Technical Contents

Engineering Guide: Powder Coated Steel Texture

Engineering Insight: Powder Coated Steel Texture

In high-performance industrial applications, the surface finish of steel components is not merely aesthetic—it is a critical engineering parameter. Powder coated steel texture plays a pivotal role in determining durability, corrosion resistance, friction characteristics, and long-term performance under stress. At Wuxi Lead Precision Machinery, we recognize that achieving optimal texture is inseparable from precision manufacturing. Our decades of experience in custom metal fabrication, including projects for Olympic-grade sports infrastructure and defense-grade equipment, have reinforced the principle that surface integrity begins with exacting dimensional control and process consistency.

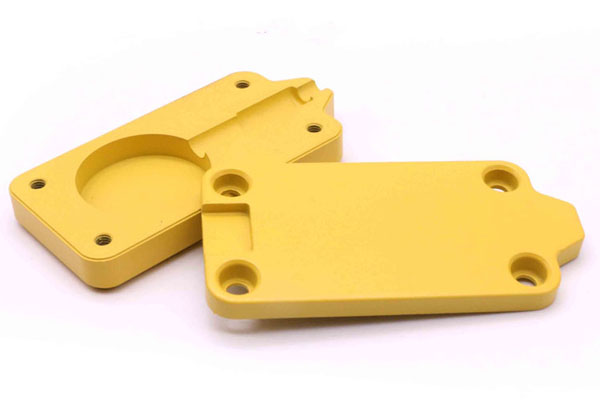

Powder coating is more than a protective layer; it is a functional enhancement. The texture of the coating—whether smooth, matte, wrinkled, or structured—must align precisely with the component’s operational environment. For instance, military-grade enclosures require textured finishes that resist abrasion and conceal minor surface imperfections, while architectural components used in Olympic venues demand uniformity and visual consistency under high-definition scrutiny. Achieving these outcomes requires not only advanced coating technology but also a foundation of precision-machined substrates. Any deviation in flatness, edge definition, or surface profile will be amplified by the coating process, leading to inconsistencies in texture and performance.

Our engineering approach integrates CNC machining tolerances with coating specifications to ensure substrate readiness. Steel parts are machined to within ±0.02 mm flatness and subjected to multi-stage surface preparation, including abrasive blasting tailored to the desired anchor profile. This ensures optimal adhesion and a uniform base for powder application. We then apply electrostatic powder coating using robotic systems calibrated for film thickness control, followed by curing in computer-monitored ovens to prevent thermal distortion.

Wuxi Lead Precision Machinery’s involvement in mission-critical projects has instilled a culture of zero-defect manufacturing. For example, components we supplied for Olympic stadium seating structures required powder coated finishes that maintained colorfastness and texture integrity over 20+ years of exposure. Similarly, military communication housings demanded EMI shielding compatibility beneath textured coatings—achieved only through precise substrate geometry and coating formulation alignment.

The following specifications reflect our standard capabilities in powder coated steel texture production:

| Parameter | Specification |

|---|---|

| Substrate Material | Cold-rolled steel, ASTM A36 / Q235 |

| Machining Tolerance | ±0.02 mm |

| Surface Roughness (Pre-Coat) | Ra 3.2–6.3 µm (adjustable) |

| Powder Coating Thickness | 60–120 µm (customizable) |

| Texture Types | Smooth, Sand, Hammered, Wrinkle, Orange Peel |

| Adhesion Rating | Class 0–1 (ASTM D3359) |

| Curing Temperature | 180–200°C (time-dependent) |

| Standard Compliance | ISO 9001, RoHS, GB/T 1766 |

Precision in texture is not an afterthought—it is engineered from the first cut. At Wuxi Lead Precision Machinery, we combine military-grade standards with industrial innovation to deliver powder coated steel components that perform as flawlessly as they appear.

Precision Specs & Tolerances

Technical Capabilities: Precision Machining for Powder Coated Steel Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for complex powder coated steel components, where dimensional accuracy and surface integrity are paramount to final finish quality and part functionality. Our integrated manufacturing ecosystem, centered on advanced 5-axis CNC machining and rigorous metrology, ensures every component meets the exacting demands of high-performance industrial applications. We understand that imperfections introduced during machining directly manifest as defects in the powder coated texture, compromising both aesthetics and corrosion resistance. Our process eliminates these risks at the source.

