Technical Contents

Engineering Guide: Custom Aluminum Plate

Engineering Insight: Custom Aluminum Plates – Where Precision Defines Performance

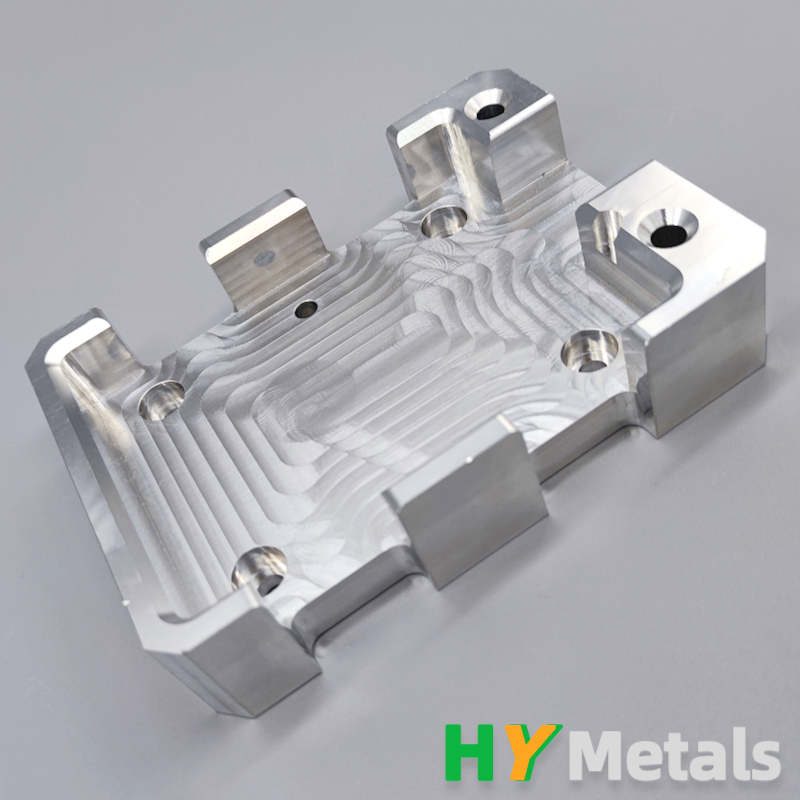

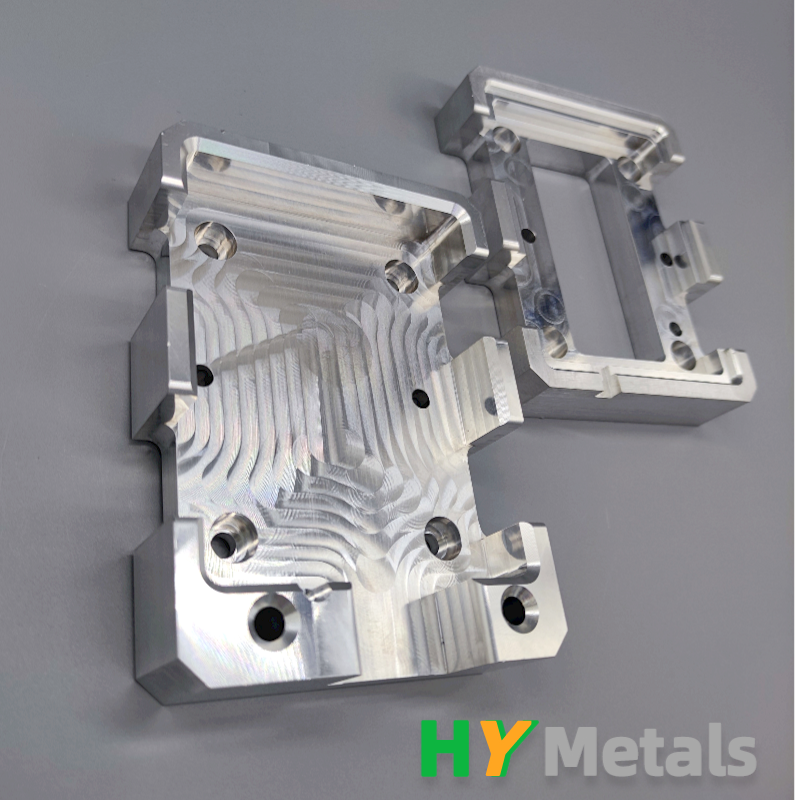

In high-performance industrial applications, custom aluminum plates are far more than simple structural components—they are engineered solutions that demand exacting standards in dimensional accuracy, material integrity, and surface finish. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise the functionality, safety, and longevity of critical systems. This is why precision is not just a goal but a foundational principle in every custom aluminum plate we manufacture.

