Technical Contents

Engineering Guide: Stainless Steel Pla

Engineering Insight: Precision Imperatives in Stainless Steel Part Manufacturing

In high-performance industrial applications, stainless steel components demand micron-level precision to fulfill critical functional requirements. Surface integrity directly impacts corrosion resistance—improper machining can compromise the passive oxide layer, accelerating degradation in harsh environments like chemical processing or marine systems. Dimensional accuracy is equally vital; even minor deviations in load-bearing parts risk catastrophic failure under cyclic stress. At Wuxi Lead Precision Machinery, we treat stainless steel not merely as a material but as a performance variable where tolerances, grain structure, and residual stress must be engineered into every component.

Stainless steel’s inherent properties present unique challenges. Its tendency toward work hardening during cutting requires optimized feed rates and tool geometries to prevent micro-fractures. Thermal management is non-negotiable—excessive heat input alters metallurgical properties, reducing fatigue strength. Our CNC processes integrate real-time thermal monitoring and adaptive toolpath algorithms to maintain material integrity. For aerospace hydraulic manifolds or semiconductor chamber components, we achieve ±0.002mm tolerances through multi-axis simultaneous machining, ensuring leak-proof interfaces and flawless sealing surfaces. This precision isn’t incidental; it stems from rigorous process validation against ASTM A262 and ISO 1302 standards.

Wuxi Lead’s expertise is forged in projects where failure is unthinkable. We supplied mission-critical structural supports for Beijing 2022 Winter Olympic venues, where sub-zero temperatures demanded flawless weld integrity in duplex stainless steel assemblies. Similarly, our naval-grade components for defense contractors undergo MIL-STD-810H environmental testing, surviving 2,000-hour salt fog exposure without pitting. These projects underscore our commitment to zero-defect manufacturing—a philosophy embedded in every technician’s workflow and every machine’s calibration cycle.

Our technical capabilities are anchored in measurable outcomes. Below are representative specifications for common high-demand applications:

| Parameter | Standard Capability | High-Precision Tier | Industry Standard |

|---|---|---|---|

| Tolerance (mm) | ±0.01 | ±0.002 | ±0.05 |

| Surface Roughness (Ra) | 0.8 μm | 0.2 μm | 3.2 μm |

| Material Grades | 304/316/L, 17-4PH | 904L, 6% Mo super austenitic | 304/316 only |

| Max Part Weight | 5,000 kg | 1,200 kg | 2,000 kg |

| Lead Time (Complex) | 18 days | 25 days | 30+ days |

This precision translates to tangible client value: extended service life in corrosive environments, reduced assembly rework, and compliance with stringent regulatory frameworks like ASME BPVC Section VIII. For medical implant fixtures or nuclear valve components, our traceability system logs every machining parameter against material heat numbers—providing auditable proof of performance.

When your application demands stainless steel parts that perform under extreme conditions, precision isn’t a specification—it’s the foundation of reliability. Wuxi Lead Precision Machinery delivers engineered certainty, proven where global standards converge with uncompromising operational demands. Partner with us to transform material potential into mission-critical reality.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the most demanding industrial applications. Our expertise in machining stainless steel pla components combines precision engineering, state-of-the-art equipment, and rigorous quality assurance protocols to ensure every part meets exacting specifications. As a trusted partner in high-integrity manufacturing, we specialize in producing complex geometries and critical components where reliability, durability, and dimensional accuracy are non-negotiable.

