Technical Contents

Engineering Guide: 3Dprint Service

Engineering Insight Precision in Metal Additive Manufacturing

Precision defines the viability of metal 3D printing for mission-critical applications. In high-end custom manufacturing, dimensional accuracy and repeatability are not optional specifications—they are fundamental requirements determining component functionality, assembly integrity, and ultimate product performance. Standardized tolerances common in prototyping-grade systems are wholly inadequate for aerospace actuators, medical implants, or defense subsystems where micron-level deviations compromise safety and efficiency. True industrial metal additive manufacturing demands rigorous process control, advanced metrology integration, and deep metallurgical expertise to consistently achieve the tight tolerances required by demanding sectors. At Wuxi Lead Precision Machinery, we engineer this precision into every build, transforming complex digital designs into certified, mission-ready metal components.

Our commitment to uncompromising accuracy is validated through direct experience delivering components for projects where failure is not an option. We have successfully manufactured precision titanium assemblies for Olympic Games infrastructure systems requiring flawless integration under extreme environmental loads. Furthermore, our facility adheres to stringent military-grade quality protocols, producing critical subsystems where dimensional stability across thermal cycles and mechanical stress is non-negotiable. This heritage—forged in applications demanding absolute reliability—shapes our entire approach to metal additive services. We understand that precision extends beyond the printer; it encompasses powder characterization, parameter optimization, in-process monitoring, and post-build validation using coordinate measuring machines traceable to national standards.

The technical foundation for achieving this level of precision is reflected in our core system capabilities and process controls. Below are the key specifications governing our industrial metal 3D printing service for demanding applications.

| Specification | Capability | Relevance to Precision |

|---|---|---|

| Layer Thickness | 20 – 50 μm | Enables fine feature resolution and smooth surface finish |

| Build Volume | 250 x 250 x 350 mm | Supports complex, integrated parts while maintaining thermal stability |

| Material Systems | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg | Aerospace/medical grade alloys with certified chemistry |

| Positional Accuracy | ± 0.05 mm | Critical for mating surfaces and assembly interfaces |

| Surface Roughness (As-Built) | Ra 8 – 12 μm | Provides consistent baseline for precision finishing |

Achieving true engineering-grade results requires moving beyond basic machine operation. It necessitates integrating additive expertise with traditional precision machining knowledge—understanding how build orientation affects residual stress, how support structures influence final geometry, and how thermal post-processing optimizes material properties. Wuxi Lead Precision Machinery operates at this convergence point. Our engineers collaborate with clients from design for additive manufacturing (DfAM) through final inspection, ensuring the printed component meets not just dimensional drawings, but the functional demands of its operational environment. When your application demands metal parts built to exacting standards, precision must be engineered in from the first layer. We deliver exactly that.

