Technical Contents

Engineering Guide: Cnc Instant Quote

Engineering Insight: The Critical Role of Precision in CNC Instant Quote Systems

In the world of high-end manufacturing, precision is not a luxury—it is a fundamental requirement. When integrating CNC instant quote systems into production workflows, the accuracy of specifications, tolerances, and material selections directly impacts the reliability and performance of the final component. At Wuxi Lead Precision Machinery, we understand that even the most advanced quoting platform must be grounded in engineering rigor and deep manufacturing expertise. Our decades-long commitment to precision has enabled us to serve sectors where failure is not an option: Olympic-grade sports technology and mission-critical military applications.

Our involvement in Olympic projects—such as manufacturing lightweight, high-strength components for competitive bobsleds and track cycling frames—demanded micron-level tolerances and flawless repeatability. These components were subjected to extreme mechanical stress and aerodynamic scrutiny, where deviations of even 0.01 mm could compromise performance. Similarly, in defense-sector contracts, we produced structural and actuation parts for surveillance and mobility platforms, where environmental resilience and dimensional stability under thermal and vibrational load were non-negotiable. These experiences have shaped our philosophy: precision begins at the quote stage.

A CNC instant quote is more than a price estimator—it is the first technical agreement between manufacturer and client. At Lead Precision, our quoting engine is calibrated using real-world machining data from over 15,000 completed precision runs. This ensures that lead times, feasibility assessments, and cost projections reflect not just algorithmic logic, but actual shop-floor capability. Unlike generic platforms that rely on broad assumptions, our system factors in material anisotropy, tool deflection, thermal expansion coefficients, and post-processing requirements—variables often overlooked but critical to high-integrity outcomes.

We do not treat every part as a standalone transaction. Instead, our quoting process incorporates design-for-manufacturability (DFM) feedback in real time, allowing engineers to optimize wall thicknesses, fillet radii, and tolerance stacks before production begins. This proactive approach reduces iteration cycles, minimizes waste, and accelerates time-to-market—especially vital in aerospace, medical, and advanced robotics sectors.

Below is a representative specification profile reflecting the capabilities underpinning our instant quote accuracy:

| Parameter | Standard Capability | High-Precision Option | Notes |

|---|---|---|---|

| Tolerance | ±0.025 mm | ±0.005 mm | CMM-verified |

| Surface Finish | Ra 3.2 µm | Ra 0.4 µm | Achieved via fine milling or polishing |

| Materials | Aluminum, Steel, Stainless, Titanium, Plastics | Inconel, Hastelloy, PEEK | Full material certification available |

| Max Work Envelope | 1200 x 800 x 600 mm | 800 x 500 x 400 mm | Precision zone for tight tolerances |

| Lead Time (Standard) | 7–10 days | 12–15 days | Expedited options available |

Our instant quote system is not a shortcut—it is a precision gateway, built on battlefield-tested experience and engineered for excellence. When you request a quote from Wuxi Lead, you’re accessing the same standards that propel athletes to gold and protect national assets. Precision isn’t just promised. It’s proven.

