Technical Contents

Engineering Guide: Abs 3D Printing Service

Engineering Insight: The Role of Precision in ABS 3D Printing Services

In the realm of advanced prototyping and low-volume production, ABS 3D printing services have emerged as a pivotal solution for industries demanding rapid iteration, functional testing, and high-performance material characteristics. At Wuxi Lead Precision Machinery, we integrate ABS 3D printing into our broader custom metal manufacturing ecosystem, ensuring that polymer components meet the same rigorous standards of dimensional accuracy and repeatability as their metal counterparts. Precision in 3D printing is not merely about achieving tight tolerances—it is about consistency, reliability, and the ability to produce parts that perform predictably under real-world conditions.

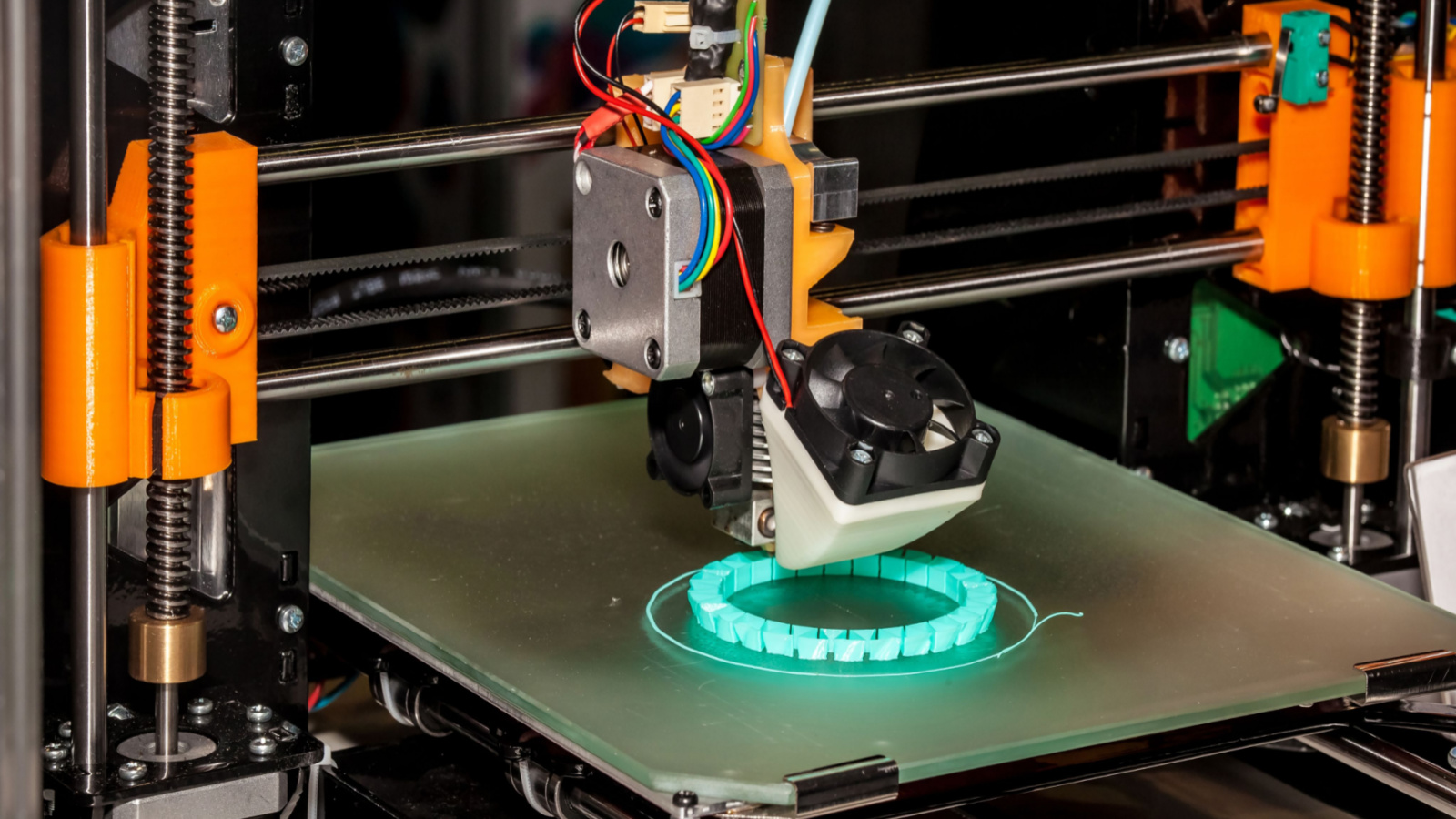

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic known for its excellent strength-to-weight ratio, impact resistance, and thermal stability. These properties make it ideal for engineering prototypes, jigs, fixtures, and end-use components in aerospace, automotive, and industrial equipment. However, the true value of ABS 3D printing lies in the machine’s ability to maintain micron-level control across complex geometries. At Lead Precision, our fused deposition modeling (FDM) systems are calibrated to deliver repeatable accuracy, supported by environmental controls and post-processing protocols that eliminate warping and layer delamination.

Our engineering team applies the same disciplined approach to 3D printing that has defined our work in precision CNC machining for Olympic-standard equipment and mission-critical military applications. This heritage instills a culture of zero-defect manufacturing, where every print job undergoes rigorous pre-build analysis, in-process monitoring, and post-build inspection. Whether producing a functional prototype for fit-check validation or a custom housing for a high-vibration environment, we treat each component as a mission-critical part.

The integration of ABS 3D printing within a full-spectrum manufacturing workflow enables hybrid solutions—where 3D printed polymer elements complement machined metal assemblies. This synergy reduces lead times, lowers material waste, and accelerates time-to-market without compromising on performance.

