Technical Contents

Engineering Guide: Automotive Plastic Injection Molding

Engineering Insight: Precision as the Non-Negotiable Core of Automotive Plastic Injection Molding

In the demanding realm of automotive plastic injection molding, precision transcends mere quality control; it is the absolute foundation for safety, performance, and regulatory compliance. Automotive components—ranging from intricate interior sensors and fluid-handling connectors to critical under-hood brackets and lighting assemblies—operate under extreme thermal cycles, mechanical stress, and chemical exposure. Microscopic deviations in part geometry, wall thickness, or surface finish directly compromise structural integrity, sealing performance, and long-term durability. A tolerance error of mere microns can lead to catastrophic seal failure in fuel systems, misalignment in safety-critical sensor housings, or premature wear in transmission components. The automotive industry’s relentless pursuit of lightweighting and electrification further intensifies these demands, requiring thinner walls and more complex geometries where precision becomes exponentially harder to achieve consistently.

The ultimate precision of the molded plastic part is irrevocably dictated by the quality and accuracy of the metal mold tool itself. This is where advanced custom metal manufacturing expertise becomes paramount. Imperfections in mold cavity surface finish translate directly to part defects. Inconsistent cooling channel placement or dimensional inaccuracies within the mold steel cause warpage, sink marks, and internal stresses in the final component. Achieving the stringent tolerances demanded by Tier 1 suppliers and OEMs requires mold construction that operates at the absolute limits of metalworking capability—demanding sub-micron level CNC machining accuracy, exceptional thermal stability in tool steel selection and heat treatment, and metrology-grade verification at every stage.

Wuxi Lead Precision Machinery operates at this pinnacle of precision metal manufacturing, specifically engineered for the uncompromising standards of automotive injection molding tooling. Our core competency lies in transforming high-grade tool steels and alloys into molds where every micron matters. This capability is rigorously proven through mission-critical applications far beyond standard automotive requirements. We have consistently delivered molds and precision components meeting the extreme reliability and dimensional stability demands of Olympic-grade sporting equipment and sensitive military hardware, where failure is not an option. This heritage directly translates to automotive molding: our processes ensure cavity and core blocks achieve near-perfect geometry, cooling systems are optimized for uniform thermal management, and critical shut-off surfaces guarantee zero flash—resulting in molded parts that consistently meet or exceed automotive specifications like ISO 2768-mK, VDA 19.1, and stringent OEM internal standards.

The table below outlines the precision benchmarks achievable through our integrated metal manufacturing process for automotive injection molds:

| Specification Category | Capability Range | Automotive Relevance |

|---|---|---|

| Linear Dimensional Tolerance | ±0.002 mm to ±0.005 mm | Critical for sealing surfaces, mating parts, sensor alignment |

| Geometric Tolerance (GD&T) | ±0.003 mm (Position, Profile) | Ensures assembly integrity and functional performance |

| Surface Roughness (Cavity) | Ra 0.025 µm to Ra 0.1 µm (Mirror) | Directly impacts part ejection, gloss, and adhesion |

| Cooling Channel Accuracy | ±0.01 mm positional, ±0.005 mm ID | Eliminates part warpage and cycle time inconsistencies |

| Tool Steel Hardness Control | Within ±1.5 HRC of target | Guarantees mold longevity under high-cycle production |

This level of metal manufacturing precision is not optional in modern automotive supply chains; it is the essential prerequisite for producing injection molded components that ensure vehicle safety, performance, and the relentless innovation driving the industry forward. Wuxi Lead Precision Machinery delivers this foundational capability, built on proven experience where precision is measured in microns and consequences are measured in mission success.