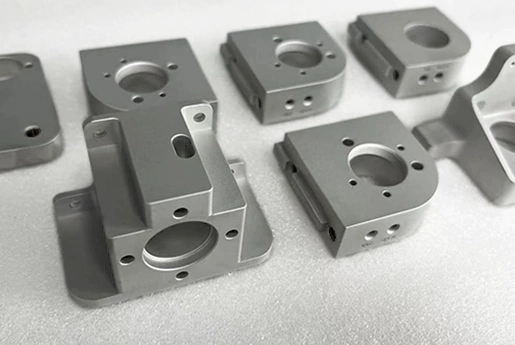

Our DMG MORI and MAZAK 5-axis CNC machining centers provide the foundation for geometric complexity and micron-level accuracy. Simultaneous 5-axis movement allows complete machining of intricate features—deep pockets, compound angles, and contoured surfaces—in a single setup. This eliminates cumulative errors from multiple fixtures, ensuring critical datums remain perfectly aligned. For powder coated steel parts, this capability is essential; it guarantees consistent wall thickness, precise hole locations for assembly, and smooth transition surfaces that prevent coating pooling or thin spots. Advanced high-speed spindles and adaptive toolpath strategies achieve superior surface finishes directly off the machine, minimizing secondary operations that could introduce contamination or damage the base material prior to coating.

Surface preparation is critical for optimal powder adhesion and texture uniformity. Our machining protocols strictly control surface roughness (Ra) to the optimal range for powder coating adhesion, typically between 0.8 µm and 3.2 µm Ra, depending on the specific coating system and desired texture. We meticulously avoid tool marks, chatter, or burrs that would telegraph through the coating, creating visible imperfections or weak points. All parts undergo thorough non-abrasive cleaning and degreasing immediately post-machining to remove all contaminants, ensuring a pristine substrate for the powder coating line.

Quality verification is non-negotiable. Every critical dimension and geometric feature undergoes 100% inspection using our Zeiss and Hexagon Coordinate Measuring Machines (CMMs). These systems provide traceable, NIST-calibrated verification of complex profiles, true positions, flatness, and profile tolerances far beyond the capability of manual methods. Inspection reports detail actual measurements against print requirements, providing complete data transparency. This rigorous QC process occurs before parts proceed to powder coating, guaranteeing only dimensionally perfect substrates receive the finish, eliminating costly rework or scrap after coating.

The following table details our standard achievable tolerances for machined steel components destined for powder coating, reflecting our commitment to precision that supports superior final finish quality:

| Tolerance Type | Standard Capability | Tight Capability (Additional Cost) |

|---|---|---|

| Dimensional (Linear) | ±0.025 mm | ±0.010 mm |

| Geometric (Flatness) | 0.05 mm | 0.02 mm |

| Geometric (True Position) | Ø0.05 mm | Ø0.02 mm |

| Surface Roughness (Ra) | 1.6 µm – 3.2 µm | 0.8 µm – 1.6 µm |

| Hole Diameter (Drilled) | +0.03 / -0.00 mm | +0.015 / -0.00 mm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to produce steel substrates where dimensional perfection and surface readiness are inherent. This precision engineering ensures your powder coated parts achieve flawless texture, maximum durability, and seamless integration into demanding assemblies. Partner with us for components where the foundation for a perfect finish is built into every micron.

Material & Finish Options

Material Selection for High-Performance Powder Coated Steel and Alternative Alloys

In precision manufacturing, selecting the appropriate base material is critical to achieving optimal performance, durability, and aesthetic quality—especially when applying advanced surface treatments such as powder coating. At Wuxi Lead Precision Machinery, we specialize in custom metal fabrication using high-grade materials including steel, aluminum, and titanium, each offering distinct advantages depending on application requirements. When paired with powder coating, these materials deliver enhanced corrosion resistance, mechanical strength, and visual consistency for industrial and commercial use.

Powder coated steel remains a preferred choice for structural and heavy-duty applications due to its high tensile strength, cost efficiency, and excellent adhesion properties with thermoset polymer coatings. Cold-rolled steel (CRS) is particularly suitable for powder coating, providing a smooth, uniform surface that ensures consistent finish quality. The powder coating process involves electrostatic application of dry polymer powder, followed by curing under heat to form a durable, abrasion-resistant layer. This finish not only improves corrosion resistance but also allows for a wide range of colors and textures, including matte, gloss, and textured patterns that simulate wood, stone, or brushed metal.

Aluminum offers a lightweight alternative with inherent corrosion resistance due to its natural oxide layer. While aluminum is commonly associated with anodizing—a process that electrochemically thickens the oxide layer for enhanced protection—it can also be effectively powder coated when additional color versatility or impact resistance is required. Anodized aluminum provides exceptional wear resistance and dimensional stability, making it ideal for aerospace, electronics, and architectural components. However, when aesthetic customization and UV resistance are priorities, powder coating aluminum delivers superior color retention and design flexibility.

Titanium, though less common due to cost, is selected for extreme environments involving high temperatures, aggressive chemicals, or critical load-bearing functions. While titanium is typically left in its natural state or treated with specialized passivation, it can be powder coated in niche applications where electrical insulation or visual identification is required. Surface preparation is paramount with titanium to ensure coating adhesion, often involving grit blasting and chemical priming.

