Technical Contents

Engineering Guide: Industrial 3D Printing Services

Engineering Insight Precision as the Non-Negotiable in Industrial 3D Printing Services

Industrial 3D printing transcends prototyping; it delivers mission-critical end-use components where dimensional integrity directly impacts performance, safety, and system longevity. In sectors like aerospace, defense, and high-performance energy, tolerances measured in microns are not aspirational targets but absolute requirements. Sub-millimeter deviations in turbine blades, hydraulic manifolds, or structural brackets can induce catastrophic fatigue, flow inefficiencies, or assembly failures under operational stress. True industrial additive manufacturing demands metrology-grade validation at every stage – from powder characterization and laser calibration to in-situ monitoring and post-process metrology. This level of precision engineering separates production-ready services from basic fabrication.

Wuxi Lead Precision Machinery operates at this demanding threshold. Our facility is engineered for repeatability, not just capability. We implement closed-loop process control systems synchronized with coordinate measuring machines (CMM) and optical scanners, ensuring every build adheres to AS9100 and NADCAP standards. This rigor is validated by our track record: delivering titanium lattice structures for Olympic venue seismic dampers requiring ±0.03mm positional accuracy and producing flight-certified nickel alloy fuel nozzles for military propulsion systems where internal channel geometry tolerances are non-negotiable. These projects underscore that precision in industrial 3D printing is not merely about hitting a target dimension; it is about guaranteeing material homogeneity, residual stress management, and fatigue resistance through controlled thermal profiles and stringent post-processing protocols.

The table below outlines the precision benchmarks achievable within our certified production environment for critical metal components:

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Dimensional Accuracy | ±0.02 mm to ±0.05 mm | Ensures seamless integration into complex assemblies |

| Surface Roughness (As-Built) | Ra 8–12 µm | Minimizes post-machining for critical flow surfaces |

| Feature Resolution | 0.1 mm internal channels | Enables complex conformal cooling & lightweighting |

| Material Density | >99.95% | Guarantees mechanical properties matching wrought specs |

| Repeatability (CpK) | ≥1.67 | Statistical process control for zero-failure outcomes |

Achieving this level of consistency requires deep metallurgical expertise combined with advanced machine calibration. Our engineers optimize scan strategies and support structures based on finite element analysis (FEA) to counteract distortion, while our in-house heat treatment and HIP (Hot Isostatic Pressing) capabilities eliminate internal voids. This holistic approach transforms additive manufacturing from a novel process into a reliable production pillar. When your application demands zero-failure outcomes under extreme conditions, precision cannot be an afterthought – it must be the foundation. Wuxi Lead Precision Machinery provides the engineering discipline and certified processes to make it your reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced industrial 3D printing services integrated with high-precision metal manufacturing capabilities, enabling the production of complex, high-performance components for aerospace, medical, energy, and industrial automation sectors. Our technical infrastructure combines state-of-the-art additive manufacturing with precision subtractive processes to ensure dimensional accuracy, material integrity, and repeatability across both prototyping and serial production runs.

Our industrial 3D printing operations are centered on metal laser powder bed fusion (LPBF) technology, supporting a range of high-grade alloys including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel (718, 625), and aluminum (AlSi10Mg). These systems enable the fabrication of geometrically intricate parts with internal channels, lattice structures, and topology-optimized designs that are unachievable through traditional machining alone. Layer resolution as fine as 20 microns ensures surface quality and detail fidelity, while controlled build environments maintain material consistency and minimize residual stress.

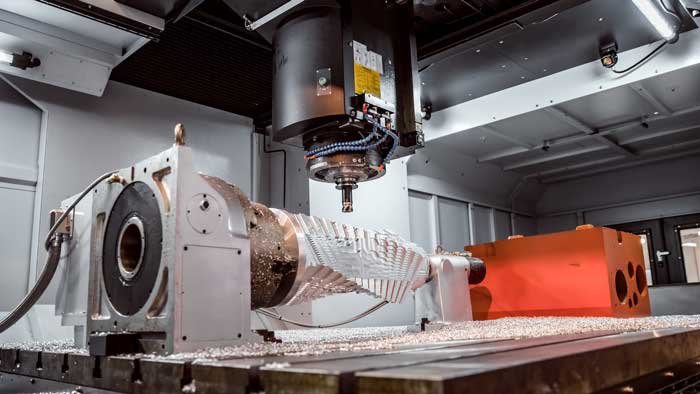

Post-processing is a critical phase in our workflow, where additive components undergo thermal stress relief, support removal, and precision surface treatments. For mission-critical applications, we integrate 5-axis CNC machining to achieve tight-tolerance features, sealing surfaces, and fine finishes on 3D printed substrates. This hybrid approach leverages the design freedom of additive manufacturing with the accuracy and surface integrity of multi-axis milling, resulting in components that meet stringent functional and regulatory standards.