Precision Specs & Tolerances

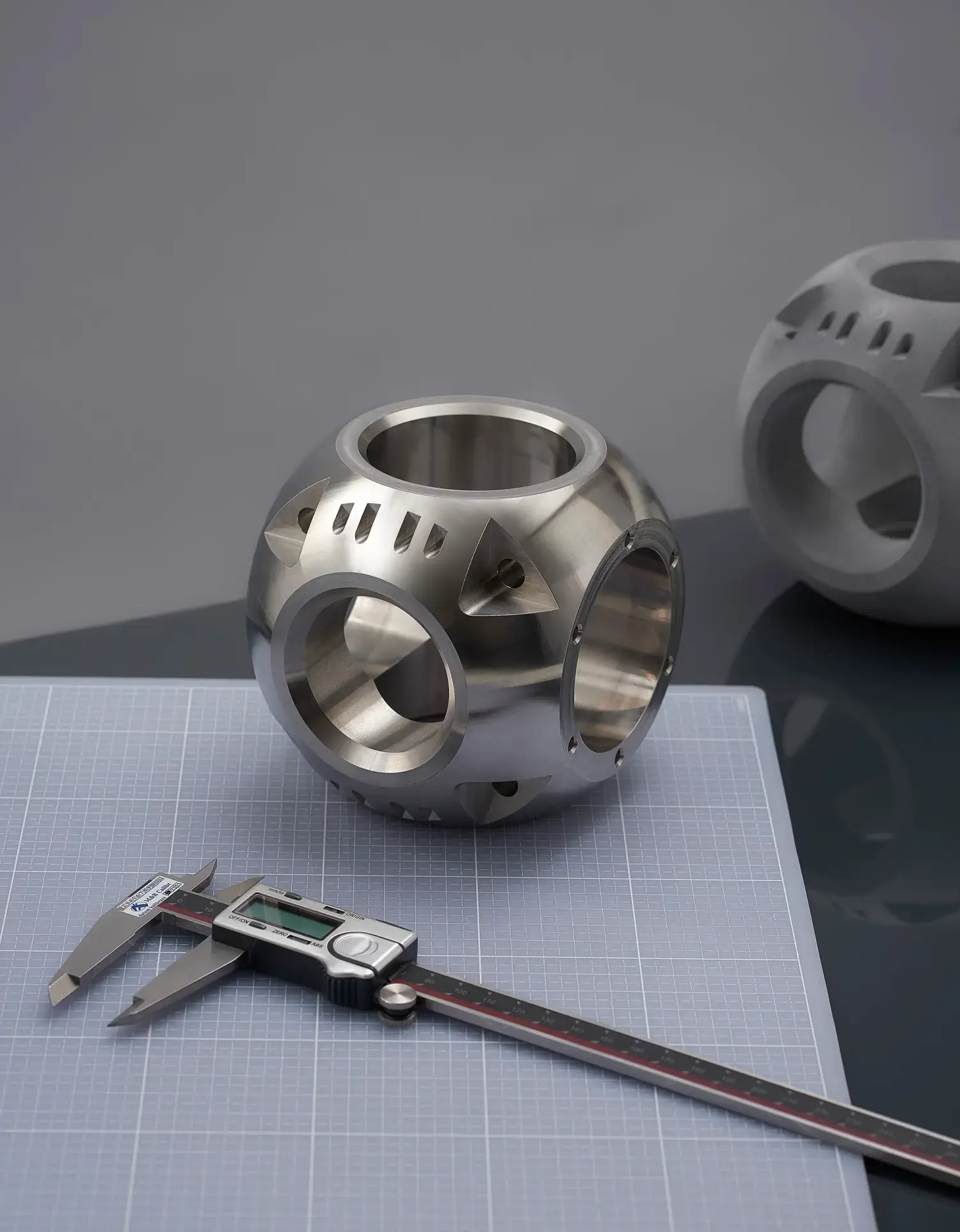

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical components through advanced multi-axis CNC machining and rigorous quality validation. Our technical infrastructure is engineered to transform complex designs into flawless physical realities, directly enabling the speed and accuracy of our instant quoting system. At the core of our production capability are 22 state-of-the-art 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems eliminate the need for multiple setups by machining complex geometries—such as organic aerospace contours, medical implant cavities, and hydraulic manifolds—in a single operation. This integrated approach reduces cumulative error, accelerates lead times by up to 40%, and ensures micron-level consistency across all critical features. Our machines maintain thermal stability through closed-loop coolant systems and real-time spindle monitoring, guaranteeing repeatability even during extended production runs.

Quality control is non-negotiable. Every component undergoes comprehensive inspection via our Zeiss CONTURA G3 Coordinate Measuring Machine (CMM), operating within a climate-controlled metrology lab maintained at 20°C ±0.5°C. The CMM executes fully automated inspection routines programmed directly from your CAD model, validating geometric dimensioning and tolerancing (GD&T) to ISO 10360 standards. This generates traceable, AS9100-compliant inspection reports with full point-cloud analysis, ensuring absolute conformance before shipment. Our QC process integrates seamlessly with production, allowing immediate correction of deviations and eliminating scrap—critical for high-value, low-volume aerospace and semiconductor components.

