Technical Contents

Engineering Guide: United Sheet Metal Company

Engineering Insight: united sheet metal company

In the realm of modern manufacturing, precision is not merely a quality benchmark—it is a foundational requirement. For high-performance industries such as aerospace, defense, and advanced infrastructure, even micrometer-level deviations can compromise structural integrity, safety, and system functionality. united sheet metal company operates at the forefront of this demanding landscape, where engineering excellence and dimensional accuracy are non-negotiable. The integration of advanced CNC technology, rigorous material science, and disciplined process control defines the standard of precision that customers now expect.

At Wuxi Lead Precision Machinery, we understand that precision begins long before the first cut is made. It starts with design validation, material selection, and toolpath optimization. Our engineering team leverages decades of experience in high-stakes fabrication environments, including projects tied to Olympic infrastructure developments and military-grade equipment manufacturing. These applications demand not only repeatability and tolerance adherence but also full traceability and compliance with international standards such as ISO 9001 and MIL-STD-810.

Our collaboration with partners like united sheet metal company is built on a shared commitment to excellence. By combining Lead Precision’s expertise in CNC turret punching, laser cutting, and automated bending systems with united sheet metal company’s fabrication mastery, we deliver components that meet exacting specifications under tight deadlines. This synergy ensures minimal waste, reduced cycle times, and consistent output across production runs—critical factors in large-scale or mission-critical operations.

Precision engineering also extends to the equipment used in fabrication. At Wuxi Lead, our machines are calibrated daily and operate within tightly controlled environmental conditions to eliminate thermal drift and mechanical variance. Advanced feedback systems and in-process inspection tools allow real-time monitoring of dimensional accuracy, ensuring every part conforms to blueprint requirements.

Below are key performance specifications achieved through our integrated engineering and manufacturing approach:

| Specification | Value | Standard/Testing Method |

|---|---|---|

| Positional Accuracy | ±0.02 mm | ISO 230-2 |

| Repeatability | ±0.01 mm | ISO 230-2 |

| Material Thickness Range | 0.5 – 6.0 mm | Cold Rolled Steel, Aluminum, Stainless |

| Tolerance Class | IT7–IT9 | ISO 2768 |

| Surface Roughness (Ra) | ≤1.6 μm | ISO 1302 |

| Laser Cutting Kerf Width | 0.1 – 0.2 mm | Fiber Laser 6kW |

These figures reflect more than technical capability—they represent a culture of discipline, continuous improvement, and accountability. Whether producing intricate panels for secure communication enclosures or structural elements for rapid deployment shelters, Wuxi Lead Precision Machinery ensures that every product supports the operational reliability required by united sheet metal company and its elite clientele.

Precision is not an outcome—it is a process. And at Wuxi Lead, it is engineered into every stage of production.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Sheet Metal Solutions

Wuxi Lead Precision Machinery delivers uncompromising accuracy and versatility in sheet metal fabrication, specifically engineered to meet the stringent demands of high-end industrial applications. Our core strength lies in advanced multi-axis machining, eliminating the limitations of conventional processes and enabling the production of highly complex geometries from a single setup. This integrated approach significantly reduces lead times, minimizes cumulative error, and ensures superior part consistency critical for aerospace, medical, and advanced automation sectors.

Central to our capability is a dedicated fleet of state-of-the-art 5-axis CNC milling and turning centers. These machines feature simultaneous 5-axis contouring, allowing intricate 3D surfaces, deep cavities, and undercuts to be machined with exceptional precision directly from solid stock or near-net shapes. Utilizing high-rigidity spindles, advanced toolpath strategies, and real-time adaptive control, we achieve superior surface finishes and maintain tight tolerances across diverse materials including aluminum alloys, stainless steels, titanium, and specialty alloys. The elimination of secondary operations inherent in 5-axis machining translates directly to enhanced part integrity and reduced total production cost for our clients.

Rigorous quality control is not an endpoint but an embedded process within our manufacturing workflow. Every critical dimension and feature undergoes validation using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Mitutoyo CMM systems, operating under ISO 17025 accredited procedures, provide traceable, micron-level verification of complex geometries against nominal CAD data. This comprehensive inspection regime, combined with in-process probing on machining centers, ensures 100% compliance with customer specifications and stringent industry standards before any component leaves our facility. Statistical Process Control (SPC) methodologies are actively employed to monitor capability and drive continuous improvement.

The following table details our standard achievable geometric tolerances for critical sheet metal fabrication and machining processes, reflecting our commitment to dimensional integrity:

| Feature | Specification | Process Impact |

|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | Ensures precise fit for assembly interfaces |

| Hole Position | ±0.0125 mm (±0.0005″) | Critical for bolt patterns and alignment |

| Flatness | 0.05 mm per 100 mm | Guarantees sealing surfaces and stability |

| Perpendicularity | 0.025 mm | Maintains structural integrity and function |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | Meets functional and aesthetic requirements |

| Angular Features | ±0.05° | Essential for complex 3D assemblies |

Wuxi Lead Precision Machinery provides United Sheet Metal Company with more than just fabrication; we deliver a certified, repeatable process where extreme precision and complex geometry are standard requirements, not exceptions. Our technical infrastructure and quality culture ensure your most demanding sheet metal components are manufactured to exacting specifications, on time and with full traceability. Partner with us for solutions where dimensional accuracy is non-negotiable.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a foundational decision in sheet metal fabrication, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we support partners like United Sheet Metal Company with engineered material solutions tailored to demanding industrial applications. Among the most widely used materials in high-precision fabrication are aluminum, steel, and titanium—each offering distinct mechanical and chemical properties suited to specific operational environments.