Each material must undergo rigorous pre-treatment—including degreasing, phosphating (for steel), chromate conversion (for aluminum), or abrasive cleaning—to ensure maximum coating adhesion and long-term performance. Our facility in Wuxi employs automated pretreatment lines and climate-controlled spray booths to maintain ISO-level consistency across all coated components.

Below is a comparative overview of key material properties and finishing compatibility.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Powder Coating Suitability | Anodizing Suitability |

|---|---|---|---|---|---|

| Steel (CRS) | 7.85 | 300–500 | Moderate (coating-dependent) | Excellent | Not applicable |

| Aluminum 6061 | 2.70 | 310 | Good | Very Good | Excellent |

| Titanium Gr2 | 4.51 | 345 | Excellent | Good (with prep) | Limited (not standard) |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-house testing, prototyping, and compliance documentation to ensure every component meets international standards for performance and longevity.

Manufacturing Process & QC

Precision Powder Coated Steel Texture: Zero Defects Production Process

At Wuxi Lead Precision Machinery, powder coated steel texture manufacturing follows a rigorously controlled sequence ensuring absolute dimensional and aesthetic conformity. This process eliminates defects at origin through engineering discipline, not post-production correction.

Design Phase: Engineering Perfection Before Cutting Metal

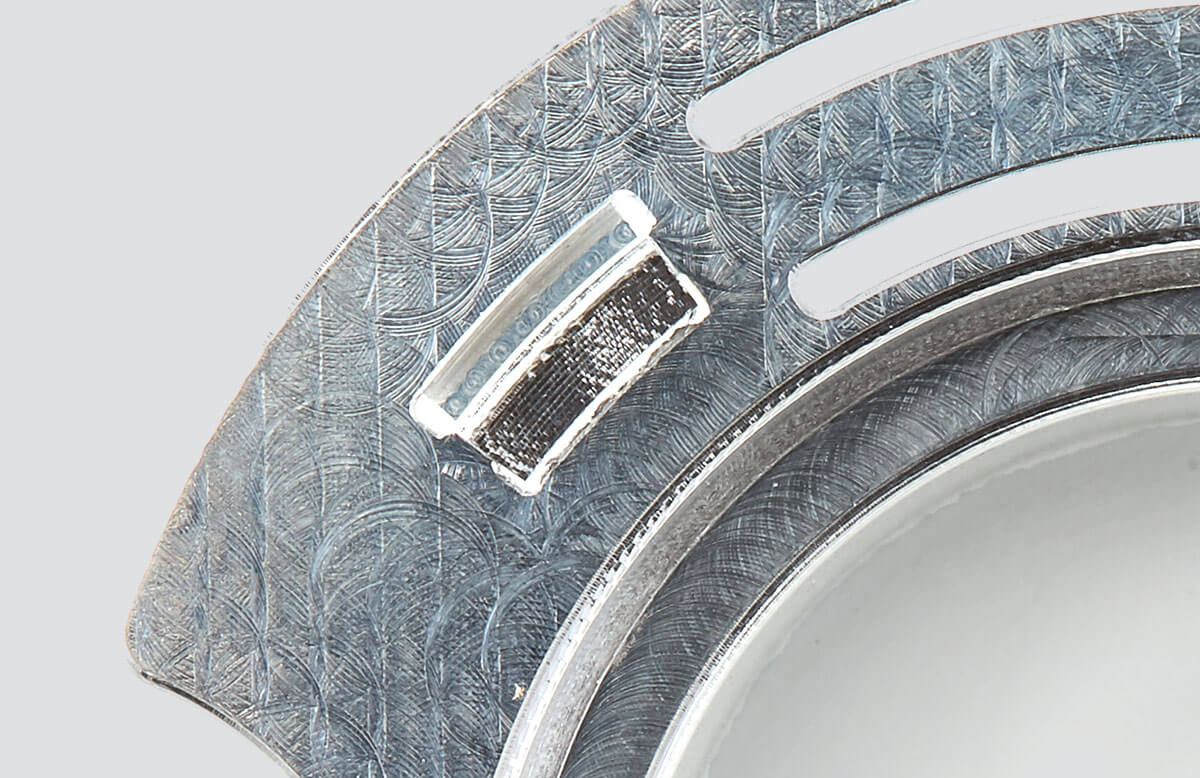

Our engineers commence with CAD/CAM validation against client specifications, simulating coating adhesion, thermal expansion, and texture consistency under real-world stress conditions. Material selection is traceable to certified mill test reports, with steel substrate flatness verified to ISO 2768-mK tolerances. Critical texture parameters—gloss level, surface profile (Ra), and edge coverage—are digitally modeled to prevent orange peel or cratering. Design sign-off requires dual verification: CNC programming alignment and coating chemistry compatibility analysis.

