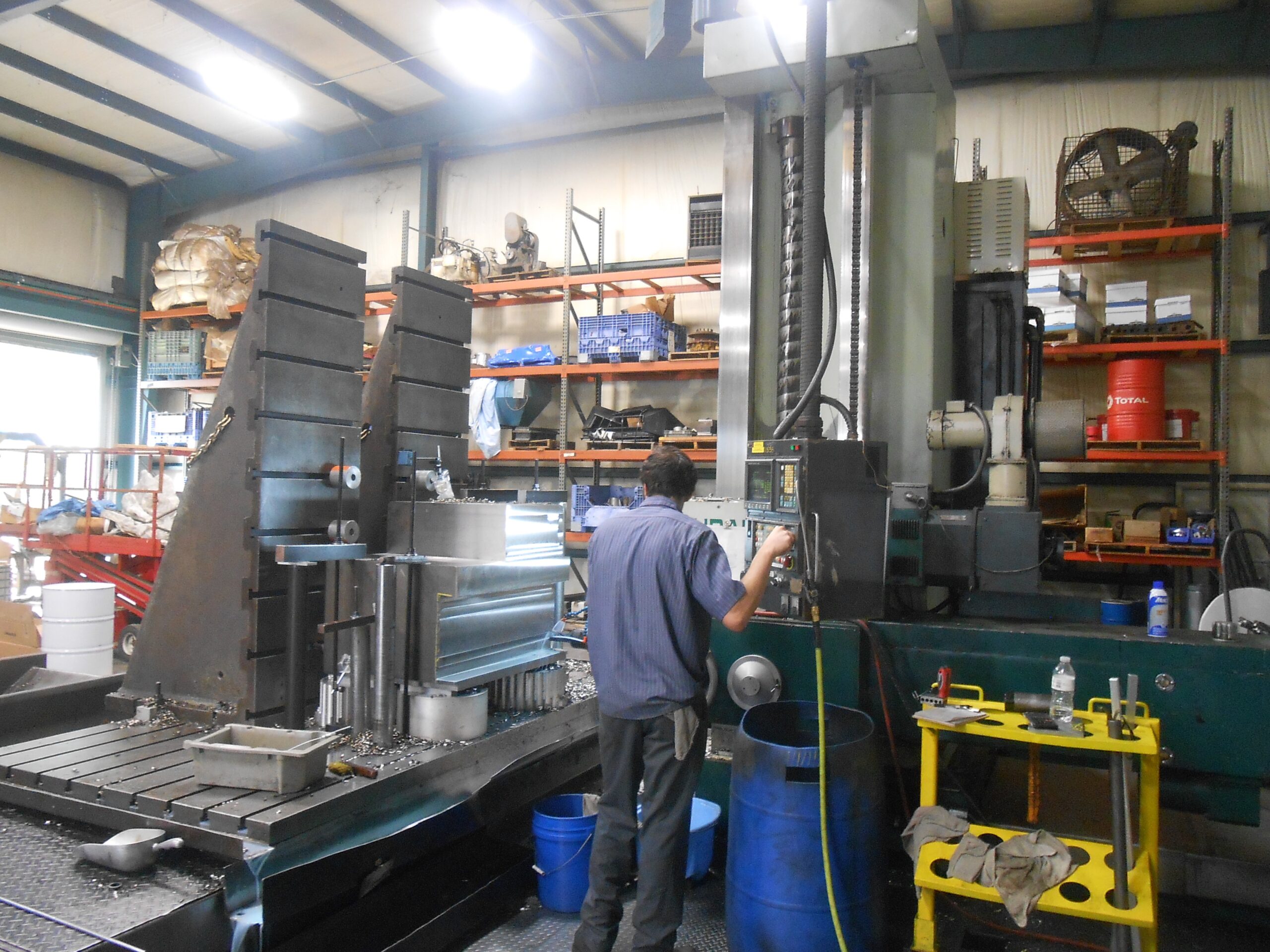

Precision begins at the design stage. Utilizing advanced 3D modeling and finite element analysis (FEA), we simulate thermal distribution, stress points, and ejection dynamics to optimize mold performance before any metal is cut. Our CNC machining centers, equipped with 5-axis capabilities and laser probing systems, ensure that tolerances are held within ±0.002 mm—a level of accuracy essential for b and b mold functionality. Surface finishes are controlled to Ra ≤ 0.05 µm where required, ensuring clean part release and optical-grade results.