Precision Specs & Tolerances

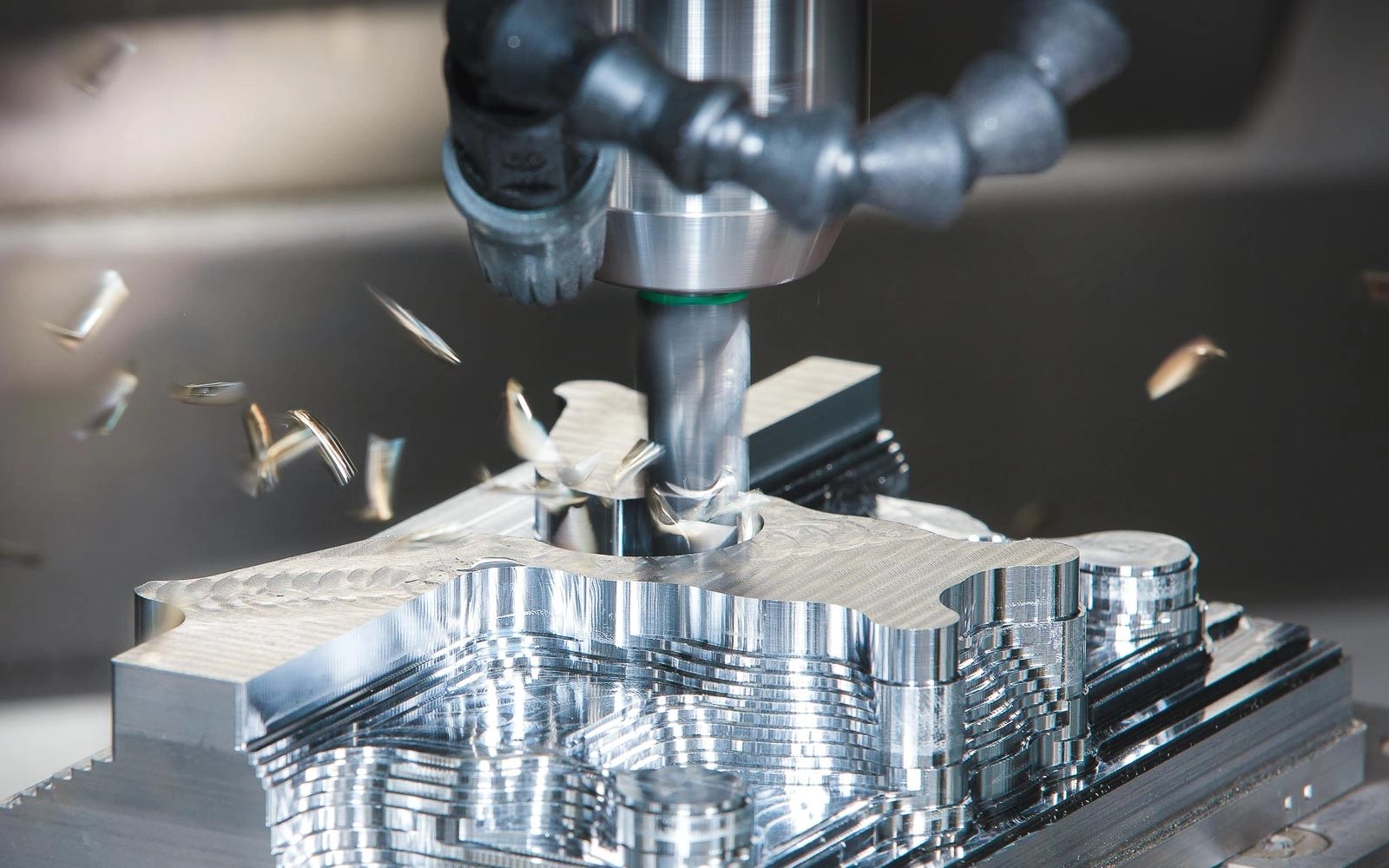

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance industries including aerospace, medical, energy, and precision automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. Our multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while maintaining tight tolerances across intricate features. This capability is essential for components requiring undercuts, deep cavities, or organic contours that cannot be achieved through conventional 3-axis methods.

All machining operations are supported by high-rigidity machine beds, thermal compensation systems, and real-time tool monitoring to ensure process stability. We work with a wide range of engineering-grade metals, including titanium alloys, Inconel, stainless steel, aluminum alloys, and tool steels, tailored to meet specific performance requirements such as corrosion resistance, high-temperature stability, or mechanical strength. Our programming team utilizes advanced CAM software to optimize toolpaths, minimize cycle times, and ensure consistent material removal rates, resulting in superior part integrity and dimensional repeatability.

Quality assurance is embedded throughout the manufacturing process. Every critical dimension is verified using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), providing non-contact and tactile measurement with micron-level precision. Our CMM inspection routines are fully programmable and repeatable, aligned with ISO 10360 standards, and integrated into first-article inspection (FAI) and batch validation protocols. In addition to CMM, we employ surface roughness testers, optical comparators, and hardness testing equipment to validate material and finish specifications.

All inspection data is documented and traceable, supporting full compliance with AS9100, ISO 9001, and customer-specific quality requirements. Our quality engineers work in parallel with production teams to implement corrective actions and continuous improvement measures, ensuring zero-defect delivery across both prototype and high-volume production runs.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled conditions.

| Feature | Standard Tolerance | Typical Surface Finish (Ra) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | 0.8 µm | Up to 300 mm |

| Hole Diameter | +0.010 / -0.000 mm | 0.8 µm | Reamed or honed |

| Counterbore/Spotface | ±0.025 mm | 3.2 µm | Machined surfaces |

| Angular Features | ±0.05° | 1.6 µm | 5-axis simultaneous |

| Positional Tolerance | ±0.01 mm | 1.6 µm | GD&T compliant |

| Surface Profile | ±0.02 mm | 0.8 µm | Freeform contours |

These specifications reflect our commitment to precision engineering and process control. Wuxi Lead Precision Machinery ensures that every component meets the highest standards of accuracy, reliability, and performance in mission-critical applications.