Quality assurance is maintained throughout the production cycle. All critical dimensions and geometries are verified using coordinate measuring machine (CMM) inspection, ensuring full compliance with ASME Y14.5 and ISO 1101 standards. Our metrology lab is equipped with a 7-axis Zeiss PRISMO ULTRA CMM with 0.8 µm volumetric accuracy, enabling high-resolution inspection of complex freeform surfaces and internal features via probing and scanning techniques. Additionally, first article inspection (FAI) and production part approval process (PPAP) documentation are available upon request.

The following table outlines the standard technical specifications and achievable tolerances across our industrial 3D printing and hybrid manufacturing processes:

| Parameter | Capability |

|---|---|

| Build Volume (Max) | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Material Options | Ti6Al4V, 316L, 17-4 PH, Inconel 718/625, AlSi10Mg |

| Surface Roughness (as-built) | Ra 8 – 12 µm |

| Surface Roughness (polished) | Ra 0.4 – 1.6 µm |

| Dimensional Tolerance (typical) | ±0.05 mm / 0.1 mm per 100 mm |

| Post-Processing | Stress relief, HIP, CNC milling, polishing, coating |

| Inspection Standards | CMM, GD&T, FAI, PPAP |

By combining industrial 3D printing with 5-axis CNC finishing and rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of precision, reliability, and performance in demanding industrial environments.

Material & Finish Options

Material Selection for Industrial Metal Additive Manufacturing

Material selection is a critical engineering decision in industrial 3D printing, directly impacting part performance, durability, and cost-effectiveness. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your application’s specific mechanical, thermal, and environmental demands. Aluminum alloys offer an exceptional strength-to-weight ratio and thermal conductivity, making them ideal for aerospace brackets, heat exchangers, and lightweight automotive components. Common high-performance alloys like AlSi10Mg and Scalmalloy provide good castability and fatigue resistance within the additive process. Steel variants, particularly maraging steels (e.g., 18Ni300) and stainless steels (e.g., 17-4 PH, 316L), deliver superior strength, hardness, and wear resistance. These are essential for demanding tooling, injection molding cores, and high-stress mechanical parts requiring tight tolerances and longevity. Titanium alloys, especially Ti-6Al-4V (Grade 5), represent the pinnacle for high-value applications demanding extreme strength-to-weight ratios, exceptional corrosion resistance, and biocompatibility. This makes titanium indispensable for critical aerospace structural components, medical implants, and marine hardware operating in harsh environments.

Understanding the precise material behavior during the laser powder bed fusion (LPBF) process is paramount. Key properties like thermal conductivity, laser absorptivity, and susceptibility to residual stress dictate build parameters and post-processing requirements. Below is a comparative overview of essential specifications for common industrial AM metals:

| Material Category | Key Alloys | Typical Tensile Strength (MPa) | Typical Elongation (%) | Critical Considerations for AM |

|---|---|---|---|---|

| Aluminum | AlSi10Mg, Scalmalloy | 280 – 480 | 8 – 12 | High reflectivity requires optimized laser settings; prone to hot cracking; excellent thermal management needed |

| Steel | 18Ni300, 17-4 PH, 316L | 900 – 1300 (as-built) | 10 – 25 | Martensitic steels require careful heat treatment; stainless offers good corrosion resistance; high density |

| Titanium | Ti-6Al-4V (Gr5) | 900 – 1000 | 10 – 15 | Requires strict inert gas environment; excellent biocompatibility; high cost; superior corrosion resistance |

Surface finish and functional enhancement are equally vital. For aluminum components, anodizing is a highly effective post-processing step. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification. For mission-critical applications demanding maximum hardness and abrasion resistance, Type III (hardcoat) anodizing is essential. This process creates a significantly thicker, denser oxide layer, crucial for parts exposed to extreme friction or harsh chemicals. It is imperative to note that anodizing is specific to aluminum; titanium and steel require alternative surface treatments like passivation, shot peening, or specialized coatings.

Selecting the optimal material and finish requires deep process knowledge. Wuxi Lead Precision Machinery leverages extensive LPBF expertise and material science understanding to guide your selection. We analyze your part geometry, loading conditions, environmental exposure, and functional lifespan to recommend the precise alloy and post-processing sequence, ensuring your additive manufactured components meet the highest industrial standards for performance and reliability. Consult our engineering team early in the design phase for optimal results.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production journey for industrial 3D printing services begins with a rigorous design phase rooted in engineering excellence. Our in-house team of mechanical and materials engineers collaborates closely with clients to translate conceptual requirements into manufacturable, high-performance metal components. Utilizing advanced CAD software and simulation tools such as ANSYS and SolidWorks, we perform structural, thermal, and fluid dynamic analyses to optimize part geometry for strength, weight, and function. Design for Additive Manufacturing (DfAM) principles are applied to eliminate unnecessary mass, consolidate assemblies, and enable internal features unachievable through traditional methods. Every design undergoes a formal Design Failure Mode and Effects Analysis (DFMEA) to preempt potential weaknesses. This ensures that the digital blueprint not only meets functional specifications but is also aligned with the metallurgical and dimensional capabilities of our metal additive systems.

