Technical Contents

Engineering Guide: Machine Injection Molding

Engineering Insight Precision Imperatives in Machine Injection Molding

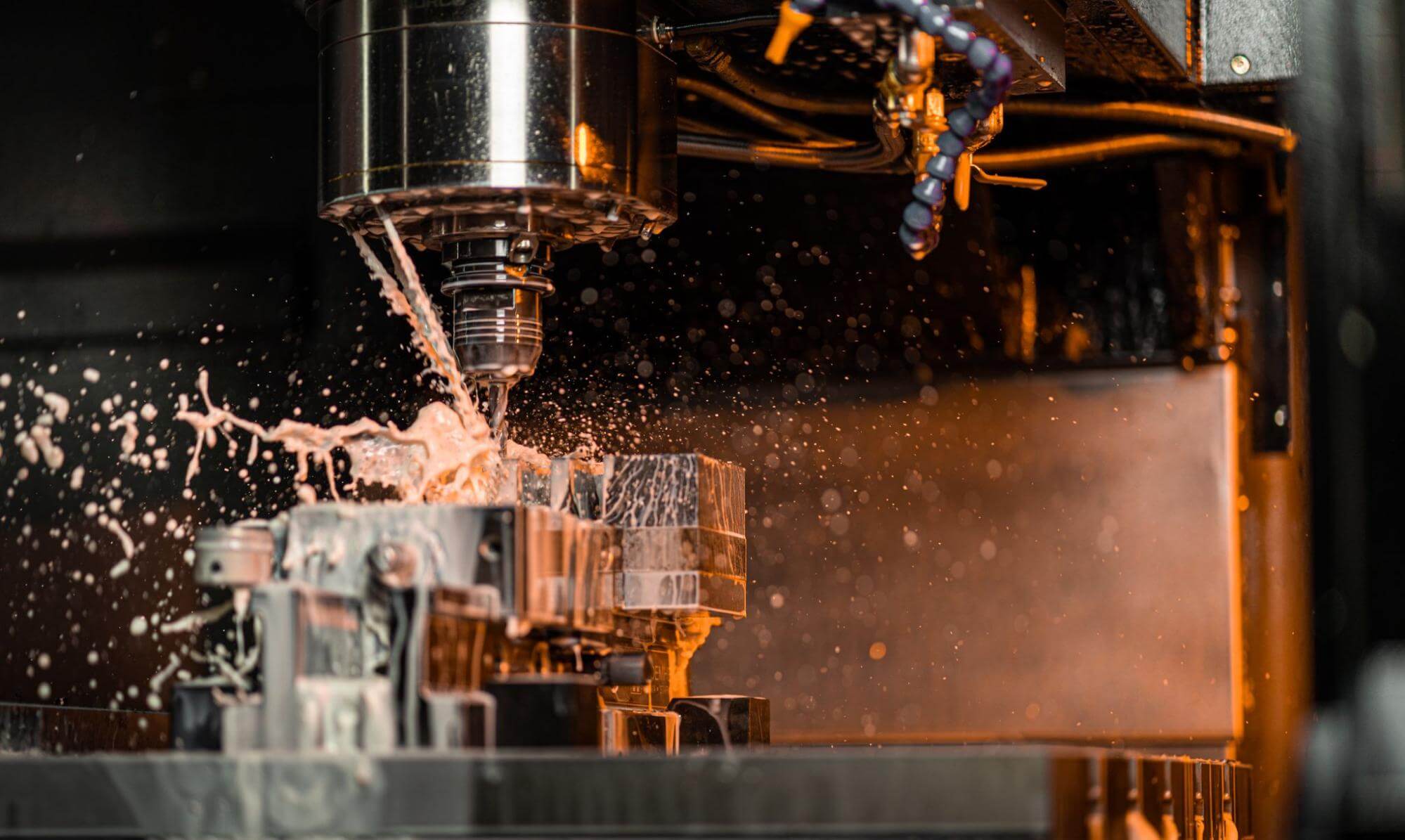

In high-stakes injection molding applications, precision transcends mere specification—it dictates functional integrity, assembly success, and lifecycle reliability. Minute deviations in cavity geometry, thermal distribution, or clamping force propagate into critical failures: sealing surfaces leak, moving components bind, and dimensional stack-ups disrupt automated assembly lines. For aerospace hydraulic manifolds or medical diagnostic housings, tolerances below ±0.02mm are non-negotiable. Achieving this demands more than advanced machinery; it requires holistic engineering rigor from material science to process validation. At Wuxi Lead Precision Machinery, we treat precision as a systemic outcome, not a machine attribute. Our approach integrates finite element analysis for thermal distortion prediction, real-time cavity pressure monitoring, and closed-loop servo control to counteract viscosity fluctuations. This discipline is validated through projects where failure is inconceivable—such as structural components for Olympic venue infrastructure and mission-critical housings for defense systems. These engagements demanded zero-defect delivery under extreme environmental cycles, proving our capability to sustain micron-level accuracy across high-volume production.