Material & Finish Options

Material Selection Fundamentals for Precision Metal Additive Manufacturing

Selecting the optimal material is paramount for achieving functional performance, longevity, and cost-efficiency in custom metal 3D printed components. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your specific application demands, environmental exposure, and post-processing requirements. Aluminum, steel, and titanium alloys represent the core high-performance materials for industrial additive manufacturing, each offering distinct advantages.

Aluminum Alloys (e.g., AlSi10Mg, 6061-T6 equivalent)

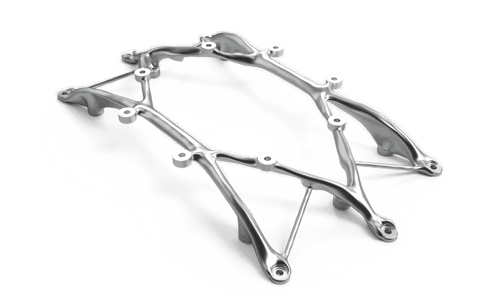

Aluminum dominates applications requiring an exceptional strength-to-weight ratio and inherent thermal conductivity. Its low density significantly reduces component mass, critical for aerospace, drone, and automotive lightweighting initiatives. Excellent machinability post-print allows for achieving tight tolerances on critical features. Aluminum also provides good corrosion resistance in many environments and serves as the primary substrate for anodizing finishes, enhancing surface durability and aesthetics. It is the preferred choice for complex heat exchangers, lightweight structural brackets, and fluid system components.

Stainless Steel Alloys (e.g., 316L, 17-4 PH)

Stainless steels deliver superior strength, hardness, and exceptional resistance to corrosion and high temperatures. 316L offers outstanding marine and chemical environment compatibility due to its molybdenum content, making it ideal for fluid handling, medical implants, and marine hardware. 17-4 PH provides high strength achievable through precipitation hardening, suitable for demanding applications like aerospace fittings, valve components, and tooling. These alloys maintain integrity under significant mechanical stress and harsh conditions where aluminum might falter.

Titanium Alloys (e.g., Ti-6Al-4V)

Titanium represents the pinnacle for strength-to-weight ratio combined with extraordinary corrosion resistance and biocompatibility. Its high strength rivals many steels while weighing nearly half as much. Ti-6Al-4V is the industry standard, extensively used in aerospace structural parts, critical medical implants, and high-performance motorsport components exposed to extreme environments. While material costs are higher, titanium’s performance in weight-sensitive, high-stress, or biocompatible applications justifies its selection. It is generally not anodized in the same manner as aluminum; surface treatments focus on achieving optimal biocompatibility or wear resistance.

Anodizing: The Essential Aluminum Finish

Anodizing is a critical electrochemical post-processing step exclusively for aluminum components. This process thickens the natural oxide layer, significantly enhancing surface hardness, wear resistance, and corrosion protection. It creates a porous structure that readily accepts dyes, enabling color coding or aesthetic customization without compromising material integrity. Type II (sulfuric acid) anodizing is standard for most industrial applications, while Type III (hardcoat) provides maximum abrasion resistance for high-wear parts. Anodizing is non-conductive and integral to the substrate, unlike paint or plating.

Material performance specifications guide critical design decisions. Key properties are summarized below:

| Material | Typical Yield Strength (MPa) | Typical Tensile Strength (MPa) | Density (g/cm³) | Primary Industrial Applications |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 200 – 250 | 300 – 350 | 2.67 | Lightweight structures, heat sinks, enclosures |

| Stainless 316L | 300 – 400 | 550 – 650 | 7.99 | Marine hardware, medical devices, chemical processing |

| Titanium Ti-6Al-4V | 880 – 950 | 900 – 950 | 4.43 | Aerospace components, medical implants, racing parts |

Wuxi Lead Precision Machinery leverages deep metallurgical expertise to match your project’s functional requirements with the optimal metal alloy and surface treatment. Our precision manufacturing capabilities ensure your 3D printed components meet the highest standards of performance and reliability from material inception through final finishing. Consult our engineering team to determine the precise solution for your application.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process is engineered for precision, scalability, and zero-defect delivery. We integrate advanced 3D printing technology with decades of CNC machining expertise to deliver high-performance metal components tailored to exact client specifications. Our end-to-end workflow ensures seamless transition from concept to mass production, maintaining consistency and quality at every stage.