Prototyping: Validating Performance, Ensuring Zero Defects

The transition from design to prototype is executed with the same precision as final production. Using selective laser melting (SLM) and electron beam melting (EBM) technologies, we produce functional prototypes in the intended production alloy—typically Ti6Al4V, Inconel 718, or 17-4 PH stainless steel. These prototypes undergo full-scale mechanical testing, non-destructive evaluation (NDE), and dimensional inspection via coordinate measuring machines (CMM) and 3D laser scanning. Critical characteristics such as surface roughness, porosity levels, and microhardness are verified against aerospace and medical-grade standards. Any deviations trigger a closed-loop corrective action, with design or process parameters adjusted before progression. This phase is not merely about validation—it is a critical step in our zero-defect philosophy, eliminating risks before scaling to volume.

Mass Production: Consistency, Control, and Traceability

Once design and prototype are fully qualified, we initiate scalable metal additive manufacturing with full process control. Our production cells operate under strict environmental and parameter monitoring, with each build recorded in real time for laser power, scan speed, layer thickness, and chamber atmosphere. Post-build heat treatment, stress relieving, and precision machining are performed in-house to achieve final tolerances down to ±0.02 mm. Every component is serialized and tracked through our quality management system, ensuring complete material and process traceability. Final inspection includes radiographic testing (RT) and penetrant testing (PT) where applicable, guaranteeing zero internal or surface defects.

The result is a seamless, auditable transition from concept to high-integrity metal parts—engineered for performance, validated for reliability, and produced without compromise.

| Production Specification | Detail |

|---|---|

| Supported Materials | Ti6Al4V, Inconel 718, 316L, 17-4 PH, AlSi10Mg |

| Layer Thickness Range | 20–60 μm |

| Build Envelope (Max) | 250 × 250 × 325 mm |

| Dimensional Accuracy | ±0.02 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm; post-processed down to Ra 1.6 μm |

| Post-Processing Capabilities | HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001, AS9100, NADCAP (NDE) |

| Lead Time (Prototype to Production) | 7–14 days (depending on complexity) |

Why Choose Wuxi Lead Precision

Strategic Partnership for Advanced Metal Additive Manufacturing

In today’s volatile industrial landscape, supply chain resilience and geometric complexity demand more than standard fabrication. Wuxi Lead Precision Machinery transcends conventional contract manufacturing by integrating industrial 3D printing with decades of CNC engineering mastery. We partner with forward-thinking enterprises to transform design constraints into competitive advantages—turning high-risk, low-yield components into reliable, high-performance assets. Our collaboration model begins with your engineering challenges, not our machine capabilities. We deploy DFAM (Design for Additive Manufacturing) expertise to optimize part topology, material selection, and post-processing workflows, ensuring your components meet stringent aerospace, energy, and medical device requirements while reducing lead times by up to 65%.

Precision is non-negotiable in mission-critical applications. Our certified metal additive systems operate within rigorously controlled environments, adhering to ISO 9001 and AS9100 standards. Every build undergoes in-situ monitoring and multi-axis metrology validation, eliminating guesswork in qualification. The table below outlines our core production specifications for industrial-grade metal printing:

| Parameter | Specification | Industrial Relevance |

|---|---|---|

| Build Volume | Ø250 x 325 mm to 500 x 500 x 400 mm | Accommodates complex assemblies & large-scale tooling |

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr | Certified aerospace/medical alloys with traceability |

| Layer Thickness | 20–50 µm | Surface finish as low as Ra 4.5 µm pre-machining |

| Positional Accuracy | ±25 µm over 100 mm | Meets ASME Y14.5 geometric tolerancing |

| Post-Processing | HIP, CNC milling, stress-relief, CMM | Ensures fatigue resistance & dimensional stability |

This technical foundation enables us to solve problems legacy manufacturing cannot address: consolidating multi-part assemblies, embedding conformal cooling channels, or producing lattice structures for weight-critical applications. But capability alone is insufficient. Our engineers collaborate at the schematic stage—conducting feasibility analyses, cost-per-part modeling, and failure-mode simulations—to de-risk your transition to additive production. We treat your intellectual property with military-grade security protocols, providing full digital thread documentation for audit compliance.

Initiate your qualification review by contacting our engineering team at [email protected]. Specify your component’s operational environment, material requirements, and target volume. Within 48 hours, you will receive a tailored assessment including build orientation strategy, material certification documentation, and a timeline for first-article submission. For urgent prototyping needs, our rapid-response cell guarantees 5-day turnaround on qualified designs. Wuxi Lead Precision Machinery does not sell prints; we deliver certified solutions engineered for your production floor. Let us prove why global leaders in turbine manufacturing and surgical robotics trust our partnership model. Your next breakthrough component begins with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.