Material selection is equally critical. We work with high-hardness tool steels such as H13, S136, and P20+, often enhanced with nitriding or PVD coatings to extend service life under abrasive or corrosive conditions. Each mold undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators to validate geometric conformity.

The table below outlines key precision specifications consistently achieved in our b and b mold production:

| Specification | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimension | ±0.01 mm | ±0.002 mm |

| Flatness | 0.01 mm/m | 0.005 mm/m |

| Parallelism | 0.01 mm | 0.003 mm |

| Surface Roughness (Ra) | 0.2 µm | ≤ 0.05 µm |

| Hole Position Accuracy | ±0.01 mm | ±0.005 mm |

At Wuxi Lead Precision Machinery, we view precision not as a target, but as a foundational principle. For b and b mold applications, this commitment translates into reliability, efficiency, and superior end-part quality—values that define leadership in advanced manufacturing.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Mold Applications

At Wuxi Lead Precision Machinery, we deliver the uncompromising precision and process control essential for high-performance mold manufacturing. Our core strength lies in integrating advanced multi-axis machining with rigorous metrology, specifically engineered to meet the stringent geometric and surface finish requirements of complex mold cores, cavities, inserts, and electrodes. This capability directly translates to reduced cycle times, extended mold life, and superior part quality for your production.

Our foundation is a modern fleet of high-torque, high-accuracy 5-axis CNC machining centers, including models from DMG MORI and MAZAK. These systems enable the complete machining of intricate 3D geometries in a single setup, eliminating cumulative errors inherent in multi-operation workflows. This is critical for maintaining the precise alignment of mold halves, undercuts, and fine texture details. Advanced toolpath strategies minimize tool deflection and thermal distortion, ensuring consistent wall thicknesses and critical draft angles down to the micron level. Material versatility spans hardened tool steels (H13, S7, P20+Ni), stainless grades, aluminum alloys, and specialized composites, all processed under optimized parameters to preserve material integrity and achieve mirror-like finishes where required.

Quality assurance is not a final step but an integrated process. Every critical feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM), including Zeiss CONTURA and GLOBAL series systems. Our ASQ-certified metrology team performs full 3D dimensional analysis against CAD models, validating complex contours, positional tolerances, and form accuracy. Statistical Process Control (SPC) data is generated for key characteristics, providing traceable evidence of conformance and enabling proactive process refinement. This systematic approach guarantees that dimensional stability is maintained throughout the entire mold assembly, preventing common failure points like flash, part ejection issues, or premature wear.

The following table details our standard achievable tolerance capabilities for critical mold features, reflecting our process capability under controlled conditions. Actual project tolerances are always defined collaboratively during engineering review based on material, geometry, and functional requirements.

| Feature Category | Standard Capability | Critical Feature Capability | Key Application Impact |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Core/cavity alignment, part fit |

| Geometric Form (Flatness, Roundness) | 0.010 mm | 0.003 mm | Sealing surfaces, sliding components |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | Ejector pin holes, cooling channels |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (Polished) | Aesthetic finish, release properties |

| Angular Features | ±0.05° | ±0.02° | Draft angles, complex undercuts |

This level of precision engineering ensures your molds perform reliably at peak efficiency from the first shot. We partner with clients like B&B Mold during the design phase to optimize manufacturability, leveraging our technical expertise to transform complex concepts into robust, high-yielding production tools. Contact our engineering team to discuss how our technical capabilities can be applied to your next precision mold project.