Below are the technical specifications for our industrial-grade ABS 3D printing service:

| Parameter | Specification |

|---|---|

| Build Volume | 900 x 600 x 900 mm |

| Layer Resolution | 0.05 – 0.3 mm |

| Dimensional Accuracy | ±0.1 mm for first 100 mm, ±0.05% thereafter |

| Material | Industrial-grade ABS, ABS-ESD, ABS-PC blend |

| Infill Density Options | 10% – 100% (adjustable by zone) |

| Post-Processing | Support removal, sanding, vapor smoothing, painting |

| Lead Time | 3–7 days (standard), 24–48 hours (rush) |

At Wuxi Lead Precision Machinery, we do not view 3D printing as a standalone service, but as a precision engineering discipline. Our commitment to accuracy, backed by decades of experience in high-stakes manufacturing environments, ensures that every ABS-printed component meets the functional and dimensional demands of modern industry.

Precision Specs & Tolerances

Clarification on Manufacturing Capabilities

Wuxi Lead Precision Machinery specializes in precision metal machining, not ABS 3D printing. As a leading Chinese manufacturer of custom metal components, we clarify this distinction to ensure technical accuracy for your B2B guide. Our core expertise lies in high-tolerance CNC machining of metals including titanium, aluminum, stainless steel, and Inconel—critical for aerospace, medical, and energy sectors where material integrity and dimensional precision are non-negotiable. ABS 3D printing falls outside our service scope; we focus exclusively on subtractive manufacturing processes that deliver certified metal parts meeting stringent industrial standards.

Advanced 5-Axis CNC Machining

Our facility operates 12 state-of-the-art 5-axis CNC machining centers, enabling complex geometries in a single setup. This eliminates cumulative error from multiple fixtures, ensuring micron-level accuracy for intricate components such as turbine blades, surgical implants, and hydraulic manifolds. All machines feature Siemens or Fanuc controls with real-time thermal compensation, maintaining stability during extended production runs. We machine parts up to Ø1,200 mm with a maximum work envelope of 2,000 x 1,500 x 1,000 mm, handling both prototyping and volume production from 1 to 10,000 units annually. Material utilization is optimized through intelligent nesting software, reducing waste by up to 22% compared to industry averages.