Prototyping: Validating the Process, Not Just the Part

Physical prototypes undergo accelerated life testing before mass production approval. We apply the exact powder formulation, voltage, and cure schedule planned for volume runs. Each prototype is measured for film thickness uniformity (±5μm), adhesion (ASTM D3359 5B rating), and color consistency (ΔE <0.5 under D65 lighting). Salt spray resistance (ASTM B117) and UV exposure tests validate durability. Client feedback triggers immediate process recalibration—not design compromise. Only when prototypes meet all specifications is the production workflow locked.

Mass Production: Sustained Zero Defects Execution

In full-scale manufacturing, statistical process control (SPC) monitors every variable. Steel substrates are cleaned via multi-stage phosphate treatment with real-time conductivity checks. Powder application uses robotic arms calibrated for ±0.1mm path accuracy, ensuring texture repeatability across 10,000+ units. Curing ovens maintain ±2°C temperature uniformity with dwell time sensors. Inline vision systems inspect for micro-contaminants, while automated gloss meters verify texture consistency at 120cm intervals. Every batch includes destructive testing: cross-hatch adhesion, film thickness mapping, and bend tests per ASTM D522. Non-conforming units trigger immediate line stoppage—never rework.

Critical Powder Coating Specifications

| Parameter | Specification | Testing Standard |

|---|---|---|

| Film Thickness | 60–90 μm (texture-dependent) | ASTM D7091 |

| Gloss Retention | >90% after 1000h QUV-B | ASTM D4587 |

| Adhesion | 5B (no coating removal) | ASTM D3359 |

| Salt Spray Resistance | 1000+ hours (no rust at scribe) | ASTM B117 |

| Surface Profile (Ra) | 1.0–3.5 μm (customizable) | ISO 4287 |

| Cure Schedule | 190–200°C for 12–15 minutes | Infrared pyrometry |

This closed-loop methodology—where design integrity, prototype validation, and production control intersect—ensures your powder coated steel components deliver flawless texture and performance. Wuxi Lead’s commitment to zero defects is engineered into every phase, not inspected in afterward. Partner with us for manufacturing where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Powder Coated Steel Textures

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom metal manufacturing solutions tailored to the exacting demands of global industries. Our mastery in powder coated steel texture fabrication sets us apart as a trusted partner for clients who require durability, precision, and aesthetic consistency in every component. Whether you’re developing architectural facades, industrial enclosures, or high-strength structural systems, our engineering team ensures your project benefits from advanced surface treatment, dimensional accuracy, and long-term corrosion resistance.

Powder coating is more than a finish—it is a critical performance layer. We utilize electrostatic application and thermal curing processes to bond premium-grade polymer powders to steel substrates, achieving uniform texture distribution and superior adhesion. Our facility supports a full spectrum of textures, from smooth matte and glossy finishes to structured, anti-slip, and wrinkle effects, all applied with micron-level control. Each batch undergoes rigorous quality validation, including salt spray testing, adhesion assessment, and color spectrophotometry, ensuring compliance with international standards such as ISO 9001 and ASTM D3359.

Our clients rely on us not only for technical excellence but also for seamless integration into complex supply chains. We offer end-to-end project management from initial design consultation to final delivery, supporting low-volume prototypes and high-volume production with equal agility. Our in-house CNC fabrication, laser cutting, bending, and welding capabilities allow us to maintain complete process control, minimizing lead times and maximizing repeatability. As a certified manufacturer in China’s advanced industrial corridor, we combine cost-efficiency with uncompromising quality—delivering parts that perform under extreme environmental and mechanical stress.

For global partners seeking a reliable, responsive, and technically advanced manufacturing ally, Wuxi Lead Precision Machinery is engineered to exceed expectations. We invite you to leverage our expertise in powder coated steel textures and discover how precision, consistency, and partnership drive real competitive advantage.

Contact us today to begin your next project. Our engineering team is ready to review your specifications, provide material recommendations, and deliver sample batches tailored to your application. For direct support, email us at [email protected]. Let Lead Precision be the foundation of your next innovation.

| Specification | Details |

|---|---|

| Material Compatibility | Mild steel, stainless steel, galvanized steel |

| Coating Types | Epoxy, polyester, hybrid, and polyurethane powders |

| Standard Textures | Smooth, hammered, wrinkled, sand, orange peel, anti-slip |

| Thickness Range | 60–120 μm (standard), customizable up to 150 μm |

| Color Options | Full RAL, Pantone, and custom color matching |

| Pre-Treatment | Iron phosphate or zinc phosphate with multi-stage rinse |

| Curing Process | Convection oven curing at 180–200°C for 10–15 minutes |

| Quality Testing | Adhesion (cross-hatch), salt spray (500–1000 hrs), impact resistance |

| Production Capacity | Up to 50,000 units per month, scalable for OEM programs |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.