Aluminum is prized for its high strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. It is ideal for aerospace, transportation, and electronics enclosures where weight reduction is critical. Grade 6061-T6 is commonly specified for structural components due to its weldability and machinability. However, aluminum’s lower hardness compared to steel requires careful handling during forming and finishing operations.

Steel remains the backbone of industrial fabrication, with carbon steel and stainless steel variants serving diverse needs. Carbon steel, such as ASTM A36 or SPCC, offers high tensile strength and cost-effective formability, making it suitable for enclosures, frames, and heavy-duty machinery. Stainless steel—particularly grades 304 and 316—delivers superior corrosion resistance and aesthetic finish, making it ideal for food processing, medical equipment, and marine environments. Its higher hardness enhances wear resistance but demands more robust tooling during laser cutting and bending.

Titanium, while significantly more expensive, is unmatched in strength-to-density ratio and resistance to extreme environments. Grade 2 and Grade 5 (Ti-6Al-4V) are frequently used in aerospace, defense, and high-performance automotive applications where exposure to high temperatures and corrosive media is expected. Titanium’s low thermal conductivity and high reactivity require specialized CNC processing techniques, which Wuxi Lead Precision Machinery implements with enclosed tooling systems and inert gas shielding.

Surface finish selection further enhances material performance. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves wear and corrosion resistance while allowing for color coding. Hard anodizing (Type III) can achieve coating thicknesses up to 50 µm, suitable for high-abrasion environments. For steel, alternatives such as powder coating, galvanization, or passivation are typically used, while titanium often receives bead blasting or chemical passivation to maintain integrity without compromising performance.

Below is a comparative overview of key material specifications:

| Material | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 310 | High | Aerospace, Electronics, Transport |

| Carbon Steel | SPCC, ASTM A36 | 7.85 | 370–500 | Low (without coating) | Industrial Frames, Machinery |

| Stainless Steel | 304, 316 | 8.0 | 515–620 | Very High | Medical, Food Processing, Marine |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 4.5 | 860–1100 | Exceptional | Aerospace, Defense, High-Heat |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle costs. Wuxi Lead Precision Machinery provides comprehensive material certification and process validation to ensure every fabricated component meets exacting international standards.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Sheet Metal Fabrication Production Process

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for zero-defect outcomes, integrating rigorous engineering controls from initial concept to full-scale production. With 15 years of aerospace and medical-grade manufacturing expertise, we prioritize defect prevention over detection, ensuring every component meets exacting global standards. Our three-phase methodology—Design, Prototyping, and Mass Production—eliminates cost-driving errors while accelerating time-to-market for partners like United Sheet Metal Company.

Design Phase: Precision Engineering Foundation

We initiate collaboration during the design stage, applying Design for Manufacturability (DFM) principles to optimize geometry, material selection, and tooling strategy. Our engineers conduct virtual stress analysis and laser-cut path simulations using Siemens NX software, identifying potential deformation or tolerance stack-up risks before physical work begins. Critical parameters like bend allowance, kerf width, and grain direction are validated against ISO 2768-mK standards, ensuring manufacturability aligns with functional requirements. This phase reduces downstream rework by up to 40% through proactive error elimination.