Precision Specs & Tolerances

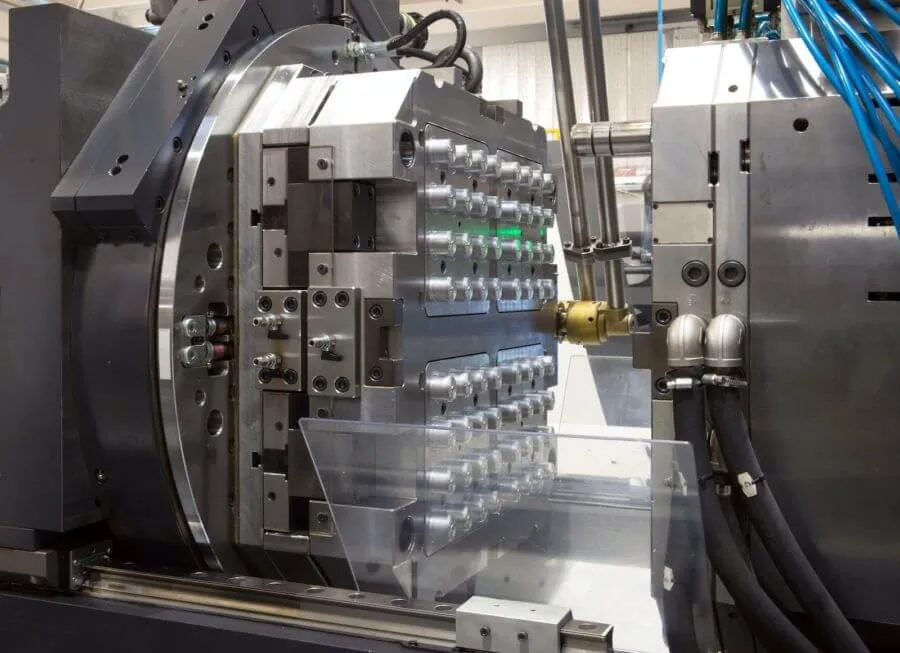

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the exacting standards of the automotive plastic injection molding industry. Our facility is equipped with state-of-the-art 5-axis CNC machining centers, enabling us to produce highly complex mold bases, inserts, and precision components with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool positioning and reduced setup times. This translates into faster production cycles, minimized human error, and exceptional geometric consistency—critical factors when manufacturing molds that require tight integration and long-term durability.

Our machining processes are supported by a rigorous quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Every component undergoes comprehensive dimensional verification using Zeiss and Hexagon CMM systems, capable of measuring down to ±0.001 mm. This level of metrology ensures full compliance with GD&T (Geometric Dimensioning and Tolerancing) requirements and customer-specific blueprints. Data from each inspection is documented and archived, providing full traceability for every production batch—a necessity for automotive Tier 1 suppliers and OEMs requiring audit-ready documentation.

We specialize in manufacturing mold components that demand high precision and thermal stability, including cavity plates, core supports, ejector systems, and alignment bushings. Materials are selected based on performance criteria such as wear resistance, hardness, and machinability, including P20, 718H, H13, S136, and other tool steels. All materials are pre-hardened or heat-treated as required, with stress-relieving processes integrated into the machining sequence to prevent post-machining deformation.

Surface finishing is performed using high-speed milling techniques and fine electrode EDM where necessary, achieving surface roughness values as low as Ra 0.2 µm. This ensures optimal release characteristics and extended mold life in high-volume injection molding applications. In addition, all machined parts are deburred, cleaned, and inspected for edge integrity to prevent flash formation and premature wear during operation.

Our technical team works closely with clients during the design-for-manufacturability (DFM) phase, offering insights into mold layout optimization, cooling channel placement, and parting line definition. This collaborative approach reduces time-to-market and enhances overall mold performance.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and consistency across all production runs.

| Feature | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometer |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM, Optical Comparator |

| Flatness | 0.01 mm/m² | 0.005 mm/m² | Surface Plate, CMM |

| Parallelism | 0.012 mm | 0.006 mm | CMM, Dial Indicator |

| Perpendicularity | 0.015 mm | 0.008 mm | CMM, Square Block |

| Surface Roughness (Ra) | ≤0.8 µm | ≤0.2 µm | Surface Roughness Tester |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for high-end automotive mold manufacturers seeking reliability, repeatability, and technical excellence in every component produced.

