Technical Contents

Engineering Guide: Pcb Cnc Machine

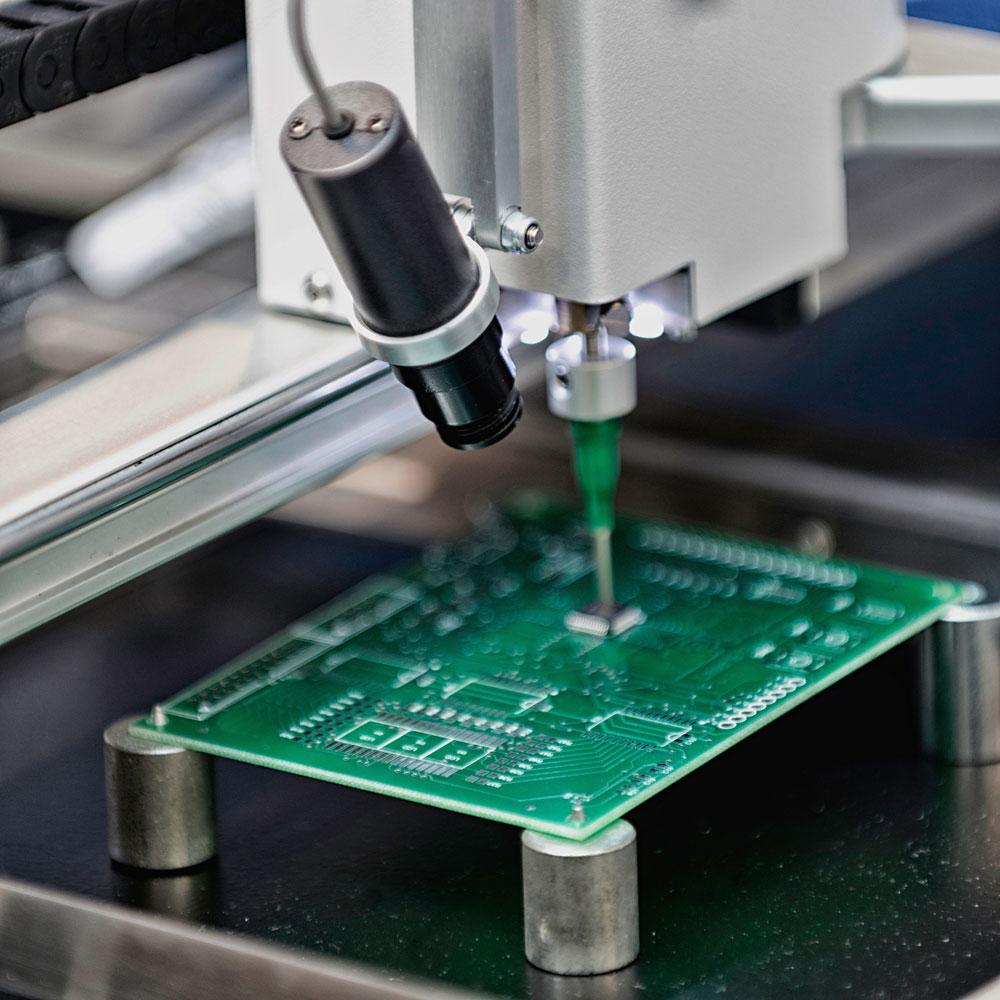

Engineering Insight Precision Imperatives in PCB CNC Machining

Achieving micron-level precision in PCB manufacturing is non-negotiable for modern electronics. Circuit features continue shrinking while layer counts increase, demanding CNC machines capable of sub-micron tolerances consistently. A single micron of positional error can compromise trace integrity, cause micro-vias to misalign, or create impedance mismatches in high-frequency designs. This precision directly impacts yield rates, signal integrity, and the ultimate reliability of end products – from 5G infrastructure to medical implants. The challenge extends beyond raw machine accuracy; it encompasses thermal stability during extended production runs, vibration isolation in industrial environments, and the dynamic responsiveness of the motion control system when machining complex multi-layer stacks. Minute thermal expansion in the machine structure or spindle can induce errors exceeding the feature size itself. Consequently, the CNC platform must integrate advanced materials, real-time compensation algorithms, and rigorous environmental management to maintain dimensional fidelity throughout the machining cycle.

