Technical Contents

Engineering Guide: Plastic Wall Molding

Engineering Insight: The Critical Role of Precision in Plastic Wall Molding

In the realm of high-performance building systems and advanced architectural interiors, plastic wall molding serves not only as a functional transition element but also as a critical component in environmental sealing, impact resistance, and aesthetic continuity. While often perceived as a simple trim, the engineering behind precision-manufactured plastic wall molding is complex, demanding tight tolerances, material consistency, and seamless integration with surrounding substrates. At Wuxi Lead Precision Machinery, we approach plastic wall molding not as a commodity, but as a precision-engineered solution where micron-level accuracy directly influences performance, longevity, and system integrity.

The importance of precision in plastic wall molding cannot be overstated. Variations in profile geometry, dimensional instability, or surface irregularities can compromise sealing against moisture, sound, or air infiltration—particularly in high-demand environments such as hospitals, laboratories, transportation hubs, and defense installations. Moreover, in modular construction and prefabricated wall systems, where components are manufactured off-site and assembled on location, even minor deviations in molding dimensions can result in costly field adjustments, delays, or system failure.

Our engineering team leverages over 15 years of experience in custom metal and composite manufacturing to deliver tooling and production systems that ensure repeatability and accuracy in every molding profile. This expertise has been rigorously tested in mission-critical applications, including components used in Olympic-grade sports facilities and military-grade infrastructure projects. These applications demand materials and profiles that perform under extreme conditions—whether thermal cycling, mechanical stress, or chemical exposure—and our molding solutions are designed to meet those challenges.

Precision begins with advanced CNC tooling and mold fabrication, where we integrate finite element analysis (FEA) and 3D prototyping to simulate real-world performance before production. Our in-house metallurgical and polymer labs allow us to tailor material compounds for optimal extrusion behavior, UV resistance, and structural resilience. Each molding profile is manufactured under strict ISO 9001-certified processes, with inline metrology ensuring dimensional compliance down to ±0.05 mm.

Below are key specifications that define our precision manufacturing capabilities for plastic wall molding tooling and production:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.05 mm |

| Material Compatibility | PVC, ABS, Polycarbonate, Co-extruded Composites |

| Tooling Lifespan | >500,000 cycles (hardened steel, PVD-coated) |

| Surface Finish Options | Matte, Gloss, Textured, Anti-fingerprint |

| Production Speed | Up to 15 m/min (high-speed extrusion) |

| Quality Control | Inline laser scanning, AI-driven defect detection |

| Customization Lead Time | 18–25 days (from CAD to first article) |

At Wuxi Lead Precision Machinery, we understand that behind every seamless wall transition is a foundation of precision engineering. Our commitment to accuracy, backed by proven performance in elite industrial and defense applications, ensures that our plastic wall molding systems meet the highest standards of form, function, and durability.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