Material behavior under injection conditions remains a primary precision challenge. Polymers exhibit nonlinear shrinkage rates influenced by cooling gradients, molecular orientation, and residual stress. Without precise thermal management, warpage exceeds 0.5mm per 100mm—a margin that renders parts unusable in tight-tolerance assemblies. Our engineering protocols address this through multi-zone mold temperature control calibrated to ±0.5°C and adaptive cooling channel designs that homogenize heat extraction. This mitigates sink marks and internal stresses, ensuring dimensional stability post-ejection. Furthermore, we prioritize machine rigidity; our custom-built platens and tie-bar systems maintain parallelism within 0.01mm/m under full tonnage, eliminating flash-induced tolerance drift during extended runs.

The following specifications reflect our precision engineering baseline for critical applications:

| Specification | Capability | Relevance to Precision |

|---|---|---|

| Positional Accuracy | ±0.005mm | Ensures core/cavity alignment for zero flash |

| Thermal Stability | ±0.5°C (mold surface) | Minimizes differential shrinkage |

| Clamping Force Uniformity | ±1% across platen | Prevents parting line mismatch |

| Material Compatibility | PEEK, PEI, PPS, Metals | Handles high-temp resins without degradation |

| Process Repeatability | Cpk ≥ 1.67 | Guarantees batch-to-batch consistency |

Precision in injection molding is ultimately a measure of engineering accountability. It requires anticipating how microscopic material interactions scale into macroscopic performance. Wuxi Lead’s Olympic and military project heritage instills this mindset: every mold we engineer undergoes 120+ validation checkpoints, from steel hardness verification to in-mold strain analysis. For manufacturers where component failure risks safety or reputation, this systematic precision isn’t optional—it’s the foundation of supply chain trust. Partner with us to transform tolerance requirements into guaranteed outcomes.

Precision Specs & Tolerances

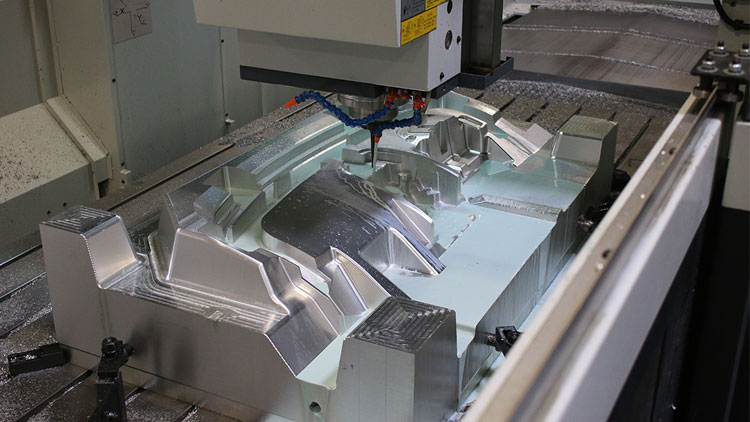

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the rigorous demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. At the core of our precision manufacturing infrastructure is our 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. This multi-axis capability allows simultaneous cutting from five different angles, minimizing setup time, reducing human error, and ensuring tight integration of intricate features within a single workholding cycle. Our 5-axis CNC systems are operated by certified machinists and supported by advanced CAD/CAM software, ensuring optimal toolpath efficiency and part consistency across both prototyping and high-volume production runs.

To maintain the highest standards of quality and repeatability, every component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM inspection process provides full 3D metrology validation, verifying dimensional accuracy, geometric tolerances, and alignment of critical features against original design specifications. This data-driven quality control methodology ensures full traceability and compliance with international standards such as ISO 9001 and AS9100. All inspection reports are documented and archived, offering customers complete transparency and confidence in part conformance.

Our technical expertise extends beyond machining and inspection to encompass material selection, design for manufacturability (DFM) analysis, and finishing processes tailored to application requirements. We work with a broad range of engineering metals, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys, ensuring compatibility with demanding operational environments. Whether producing thin-walled enclosures, high-precision housings, or complex structural components, our manufacturing workflow is designed for maximum precision, efficiency, and scalability.