Wuxi Lead Precision Machinery addresses these critical demands through engineered solutions focused on intrinsic stability and intelligent control. Our PCB CNC platforms utilize granite composite bases for exceptional damping and thermal inertia, minimizing deflection and drift. Direct-drive linear motors on all axes eliminate backlash and provide the smooth, high-resolution motion essential for fine feature routing and micro-drilling. Crucially, our proprietary thermal management system actively monitors critical points and dynamically compensates for thermal growth, ensuring accuracy remains within specification even during 24/7 operation. This holistic approach to precision engineering is validated not only through stringent ISO calibration but through deployment in the most demanding applications.

The following specifications represent the core precision capabilities of our flagship PCB CNC machining centers, engineered for uncompromising performance in high-mix, high-complexity production:

| Parameter | Specification | Significance for PCB Manufacturing |

|---|---|---|

| Positioning Accuracy | ±1.5 µm (ISO 230-2) | Ensures exact placement of micro-vias and fine traces |

| Repeatability | ±0.8 µm | Guarantees consistent feature replication across panels |

| Spindle Runout (TIR) | ≤ 0.5 µm | Critical for clean hole walls and burr-free routing |

| Thermal Drift Comp. | < 2 µm over 8 hours | Maintains accuracy during extended production cycles |

| Linear Axis Resolution | 0.05 µm | Enables precise control for intricate contour machining |

This commitment to measurable precision is proven in action. Lead Precision CNC systems were selected for critical components in Olympic venue infrastructure, machining complex LED display interconnects where failure was not an option. Similarly, our machines meet stringent military-grade specifications (MIL-PRF-31032) for avionics and defense electronics, where traceability and absolute dimensional conformity are mandated. These projects demanded and validated our ability to deliver micron-perfect results under rigorous quality audits. For PCB manufacturers targeting high-reliability markets, partnering with a machine builder possessing this depth of proven precision engineering expertise is fundamental to achieving competitive yield, quality, and market access. Precision isn’t merely a specification; it is the cornerstone of viable advanced PCB production.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, specifically engineered to meet the stringent demands of high-performance PCB (Printed Circuit Board) manufacturing. Our 5-axis CNC machining centers represent the forefront of industrial automation and accuracy, enabling complex geometries, tight tolerances, and superior surface finishes essential for modern electronic components. These multi-axis systems allow simultaneous movement across five axes, providing unparalleled flexibility in machining intricate features on PCB molds, housings, connectors, and insulating substrates with minimal setup changes.

Our 5-axis CNC platforms are equipped with high-speed spindles, thermal compensation systems, and dynamic tool path optimization to ensure consistent material removal rates and dimensional stability. This level of control is critical when working with delicate composite materials such as FR-4, polyimide, and ceramic-filled PTFE, commonly used in high-frequency and high-reliability PCB applications. The integration of advanced CNC controls and real-time monitoring systems ensures process repeatability and minimizes human intervention, resulting in reduced cycle times and enhanced throughput without compromising quality.

To uphold the highest standards of precision, every machined component undergoes rigorous quality control through Coordinate Measuring Machine (CMM) inspection. Our CMM systems utilize tactile and optical probing technologies to verify critical dimensions, geometric tolerances, and surface profiles against original CAD models. This metrology-driven validation process ensures full traceability and compliance with international standards such as ISO 2768 and IPC-6012 for printed board performance.

All inspection data is documented and archived for each production batch, supporting full quality audits and customer certification requirements. This closed-loop quality assurance system is integral to our commitment to zero-defect manufacturing, especially for mission-critical industries including telecommunications, aerospace, medical devices, and industrial automation.

The following table outlines the standard technical specifications and achievable tolerances for our PCB CNC machining services:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Center |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (Standard) | ±0.01 mm per 100 mm |

| Geometric Tolerance | ±0.008 mm (flatness, parallelism, etc.) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (adjustable per requirement) |

| Minimum Feature Size | 0.2 mm (milling) |

| Materials Supported | FR-4, PTFE, Polyimide, Ceramic Composites, Aluminum, Brass |

| Inspection Method | CMM (Coordinate Measuring Machine) |

| Compliance Standards | ISO 9001, ISO 2768, IPC-6012 |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with disciplined quality assurance to deliver PCB-related components that meet the exacting needs of advanced electronics manufacturing. Our technical capabilities are designed not only to achieve precision but to sustain it across high-volume production runs.

