Technical Contents

Engineering Guide: Plastic Injection Mold Reseller

Engineering Insight: The Critical Role of Precision in Plastic Injection Mold Reselling

In the highly competitive landscape of custom metal manufacturing, plastic injection mold resellers serve as vital intermediaries between advanced production capabilities and end-market demands. However, the success of any reseller hinges not just on market reach, but on the engineering precision and reliability of their manufacturing partners. At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is the foundation upon which performance, repeatability, and customer trust are built.

Plastic injection molds are complex tooling systems designed to operate under extreme thermal and mechanical stress. Even micron-level deviations in mold cavity dimensions can lead to part warpage, flash, or structural failure—costly outcomes in industries where consistency is non-negotiable. For resellers representing high-end applications such as medical devices, aerospace components, or automotive systems, the margin for error is effectively zero. This is where the engineering rigor of a proven manufacturer becomes indispensable.

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in the design and production of precision molds and custom metal components. Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 standards, ensuring that every process—from initial CAD modeling to final surface finishing—is traceable and repeatable. What sets us apart is our proven track record in mission-critical sectors: we have delivered components used in Olympic-grade athletic equipment and supplied precision-machined parts for defense and military applications. These projects demanded not only flawless dimensional accuracy but also materials compliance, longevity under stress, and absolute consistency across production runs.

For plastic injection mold resellers, aligning with a manufacturer of this caliber means offering clients more than just a product—they gain access to engineered reliability. Our in-house capabilities include CNC machining, EDM, high-speed milling, and automated quality inspection using Zeiss CMM systems. This vertical integration allows us to maintain tight tolerances and rapid iteration, essential for reducing time-to-market without sacrificing quality.

Below are key technical specifications that define our precision molding standards:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm |

| Mold Base Materials | P20, 718H, NAK80, S136, H13 |

| Surface Finish | SPI #A1 (Mirror Polish) to SPI #D3 (Textured) |

| Maximum Mold Size | 1200 × 800 × 700 mm |

| Lead Time (Average) | 25–35 days (complex molds) |

| Quality Control | Full CMM reporting, First Article Inspection (FAI), PPAP documentation |

By partnering with Wuxi Lead Precision Machinery, plastic injection mold resellers position themselves as providers of engineered excellence, not just commodity tooling. In an era where global buyers demand transparency, precision, and performance, our manufacturing heritage and technical discipline offer a decisive competitive advantage.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mold Reseller Success

Wuxi Lead Precision Machinery delivers uncompromising technical execution for plastic injection mold resellers requiring certified dimensional accuracy and repeatability. Our integrated manufacturing ecosystem centers on advanced 5-axis CNC machining platforms, specifically DMG MORI CTX beta 1250 and DMU 80 monoBLOCK systems. These machines enable single-setup processing of complex mold bases, cavities, and cores with simultaneous multi-surface interpolation, eliminating cumulative error from multiple fixtures. This capability is critical for molds demanding tight alignment of sliders, lifters, and cooling channels—directly reducing your end-client’s trial-and-error costs during mold validation. Material versatility spans P20, H13, S136, and beryllium-copper alloys, processed under strict thermal management protocols to ensure microstructural stability.

Precision Measurement Verification anchors our quality commitment. Every critical mold component undergoes full-spectrum inspection via Zeiss CONTURA G2 coordinate measuring machines (CMM), operating within ISO 17025-accredited environmental controls. Our CMM workflow executes automated GD&T analysis against 3D CAD models, generating AS9102-compliant First Article Inspection reports. This digital traceability provides resellers with auditable proof of conformance, mitigating liability risks when supplying automotive or medical device manufacturers. Surface integrity is equally rigorously validated; Talysurf CLI 2000 profilometers quantify Ra values to 0.05 µm, ensuring optimal release characteristics and texture replication for high-gloss or matte finishes.

The table below reflects achievable tolerance benchmarks across core processes, validated through 12 months of production data for mold components:

| Process | Tolerance Range | Surface Finish (Ra) |

|---|---|---|

| 5-Axis CNC Milling | ±0.005 mm | 0.4 – 0.8 µm |

| Precision Grinding | ±0.002 mm | 0.1 – 0.2 µm |

| Wire/EDM Machining | ±0.003 mm | 0.8 – 1.6 µm |

These specifications are not theoretical ideals but production realities sustained through our closed-loop manufacturing system. Real-time tool wear compensation, in-process probing, and statistical process control (SPC) dashboards ensure consistency across batches. For resellers, this translates to predictable mold performance: reduced clamp tonnage requirements, elimination of flash-related defects, and extended mold life exceeding 500,000 cycles for standard applications.