Material & Finish Options

Material Selection for High-Performance Automotive Injection Molds

Selecting the optimal mold material is critical for achieving precision, longevity, and cost efficiency in automotive plastic injection molding. At Wuxi Lead Precision Machinery, we prioritize materials that withstand high-cycle production while maintaining dimensional stability under thermal stress. Aluminum, steel, and titanium each serve distinct roles based on part complexity, volume, and environmental demands. Aluminum alloys like 7075-T6 offer superior thermal conductivity, accelerating cooling cycles for rapid prototyping or low-volume production of interior components. However, their lower hardness limits use in abrasive-filled polymers or extended high-volume runs.

Tool steels such as P20, H13, and S136 dominate mainstream automotive applications. P20 provides balanced machinability and toughness for moderate-volume exterior trims, while H13 excels in high-temperature scenarios like under-hood components due to its exceptional thermal fatigue resistance. For corrosion-prone environments—such as fluid-handling systems—S136 stainless steel delivers unmatched resistance to acidic or hygroscopic resins, ensuring cavity integrity over millions of cycles. Titanium alloys, though less common, are reserved for extreme scenarios requiring ultra-high strength-to-weight ratios and non-magnetic properties, such as specialized sensor housings in electric vehicles.

Surface finishing, particularly anodizing, significantly enhances mold performance. Hard anodizing (Type III) applied to aluminum molds creates a wear-resistant ceramic layer up to 50 µm thick, reducing galling during ejection of complex geometries like dashboard vents. For steel molds, nitriding or PVD coatings are typically preferred; anodizing is ineffective on ferrous substrates. Always specify anodizing requirements early in design to avoid dimensional interference with tight-tolerance features.

Material choice directly impacts total cost of ownership. While aluminum molds cost 30% less upfront than steel, their lifespan may be 1/10th for high-volume production of door panels. Our engineering team evaluates resin abrasiveness, annual part volume, and surface finish requirements to recommend the most economical solution. Below are key comparative properties:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Automotive Applications |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | Low | Prototype dash components, low-volume interior clips |

| P20 Steel | 28-32 | 30 | Moderate | Door panels, console housings (100k–500k cycles) |

| H13 Steel | 48-52 | 25 | Good | Headlight housings, under-hood brackets (500k+ cycles) |

| S136 Steel | 50-54 | 20 | Excellent | Fuel system connectors, coolant valves |

| Titanium Gr5 | 36-40 | 7 | Exceptional | EV battery sensor mounts, aerospace-derived parts |

Partnering with Wuxi Lead ensures data-driven material selection aligned with your production targets. We combine metallurgical expertise with CNC precision to transform material specifications into molds that deliver consistent part quality. Consult our engineering team to optimize your next automotive mold build for performance and lifecycle value.

Manufacturing Process & QC

The production process for automotive plastic injection molding at Wuxi Lead Precision Machinery follows a rigorously controlled sequence—Design, Prototyping, and Mass Production—engineered to achieve zero defects and ensure full compliance with automotive industry standards. Each phase integrates precision engineering, advanced simulation, and real-time quality monitoring to deliver components that meet the exact functional, aesthetic, and durability requirements of automotive applications.

Design begins with a collaborative engineering review, where our team works directly with the client to analyze part geometry, material selection, gate placement, and mold flow dynamics. Utilizing 3D CAD modeling and Moldflow simulation software, we predict potential defects such as warpage, sink marks, or air traps before tooling begins. This data-driven approach ensures optimal mold design, cycle time efficiency, and material utilization. All designs adhere to ISO 13485 and IATF 16949 standards, with full documentation for traceability and design for manufacturability (DFM) validation.

Prototyping follows design approval, using high-precision CNC-machined molds or 3D-printed tooling for initial sample production. This stage allows for functional testing, fit checks, and material performance evaluation under real-world conditions. We produce pilot batches of 50 to 500 units, subjecting them to rigorous dimensional inspection via coordinate measuring machines (CMM) and optical scanning. Any deviations are addressed through iterative adjustments to the mold or process parameters. This phase reduces risk and accelerates time-to-market by identifying issues early, before full-scale tooling is committed.

Mass production commences only after client approval of prototype samples and process validation. Our facility employs state-of-the-art electric and hybrid injection molding machines from leaders such as Fanuc and Engel, ensuring repeatable precision and energy efficiency. Each production run is supported by automated in-process inspection systems, including vision inspection and real-time cavity pressure monitoring. Statistical process control (SPC) is implemented at every stage, with data logged for full batch traceability. All molds are maintained under a preventive maintenance schedule, and environmental controls ensure consistent temperature and humidity for material stability.