Material & Finish Options

Material selection is a critical decision in custom metal manufacturing, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining for high-demand industries such as aerospace, automotive, and medical devices. Our expertise enables us to guide clients through optimal material and surface treatment choices tailored to functional requirements and environmental conditions.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suited for applications requiring lightweight components without sacrificing structural integrity. Grade 6061-T6 is commonly used for general-purpose parts due to its weldability and corrosion resistance, while 7075-T6 offers higher strength for more demanding applications. Aluminum’s natural oxide layer provides some protection, but for enhanced durability and aesthetics, anodizing is recommended.

Steel remains the standard for high-strength, wear-resistant components. Among the most frequently used variants are stainless steel 304 and 316, which offer excellent corrosion resistance and are ideal for medical and food-grade applications. For structural or load-bearing parts, alloy steels such as 4140 or tool steels like H13 are preferred due to their hardness and fatigue resistance. While steel does not anodize, surface treatments such as passivation, plating, or powder coating can be applied to improve longevity and appearance.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosion make it indispensable in aerospace and medical implant manufacturing. Though more challenging to machine and higher in cost, titanium delivers unmatched performance where reliability under stress is non-negotiable.

Anodizing is a key surface treatment for aluminum components, enhancing wear and corrosion resistance while allowing for color coding and improved aesthetics. The process creates a controlled oxide layer that integrates with the base material, ensuring it does not peel or flake. Type II anodizing (sulfuric acid anodizing) is standard for decorative and moderate protection needs, while Type III (hard anodizing) provides a thicker, harder coating suitable for industrial and military applications. We offer precision anodizing services with tight control over coating thickness and color consistency.

Below is a comparison of key material properties for common alloys used in custom manufacturing.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Typical Surface Treatment |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Enclosures, brackets, heat sinks | Type II/III Anodizing |

| Aluminum 7075-T6 | 572 | 2.8 | Aerospace components | Hard Anodizing |

| Stainless 304 | 505 | 8.0 | Medical devices, food equipment | Passivation, Polishing |

| Stainless 316 | 570 | 8.0 | Marine, chemical processing | Electropolishing |

| Steel 4140 | 655 | 7.85 | Shafts, tooling | Chrome Plating, Nitriding |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aircraft, implants | Anodizing (non-color), Passivation |

At Wuxi Lead Precision Machinery, we combine advanced CNC capabilities with deep materials knowledge to deliver components that meet exacting technical standards. Our engineering team works closely with clients to select the optimal material and finish combination, ensuring performance, compliance, and cost-effectiveness across the product lifecycle.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production workflow for custom metal components, specifically engineered for high-performance molds like blow molding and bottle molds. Our integrated approach ensures dimensional accuracy, material integrity, and operational reliability from initial design through mass production, with zero defects as the non-negotiable standard.

Design Phase

Collaborative engineering begins with detailed client specifications and 3D CAD models. Our team conducts comprehensive Design for Manufacturability (DFM) analysis, identifying potential thermal distortion, stress points, or cooling inefficiencies unique to mold applications. Finite Element Analysis (FEA) simulates thermal cycling and pressure loads, optimizing cavity geometry and ejector systems. Critical tolerances are defined per ISO 2768-mK standards, with material selection (e.g., P20, H13, or custom alloy steels) validated against corrosion resistance and wear requirements. Client sign-off on finalized designs includes explicit agreement on inspection protocols and critical-to-quality (CTQ) parameters.

Prototyping Phase

Rapid prototyping transforms validated designs into physical test units using 5-axis CNC milling and sinker EDM. Each prototype undergoes rigorous dimensional validation via CMM and optical comparators, with surface roughness measured to Ra 0.4 µm or finer for cavity surfaces. Functional testing replicates injection pressures up to 150 MPa and thermal cycles exceeding 500,000 shots. Any deviations trigger immediate root-cause analysis and design iteration. This phase confirms mold flow dynamics, ejection stability, and part consistency, reducing mass production risks by 90%. Only prototypes passing 100% of CTQ checks advance to full-scale manufacturing.

