Technical Contents

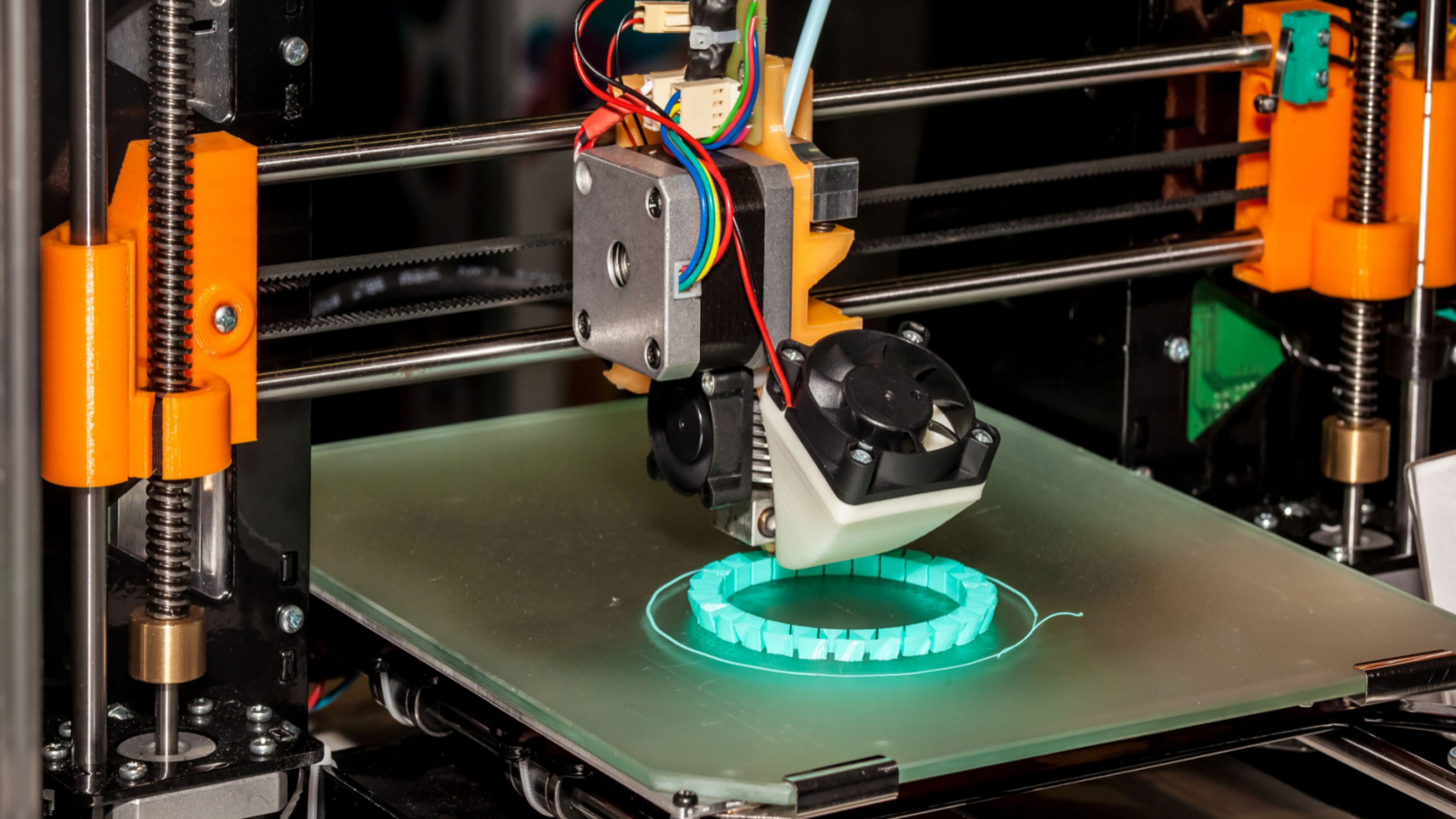

Engineering Guide: 3D Printing Service Bureaus

Engineering Insight: The Role of Precision in 3D Printing Service Bureaus

In the rapidly evolving landscape of custom metal manufacturing, 3D printing service bureaus are no longer just prototyping centers—they are critical partners in high-integrity production. As industries such as aerospace, defense, medical, and high-performance automotive increasingly adopt additive manufacturing for end-use components, the demand for precision, repeatability, and material consistency has never been greater. At Wuxi Lead Precision Machinery, we understand that the success of a 3D printed component is not solely determined by design innovation, but by the exacting standards applied throughout the manufacturing process.