Prototyping Phase: Validation Under Real Conditions

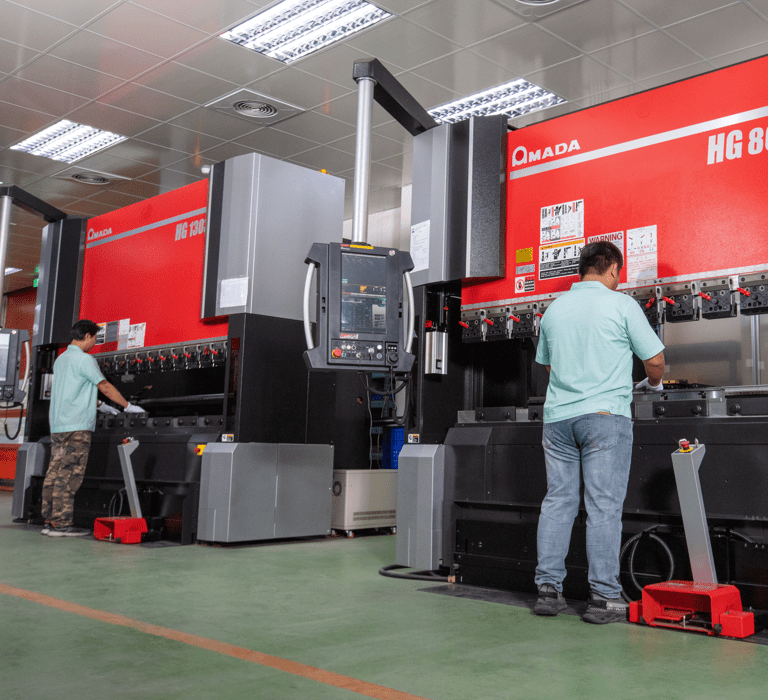

Prototypes are produced on the same production-grade machinery used for final runs—Amada LC-3015 AJ fiber lasers and TruBend 7030 press brakes—ensuring process consistency. Each prototype undergoes full metrology validation via Zeiss CONTURA CMM systems, with reports detailing dimensional accuracy against CAD models. We perform iterative adjustments based on empirical data, not assumptions, focusing on critical-to-quality (CTQ) features. This phase confirms tooling stability, material behavior, and secondary operation sequencing, guaranteeing the production process blueprint is defect-proofed.

Mass Production: Sustained Zero-Defect Execution

Our production floor operates under closed-loop Statistical Process Control (SPC), with real-time monitoring of laser power, press brake tonnage, and robotic handling. Every 50th part undergoes automated inline inspection via vision systems, while first-article and end-of-batch checks follow AS9102 aerospace protocols. Material traceability is maintained through blockchain-secured logs, linking each component to its raw material heat number and process parameters. This system achieves sub-0.1% defect rates, validated by our ISO 9001:2015 and IATF 16949-certified quality management framework.

Process Capability Specifications

| Parameter | Design Phase Tolerance | Prototyping Tolerance | Mass Production Tolerance | Measurement Method |

|---|---|---|---|---|

| Linear Dimension | ±0.1 mm | ±0.05 mm | ±0.03 mm | CMM (ISO 10360-2) |

| Hole Position | ±0.15 mm | ±0.08 mm | ±0.05 mm | Vision System (ASME B89.4.19) |

| Bend Angle | ±0.5° | ±0.3° | ±0.2° | Laser Angle Sensor |

| Surface Roughness (Ra) | 3.2 µm | 1.6 µm | 0.8 µm | Profilometer (ISO 4287) |

This integrated approach transforms theoretical designs into flawless physical products. By embedding quality into each phase—rather than inspecting it in—we deliver consistent, auditable results that protect your reputation and reduce total cost of ownership. Partner with Wuxi Lead to convert precision engineering into your competitive advantage.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to elevate your sheet metal fabrication capabilities to the highest industrial standards. As a globally recognized leader in precision engineering, we deliver advanced manufacturing solutions tailored to the complex demands of high-end industrial clients. Our collaboration with United Sheet Metal Company is built on a foundation of technical excellence, operational reliability, and long-term value creation.

At Wuxi Lead, we specialize in end-to-end sheet metal fabrication processes, including laser cutting, CNC punching, precision bending, robotic welding, and automated assembly. Our facility operates under strict ISO 9001 and ISO 14001 certifications, ensuring every component meets exacting quality and environmental standards. With over 15 years of experience serving aerospace, energy, transportation, and industrial equipment sectors, we bring deep domain expertise to every partnership.

Our investment in state-of-the-art machinery and digital manufacturing systems enables unmatched repeatability, tight tolerance control, and rapid turnaround times. We understand that in high-mix, low-volume production environments, flexibility and precision are non-negotiable. That’s why our production lines integrate real-time monitoring, automated material handling, and in-process quality verification to minimize variability and maximize throughput.

When you partner with Wuxi Lead, you gain more than a supplier — you gain a strategic manufacturing ally. Our engineering team works closely with your design and operations staff to optimize part manufacturability, reduce material waste, and streamline assembly integration. From prototype development to full-scale serial production, we ensure seamless scalability and consistent output quality.

We are committed to transparency, responsiveness, and continuous improvement. Every project is managed through a dedicated account engineer who provides regular updates, technical documentation, and logistical coordination. Our supply chain is resilient, with dual sourcing for critical components and a robust inventory management system to support just-in-time delivery.

To explore how Wuxi Lead Precision Machinery can enhance your fabrication capabilities, contact us today at [email protected]. Let us demonstrate how precision, reliability, and partnership drive superior manufacturing outcomes.

Technical Specifications and Capabilities

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm (steel), up to 12 mm (aluminum) |

| Max. Laser Cutting Area | 4000 mm × 2000 mm |

| CNC Punching Capacity | Up to 60 tons, multi-tool turret |

| Bending Length | Up to 6000 mm |

| Bending Tolerance | ±0.1° angular, ±0.2 mm linear |

| Welding Processes | MIG, TIG, Spot, Robotic Arc |

| Surface Treatments | Powder coating, anodizing, plating, passivation |

| Quality Standards | ISO 9001:2015, ISO 14001:2015, RoHS compliant |

| Lead Time (Average) | 7–15 days, depending on complexity and volume |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks, CATIA |

Contact us at [email protected] to begin a partnership grounded in precision, performance, and mutual success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.