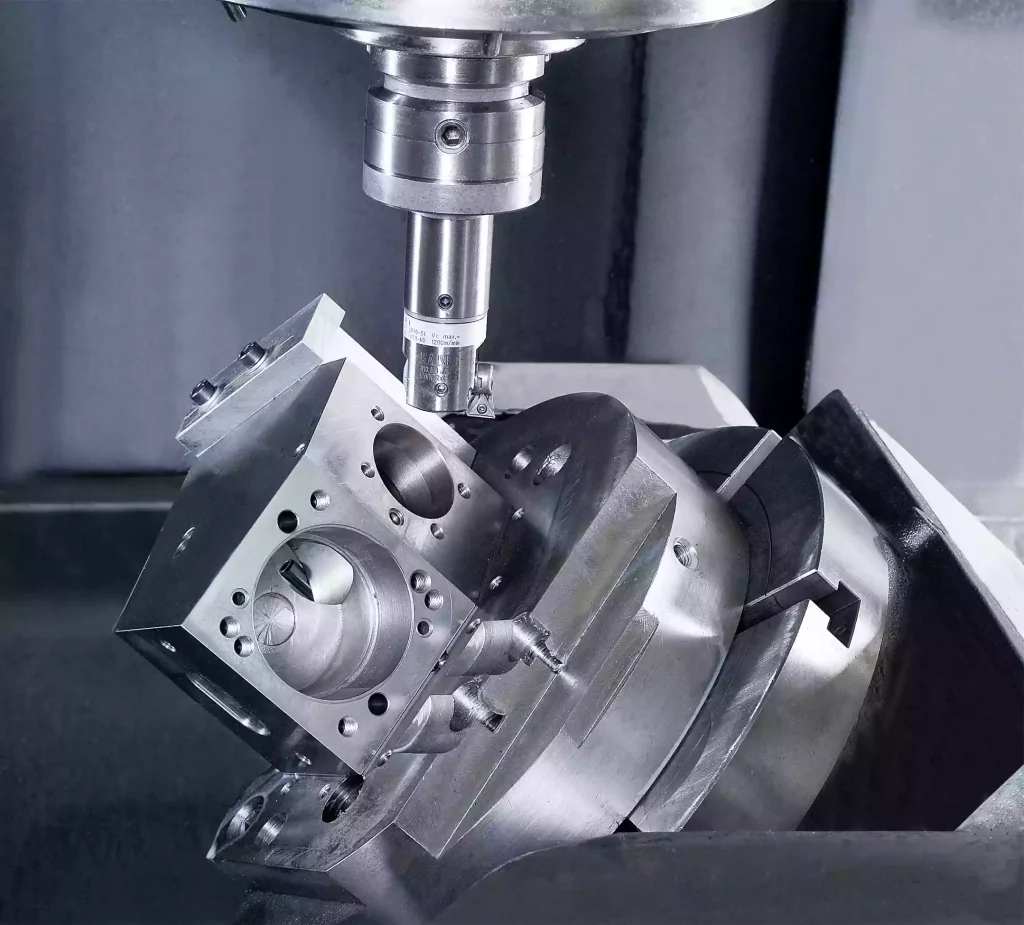

At the core of our technical capabilities is our 5-axis CNC machining technology. This advanced platform enables simultaneous multi-axis movement, allowing for intricate contours, tight tolerances, and superior surface finishes on stainless steel pla materials. Unlike conventional 3-axis systems, our 5-axis machines reduce the need for multiple setups, minimizing human error and significantly improving throughput. The result is a highly efficient process that maintains consistency across both prototyping and full-scale production runs. Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure optimal performance and material integrity throughout the machining cycle.

Material selection is critical in stainless steel pla fabrication, and we work with a range of premium-grade alloys including 304, 316, 17-4 PH, and other corrosion-resistant variants. Each material is processed under controlled conditions to preserve its mechanical and chemical properties. Our skilled machinists apply deep metallurgical knowledge to optimize cutting parameters, toolpath strategies, and coolant application, ensuring minimal thermal distortion and maximum part longevity.

Quality control is integrated at every stage of production. All stainless steel pla components undergo comprehensive inspection using our Coordinate Measuring Machine (CMM) system. This metrology-grade equipment provides micron-level verification of geometric dimensions, positional tolerances, and surface profiles. Data from CMM reports is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements. In addition to dimensional accuracy, we perform material verification, surface roughness testing, and visual inspection under magnification to guarantee defect-free deliverables.

The following table outlines our standard technical specifications and achievable tolerances for stainless steel pla machining:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.02 mm | ±0.01 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finish) |

| Feature Size Resolution | 0.1 mm | 0.05 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom upon request |

| Angular Tolerance | ±0.1° | ±0.05° |

Our technical capabilities are designed to meet the challenges of aerospace, medical, semiconductor, and high-performance industrial sectors. With 5-axis precision, rigorous CMM validation, and a commitment to engineering excellence, Wuxi Lead Precision Machinery ensures that every stainless steel pla component exceeds functional and quality expectations.