Aluminum, with its favorable strength-to-weight ratio, corrosion resistance, and thermal conductivity, is a material of choice across aerospace, defense, transportation, and high-end machinery sectors. However, its true potential is only unlocked when machined to exact specifications. Whether it’s a mounting plate for satellite instrumentation or a load-bearing component in armored vehicle systems, the performance of the final assembly hinges on the consistency and accuracy of the aluminum substrate.

Our engineering team applies advanced CNC milling, turning, and surface finishing techniques to achieve tolerances as tight as ±0.005 mm. This level of precision ensures seamless integration with mating components, reduces assembly stress, and enhances overall system reliability. We utilize state-of-the-art coordinate measuring machines (CMM) and laser scanning technologies for real-time quality verification, ensuring every plate meets or exceeds client specifications.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in custom aluminum fabrication, serving clients in mission-critical industries including military defense and large-scale infrastructure. Notably, our components have been integrated into structural systems for Olympic-grade sports facilities, where safety, durability, and dimensional accuracy are non-negotiable. These projects demanded not only strict adherence to international standards (such as ISO 9001 and AS9100) but also the ability to scale production without compromising quality—a capability we have consistently demonstrated.

Our expertise extends beyond machining to include material selection guidance, thermal treatment optimization, and surface engineering such as anodizing or chemical conversion coatings. We work closely with design engineers to optimize part geometry for manufacturability, minimizing waste and improving performance under dynamic loads.

The table below outlines typical specifications we achieve for custom aluminum plates:

| Parameter | Standard Capability | High-Precision Option | Notes |

|---|---|---|---|

| Material Grades | 6061, 7075, 5083, 2024 | Custom alloys available | Aerospace and marine-grade options |

| Tolerance | ±0.02 mm | ±0.005 mm | Achieved via CNC machining |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm | Polished or bead-blasted finishes |

| Max Plate Size | 2000 mm × 1000 mm × 300 mm | Custom upon request | Full 5-axis machining capacity |

| Finishing Options | Mill finish, anodizing, powder coating | Custom coatings | Salt spray tested for corrosion resistance |

| Quality Certification | ISO 9001:2015 | AS9100, MIL-STD available | Full traceability and inspection reports |

Precision in custom aluminum plate manufacturing is not an incremental advantage—it is the difference between success and failure in demanding environments. At Wuxi Lead Precision Machinery, we combine technical excellence with proven experience in elite industrial applications to deliver components that perform under the most rigorous conditions.

Precision Specs & Tolerances

Technical Capabilities for Custom Aluminum Plate Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision in custom aluminum plate manufacturing for aerospace, medical, and high-performance industrial applications. Our integrated 5-axis CNC machining centers form the backbone of complex geometry production, enabling single-setup machining of intricate features with micron-level accuracy. This eliminates cumulative errors inherent in multi-operation workflows, ensuring critical datums and tight positional tolerances are maintained across all surfaces. Our Haas and DMG MORI systems utilize high-rigidity spindles and adaptive toolpath strategies to minimize vibration and thermal drift during deep pocketing, thin-wall contouring, and multi-faceted milling operations on 6061-T6, 7075-T6, and specialty aluminum alloys.

Quality assurance is embedded at every process stage through systematic CMM inspection. All critical dimensions undergo first-article validation and in-process verification using Zeiss CONTURA coordinate measuring machines within a temperature-stabilized metrology lab. Our inspection protocols adhere to AS9100 and ISO 17025 standards, with full traceability to NIST-certified artifacts. Real-time SPC data analysis identifies process drift before non-conformities occur, while comprehensive reports—including GD&T callouts, surface roughness maps, and deviation heatmaps—are provided with every shipment. This closed-loop system guarantees repeatability across production runs, whether prototyping or high-volume orders.

Our technical expertise extends beyond machining to material optimization. We collaborate with clients during DFM analysis to select optimal aluminum grades, heat treatments, and fixture strategies that mitigate distortion while maximizing yield. Secondary operations—including precision tapping, honing, and micro-milling—are performed within the same controlled environment to maintain dimensional integrity.