The process begins with collaborative design engineering. Our team works closely with clients to analyze part functionality, material requirements, and production volume. Using high-precision CAD and simulation tools, we optimize geometries for additive manufacturability, ensuring structural integrity while minimizing weight and material waste. Design for manufacturability (DFM) reviews are conducted to preempt potential issues, reducing lead time and eliminating rework.

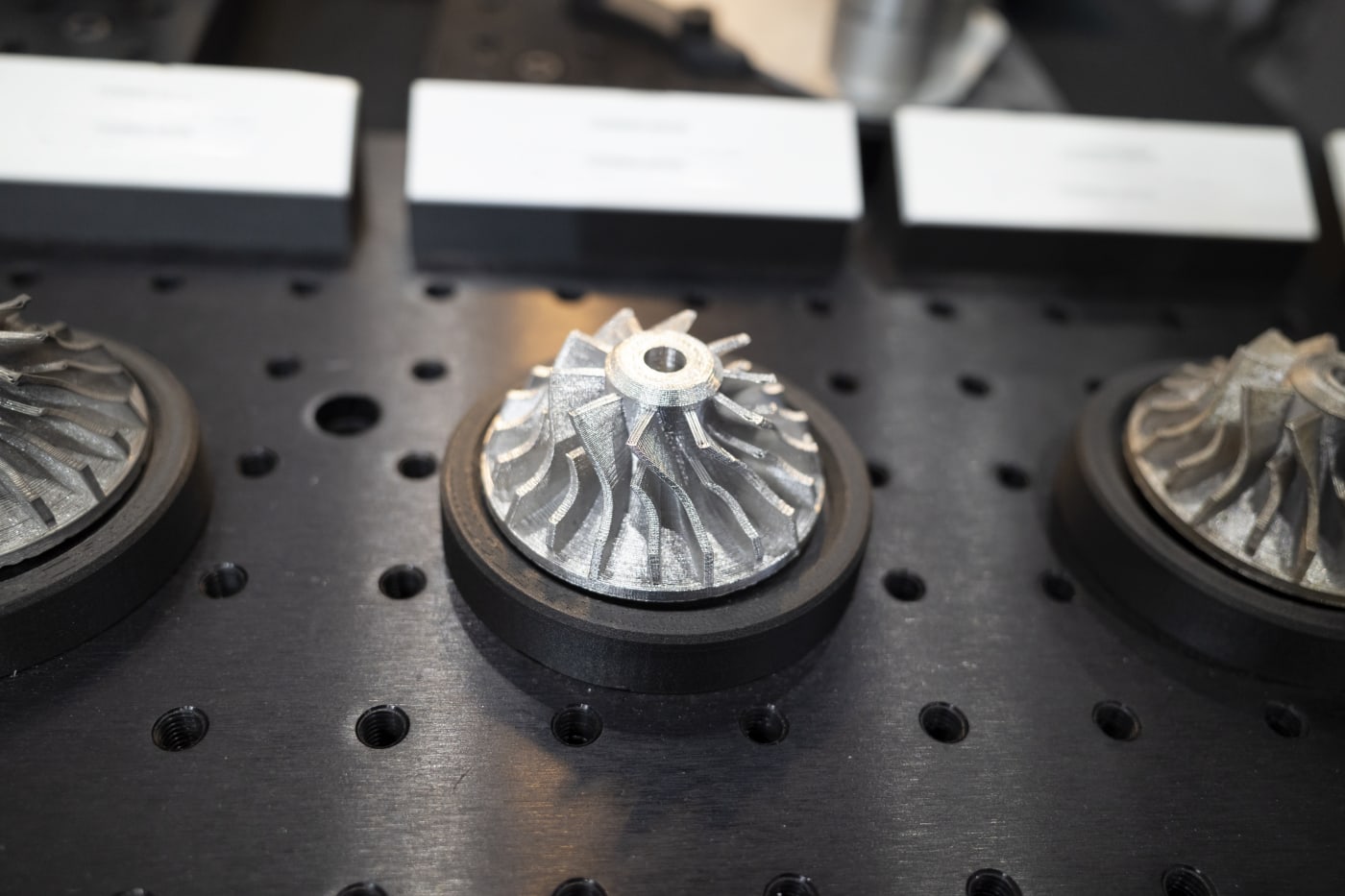

Once the design is finalized, we proceed to prototyping using state-of-the-art metal 3D printing systems. This stage allows rapid physical validation of form, fit, and function. Prototypes are produced in the same high-grade alloys intended for final production—such as titanium, Inconel, stainless steel, and aluminum—ensuring accurate performance testing under real-world conditions. Each prototype undergoes rigorous metrology inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.02 mm.