Material & Finish Options

Material Selection for Precision Metal Components: Aluminum, Steel, and Titanium

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, our CNC machining expertise ensures each material’s inherent properties are fully leveraged for your specific application demands. Understanding the core characteristics of aluminum, steel, and titanium is critical for informed decision-making in high-precision engineering.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and superior machinability. These properties make aluminum ideal for aerospace components, automotive parts, and structural frames where weight reduction is paramount. Its natural corrosion resistance, especially when enhanced through finishing processes, suits outdoor and marine environments. However, aluminum’s lower hardness compared to steel necessitates careful design consideration for high-wear applications. Our CNC centers excel in producing tight-tolerance aluminum parts with smooth surface finishes, minimizing secondary operations.

Carbon steel and stainless steel variants provide unmatched strength, durability, and wear resistance. 304 and 316 stainless steels are preferred for medical devices, food processing equipment, and marine hardware due to their excellent corrosion resistance and hygienic properties. Carbon steels like 1045 or 4140 deliver high tensile strength for heavy-duty machinery and tooling but require protective finishes like plating or painting in corrosive settings. Machining steel demands robust tooling and precise parameters; our advanced CNC mills and lathes consistently achieve micron-level accuracy on these demanding materials, ensuring structural integrity and dimensional stability.

Titanium, especially Grade 5 (Ti-6Al-4V), is the premium choice for extreme environments. Its extraordinary strength-to-weight ratio, biocompatibility, and resistance to corrosion—even in seawater and chlorides—make it indispensable for aerospace, biomedical implants, and chemical processing. While titanium’s challenging machinability increases production complexity and cost, our specialized tooling strategies and controlled cutting environments maximize efficiency and surface quality, turning this difficult material into reliable, high-performance components.

Surface finishes significantly augment material performance. Anodizing is exclusively applicable to aluminum, creating a durable, corrosion-resistant oxide layer that accepts color dyes for identification or aesthetics. For steel, electroplating (zinc, nickel) or passivation (stainless steel) are standard corrosion-protection methods. Titanium typically requires specialized treatments like acid etching or thermal oxidation for enhanced biocompatibility or wear resistance. Wuxi Lead integrates finish selection early in the design phase, ensuring compatibility with material properties and functional requirements.

Material properties directly influence manufacturability and final part performance. The following table summarizes key characteristics for common engineering alloys:

| Material | Typical Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Excellent (A1) |

| Stainless 304 | 8.0 | 505 | Excellent | Moderate (B2) |

| Titanium Gr5 | 4.4 | 880 | Exceptional | Difficult (C3) |

| Carbon Steel 1045 | 7.8 | 570 | Poor (unprotected) | Good (A2) |

Consult Wuxi Lead’s engineering team to align material selection with your performance criteria, environmental exposure, and lifecycle costs. We provide comprehensive material certification and process validation, guaranteeing components that meet the most stringent industrial standards. Partner with us to transform material science into precision-engineered reality.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production of high-performance stainless steel pla begins with a rigorously structured design phase. Our engineering team collaborates closely with clients to translate functional requirements, dimensional constraints, and environmental conditions into optimized 3D CAD models. Utilizing advanced simulation software, we conduct finite element analysis (FEA) to predict stress distribution, thermal behavior, and structural integrity under operational loads. This ensures that every design is not only manufacturable but also resilient in real-world applications. Material selection is a critical component—grade 304, 316, or 316L stainless steel is chosen based on corrosion resistance, tensile strength, and surface finish requirements. All design files are validated through internal design for manufacturability (DFM) reviews to eliminate potential production bottlenecks before any physical work begins.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move into the prototyping stage—a non-negotiable step in our zero-defect philosophy. Using CNC milling and precision turning, we produce functional prototypes from the same grade of stainless steel intended for mass production. These prototypes undergo comprehensive metrological inspection using coordinate measuring machines (CMM) to verify dimensional accuracy within ±0.005 mm. Surface roughness, edge consistency, and geometric tolerances are also evaluated per ISO 1302 standards. Clients receive full inspection reports and physical samples for functional testing, allowing for design validation under actual operating conditions. Any deviations trigger immediate engineering feedback loops, ensuring corrections are implemented before tooling and production setup.