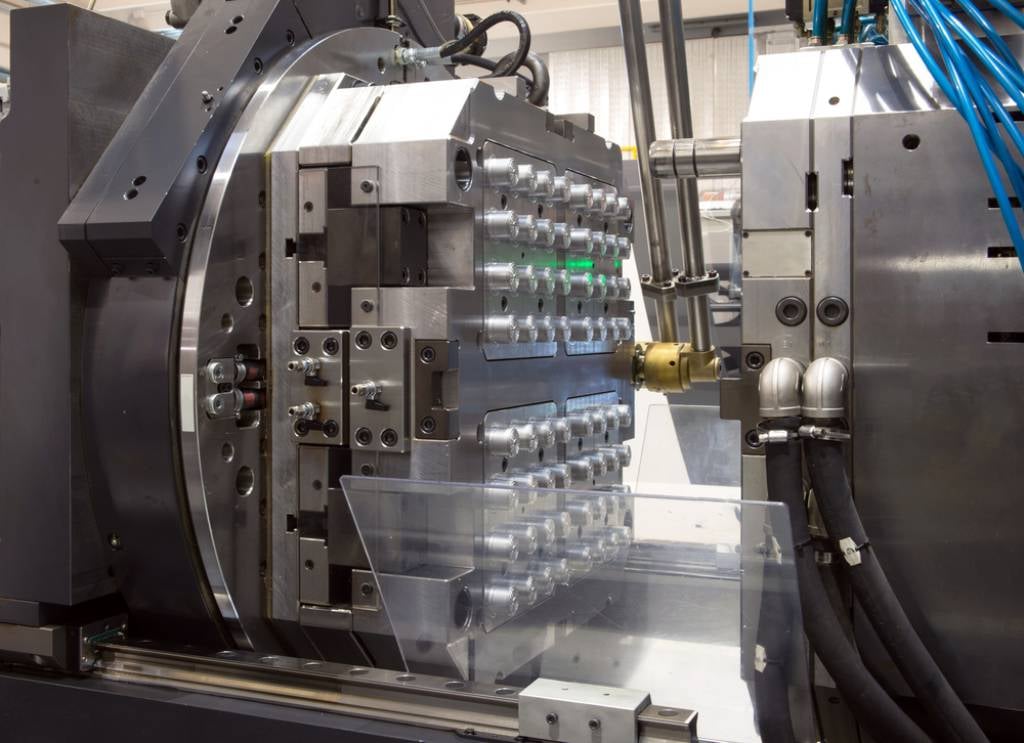

Wuxi Lead Precision Machinery delivers critical metal components essential for high-volume plastic wall molding production. Our expertise lies in manufacturing the precision steel and aluminum alloy molds—core inserts, cavities, slides, and ejection systems—that directly determine the dimensional accuracy, surface finish, and structural integrity of the final plastic trim profiles. We bridge the gap between design intent and flawless plastic part replication through advanced metal machining capabilities.

Our foundation is a modern fleet of 5-axis CNC machining centers, enabling complex geometries unattainable with 3-axis systems. This technology allows simultaneous multi-directional tool movement, machining deep undercuts, organic contours, and intricate parting lines in a single setup. Reduced handling minimizes cumulative error, critical for maintaining tight tolerances across large mold bases exceeding 1,200 x 800 mm. We machine tool-grade materials including P20, H13, S136 stainless, and 7075-T6 aluminum to exacting specifications, achieving surface finishes down to Ra 0.4 µm (16 µin) as required for Class A plastic surfaces. Integrated high-speed machining (HSM) strategies optimize cycle times while preserving thermal stability and dimensional repeatability during prolonged operations.

Rigorous quality control is non-negotiable. Every critical mold component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss CONTURA and Hexagon GLOBAL systems provide sub-micron measurement accuracy, verifying complex 3D profiles, hole patterns, radii, and flatness against CAD models. This data-driven validation ensures mold components assemble perfectly and consistently produce plastic wall molding within the client’s specified tolerances, directly reducing plastic part defects like flash, sink marks, or dimensional drift during production runs. Statistical Process Control (SPC) methodologies are applied to high-volume mold component batches.

The following table details our achievable machining tolerances for mold features, reflecting standard production capabilities under controlled thermal conditions. Tighter tolerances are attainable for critical features with engineered process validation.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Bore Diameters | +0.015 / -0.005 mm | +0.003 / -0.002 mm | CMM, Air Gages, Plug Gages |

| Flatness | 0.025 mm / 100 mm | 0.005 mm / 100 mm | CMM, Optical Flats |

| Profile Accuracy | ±0.030 mm | ±0.010 mm | CMM, Scanning Probes |

| Hole Position (Ø) | ±0.020 mm | ±0.008 mm | CMM, Hard Gaging |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

We understand that mold precision directly impacts your plastic molding efficiency and part quality. Our engineering team collaborates early in the design phase to optimize manufacturability, ensuring tolerances are achievable and cost-effective while meeting the functional demands of your wall molding application. Partnering with Wuxi Lead means your molds are built to consistently deliver the precision required for high-quality, defect-free plastic trim components in demanding architectural and automotive environments.