Wuxi Lead Precision Machinery’s zero-defect philosophy is enforced through a closed-loop quality system. Any non-conformance triggers immediate root cause analysis and corrective action. Final inspection includes first-article inspection reports (FAIR), PPAP documentation, and full material certification. Our integrated approach ensures every component meets the highest standards of reliability required in modern automotive systems.

| Specification | Detail |

|---|---|

| Material Compatibility | ABS, PC, PBT, PA6, PA66, PPS, PEEK |

| Tolerance Range | ±0.02 mm |

| Mold Base Standards | HASCO, DME, MISUMI |

| Machine Capacity | 50–2000 Ton |

| Production Environment | ISO Class 8 Cleanroom Available |

| Quality Standards | IATF 16949, ISO 9001, ISO 13485 |

| Tool Life | 1,000,000+ cycles (hardened steel) |

| Lead Time (Prototype) | 4–6 weeks |

| Lead Time (Production Tooling) | 8–12 weeks |

Why Choose Wuxi Lead Precision

Elevate Your Automotive Plastic Injection Molding with Precision Engineering

Achieving uncompromising quality and efficiency in automotive plastic injection molding demands more than just capable machinery; it requires a strategic partner with deep expertise in precision metal manufacturing for the most demanding applications. At Wuxi Lead Precision Machinery, we specialize in transforming complex automotive component designs into reality through the creation of high-performance, long-life injection molds. Our integrated approach, combining decades of CNC engineering excellence with rigorous quality management systems, directly addresses the critical challenges faced by Tier 1 suppliers and OEMs: reducing time-to-market, ensuring absolute dimensional stability, and guaranteeing zero-defect production runs under stringent automotive standards.

We understand that the mold is the foundation of your plastic part’s success. Our engineering team collaborates closely from the initial concept stage, leveraging advanced simulation software to optimize mold flow, cooling channels, and structural integrity. This proactive design phase prevents costly iterations and production delays. Utilizing state-of-the-art CNC machining centers, wire EDM, and surface grinding technologies, we fabricate molds with micron-level accuracy, critical for components requiring Class A surfaces, tight tolerances, or complex overmolding sequences. Every process, from material selection (including hardened tool steels and specialized alloys) to final assembly and polishing, adheres to ISO 9001 and IATF 16949 protocols, ensuring consistency batch after batch.

Our commitment extends beyond mold delivery. We provide comprehensive support throughout the production lifecycle, including mold trials, process validation assistance, and responsive technical service to minimize downtime. This holistic partnership model ensures your injection molding operations achieve maximum uptime, superior part repeatability, and significant cost savings over the mold’s operational life. For automotive applications where failure is not an option—dashboard components, lighting assemblies, interior trim, under-hood connectors, and fluid system parts—reliance on a moldmaker with proven automotive pedigree is non-negotiable.

Wuxi Lead Precision Machinery delivers the technical capability required for the most advanced automotive programs:

| Specification | Capability | Automotive Application Example |

|---|---|---|

| Mold Tonnage Range | 80T – 2500T | Large interior panels, structural brackets |

| Cavity Count | 1 – 32+ | High-volume fasteners, sensor housings |

| Tolerance Precision | ±0.002 mm (micron-level) | Sealing surfaces, optical lenses |

| Lead Time (Complex) | 8 – 14 Weeks (Optimized) | Accelerated program launches |

| Material Expertise | P20, H13, S136, Stainless, Beryllium | Corrosive fluid systems, high-wear components |

Initiate your precision molding project today. Contact our engineering team directly at [email protected] to discuss your specific automotive component requirements. Provide your target volumes, material specifications, and quality benchmarks. We will respond within 24 business hours with a detailed capability assessment and preliminary timeline. Partner with Wuxi Lead Precision Machinery to convert engineering complexity into manufacturing certainty—where every micron matters for your vehicle’s performance and safety. Let us build the foundation for your next generation of automotive innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.