Mass Production: Consistency Through Automation and Control

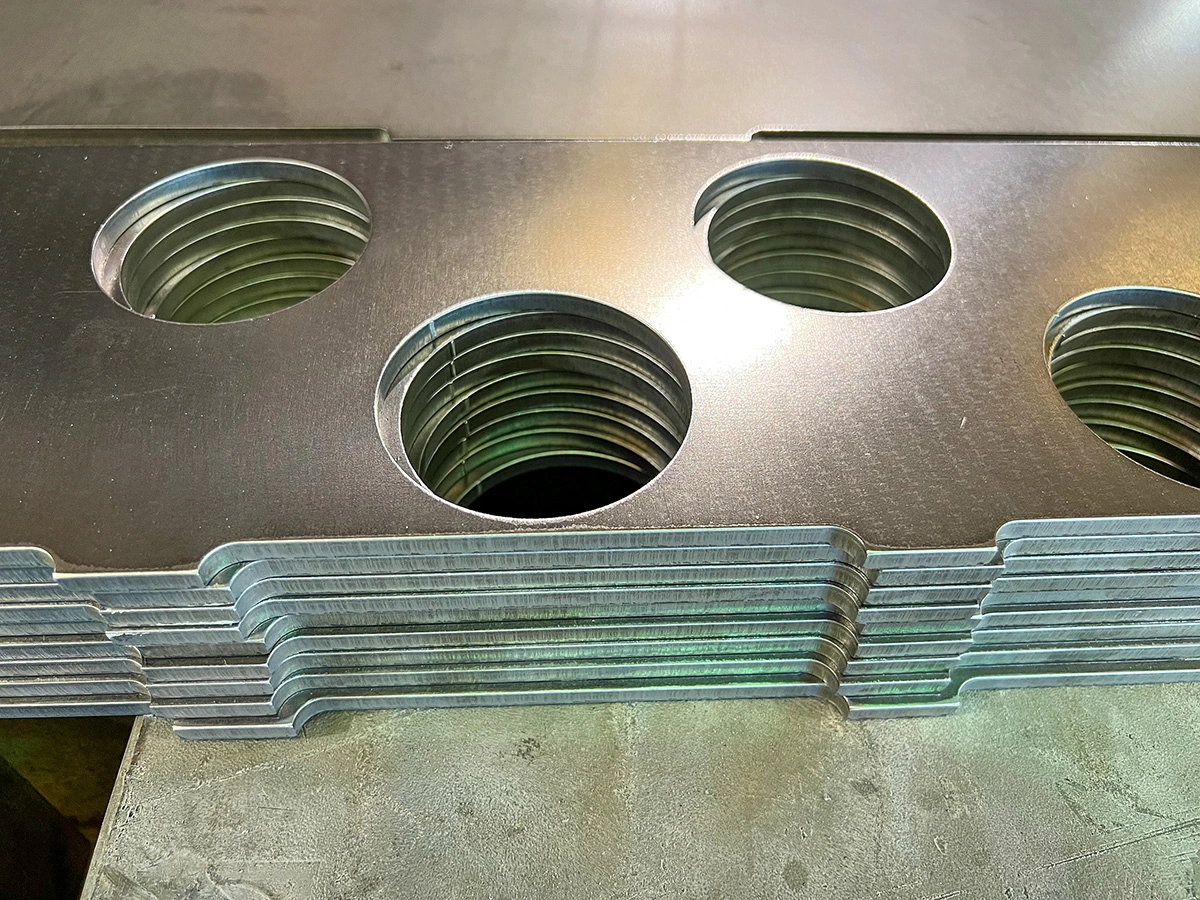

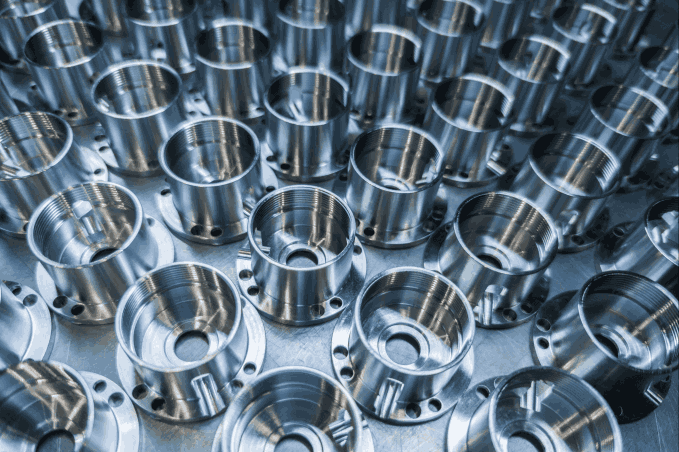

With prototype approval, Wuxi Lead initiates mass production under a fully controlled manufacturing environment. Our CNC machining centers operate with automated tool calibration and in-process probing to maintain dimensional stability across batches. Each stage—from blanking and forming to drilling, threading, and surface finishing—is monitored in real time using statistical process control (SPC) methodologies. Every stainless steel pla undergoes 100% visual inspection and batch sampling for hardness testing and salt spray resistance (per ASTM B117). Final products are cleaned, passivated, and packaged in anti-corrosive materials to preserve integrity during transit.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Grades | SS304, SS316, SS316L |

| Dimensional Tolerance | ±0.005 mm (standard), ±0.002 mm (precision) |

| Surface Roughness (Ra) | 0.8 µm (standard), 0.4 µm (polished finish) |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days after prototype approval |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical-grade options) |

| Testing Protocols | CMM, SPC, Salt Spray, Hardness, Visual AOI |

Our integrated process—anchored in precision design, validated prototyping, and tightly controlled mass production—ensures every stainless steel pla meets the highest standards of performance, reliability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Stainless Steel Plate Excellence

At Wuxi Lead Precision Machinery, we transform stainless steel plate specifications into mission-critical components with zero tolerance for deviation. As a Tier-1 supplier to aerospace, energy, and medical OEMs, our 15-year expertise in precision plate fabrication ensures your projects meet the most stringent global standards. Our vertically integrated facility in Wuxi houses 42 advanced CNC machining centers, including 5-axis DMG MORI systems and automated grinding lines, dedicated exclusively to stainless steel plate processing. We eliminate supply chain vulnerabilities by controlling every phase—from raw material certification to final inspection—within our ISO 9001:2015 and AS9100D-certified campus. When your application demands micron-level flatness or corrosion-resistant integrity in 304, 316L, or duplex alloys, our processes deliver repeatability where others compromise.