Our technical infrastructure extends beyond hardware. Dedicated mold engineering teams collaborate with resellers during DFM reviews, identifying manufacturability risks before steel cutting begins. This proactive approach minimizes costly revisions and accelerates time-to-market for your clients. Every mold leaves Wuxi Lead with full metrology data packages, enabling seamless integration into your quality assurance workflows. For plastic injection mold resellers, we provide not just components, but quantifiable risk reduction and margin protection through engineering excellence. Partner with us to transform technical capability into your competitive advantage.

Material & Finish Options

Material selection is a critical phase in the development of high-performance plastic injection molds, directly influencing mold longevity, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision molds, leveraging advanced material science to meet diverse industrial demands. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal requirements, and cost constraints.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototype and low-to-medium volume production molds. Their high thermal conductivity enables faster cooling cycles, reducing cycle times and increasing throughput during trial runs or short production batches. Aluminum is also easier to machine, allowing for faster lead times and complex geometries. However, its lower hardness and wear resistance make it less suitable for long production runs or abrasive resins.

Steel remains the standard for high-volume injection molding. Hardened tool steels such as P20, H13, and S136 offer excellent durability, resistance to wear, and dimensional stability under prolonged use. These materials withstand the mechanical stress of repeated injection cycles and are ideal for molds producing tens of thousands to millions of parts. Stainless variants like S136 also provide corrosion resistance, making them suitable for medical or optical components requiring high surface purity.

Titanium, while less common in standard mold construction, is gaining traction in specialized applications where extreme strength-to-density ratio and corrosion resistance are paramount. Though costly and challenging to machine, titanium molds are used in high-temperature environments or aerospace components where weight reduction and long-term reliability are critical. Its biocompatibility also makes it suitable for medical-grade molding applications.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing aluminum increases surface hardness, improves wear resistance, and provides electrical insulation. Type II (sulfuric acid) anodizing delivers a clear or dyed finish with moderate durability, while Type III (hardcoat) anodizing produces a thicker, more robust layer suitable for high-wear areas. For steel molds, alternatives such as chrome plating, nitriding, or polishing are typically used, depending on the required surface quality and resin compatibility.

Understanding the interplay between material properties and production needs ensures optimal mold performance and cost-efficiency. At Wuxi Lead Precision Machinery, we work closely with resellers and end-users to select the right material and finish combination tailored to specific application requirements.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Machinability |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Prototypes, low-volume production | Excellent |

| P20 Steel | 28–32 | 30 | Medium to high-volume production | Good |

| H13 Steel | 48–52 | 36 | High-stress, high-temperature molding | Moderate |

| S136 Steel | 50–54 | 20 | Corrosion-resistant, optical parts | Moderate |

| Titanium (Grade 5) | 36–41 | 7 | Aerospace, medical, high-end specialty | Poor |

Manufacturing Process & QC

Precision Injection Mold Production: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, we engineer plastic injection molds for resellers demanding uncompromising quality and reliability. Our end-to-end process eliminates defects at the source, ensuring your resold molds deliver consistent performance in global production environments. This begins with Integrated Design Engineering, where our CNC specialists collaborate with your team to translate concepts into manufacturable realities. We conduct rigorous Design for Manufacturability (DFM) analysis, optimizing gate locations, cooling channels, and ejection systems using Moldflow simulation. This phase identifies potential warpage, sink marks, or stress points before metal is cut, reducing rework risk by 70%. Critical tolerances are validated against ISO 2768-mK standards, with material selection (P20, 718H, S136) matched to your resin’s thermal and chemical properties.

Validated Prototyping transforms digital models into physical proof. We produce 5–10 prototype molds using hardened tool steel, machining cavities and cores to ±0.005mm accuracy on HAAS UMC-750 five-axis centers. Each prototype undergoes 1,000-cycle stress testing under production-equivalent parameters. Dimensional stability is verified via CMM against your CAD data, with surface finish measured to Ra 0.2µm. Crucially, we analyze first-article parts for flash, knit lines, and dimensional drift—addressing micro-defects invisible to standard inspection. Only molds achieving 100% conformance to your quality gate criteria advance to mass production.

Zero-Defect Mass Production leverages closed-loop process control. Our automated cells integrate real-time pressure sensors, temperature monitors, and vision systems that halt cycles if deviations exceed 0.1% tolerance thresholds. Every mold undergoes 100% critical feature inspection via Zeiss CONTURA CMMs, with data logged for full traceability. We enforce statistical process control (SPC) using Minitab, maintaining Cp/Cpk values above 1.67 for all critical dimensions. This systematic approach ensures every mold shipped meets our Zero Defects Pledge: no cosmetic flaws, zero functional failures, and guaranteed 500,000+ cycle longevity.