Material & Finish Options

Material Selection for Precision PCB CNC Machining

Selecting optimal materials is critical in PCB machining where thermal management, signal integrity, and dimensional stability directly impact performance. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability with end-use requirements. Aluminum alloys dominate for heat sinks and enclosures due to exceptional thermal conductivity and lightweight properties. Steel variants like 303 or 1018 are chosen for structural brackets requiring rigidity and EMI shielding. Titanium finds niche use in aerospace-grade PCB assemblies where extreme corrosion resistance and strength-to-weight ratios justify higher machining costs. Each material demands precise CNC parameters to avoid micro-fractures or surface defects that compromise PCB functionality.

Aluminum 6061-T6 remains the industry standard for thermal management components. Its machinability allows high-speed milling with minimal tool wear, producing smooth surfaces essential for solder adhesion. However, raw aluminum lacks wear resistance and is prone to galvanic corrosion. Steel offers superior hardness for mounting hardware but requires slower feed rates to prevent work hardening. Titanium Grade 2 excels in harsh environments but necessitates rigid machine setups and specialized cutters to manage its low thermal conductivity and tendency to gall.

Anodizing is the definitive surface treatment for aluminum PCB components. This electrochemical process creates a durable, non-conductive oxide layer that enhances corrosion resistance and provides electrical insulation critical for high-voltage applications. Hard anodizing (Type III) achieves thicknesses of 25–50 µm for severe wear environments, while standard sulfuric anodizing (Type II) suffices for most PCB enclosures. Crucially, anodizing preserves dimensional tolerances within ±0.005 mm when controlled precisely—achieved through our CNC systems’ integrated process monitoring. Avoid chromate conversion coatings for PCBs; they lack the dielectric strength required for modern high-frequency circuits.

Material performance metrics guide optimal selection. The following table compares key properties relevant to PCB machining:

| Material | Thermal Conductivity (W/m·K) | Machinability Rating | Typical PCB Application |

|---|---|---|---|

| Aluminum 6061 | 167 | 100% (Benchmark) | Heat sinks, chassis, enclosures |

| Steel 303 | 16 | 70% | EMI shields, mounting hardware |

| Titanium Gr2 | 17 | 35% | Aerospace connectors, medical |

Wuxi Lead’s 5-axis CNC platforms deliver micron-level accuracy across all three materials through adaptive spindle control and thermal compensation systems. For aluminum, we optimize high-RPM strategies to prevent built-up edge; for titanium, our low-vibration toolpaths eliminate chatter marks that could initiate corrosion. Always specify anodizing requirements during design phase—our engineering team validates coating compatibility with tight-tolerance features like threaded inserts or grounding pads. Consult our application specialists to match material and finish specifications with your PCB’s operational demands, ensuring reliability from prototyping to high-volume production.

Manufacturing Process & QC

The production process for PCB CNC machines at Wuxi Lead Precision Machinery follows a disciplined, three-phase methodology—Design, Prototyping, and Mass Production—engineered to achieve zero defects and uncompromising precision. Each stage integrates advanced engineering protocols, real-time data monitoring, and stringent quality validation to ensure every machine meets the highest standards of performance, reliability, and repeatability required in modern PCB manufacturing.

Design begins with a comprehensive analysis of customer specifications, production volume requirements, and substrate materials. Our engineering team utilizes integrated CAD/CAM/CAE platforms to model machine kinematics, toolpath optimization, and thermal stability. Finite element analysis (FEA) is applied to predict structural behavior under operational stress, ensuring rigidity and minimizing vibration. All design parameters are validated against IPC-2221 and ISO 13041 standards, with a focus on micron-level accuracy, tool life optimization, and minimal maintenance cycles. Thermal compensation algorithms and spindle dynamics are simulated to guarantee consistent cutting performance across diverse PCB materials, including FR-4, polyimide, and high-frequency laminates.

Prototyping transforms validated designs into fully functional test units. Each prototype undergoes a 72-hour continuous dry run followed by controlled production trials using customer-specified PCB stack-ups. In-process monitoring captures spindle load, positional accuracy, and dust extraction efficiency. Laser interferometry verifies linear positioning accuracy to within ±2 µm, while acoustic emission sensors detect early signs of tool wear or misalignment. Feedback from this phase drives iterative refinements in motion control parameters and software logic. Only after achieving 100% pass rate on dimensional tolerance, edge quality, and cycle time benchmarks is the design released for mass production.