Our technical capabilities are engineered for complex plate geometries that standard vendors cannot sustain. The table below details our certified production parameters for stainless steel plate machining:

| Specification | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Thickness | 0.5 mm – 150 mm | ASTM A240/A480 |

| Dimensional Tolerance | ±0.005 mm (critical features) | ISO 2768-mK / GD&T |

| Surface Flatness | ≤ 0.02 mm per 300 mm² | ISO 1101 |

| Surface Finish | Ra 0.1 µm (mirror) to Ra 3.2 µm | ASTM A967 (passivation) |

| Max Work Envelope | 3000 x 1500 x 800 mm | Custom fixturing available |

| Material Traceability | Full MTR with PMI verification | EN 10204 3.1 |

This precision is non-negotiable in applications where plate integrity determines system longevity. Our engineering team collaborates at the RFQ stage to optimize your design for manufacturability—reducing scrap rates by 22% on average through strategic grain orientation analysis and stress-relief sequencing. We deploy Zeiss CONTURA CMMs and laser trackers for in-process validation, ensuring 100% of your plates achieve first-article approval on the first run. Unlike commodity suppliers, we treat every order as a proprietary partnership: your thermal treatment profiles and edge-conditioning requirements are embedded into our CAM workflows, not appended as afterthoughts.

Choosing Wuxi Lead Precision means securing a partner invested in your operational continuity. Our lean manufacturing cells maintain 98.7% on-time delivery for plate orders, with dedicated project managers providing real-time production visibility via encrypted client portals. We absorb the risk of material volatility through long-term contracts with Baosteel and POSCO, guaranteeing price stability for multi-year programs. When your project timeline demands acceleration without quality trade-offs, our 24/7 high-mix production lines deliver certified components in 15 days—40% faster than industry benchmarks.

Initiate your precision plate project with engineering rigor that matches your specifications. Contact our technical sales team at Contact [email protected] with your drawings and volume requirements. Our CNC engineers will respond within 4 business hours with a feasibility assessment and optimized cost analysis—no generic quotes, only actionable engineering pathways. For stainless steel plates that perform under extreme conditions, trust the partner certified by Siemens and GE Healthcare for zero-defect delivery. Wuxi Lead Precision Machinery: Where plate geometry meets absolute certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.