The following table outlines the key technical tolerances achievable across our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and geometry |

| Angular Tolerances | ±0.1° | ±0.05° | Verified via CMM and optical probes |

| Positional Accuracy | ±0.02 mm | ±0.01 mm | Critical for hole patterns and mating features |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved with fine finishing toolpaths |

| Geometric Tolerances (Flatness, Roundness) | ±0.03 mm | ±0.01 mm | Fully validated by CMM inspection |

These capabilities are integrated into a seamless production ecosystem that prioritizes precision, repeatability, and on-time delivery. Wuxi Lead Precision Machinery is committed to pushing the boundaries of what is possible in custom metal manufacturing, providing clients with technically superior components built to perform in the most demanding applications.

Material & Finish Options

Material Selection for High-Performance Injection Molding Tooling

Selecting the optimal material for injection molding tooling is critical for achieving part quality, production efficiency, and tool longevity. At Wuxi Lead Precision Machinery, we engineer tooling solutions where material properties directly impact thermal management, wear resistance, and dimensional stability under high-pressure cycles. Aluminum, steel, and titanium each serve distinct applications, and surface finishes like anodizing further enhance performance. Understanding these options ensures your tooling aligns with production volume, part complexity, and material requirements.

Aluminum alloys, particularly 7075-T6, offer exceptional machinability and thermal conductivity. This makes them ideal for rapid prototyping, low-to-medium volume production, and molds requiring quick heat dissipation. Aluminum tooling reduces cycle times significantly compared to steel, lowering initial costs for short runs. However, its lower hardness limits use with abrasive engineering resins or ultra-high-volume applications exceeding 100,000 cycles.

Tool steels like P20, H13, and S136 dominate high-volume production. P20 provides balanced toughness and polishability for general-purpose molds. H13 excels in thermal fatigue resistance for hot-runner systems or molds processing high-temperature plastics. Stainless variants like S136 offer superior corrosion resistance for medical or optical components. Steel’s high hardness (typically 28-54 HRC) ensures longevity exceeding 1 million cycles but requires longer machining times and higher initial investment.

Titanium alloys (e.g., Ti-6Al-4V) are reserved for extreme applications demanding non-ferrous properties, exceptional strength-to-weight ratios, and corrosion resistance in aggressive chemical environments. While costly and challenging to machine, titanium’s thermal stability suits specialized molds for aerospace or chemical-resistant components. Its use remains niche due to cost and machining complexity but delivers unmatched performance where standard materials fail.

Anodizing is a critical surface treatment for aluminum tooling. This electrochemical process creates a hard, wear-resistant oxide layer that significantly extends mold life in abrasive applications. Type II (sulfuric acid) anodizing improves lubricity and corrosion resistance, while Type III (hardcoat) anodizing achieves thicknesses up to 50µm for severe wear conditions. Anodized aluminum molds reliably handle glass-filled resins and achieve 50,000+ cycles, bridging the gap between standard aluminum and steel tooling costs.

Key Material Properties Comparison

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications | Max Cycle Range |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130-150 | Prototypes, low-volume production | 10,000 – 50,000 |

| P20 Tool Steel | 28-32 | 28-36 | General high-volume consumer parts | 500,000 – 1M+ |

| H13 Tool Steel | 44-52 | 25-30 | Hot-runner systems, high-temp resins | 1M+ |

| Titanium Ti-6Al-4V | 32-36 (equiv.) | 6-7 | Aerospace, chemical-resistant components | Highly variable |

Material choice fundamentally shapes your injection molding economics and output quality. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to optimize material selection and surface treatments for your specific application. Our engineering team collaborates to balance performance requirements with cost efficiency, ensuring your tooling delivers precision, durability, and maximum ROI. Consult us early in the design phase to avoid costly revisions and production delays.

Manufacturing Process & QC

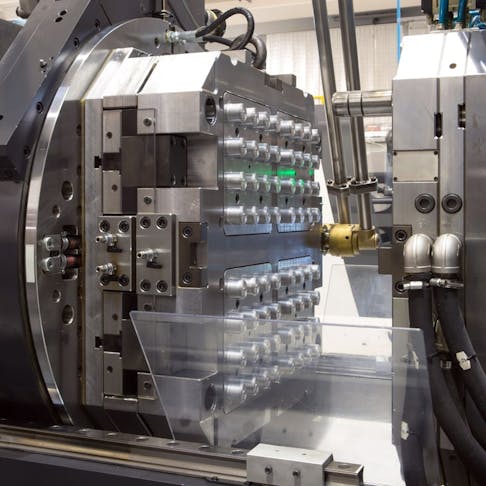

The production process for high-precision metal components via machine injection molding at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure zero defects, maximum repeatability, and full compliance with international quality standards. This integrated approach enables us to deliver custom metal parts with exceptional dimensional accuracy, material consistency, and functional reliability for industries such as aerospace, medical devices, and automotive systems.