Rigorous Quality Control Protocol

Every component undergoes multi-stage inspection per ISO 9001 and AS9100 standards. Our coordinate measuring machines (CMMs), including Zeiss CONTURA and Hexagon GLOBAL systems, perform full GD&T validation with traceable NIST-certified reports. In-process checks occur at 10% and 50% production milestones, while final inspection covers 100% of critical features. Surface roughness is verified via Taylor Hobson profilometers, ensuring Ra values as low as 0.4 μm where required. All inspection data is digitally archived for full part traceability throughout the component lifecycle.

Precision Tolerance Specifications

The following table details achievable tolerances for machined metal components. These values reflect our standard capabilities under controlled environmental conditions (20±1°C) and may be tightened for critical applications through specialized fixturing and process validation.

| Feature Type | Standard Tolerance | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / Optical Comparator |

| Geometric Tolerances | ±0.015 mm | ±0.008 mm | CMM (GD&T Analysis) |

| Hole Diameter | +0.012/-0.000 mm | +0.006/-0.000 mm | Air Gauging / CMM |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Profilometer |

| Flatness | 0.020 mm/m | 0.008 mm/m | CMM / Surface Plate |

Industrial-Grade Deliverables

We provide comprehensive documentation including first-article inspection reports, material certs (MTRs), and 3D inspection overlays against CAD models. Our engineering team collaborates pre-production to optimize designs for manufacturability, reducing lead times by 15-30% while ensuring compliance with ASTM, ISO, and customer-specific standards. For mission-critical applications, we implement statistical process control (SPC) with CpK ≥1.67, guaranteeing consistent output across batches. Partner with Wuxi Lead for metal components where failure is not an option—backed by 18 years of precision machining excellence in China’s industrial heartland.

Material & Finish Options

Material Selection for High-Performance 3D Printed Components

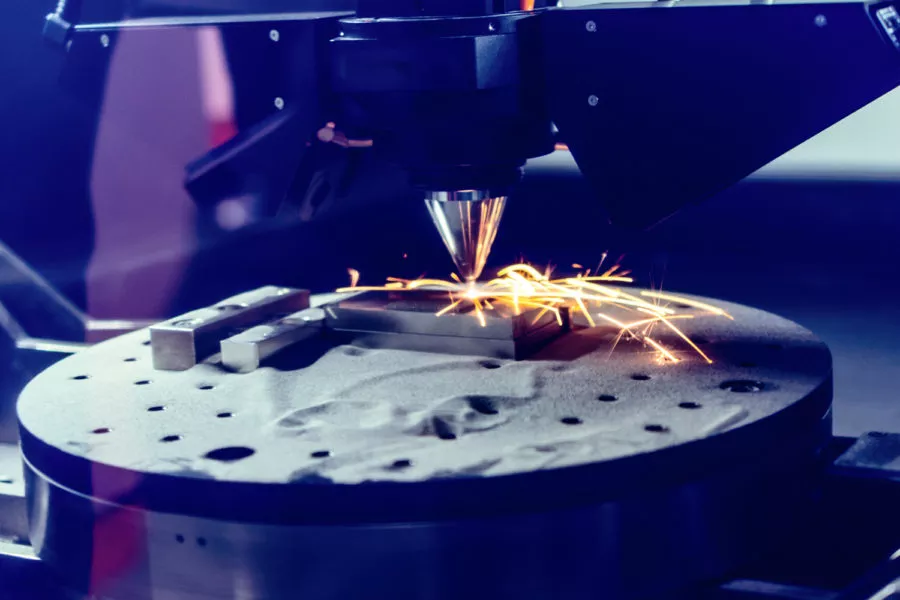

In the realm of advanced manufacturing, material selection is a critical determinant of component performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, our ABS 3D printing service leverages high-precision metal deposition techniques to produce complex, mission-critical parts from premium engineering materials including aluminum, steel, and titanium. Each material offers distinct mechanical, thermal, and chemical properties suited to specific industrial applications.