Mass Production is executed on a lean manufacturing line with full traceability. Each machine is assembled using calibrated torque tools, and critical components such as linear guides and ball screws are tagged with QR codes for lifecycle tracking. Automated optical inspection (AOI) confirms PCB routing accuracy during test runs, while environmental stress screening (ESS) exposes units to variable thermal and vibration loads to identify latent defects. Final validation includes a 48-hour endurance test under maximum load conditions. The entire process is governed by a closed-loop quality management system compliant with ISO 9001:2015, enabling real-time deviation correction and zero-defect delivery.

The following table outlines key performance specifications achieved through this process:

| Specification | Value | Standard/Test Method |

|---|---|---|

| Positioning Accuracy | ±2 µm | ISO 230-2 |

| Repeatability | ±1 µm | ISO 230-2 |

| Spindle Speed Range | 60,000 – 120,000 rpm | ISO 1940-1 |

| Maximum Feed Rate | 1,200 mm/s | Internal Test Protocol |

| Tool Life Monitoring | Real-time load sensing | Proprietary Algorithm |

| Minimum Feature Size | 0.1 mm | IPC-6012 Class 3 |

| Dust Extraction Efficiency | >98% | GB/T 16157 |

This end-to-end process ensures that every PCB CNC machine delivered by Wuxi Lead Precision Machinery operates at the pinnacle of precision, durability, and process stability, empowering global electronics manufacturers with defect-free production capability.

Why Choose Wuxi Lead Precision

Elevate Your PCB Production with Engineered Precision

In the demanding realm of printed circuit board manufacturing, tolerances measured in microns separate success from costly scrap. Generic CNC solutions cannot consistently deliver the surface finish, dimensional accuracy, and thermal stability required for high-density interconnects, rigid-flex substrates, or advanced HDI applications. At Wuxi Lead Precision Machinery, we engineer CNC platforms exclusively for PCB fabrication challenges, where 0.001mm positioning repeatability and sub-5μm surface roughness are non-negotiable standards. Our machines integrate proprietary motion control algorithms and vibration-damped cast iron bases to eliminate micro-chatter during micro-milling, laser routing, and drill-depth sensing operations. This eliminates the hidden costs of rework, material waste, and production bottlenecks that plague manufacturers relying on repurposed industrial equipment.

Technical Excellence Built into Every System

Our flagship PCB CNC platforms are validated under ISO 2768-mK standards and feature dual-stage thermal compensation systems to maintain accuracy across 24/7 production cycles. The table below details core specifications critical for next-generation PCB workflows:

| Specification | Value | Industry Impact |

|---|---|---|

| Positioning Accuracy | ±0.001mm | Ensures perfect via alignment in HDI stacks |

| Spindle Runout | ≤0.0005mm (at 60,000 RPM) | Eliminates drill wander in 0.1mm microvias |

| Surface Roughness (Ra) | 0.8μm – 3.2μm | Meets IPC-6012 Class 3 surface requirements |

| Thermal Drift Control | ±1.5μm over 8 hours | Maintains dimensional stability in uncontrolled environments |

| Vacuum Table Flatness | ±0.005mm across 500x500mm | Prevents substrate warpage during milling |

Your Partnership Includes More Than Hardware

Choosing Lead Precision means gaining a dedicated engineering extension of your team. We conduct on-site process audits to optimize toolpaths, material feeds, and coolant strategies specific to your FR-4, polyimide, or ceramic substrates. Our global service network provides 24/7 remote diagnostics and on-call field engineers who resolve 92% of critical issues within 4 business hours—minimizing line stoppages. Clients consistently report 18-22% reductions in scrap rates and 30% faster changeover times after integration. This is precision engineering translated into measurable ROI: higher yield, accelerated time-to-market, and uncompromised reliability for aerospace, medical, and 5G infrastructure applications.

Initiate Your Precision Transformation

The complexity of next-generation PCBs demands a partner with proven mastery in micron-level machining—not just equipment sales. Wuxi Lead Precision Machinery delivers the convergence of German-grade engineering rigor and responsive Chinese manufacturing agility. Contact our technical sales team to schedule a confidential production assessment. We will analyze your current pain points, demonstrate machine performance with your actual substrates, and provide a detailed cost-per-part analysis. Email [email protected] with your substrate materials, tolerance requirements, and target throughput. Our engineers will respond within 4 business hours with actionable solutions—not generic brochures. Trust the partner trusted by tier-1 PCB fabricators across 27 countries to turn precision specifications into production reality. Your journey toward zero-defect manufacturing starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.