Tolerances define our commitment to excellence. The table below reflects achievable standards under controlled production conditions, forming the technical foundation of our instant quote accuracy.

| Feature Type | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Geometric (GD&T) | ±0.05 mm | ±0.01 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm |

| Hole Positioning | ±0.03 mm | ±0.008 mm |

| Thread Accuracy | 6H/6g | 4H/4g |

These capabilities translate directly into the reliability of our instant quoting platform. Unlike generic quoting tools, our system cross-references your CAD file against real-time machine capacity, material databases, and proven tolerance benchmarks. When you submit a design, our algorithms instantly assess manufacturability against these documented capabilities—no guesswork, no inflated lead times. This precision-engineered workflow ensures the quote you receive reflects actual shop-floor execution, not theoretical best-case scenarios.

For industries where a micron impacts performance, Wuxi Lead’s fusion of 5-axis agility and metrology-grade validation delivers confidence in every specification. Trust our instant quote to reflect what we can achieve—not what we hope to achieve. Contact our engineering team to discuss how these capabilities solve your most demanding machining challenges.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining services tailored to meet the stringent demands of aerospace, medical, automotive, and industrial equipment sectors. Understanding the mechanical properties and finishing compatibility of core materials—aluminum, steel, and titanium—enables engineers and procurement teams to make informed decisions that align with functional requirements and production timelines.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications requiring lightweight components without sacrificing structural integrity. The most commonly used grades in CNC machining are 6061-T6 and 7075-T6. While 6061 offers good weldability and moderate strength, 7075 delivers superior strength, making it ideal for high-stress environments. Aluminum’s natural oxide layer enhances corrosion resistance, but for enhanced surface protection and aesthetic appeal, anodizing is recommended.

Steel, particularly stainless steel grades such as 304 and 316, provides exceptional mechanical strength, thermal resistance, and durability. These properties make steel the preferred choice for components exposed to harsh environments or requiring long-term reliability. 316 stainless steel, with its added molybdenum content, offers improved resistance to chlorides and acids, making it suitable for marine and medical applications. Despite being more challenging to machine than aluminum, modern CNC equipment at Wuxi Lead ensures tight tolerances and smooth surface finishes even with hardened steel alloys.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice in high-performance industries due to its outstanding strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosion. It is commonly used in aerospace structural components and medical implants. While titanium is more expensive and slower to machine due to its low thermal conductivity and high reactivity, our advanced CNC tooling and cooling strategies ensure precision and efficiency throughout the machining process.

Anodizing is a key finishing process for aluminum components, enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing is commonly used for general applications and allows for color dyeing, while Type III (hardcoat) anodizing produces a thicker, more durable layer suitable for industrial and military-grade parts. Anodized finishes also improve adhesion for paint primers and provide electrical insulation.

Below is a comparative overview of key material properties and finishing options:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications | Compatible Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, Enclosures | Anodizing (Type II/III), Powder Coating |

| Stainless Steel | 304, 316 | 505–760 | 8.0 | Medical, Marine, Food | Passivation, Electropolishing |

| Titanium | Grade 5 (Ti-6Al-4V) | 900–1,000 | 4.4 | Aerospace, Implants | Anodizing, Bead Blasting |

Selecting the right material and finish is essential to achieving optimal performance and cost-effectiveness in CNC-machined components. Wuxi Lead Precision Machinery supports clients with expert consultation, rapid prototyping, and high-volume production, ensuring every part meets international quality standards.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero Defect Delivery

At Wuxi Lead Precision Machinery, our CNC instant quote process initiates a rigorously defined production pathway engineered for absolute reliability. This pathway transcends simple machining; it is a closed-loop system where Zero Defects is not an aspiration but the fundamental operational standard embedded within every phase: Design, Prototyping, and Mass Production. Our integrated approach ensures manufacturability, validates performance, and guarantees consistent output meeting the most stringent aerospace, medical, and industrial specifications.

The Design Phase is where defect prevention begins. Upon receiving your CAD model and requirements via our instant quote system, our engineering team conducts an exhaustive Design for Manufacturability (DFM) analysis. We scrutinize geometric complexity, material suitability, tolerancing feasibility, and fixture requirements before any metal is cut. This proactive review identifies potential production risks early, optimizes toolpaths for stability, and ensures the design aligns with our high-precision capabilities. Client collaboration at this stage is critical; we provide actionable feedback to refine the design for optimal yield and inherent quality, eliminating root causes of potential defects at the source.

