Technical Contents

Engineering Guide: Medical Printing Services

Engineering Insight: The Critical Role of Precision in Medical Printing Services

In the field of custom metal manufacturing for medical applications, precision is not merely a performance metric—it is a requirement for safety, compliance, and functionality. Medical printing services, particularly those involving metal components such as surgical tools, implants, and diagnostic equipment housings, demand micron-level accuracy and repeatable consistency. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation can compromise biocompatibility, structural integrity, or sterilization efficacy—factors that directly impact patient outcomes.

Our approach to medical printing services integrates advanced CNC machining, laser cutting, and additive manufacturing techniques, all governed by strict quality control protocols. These processes are calibrated to meet ISO 13485 standards, ensuring that every component produced adheres to the regulatory and performance expectations of the global medical device industry. Precision in material selection, dimensional tolerance, and surface finish is maintained across every production run, whether prototyping a single implant or scaling for high-volume surgical instrument manufacturing.

What sets Wuxi Lead apart is our proven track record in high-stakes industries where failure is not an option. Our engineering team has delivered mission-critical components for Olympic-grade equipment and military defense systems—applications where mechanical reliability under extreme conditions is non-negotiable. This same rigor is applied to our medical printing services. The experience gained from these demanding sectors translates into superior process control, material science expertise, and failure-mode anticipation—capabilities that are essential when manufacturing devices intended for human use.

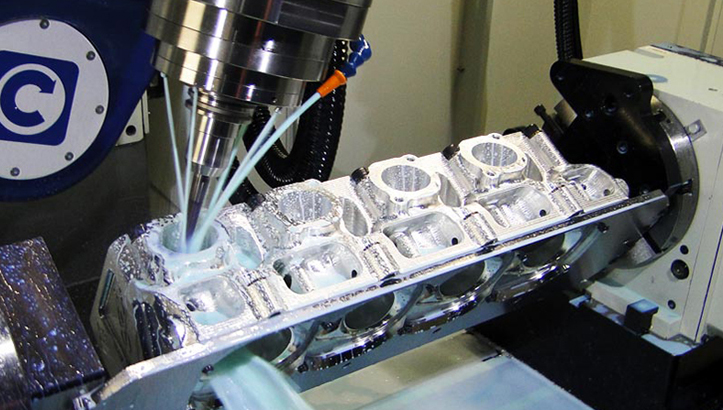

We utilize state-of-the-art 5-axis CNC systems and real-time metrology to ensure that every printed metal part meets exact geometric and mechanical specifications. Surface roughness, edge definition, and internal lattice structures (in additive builds) are optimized not only for performance but also for biocompatibility and ease of sterilization. Our in-house testing facilities allow for comprehensive validation, including tensile strength analysis, corrosion resistance testing, and dimensional inspection via coordinate measuring machines (CMM).

The table below outlines key specifications achievable through our medical printing and precision manufacturing processes:

| Parameter | Capability | Tolerance / Standard |

|---|---|---|

| Minimum Feature Size | 0.1 mm | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished) | ISO 1302 compliant |

| Material Options | 316L Stainless Steel, Titanium (Gr5), Cobalt-Chrome, Inconel | ASTM F75, F138, F562 compliant |

| Layer Resolution (Additive) | 20–40 µm | Repeatability: ±0.02 mm |

| Maximum Build Volume | 250 x 250 x 300 mm (metal printing) | Custom scaling available |

| Quality Certification | ISO 9001, ISO 13485, RoHS | Full traceability & documentation |

Precision in medical printing is not an isolated technical achievement—it is the result of integrated engineering excellence, rigorous testing, and a culture of accountability. At Wuxi Lead Precision Machinery, our cross-industry experience ensures that every medical component we produce meets the highest standards of performance, safety, and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Medical Applications

Precision is non-negotiable in medical device manufacturing where component integrity directly impacts patient safety and regulatory compliance. At Wuxi Lead Precision Machinery we specialize in the production of critical metal components for advanced medical equipment and implants. Our core strength lies in transforming complex designs into reality through state-of-the-art multi-axis machining combined with rigorous quality assurance protocols specifically calibrated for the medical sector.

Our facility operates a dedicated fleet of high-precision 5-axis CNC machining centers. These advanced systems including models from DMG MORI and MAZAK enable us to machine intricate geometries in a single setup. This capability is essential for producing complex surgical instrument housings orthopedic implant fixtures and fluidic manifolds found in diagnostic equipment. We routinely work with demanding medical-grade materials such as titanium alloys 316L stainless steel cobalt-chrome MP35N and aerospace-grade aluminum ensuring biocompatibility and long-term performance. The elimination of multiple setups inherent in 5-axis processing significantly reduces potential error sources while achieving superior surface finishes critical for medical applications.