Standard Production Tolerances for Aluminum Plate Machining

| Feature | Capability | Standard Reference |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ISO 2768-mK |

| Geometric Position | ±0.008 mm | ASME Y14.5-2018 |

| Flatness | 0.010 mm per 100 mm | ISO 1101 |

| Surface Roughness (Ra) | 0.8 μm (typical) | ISO 1302 |

| Hole Concentricity | ±0.005 mm | ISO 5458 |

| Angular Features | ±0.001° | ISO 1101 |

This precision translates directly to client value: reduced assembly scrap, extended component service life, and elimination of post-machining rework. Our engineering team provides actionable feedback during quoting to resolve potential manufacturability conflicts, ensuring your design intent is realized without cost overruns. For mission-critical applications requiring sub-5μm tolerances or specialized surface treatments, our advanced process development group implements custom tooling and in-process metrology solutions. Partner with Wuxi Lead to transform complex aluminum plate requirements into certified, high-yield production realities.

Material & Finish Options

Material Selection for Custom Aluminum Plate Fabrication

Selecting the appropriate material for custom aluminum plate applications is critical to ensuring optimal performance, durability, and cost-efficiency in precision manufacturing. At Wuxi Lead Precision Machinery, we specialize in high-tolerance CNC machining and fabrication of custom aluminum plates, tailored to meet the rigorous demands of aerospace, automotive, medical, and industrial equipment sectors. While aluminum is often the preferred choice due to its favorable strength-to-weight ratio and corrosion resistance, understanding how it compares to alternative materials such as steel and titanium is essential for informed decision-making.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are widely used in custom plate fabrication. 6061-T6 offers excellent weldability, good machinability, and moderate strength, making it ideal for structural components and general-purpose applications. In contrast, 7075-T6 provides superior strength, approaching that of many steels, while maintaining low density—making it a top choice for high-performance aerospace and defense systems. Aluminum’s natural oxide layer provides inherent corrosion resistance, which can be further enhanced through surface treatments such as anodizing.

When comparing materials, steel offers higher tensile strength and wear resistance than aluminum, but at the cost of increased weight. This makes steel better suited for applications where mass and rigidity are advantageous, such as heavy machinery bases or tooling plates. However, its susceptibility to rust—unless treated or alloyed—can be a limitation in corrosive environments. Titanium, while offering an exceptional strength-to-density ratio and outstanding corrosion resistance, comes with significantly higher material and machining costs. It is typically reserved for extreme environments such as aerospace, marine, or medical implant applications where performance justifies expense.

Surface finishing plays a pivotal role in enhancing both functionality and aesthetics. Anodizing is the most common finish for aluminum plates, creating a durable, wear-resistant oxide layer that can be dyed in various colors. Type II (sulfuric acid) anodizing is standard for decorative and moderate protection needs, while Type III (hardcoat anodizing) provides superior thickness and hardness for industrial applications requiring abrasion resistance.

Below is a comparative overview of key material properties and finishing options:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | High | Structural frames, enclosures | Anodizing, powder coating |

| Aluminum 7075-T6 | 2.8 | 572 | Moderate | Aerospace components | Hard anodizing, chromate |

| Steel (AISI 4140) | 7.8 | 655 | Low (unless coated) | Tooling, machinery bases | Zinc plating, painting |

| Titanium (Grade 5) | 4.5 | 900 | Excellent | Medical, aerospace, marine | Bead blasting, anodizing (color) |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and lifecycle costs. Our in-house anodizing and precision machining capabilities ensure consistent quality and tight tolerances across all custom aluminum plate projects.

Manufacturing Process & QC

Custom Aluminum Plate Manufacturing: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our custom aluminum plate production adheres to a rigorously defined workflow ensuring absolute dimensional integrity and material performance for mission-critical applications. We integrate advanced engineering with closed-loop quality systems across three non-negotiable phases: Design Validation, Precision Prototyping, and Zero-Defect Mass Production. This structured approach mitigates risk and guarantees conformance to aerospace, medical, and semiconductor industry standards.

The process initiates with comprehensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates with client CAD data to scrutinize geometric complexity, tolerance stack-ups, and material selection against specified aluminum alloys (e.g., 6061-T6, 7075-T73). Critical factors like thermal distortion during machining, clamping strategies, and optimal toolpath sequencing are simulated using Mastercam and Siemens NX software. This phase identifies potential weaknesses early, ensuring the design is inherently producible to micron-level tolerances before any material is cut. Approved designs progress with full material traceability documentation.