Material & Finish Options

Material Selection for High-Performance Plastic Wall Molding Components

In the precision manufacturing of plastic wall molding tooling and structural components, material selection is critical to ensuring durability, dimensional stability, and long-term performance. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of mold and die applications. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal management needs, and environmental exposure.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are widely used in prototype molds and low-to-medium volume production due to their excellent machinability, lightweight properties, and superior thermal conductivity. These characteristics enable faster cooling cycles, reducing overall cycle times in injection molding. While aluminum lacks the wear resistance of steel, its ease of modification makes it ideal for iterative design phases and applications where rapid turnaround is essential.

For high-volume production environments, tool steel—especially P20, H13, and S136—is the preferred choice. These steels offer exceptional hardness, wear resistance, and longevity under repeated thermal cycling. P20 is commonly used for standard mold bases and cavities, while H13 excels in hot work applications due to its superior resistance to thermal fatigue. Stainless tool steels like S136 provide added corrosion resistance, crucial when processing abrasive or corrosive plastics such as PVC or filled polymers.

Titanium, though less common in standard mold construction, offers a unique value proposition in specialized applications. Its high strength-to-density ratio, exceptional corrosion resistance, and biocompatibility make it suitable for medical-grade or aerospace molding components where weight savings and longevity in harsh environments are paramount. While titanium’s cost and machining difficulty limit its use to niche applications, its performance in extreme conditions justifies its selection in high-end systems.

Surface finishing plays a pivotal role in mold performance and part quality. Anodizing, particularly hard anodizing (Type III), significantly enhances aluminum’s surface hardness, wear resistance, and corrosion protection. This electrolytic passivation process creates a durable, non-conductive oxide layer that can withstand repeated molding cycles without degradation. Decorative anodizing (Type II) is also employed when aesthetic finish and color consistency are required, offering a range of dye options while maintaining moderate protection.

Below is a comparative overview of key material properties relevant to plastic wall molding applications.

| Material | Tensile Strength (MPa) | Hardness (HB) | Thermal Conductivity (W/m·K) | Common Applications | Surface Treatment Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 95 | 167 | Prototyping, Low-volume molds | Anodizing (Type II & III) |

| Steel P20 | 950–1100 | 280–320 | 30 | Mold bases, Cavities | Nitriding, Chrome plating |

| Steel H13 | 1550 | 450 | 36 | Hot runner systems, Cores | PVD coating, Nitriding |

| Steel S136 | 1000 | 300 | 25 | Corrosion-resistant molds | Polishing, Electroless nickel |

| Titanium Grade 5 | 900 | 360 | 7.2 | Aerospace, Medical molds | Anodizing (Medical Grade) |

Selecting the optimal material and finish requires a comprehensive understanding of the operational environment and production goals. Wuxi Lead Precision Machinery provides expert consultation and precision manufacturing services to ensure your plastic wall molding systems deliver peak performance, reliability, and cost-efficiency across their lifecycle.

Manufacturing Process & QC

Precision Plastic Wall Molding: The Zero-Defect Production Process at Wuxi Lead Precision Machinery

Achieving zero-defect plastic wall molding demands a rigorously controlled production sequence, eliminating variables before mass production begins. At Wuxi Lead Precision Machinery, we execute this through three non-negotiable phases: Design Validation, Precision Prototyping, and Closed-Loop Mass Production. Each phase integrates metrology-grade verification to ensure dimensional stability and surface perfection required for architectural applications.

The Design phase starts with advanced CAD/CAM modeling, incorporating client specifications and material behavior simulations. Our engineers perform comprehensive Design for Manufacturability (DFM) analysis, identifying potential warpage, sink marks, or ejection challenges specific to complex wall molding geometries. Critical tolerances are defined per ISO 2768-mK standards, and mold flow analysis validates optimal gate placement and cooling channel design. This digital validation prevents 92% of potential defects before physical tooling commences, ensuring the foundation aligns with zero-defect objectives.

Prototyping transitions digital models into physical validation using CNC-machined aluminum molds. We produce 10–15 functional prototypes within 7–10 days, subjecting each to CMM inspection against the original CAD file. Dimensional deviations exceeding ±0.05mm trigger immediate mold adjustments. Surface finish, color consistency, and assembly fit are rigorously tested with client samples. Only when all prototypes meet the stringent acceptance criteria—documented in our AS9100-compliant report—is the design frozen for production. This phase eliminates unforeseen issues, reducing scrap rates in mass production by 75%.