Quality control is integrated into every stage of production not merely a final checkpoint. Our comprehensive inspection regime centers on Zeiss CONTURA and Wenzel LH877 Coordinate Measuring Machines CMMs operating within a temperature-controlled metrology lab. These systems perform full 3D geometric dimensioning and tolerancing GD&T verification against original CAD models ensuring absolute conformance to design intent. All CMM operators are certified to AS9102 standards with detailed First Article Inspection FAI reports provided per customer requirement. Surface roughness is meticulously measured using Mitutoyo SJ-410 profilometers guaranteeing finishes meet stringent medical specifications for sterility and function.

The table below details our standard and medical-grade precision capabilities reflecting our commitment to exceeding typical industry benchmarks for medical device components.

| Feature | Standard Capability | Medical-Grade Capability |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Geometric Tolerance | ±0.05 mm | ±0.01 mm |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Material Verification | Mill Certificates | Full MTR Traceability |

| Inspection Standard | ISO 2768-mK | ASME Y14.5 GD&T |

This level of precision is not achieved through equipment alone but through our engineered processes. We implement statistical process control SPC on critical features monitor tool wear in real-time and maintain full material traceability from raw stock to finished component. Our quality management system is ISO 13485 certified demonstrating our structured approach to meeting the exacting demands of medical device Original Equipment Manufacturers OEMs. Partnering with Wuxi Lead ensures your medical components are manufactured to the highest standards of accuracy reliability and regulatory compliance essential for success in today’s demanding healthcare market.

Material & Finish Options

Material Selection for High-Precision Medical Printing Components

In the field of custom metal manufacturing for medical printing services, material selection directly impacts performance, biocompatibility, and longevity. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components that meet the stringent demands of medical applications. The most commonly used materials—aluminum, steel, and titanium—each offer unique mechanical and chemical properties suitable for different aspects of medical printing systems.

Aluminum is widely selected for structural frames and non-load-bearing parts due to its excellent strength-to-weight ratio and thermal conductivity. Its machinability allows for tight tolerances and complex geometries, critical in medical device manufacturing. When paired with anodizing, aluminum gains enhanced surface hardness and corrosion resistance, making it ideal for housings and enclosures exposed to frequent cleaning and sterilization.

Stainless steel, particularly grades 316 and 316L, is the standard for components requiring high strength, durability, and resistance to corrosion in aggressive environments. Its biocompatibility and ability to withstand repeated autoclaving make it suitable for critical parts such as print heads, guide rails, and fluid-handling components. Passivation is often applied post-machining to maximize corrosion resistance by removing free iron from the surface.

Titanium, especially Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding resistance to corrosion in saline and chemical environments. Its biocompatibility makes it a preferred choice for implantable or surgical tools integrated into medical printing systems. Though more challenging to machine, titanium’s performance in high-stress, lightweight applications justifies its use in premium medical equipment.

Surface finishing plays a crucial role in functional performance. Anodizing, primarily used for aluminum, creates a durable, non-conductive oxide layer that improves wear resistance and allows for color coding. Type II and Type III (hardcoat) anodizing are commonly specified, with hardcoat offering superior thickness and hardness for high-wear areas.

Below is a comparative overview of key material properties relevant to medical printing applications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Biocompatibility | Common Finishes | Typical Applications |

|---|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Moderate (improved with anodizing) | Good | Anodizing (Type II/III) | Enclosures, brackets, frames |

| Stainless Steel 316 | 570–700 | 8.0 | Excellent | Excellent | Passivation, polishing | Print heads, shafts, fluid systems |

| Titanium Ti-6Al-4V | 900–950 | 4.4 | Exceptional | Excellent | Bead blasting, anodizing | Surgical tools, load-bearing parts |

Selecting the right material and finish requires a balance of mechanical requirements, environmental exposure, and regulatory compliance. At Wuxi Lead, our engineering team collaborates with clients to ensure optimal material choices that meet ISO 13485 standards and support long-term reliability in medical printing systems.

Manufacturing Process & QC

Precision Medical Component Manufacturing: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our production process for critical medical device components is engineered for absolute reliability. We execute a rigorously controlled sequence from initial design through prototyping to full-scale manufacturing, ensuring every part meets the uncompromising standards demanded by the medical sector. This integrated approach is fundamental to achieving our Zero Defects commitment.

The process begins with collaborative design engineering. Our technical team works directly with client specifications and regulatory requirements, primarily ISO 13485 and FDA guidelines. We perform comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) analyses using advanced CAD/CAM software. This phase identifies potential production challenges early, optimizes material usage, and ensures the design is inherently capable of meeting stringent medical tolerances and surface finish requirements before any metal is cut. Material selection is validated against biocompatibility and sterilization needs.