Prototyping employs identical 5-axis CNC machining centers used in volume production, eliminating process variation. Each prototype undergoes full first-article inspection per AS9102 standards. Coordinate Measuring Machines (CMM) verify all critical dimensions against 3D models, while surface profilometers validate Ra values and flatness. Material properties are confirmed via third-party mill test reports. Client feedback on functional fit and performance is incorporated, with engineering adjustments finalized only after joint sign-off. This phase validates the entire production ecosystem—not just the part.

Mass production activates our Zero Defects framework. Statistical Process Control (SPC) monitors key parameters (tool wear, spindle load, coolant concentration) in real-time across Haas and DMG MORI machining centers. Automated in-process gauging at critical stations halts production if deviations exceed 70% of tolerance bands. Every plate receives 100% visual inspection under controlled lighting and final CMM validation per the approved prototype. Non-conforming material is quarantined with root-cause analysis completed within 24 hours. Our ISO 9001 and AS9100 certified systems ensure full batch traceability from raw material heat number to end-of-line certification.

Critical Process Specifications Across Production Stages

| Process Stage | Key Activities | Quality Controls | Output Standards |

|---|---|---|---|

| Design Validation | DFM analysis, Thermal distortion simulation, Toolpath optimization | Tolerance stack-up review, Material suitability audit | Approved manufacturable CAD model with traceable material spec |

| Precision Prototyping | 5-axis CNC machining, Stress-relief cycles | Full FAI per AS9102, CMM inspection, Surface roughness validation | Functional prototype with full inspection report |

| Zero-Defect Mass Production | Real-time SPC, Automated in-process gauging, 100% final inspection | Statistical monitoring, Root-cause corrective action, Full batch traceability | Certified plates meeting all print tolerances with material certs |

This disciplined methodology ensures Wuxi Lead delivers custom aluminum plates that perform flawlessly in the most demanding applications. Every plate carries the assurance of engineered precision from digital concept through certified delivery.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Aluminum Plate Solutions

When precision, reliability, and performance define your product requirements, partnering with a trusted expert in custom aluminum plate manufacturing becomes critical. At Wuxi Lead Precision Machinery, we specialize in delivering high-end, application-specific aluminum components engineered to meet the exact demands of aerospace, automation, medical equipment, and advanced industrial systems. With over 15 years of experience in CNC machining, sheet metal fabrication, and precision assembly, we serve global clients who demand consistency, quality, and technical excellence.

Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC machines, laser cutting systems, and automated forming technology. This allows us to produce custom aluminum plates with tight tolerances, complex geometries, and superior surface finishes. From prototype development to high-volume production, we manage every stage in-house—ensuring faster turnaround times, full traceability, and strict adherence to international quality standards including ISO 9001:2015 and AS9100 for aerospace applications.

We understand that no two applications are identical. That’s why our engineering team works closely with your design specifications to optimize material selection, minimize waste, and enhance structural integrity. Whether you require 6061-T6 for its weldability and strength, 7075-T6 for high stress resistance, or custom alloys for specialized environments, we provide expert guidance and material certification with every order.

Our commitment extends beyond manufacturing. We offer comprehensive DFM (Design for Manufacturability) analysis, rapid quoting, and real-time production updates to ensure seamless integration into your supply chain. With export experience across North America, Europe, and Southeast Asia, we manage logistics, customs documentation, and packaging to deliver your components on schedule, every time.

Below are standard technical capabilities for custom aluminum plate fabrication at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Material Types | 6061, 6082, 7075, 5052, 2024, and custom alloys |

| Plate Thickness | 0.5 mm – 150 mm |

| Tolerance | ±0.02 mm (standard), up to ±0.005 mm (precision) |

| Max Part Size | 2000 mm × 4000 mm |

| Machining | 3-axis, 4-axis, 5-axis CNC milling and turning |

| Surface Finishes | Anodizing (Type II & III), powder coating, sandblasting, brushing, passivation |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS compliant |

| Production Volume | Prototypes to 100,000+ units annually |

Your next-generation product deserves a manufacturing partner who combines technical mastery with operational agility. At Wuxi Lead Precision Machinery, we don’t just produce parts—we engineer solutions.

Contact us today at [email protected] to discuss your custom aluminum plate requirements. Our engineering team is ready to provide a detailed quote, DFM feedback, and sample timelines within 24 hours. Let us help you achieve precision without compromise.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.