Mass Production Phase

Zero-defect mass production leverages automated CNC cells with real-time tool wear monitoring and closed-loop dimensional control. Statistical Process Control (SPC) tracks critical parameters like cavity temperature uniformity (±1°C) and clamping force consistency. Every component undergoes 100% post-machining inspection: CMM verification against GD&T callouts, ultrasonic testing for subsurface integrity, and automated vision systems detecting micro-burrs. Non-conforming parts are quarantined instantly, with corrective actions documented in our traceability system. Production batches ship with full inspection reports, including material certs and process capability indices (Cp/Cpk ≥1.67).

Key Production Specifications

| Parameter | Capability Range | Standard Tolerance | Testing Method |

|---|---|---|---|

| Linear Dimensions | 1–1200 mm | ±0.005 mm | CMM (0.0005 mm res) |

| Surface Roughness | Cavity/Runner Surfaces | Ra 0.2–0.8 µm | Profilometer |

| Geometric Tolerances | Position/Flatness | ±0.01 mm | CMM/Optical Comparator |

| Material Hardness | H13/P20 Steels | HRC 48–52 ±1 | Rockwell Tester |

| Production Volume | Prototype to 50,000 units | N/A | SPC-Monitored |

This disciplined workflow eliminates costly rework and downtime for mold operators. By embedding quality at every phase—from predictive design validation to SPC-driven mass production—we deliver molds that achieve >99.98% uptime in client operations. Partner with Wuxi Lead to transform precision engineering into your competitive advantage. Total cost of ownership decreases when zero defects become the foundation of manufacturing excellence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and speed are non-negotiable in high-end manufacturing. As a trusted partner to global leaders in automotive, aerospace, medical, and consumer electronics industries, we specialize in delivering custom metal components that meet the most demanding specifications. When you choose to collaborate with us, you are not just sourcing parts—you are gaining a strategic manufacturing ally with deep engineering expertise, cutting-edge CNC capabilities, and an unwavering commitment to quality.

Our facility in Wuxi, China, spans over 10,000 square meters and is equipped with advanced multi-axis CNC machining centers, high-precision grinding systems, and automated inspection technologies. Every process is ISO 9001:2015 certified and supported by a team of senior engineers with over 15 years of industry experience. From initial design review to final delivery, we ensure seamless integration with your supply chain, offering rapid prototyping, DFM analysis, and scalable production runs—all under strict confidentiality and compliance standards.

We pride ourselves on solving complex manufacturing challenges with precision and efficiency. Whether you require tight tolerances of ±0.002 mm, complex geometries in hardened steels, or high-mix, low-volume production, our systems are engineered to deliver consistent results. Our in-house capabilities include CNC milling, turning, wire EDM, surface grinding, and precision assembly, enabling us to handle complete part fabrication from raw material to finished component.

Below are key technical specifications that define our manufacturing capacity:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 600 mm |

| CNC Milling | 3-axis, 4-axis, 5-axis |

| CNC Turning | Diameter up to 300 mm, Length up to 600 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Tool Steel, Brass, PEEK, and more |

| Surface Finish | Ra 0.2 μm to Ra 3.2 μm (customizable) |

| Secondary Operations | Heat treatment, plating, anodizing, passivation, laser marking |

| Quality Control | CMM, optical comparators, surface roughness testers, 100% inspection reporting |

Our clients choose us not only for our technical capabilities but for our responsive partnership model. We assign a dedicated project manager to every engagement, ensuring clear communication, real-time updates, and agile problem-solving throughout the production cycle. With lead times optimized through lean manufacturing practices and a robust supply chain network, we consistently deliver on time—every time.

If you are looking for a precision manufacturing partner that combines engineering excellence with operational reliability, we invite you to contact us today. Let us help you bring your most demanding designs to life with confidence and precision.

Email us at [email protected] to begin your project consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.