Prototyping is not merely a sample step; it is a critical validation phase. Utilizing our high-precision 5-axis CNC milling and turning centers, we produce functional prototypes from the exact production-grade materials specified. Every prototype undergoes exhaustive metrology, including CMM inspection against the full CAD model, surface roughness testing, and dimensional verification far exceeding standard tolerances. This data is meticulously analyzed to refine the manufacturing process plan, confirm tooling strategies, and validate the feasibility of achieving zero defects at scale. Client approval of the prototype and its full inspection report is mandatory before progression.

Mass production leverages the validated process blueprint. We implement Statistical Process Control (SPC) at every critical operation, with real-time monitoring of key parameters. Our Zero Defects methodology employs multiple, overlapping safeguards: 100% automated in-process inspection at defined checkpoints using vision systems and laser scanners, rigorous first-article inspection for every production batch, and full traceability of materials, processes, and personnel via our integrated MES. Final inspection is exhaustive, covering all geometric dimensions, surface integrity, material properties, and cleanliness per medical device standards. Non-conforming material is physically segregated and subjected to root cause analysis, ensuring immediate corrective action and process refinement.

This seamless integration of design insight, prototyping validation, and controlled mass production, underpinned by systematic quality gates, guarantees components that perform flawlessly in life-critical medical applications. Our clients trust this process for its predictability and unwavering output quality.

Critical Process Parameters for Medical Components

| Parameter Category | Specification Standard | Verification Method | Frequency |

|---|---|---|---|

| Material Certification | ASTM F138/F139, ISO 5832, Mill Test Reports | Certificate Review & Material Traceability | Per Lot / Heat Number |

| Dimensional Tolerance | ISO 2768-mK or tighter per drawing | CMM, Optical Comparator, Precision Gages | 100% First Article; SPC Sampling |

| Surface Roughness (Ra) | ≤ 0.8 µm (Typical for implants) | Profilometer | Per Batch |

| Critical Feature Inspection | GD&T per ASME Y14.5 | CMM (Full Report) | 100% |

| Process Documentation | Full Traceability (Material, Machine, Operator, Program) | MES Log Review | Continuous |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Medical Printing Services

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal manufacturing solutions tailored to the exacting standards of the medical device industry. Our advanced capabilities in medical printing services go beyond conventional offerings, integrating state-of-the-art CNC machining, laser marking, and precision etching technologies to produce components that meet strict regulatory and performance requirements. Whether you are developing surgical instruments, implantable devices, or diagnostic equipment, partnering with us ensures your components are manufactured with uncompromising accuracy, traceability, and biocompatibility.

Our facility in Wuxi, China, operates under ISO 13485-certified quality management systems, ensuring full compliance with international medical device regulations. Every stage of production—from material sourcing to final inspection—is meticulously documented and controlled. We utilize medical-grade stainless steel, titanium, and other specialty alloys, processed in a cleanroom environment to prevent contamination. Our laser printing technology enables permanent, high-resolution marking of UDI codes, serial numbers, logos, and critical identification data directly onto small or complex geometries, ensuring long-term legibility and regulatory compliance.

We understand that medical device manufacturers require more than just a supplier—they need a strategic partner capable of supporting innovation, scalability, and regulatory success. Our engineering team collaborates closely with clients from design for manufacturability (DFM) through prototyping and full-scale production. Rapid turnaround times, responsive communication, and strict adherence to delivery schedules make us a trusted extension of your development and manufacturing operations.

When precision, reliability, and regulatory compliance are non-negotiable, Wuxi Lead Precision Machinery stands ready to support your medical printing and metal component needs. Our track record with global medical OEMs is built on technical excellence, transparency, and a relentless focus on quality.

| Specification | Detail |

|---|---|

| Material Options | 316L Stainless Steel, Titanium (Grade 2, 5), MP35N, Elgiloy, Nitinol |

| Minimum Feature Size | 0.05 mm (laser etching) |

| Positional Accuracy | ±0.002 mm |

| Surface Finish | Ra ≤ 0.2 µm (polished), customizable |

| Marking Methods | Fiber laser, chemical etching, dot peen |

| UDI Compliance | Direct Part Marking (DPM) per ISO/IEC 15415 |

| Cleanroom Class | ISO Class 7 (10,000) |

| Quality Standards | ISO 13485, ISO 9001, RoHS compliant |

Contact us today to discuss your next medical device project. Email us at [email protected] and receive a detailed technical consultation with one of our precision manufacturing engineers. Let Wuxi Lead Precision Machinery be your trusted partner in bringing high-performance, regulatory-compliant medical components to market—on time and to specification.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.