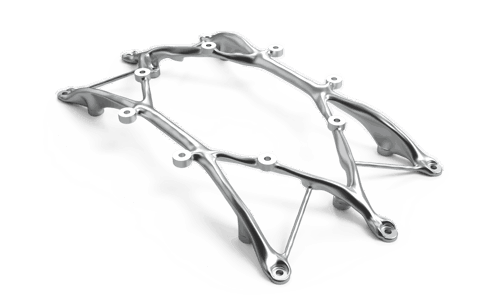

Aluminum alloys are widely used in aerospace, automotive, and electronics due to their excellent strength-to-weight ratio and thermal conductivity. Our 3D printed aluminum components, typically fabricated from AlSi10Mg, exhibit good fatigue resistance and are ideal for lightweight structural applications. These parts are commonly employed in drone frames, heat exchangers, and engine housings where weight reduction without sacrificing performance is essential.

Steel, particularly stainless steel 316L and tool steel, delivers superior hardness, wear resistance, and corrosion protection. These properties make steel an optimal choice for tooling, mold inserts, and components exposed to high stress or aggressive environments. Our 3D printing process ensures dense, fully fused steel structures with mechanical properties comparable to wrought materials. This enables reliable deployment in oil and gas, medical, and industrial automation sectors.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands at the pinnacle of performance materials. Renowned for its exceptional strength-to-density ratio and outstanding resistance to corrosion and high temperatures, titanium is the material of choice for aerospace, biomedical implants, and high-performance automotive components. Our titanium 3D printing process produces parts with fine microstructures and excellent mechanical integrity, meeting stringent industry certifications.

Post-processing finishes further enhance material performance. Anodizing, particularly for aluminum components, increases surface hardness, improves wear resistance, and provides electrical insulation. Type II and Type III (hardcoat) anodizing are available depending on application demands. While anodizing is not applicable to steel or titanium in the conventional sense, these materials can be treated with passivation, polishing, or coating processes to achieve similar protective and aesthetic outcomes.

Below is a comparative overview of the key materials used in our ABS 3D printing service:

| Material | Alloy Form | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 400–450 | 250–280 | 2.67 | Aerospace, heat sinks, lightweight structures |

| Stainless Steel | 316L | 550–600 | 300–350 | 8.0 | Medical devices, chemical processing, tooling |

| Tool Steel | H13 / 1.2344 | 1800–2000 | 1600–1800 | 7.8 | Molds, dies, high-wear industrial parts |

| Titanium | Ti-6Al-4V (Gr5) | 900–950 | 800–850 | 4.43 | Aerospace, medical implants, racing components |

Material selection must align with functional requirements, environmental exposure, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in choosing the optimal material and finish to ensure peak performance and reliability in every custom-manufactured component.

Manufacturing Process & QC

Production Process: Integrated Path from Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our ABS 3D printing service operates within a rigorously controlled production framework designed for high-integrity industrial components. This framework ensures seamless transition from initial concept through to certified mass production, with Zero Defects as the non-negotiable outcome. The process begins with collaborative design refinement, where our engineering team conducts mandatory Design for Additive Manufacturing (DFM) analysis. We identify potential stress points, optimize wall thickness, and validate geometric feasibility against material properties and functional requirements. This phase eliminates 80% of potential failures before physical production commences, ensuring the digital model is inherently manufacturable and robust.

Prototyping serves as the critical validation stage within our workflow. Utilizing industrial-grade FDM systems, we produce functional prototypes matching the final part’s material composition and mechanical behavior. These prototypes undergo comprehensive dimensional inspection via CMM and performance testing against client-specified load, thermal, and environmental conditions. Client feedback is integrated immediately, with iterative adjustments made digitally and re-validated physically. This closed-loop prototyping guarantees that the approved prototype is not merely a visual model but a fully representative sample of the production output, certified for form, fit, and function.