Upon client approval, we transition to mass production with full process validation. Our production floor integrates industrial-grade metal additive systems with secondary CNC machining, heat treatment, and surface finishing capabilities. Every production run follows standardized work instructions and real-time process monitoring to maintain repeatability. In-process inspections are embedded at critical control points, ensuring deviations are detected and corrected immediately.

Quality is non-negotiable. Our zero-defect philosophy is enforced through a comprehensive quality management system compliant with ISO 9001:2015 standards. Each component undergoes final inspection for dimensional accuracy, material properties, and surface quality. Full traceability is maintained through batch records, material certifications, and digital process logs.

The table below outlines key capabilities and specifications across our production workflow.

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Lead Time | 3–5 business days | 5–7 business days | 10–20 days (volume-based) |

| Tolerance | ±0.05 mm (design intent) | ±0.02 mm | ±0.02 mm (consistent) |

| Materials Available | Titanium, Inconel, SS316L, AlSi10Mg, Tool Steel | Same as production | Full industrial alloy range |

| Equipment Used | CAD, FEA, CFD software | SLM, DMLS, EBM systems | SLM + CNC + CMM + CMM |

| Quality Control | DFM analysis | First-article inspection | SPC, batch traceability |

| Scalability | N/A | 1–50 units | 50–10,000+ units |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures every component meets the highest standards of performance and reliability. Our integrated approach eliminates gaps between development and production, enabling faster time-to-market without compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Manufacturing Excellence

The rapid evolution of 3D printing has transformed prototyping and low-volume production, yet achieving end-use metal parts demands more than additive capabilities alone. Critical post-processing—precision machining, surface finishing, and rigorous quality validation—remains the decisive factor in part performance, durability, and compliance. Wuxi Lead Precision Machinery bridges this gap, delivering the engineering rigor and manufacturing fidelity required to transform 3D-printed metal components into certified, production-ready assets. We specialize in elevating additive outputs to meet aerospace, medical, and industrial standards where tolerances are non-negotiable and failure is not an option.

Our integrated approach combines advanced CNC machining with deep metallurgical expertise to address the inherent challenges of metal 3D printing: residual stress, surface roughness, and dimensional instability. We deploy multi-axis milling, grinding, and honing to achieve micron-level tolerances and critical geometries that additive processes alone cannot sustain. Every component undergoes stringent metrology using Zeiss CMMs and optical comparators, ensuring conformance to ISO 2768-mK or customer-specific GD&T callouts. This commitment to precision is validated through our ISO 9001:2015 certification and adherence to Western engineering protocols, eliminating the quality ambiguities often associated with offshore manufacturing.

Partnering with Lead Precision means accessing a seamless extension of your engineering team. We collaborate from the design phase to optimize part geometry for hybrid manufacturing—maximizing additive efficiency while ensuring machinability. Our facility in Wuxi houses 45+ CNC centers, including 5-axis milling, Swiss turning, and wire EDM, enabling rapid scaling from prototype to batch production without compromising repeatability. Below are core capabilities critical for high-integrity metal 3D print finishing:

| Capability | Specification Detail | Application Impact |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm tolerance | Critical sealing surfaces, bearing fits |

| Surface Finish | Ra 0.2 µm achievable via precision grinding | Fatigue resistance, fluid dynamics |

| Material Expertise | Inconel 718, Ti-6Al-4V, 17-4PH, Maraging Steel | Aerospace, medical implant compliance |

| Metrology Validation | Full first-article inspection reports (FAIR) | Regulatory audit readiness |

| Lead Time | 10–15 days for complex post-processing runs | Accelerated time-to-market |

We understand that your reputation hinges on component reliability. Our engineers proactively identify potential failure points in as-printed parts—such as internal porosity or heat-affected zones—and implement corrective machining strategies to exceed your performance benchmarks. This technical partnership reduces your risk, minimizes scrap rates, and ensures every part meets the operational demands of extreme environments.

Do not let post-processing limitations constrain your additive innovation. Contact our engineering team to discuss how Lead Precision’s manufacturing precision can transform your 3D-printed metal components into certified, high-performance solutions. Submit your RFQ or technical inquiry to [email protected]. Include material specifications, target tolerances, and application requirements for a tailored capability assessment within 24 business hours. Let us prove why global leaders trust us to deliver metal parts where precision is the only acceptable standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.