Key Quality Assurance Metrics

| Parameter | Standard | Wuxi Lead Target | Verification Method |

|————————-|——————–|——————|—————————|

| Dimensional Tolerance | ±0.02mm | ±0.005mm | CMM (ISO 10360-2) |

| Surface Roughness | Ra 0.8µm | Ra 0.2µm | Profilometer (ISO 4287) |

| Cycle Time Consistency | ±3% | ±0.5% | Real-time Sensor Logging |

| First-Pass Yield | 95% | 99.98% | SPC Charting (Cpk ≥ 1.67) |

This disciplined workflow—from precision design validation through defect-proofed mass production—ensures resellers receive molds that maximize end-customer uptime and minimize total cost of ownership. Partner with us to transform quality from a promise into a measurable asset.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to Elevate Your Plastic Injection Mold Reselling Business

In the competitive landscape of custom metal manufacturing, precision, reliability, and consistency define success. As a plastic injection mold reseller, your reputation hinges on the quality of the products you deliver—and that quality begins with your manufacturing partner. Wuxi Lead Precision Machinery stands as a trusted leader in high-precision CNC machining, mold base production, and custom metal components, engineered to meet the exacting standards of global markets.

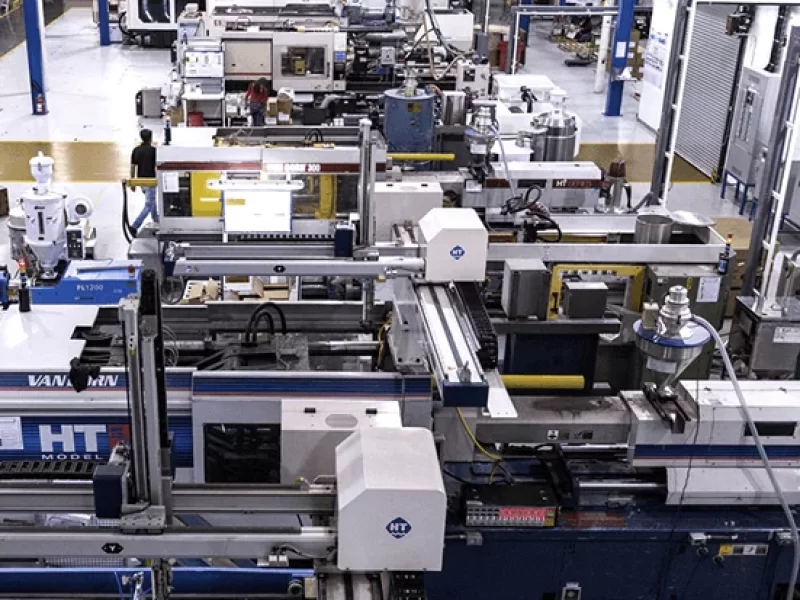

With over 15 years of advanced manufacturing experience in Wuxi, China—a recognized hub for industrial innovation—we specialize in delivering custom injection mold solutions that combine tight tolerances, superior surface finishes, and long-term durability. Our state-of-the-art facility is equipped with multi-axis CNC machines, wire EDM systems, and automated quality inspection tools, ensuring every mold base and component exceeds international benchmarks.

Our engineering team works closely with resellers to understand regional market demands, technical specifications, and delivery timelines. Whether you serve automotive, medical, consumer electronics, or industrial equipment sectors, we provide scalable production capacity and full documentation packages, including 2D/3D drawings, material certifications, and inspection reports. Every project is managed under ISO 9001-certified processes, guaranteeing consistency across batches and years of service.

We recognize that as a reseller, your success depends on supply chain stability, responsive communication, and technical support. That’s why we assign dedicated account managers to every partner, ensuring seamless coordination from initial inquiry to final shipment. Our logistics network supports FOB, CIF, and DDP delivery terms with reliable lead times, customs documentation, and packaging tailored to international freight standards.

To support your growth, we offer flexible MOQs, competitive pricing models, and co-branded technical marketing materials to strengthen your market positioning. Our molds are built using premium-grade materials such as P20, 718H, NAK80, and H13, processed with hardened cavities, corrosion-resistant coatings, and precision ejector systems for optimal performance in high-volume production environments.

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that values long-term collaboration, technical excellence, and on-time delivery. We don’t just supply molds—we enable resellers to deliver confidence, performance, and value to their end clients.

Explore how our custom metal manufacturing capabilities can strengthen your product portfolio and improve your service offering.

Technical Specifications Overview

| Feature | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Roughness | Ra 0.1 – 0.8 μm |

| Maximum Mold Size | 2000 x 1500 x 1200 mm |

| Materials | P20, 718H, NAK80, H13, S136, Stainless Steel |

| Heat Treatment | Up to 52 HRC (hardened & tempered) |

| Quality Standards | ISO 9001:2015, First Article Inspection, FAI Reports |

| Lead Time | 25–45 days (based on complexity) |

| Finishing Options | Mirror polishing, texturing, nitriding, PVD coating |

Contact us today to discuss your next project. Email [email protected] and connect with our global sales team for technical consultations, sample requests, or pricing details. Let Wuxi Lead Precision Machinery be your trusted manufacturing partner in delivering excellence—mold by mold, client by client.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.