Prototyping transforms validated designs into tangible proof. Utilizing the same HAAS, DMG MORI, and Makino CNC machining centers employed in full production, we manufacture functional prototypes under identical process conditions. This phase is not merely about form; it involves rigorous First Article Inspection (FAI) against all critical dimensions and material certifications, alongside functional testing where applicable. Dimensional reports, surface finish verification, and material traceability documentation are provided. Prototyping serves as the ultimate validation checkpoint, confirming process capability and allowing for micro-adjustments before committing to volume, ensuring the production process blueprint is flawless.

Mass Production executes the perfected process at scale, governed by our Zero Defects mandate. Every component undergoes in-process inspections at statistically determined intervals using calibrated CMMs, optical comparators, and surface testers. Real-time statistical process control (SPC) monitors critical parameters like tool wear and dimensional drift, triggering automatic process adjustments or halts if trends approach tolerance limits. Final inspection is comprehensive, not sampling-based. Full traceability, from raw material lot to finished part, is maintained. Continuous monitoring and closed-loop corrective actions ensure deviations are impossible, delivering batches where every single part meets specification without exception.

This seamless integration of Design validation, Prototyping verification, and statistically controlled Mass Production forms the backbone of our guaranteed quality output. The table below details the core activities and Zero Defects implementation for each phase.

| Phase | Key Activities | Zero Defects Implementation |

|---|---|---|

| Design | DFM Analysis, Tolerance Stack-Up Study, Material Verification, Toolpath Simulation | Proactive risk elimination, manufacturability optimization, client design refinement |

| Prototyping | Functional Part Machining, First Article Inspection (FAI), Material Certification, Dimensional Reporting | Process validation under production conditions, comprehensive measurement, functional testing |

| Mass Production | Statistical Process Control (SPC), In-Process CMM Checks, 100% Final Inspection, Full Material Traceability | Real-time deviation correction, elimination of sampling risk, closed-loop corrective actions |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer trust, reliability, and long-term value for global industrial leaders. As a premier provider of high-accuracy CNC machining services based in Wuxi, China, we specialize in delivering complex, mission-critical parts across aerospace, medical, automation, and advanced industrial sectors. When you choose to partner with us, you gain more than a supplier—you gain a committed engineering ally focused on your success.

Our facility integrates state-of-the-art 3-, 4-, and 5-axis CNC machining centers with rigorous quality control systems, including CMM inspection, surface roughness testing, and first-article reporting. Every process is ISO 9001:2015 certified and designed to meet the tightest tolerances—down to ±0.002 mm. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing ecosystem ensures rapid turnaround without compromising precision.

We understand that in high-stakes industries, time and accuracy are inseparable. That’s why our instant quote system is engineered to deliver fast, transparent pricing without sacrificing technical depth. Upload your CAD files, specify materials and finishes, and receive a detailed CNC quote within hours—not days. But our support doesn’t end at a quote. Our engineering team actively collaborates with your design staff to perform Design for Manufacturability (DFM) analysis, helping you optimize part geometry, reduce material waste, and accelerate time to market.

Partnering with Lead Precision means access to a full spectrum of value-added services, including anodizing, powder coating, laser engraving, and custom packaging. We work with a wide range of materials—from aerospace-grade aluminum alloys and titanium to engineering plastics like PEEK and PTFE—ensuring your components meet exact performance requirements.

Our global logistics network enables seamless delivery to North America, Europe, and Asia, backed by real-time production tracking and dedicated account management. With over 15 years of experience serving Fortune 500 companies and innovative startups alike, we’ve built our reputation on consistency, responsiveness, and technical excellence.

If you demand precision, speed, and partnership at the highest level, it’s time to work with a manufacturer that treats your project as mission-critical. We invite you to experience the Lead Precision difference.

For immediate assistance or to request a custom CNC machining quote, contact us directly at [email protected]. Our engineering team is ready to support your next project with technical insight and rapid turnaround.

Key Technical Capabilities

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; multi-axis Swiss machining |

| Tolerances | Up to ±0.002 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, PEEK, PTFE, Nylon |

| Max Work Envelope | 1200 x 600 x 500 mm (milling); Ø200 x 500 mm (turning) |

| Surface Finishes | As-machined, anodizing (Type II & III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, CMM reporting |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies by complexity) |

Contact [email protected] today and let our engineers help you turn precision concepts into reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.