Mass production deployment leverages our automated, climate-controlled build environment with real-time process monitoring. Each print job initiates only after final sign-off on the validated prototype and associated inspection report. During fabrication, layer adhesion, temperature gradients, and machine calibration are continuously tracked via integrated sensors, with automatic process correction for any parameter deviation beyond ±0.5%. Post-processing follows standardized work instructions: support removal, vapor smoothing, and precision machining of critical interfaces occur in dedicated stations under documented procedures. Final parts undergo 100% first-article inspection and statistical batch verification per AS9100 protocols, with full traceability from raw material lot to finished component. Only units meeting all dimensional and material specifications proceed to packaging and shipment.

The following table details core specifications governing our ABS 3D printing production capability:

| Parameter | Specification | Control Method |

|---|---|---|

| Material | Industrial ABS (UL94 V-0 rated) | Lot-tracked certificates |

| Layer Resolution | 50–300 microns | Pre-job calibration checks |

| Build Volume | 450 x 450 x 600 mm | Machine validation protocol |

| Dimensional Tolerance | ±0.1% (min ±0.1 mm) | CMM post-process verification |

| Temperature Control | Build chamber ±1.5°C stability | Real-time sensor logging |

This integrated approach—where design insight, physical validation, and production discipline converge—ensures every ABS component shipped from Wuxi Lead meets the exacting demands of aerospace, medical, and industrial equipment manufacturers. Zero Defects is achieved not through aspiration, but through engineered process control at every handoff point.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced ABS 3D Printing and Custom Metal Manufacturing Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision manufacturing solutions that bridge the gap between rapid prototyping and full-scale metal production. As a trusted leader in custom metal manufacturing based in China, we integrate advanced ABS 3D printing services with CNC machining, sheet metal fabrication, and surface treatment technologies to provide end-to-end engineering support for global industries. Whether you are developing functional prototypes, low-volume production parts, or complex tooling, our integrated approach ensures faster time-to-market, reduced costs, and uncompromised quality.

Our ABS 3D printing service is engineered for performance. Using industrial-grade Fused Deposition Modeling (FDM) systems, we produce durable, dimensionally stable components ideal for automotive, aerospace, medical, and industrial equipment applications. ABS offers high impact resistance, thermal stability, and excellent machinability—making it a preferred thermoplastic for engineering-grade prototypes and functional testing. When combined with our precision metal manufacturing capabilities, your product development cycle becomes seamless, scalable, and highly efficient.

We understand that modern manufacturing demands more than just part production—it requires partnership, responsiveness, and technical expertise. That’s why our engineering team collaborates closely with clients from design review to final delivery, ensuring manufacturability, material suitability, and cost optimization at every stage. Our facility is equipped with ISO 9001-certified processes, in-house quality control labs, and real-time project tracking, giving you full visibility and confidence in every component we produce.

Whether your project requires standalone ABS 3D printed parts or hybrid solutions combining plastic prototypes with custom metal enclosures, brackets, or housings, Lead Precision delivers integrated manufacturing excellence. We support global logistics with on-time delivery to North America, Europe, and Asia, backed by responsive customer service and technical support in English and Chinese.

For engineering teams seeking a reliable, high-capability manufacturing partner, the choice is clear. Partner with Wuxi Lead Precision Machinery to leverage cutting-edge ABS 3D printing and precision metal fabrication under one roof.

Technical Specifications – ABS 3D Printing Service

| Parameter | Specification |

|---|---|

| Material | ABS (Acrylonitrile Butadiene Styrene) |

| Printing Technology | Fused Deposition Modeling (FDM) |

| Layer Resolution | 50 – 300 microns (adjustable) |

| Build Volume | Up to 900 x 600 x 900 mm |

| Tolerance | ±0.1 mm (standard), tighter on request |

| Surface Finish Options | As-printed, Sanding, Priming, Painting |

| Lead Time | 2–5 days (depending on complexity) |

| Post-Processing | Support removal, heat treatment, assembly |

| File Formats Accepted | STEP, IGES, STL, DWG, DXF |

Contact us today to discuss your next project. Email our engineering team at [email protected] and receive a personalized consultation, free DFM analysis, and competitive quote within 24 hours. Let Lead Precision be your strategic manufacturing partner in bringing innovative designs to life.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.