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable solutions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, wall thickness, gate positioning, and thermal management for the metal injection molding (MIM) process. Material selection is carefully evaluated based on mechanical performance, corrosion resistance, and regulatory compliance. Design for manufacturability (DFM) reviews are conducted to preempt potential defects such as warpage, porosity, or density variation, ensuring a robust foundation for production.

Following design validation, we proceed to Prototyping. A small batch of components is produced using the same MIM process intended for full-scale manufacturing. This stage allows us to verify tooling performance, material behavior, and sintering characteristics under real production conditions. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and metallographic analysis to confirm dimensional accuracy and microstructural integrity. Any deviations are addressed through iterative refinement of the tooling or process parameters. This phase not only mitigates risk but also provides clients with functional samples for testing and certification.

Once the prototype is approved, we transition to Mass Production. Our automated MIM lines operate under strict statistical process control (SPC), with real-time monitoring of critical variables including injection pressure, temperature profiles, debinding rates, and sintering atmospheres. Every batch is traceable, and in-process inspections are conducted at defined intervals to maintain consistency. Our quality management system is ISO 9001 certified, and we employ 100% visual inspection via automated optical systems combined with random sampling for mechanical and chemical testing. This ensures every component meets the zero-defect objective.

The following table outlines key technical specifications of our machine injection molding process:

| Parameter | Specification |

|---|---|

| Material Range | Stainless Steel (316L, 17-4PH), Low-Alloy Steels, Cobalt-Chrome, Tungsten Alloys |

| Dimensional Accuracy | ±0.3% to ±0.1% (depending on geometry) |

| Typical Wall Thickness | 0.5 mm to 5.0 mm |

| Surface Finish (Ra) | 0.8 μm to 3.2 μm |

| Production Capacity | 10,000 to 500,000 parts per month |

| Sintering Atmosphere | Hydrogen, Vacuum, or Dissociated Ammonia |

| Secondary Operations | CNC Machining, Heat Treatment, Passivation, Laser Marking |

Wuxi Lead Precision Machinery combines engineering excellence with process discipline to deliver flawless metal components at scale. Our end-to-end control from design to delivery ensures that every part meets the highest standards of performance and reliability.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership with Wuxi Lead Precision Machinery

In the demanding landscape of custom metal manufacturing for injection molding applications, component integrity directly dictates production efficiency and end-product performance. Substandard tooling or inconsistent part fabrication leads to costly downtime, elevated scrap rates, and compromised brand reputation. Wuxi Lead Precision Machinery exists to eliminate these risks. As your dedicated engineering and manufacturing partner, we integrate advanced CNC capabilities with deep material science expertise to deliver tooling and components that meet the most stringent global standards. Our ISO 9001:2015-certified processes ensure every cavity plate, core pin, ejector component, and mold base adheres to exacting dimensional and surface finish requirements, directly enhancing your molding cycle stability and part quality.

Our technical foundation rests on state-of-the-art multi-axis machining centers and rigorous metrology protocols. The table below outlines core capabilities critical for high-performance injection mold manufacturing:

| Process | Tolerance Range | Material Compatibility | Max Work Envelope |

|---|---|---|---|

| 5-Axis CNC Milling | ±0.002 mm | P20, H13, S136, Stainless Steels, Aluminum | 1200 x 800 x 650 mm |

| Precision CNC Turning | ±0.0015 mm | Tool Steels, Titanium Alloys, Brass | Ø450 mm x 1000 mm |

| Surface/ID Grinding | Ra 0.05 µm (mirror) | Hardened Steels (up to 60 HRC) | Ø300 mm x 500 mm |

This precision translates to tangible outcomes: extended mold life exceeding 1,000,000 cycles, reduced venting issues, elimination of flash-related defects, and accelerated time-to-market for your molded products. We collaborate from initial design review through production support, leveraging finite element analysis (FEA) to optimize cooling channels and structural integrity—preventing warpage and sink marks before metal is cut. Our quality management system includes full CMM reporting, optical contour measurement, and material traceability, ensuring compliance with aerospace, medical, and automotive specifications.

Partnering with Lead Precision means accessing a single-source solution where engineering rigor meets responsive manufacturing execution. We understand that mold performance is non-negotiable in high-volume production, and our team commits to proactive communication, rapid iteration cycles, and uncompromising accountability for your project’s success. Do not accept incremental improvements when transformative precision is achievable.

Initiate your precision manufacturing partnership today. Contact our engineering team directly at [email protected] to discuss your specific injection molding challenges. Include your project specifications for a targeted capability assessment and timeline proposal within 24 business hours. Let us demonstrate how Lead Precision becomes the definitive extension of your manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.