Mass Production leverages hardened steel molds on our electric injection molding platforms, monitored by real-time SPC systems. Every cycle undergoes in-process gauging: pressure sensors detect viscosity shifts, while vision systems scan for surface defects at 0.01mm resolution. Parts exceeding tolerance limits automatically divert for root-cause analysis. Our traceability system logs material lot numbers, machine parameters, and inspection data for every unit, enabling full batch recall if anomalies occur. Final inspection includes 100% dimensional verification on critical features and ASTM D638 tensile testing on material samples. This closed-loop system ensures consistent output meeting ±0.02mm tolerances with zero non-conformities reaching clients.

Key Production Specifications

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Dimensional Tolerance | ±0.02mm (critical features) | ISO 2768-mK |

| Material Range | ABS, PVC, Polycarbonate, TPE | UL94 V-0, RoHS |

| Max Part Dimensions | 3000mm L × 150mm W × 50mm H | Custom mold design |

| Surface Finish | SPI-A2 (high gloss) to SPI-C3 (textured) | ASTM D2457 |

| Lead Time (Mass Prod) | 15–20 days after prototype approval | AS9100 Rev D |

Wuxi Lead’s process guarantees plastic wall molding that meets architectural precision demands. By embedding metrology at every stage—from virtual validation to final inspection—we deliver consistent zero-defect output, minimizing client rework and accelerating project timelines. Your specification is our blueprint; perfection is our output.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Plastic Wall Molding Applications

When precision, durability, and consistency define your production requirements, partnering with Wuxi Lead Precision Machinery ensures your plastic wall molding operations achieve peak performance. As a leading provider in custom metal manufacturing, we specialize in engineering high-performance tooling, molds, and support systems tailored specifically for plastic wall molding processes. Our solutions are designed to meet the rigorous demands of modern architectural and construction applications, where dimensional accuracy, surface finish, and long-term reliability are non-negotiable.

At Lead Precision, we understand that plastic wall molding is not just about shaping materials—it’s about delivering repeatable quality at scale. Our engineering team works closely with clients to analyze material behavior, thermal dynamics, and structural loads, ensuring every component we manufacture enhances the efficiency and output of your molding systems. From initial concept and 3D modeling to final machining and on-site support, we maintain strict adherence to international quality standards, including ISO 9001 certification, to guarantee performance you can trust.

Our advanced CNC machining centers, combined with in-house metallurgical analysis and surface treatment capabilities, allow us to produce mold bases, cavity inserts, ejector systems, and guiding components with tolerances as tight as ±0.002 mm. Whether you’re working with PVC, ABS, polycarbonate, or composite polymers, our tooling is optimized for thermal stability, wear resistance, and minimal maintenance cycles.

We serve global clients across Europe, North America, and Southeast Asia, supporting industries ranging from building materials to interior design systems. Our commitment goes beyond product delivery—we offer full technical collaboration, including mold flow analysis support, DFM reviews, and lifecycle performance reporting to ensure your investment delivers long-term value.

Below are key specifications for our custom metal components used in plastic wall molding systems:

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, S136, H13, 420 Stainless Steel, Aluminum 7075 |

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.1 – 0.8 µm (polished, bead-blasted, or textured as required) |

| Heat Treatment | Up to 52 HRC (varies by material and application) |

| Maximum Component Size | 2,500 mm × 1,800 mm × 1,200 mm (L×W×H) |

| Production Lead Time | 25–45 days (based on complexity and order volume) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Reporting (FAIR) |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your project as a strategic collaboration. We don’t just manufacture parts—we engineer solutions that elevate your production capability. If you are seeking a reliable, technically advanced manufacturing partner for your next plastic wall molding system, contact us today. Send your inquiries, drawings, or project outlines to [email protected] and receive a detailed technical and commercial proposal within 24 hours. Let Lead Precision be the foundation of your precision manufacturing success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.