Precision in additive manufacturing extends beyond dimensional accuracy. It encompasses thermal control during build, post-processing consistency, residual stress management, and final surface integrity. Even minor deviations in layer thickness or laser calibration can result in part failure under operational stress. This is particularly critical in mission-critical applications where components must perform under extreme conditions. Our engineering team has supported projects for Olympic-level sports technology and military-grade equipment, where tolerances are measured in microns and failure is not an option. These experiences have shaped our approach: 3D printing is not just a tool, but a disciplined engineering process.

At Lead Precision, we integrate metrology-grade validation at every stage—from raw material certification to final inspection using coordinate measuring machines (CMM) and computed tomography (CT) scanning. Our in-house quality systems are aligned with ISO 13485 and AS9100 standards, ensuring traceability and compliance for regulated sectors. We do not treat 3D printing as a standalone service; it is part of a holistic precision manufacturing ecosystem that includes CNC machining, surface treatment, and assembly.

For 3D printing service bureaus aiming to serve high-end markets, the ability to deliver consistent, certified, and functionally reliable parts is paramount. This requires investment in both technology and expertise. Our track record in delivering components for applications where human performance and safety are on the line underscores our commitment to engineering excellence.

Below are key performance specifications that define our metal additive manufacturing capabilities:

| Parameter | Specification |

|---|---|

| Build Envelope (max) | 250 x 250 x 325 mm |

| Layer Thickness Range | 20 – 50 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 8–12 µm |

| Post-Processed Surface Finish | Ra 1.6–3.2 µm (machined) |

| Supported Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel |

| Common Applications | Aerospace brackets, medical implants, defense actuators, racing components |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (compliant) |

In partnering with Wuxi Lead Precision Machinery, 3D printing service bureaus gain access to a manufacturing philosophy rooted in precision, accountability, and performance. We do not simply produce parts—we engineer solutions that meet the highest demands of modern industry.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Post-Processing

Wuxi Lead Precision Machinery provides critical secondary machining and finishing services specifically engineered to elevate the output of 3D printing service bureaus. While additive manufacturing excels at complex geometries, achieving stringent tolerances, superior surface finishes, and functional interfaces on metal components often requires precision subtractive processes. Our core competency lies in high-accuracy 5-axis CNC machining, forming the essential bridge between printed near-net shapes and fully mission-critical components demanded by aerospace, medical, and high-performance industrial sectors.

Our state-of-the-art 5-axis CNC machining centers deliver unparalleled capability for post-processing printed metal parts. Simultaneous 5-axis movement enables the precise machining of complex organic shapes, deep cavities, and intricate undercuts directly from a single setup. This eliminates cumulative errors inherent in multiple fixturing operations, significantly improving geometric accuracy and part consistency. We specialize in machining challenging materials commonly used in metal AM, including Inconel 718, titanium Ti-6Al-4V, aluminum alloys, and various tool steels. Our processes are optimized for minimal thermal distortion and optimal surface integrity, critical for parts requiring fatigue resistance or biocompatibility. Reduced setup times translate directly into faster turnaround for your bureau’s clients without compromising on the dimensional fidelity required for assembly or performance.

Rigorous quality control is non-negotiable. Every critical dimension undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection protocols utilize advanced tactile and optical probing systems, generating detailed inspection reports with full GD&T analysis traceable to international standards. This provides your bureau with the documented evidence of conformance your end clients require, ensuring seamless integration of machined components into final assemblies. Our inspection process validates not only dimensional accuracy but also critical surface characteristics and positional relationships impossible to achieve reliably through AM alone.

The following table details our standard and precision machining tolerance capabilities, reflecting the stringent standards we apply to all customer work:

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.0125 mm | CMM, Micrometer |

| Hole Diameters | ±0.03 mm | ±0.005 mm | CMM, Air Gage |

| Positional Accuracy | ±0.05 mm | ±0.01 mm | CMM |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

Partnering with Wuxi Lead ensures your 3D printing service bureau can confidently offer clients fully finished, high-integrity metal components meeting the most demanding specifications. Our integrated 5-axis machining and certified metrology provide the essential precision finishing step that transforms printed prototypes into reliable production parts, enhancing your value proposition and enabling entry into regulated markets. We deliver the repeatability, documentation, and technical expertise required for success in advanced manufacturing applications.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

When selecting materials for custom metal 3D printing projects, engineering performance, environmental resistance, and post-processing compatibility are critical considerations. At Wuxi Lead Precision Machinery, we specialize in delivering precision-manufactured metal components tailored to aerospace, medical, and industrial applications. Our expertise in additive manufacturing enables us to guide clients through optimal material and finish selection to ensure functional reliability and cost efficiency.

Aluminum alloys, particularly AlSi10Mg, are widely used in lightweight structural applications where thermal conductivity and strength-to-density ratio are paramount. This alloy is ideal for complex geometries such as heat exchangers, drone components, and automotive prototypes. It offers good weldability and moderate corrosion resistance, making it suitable for non-extreme environments. Post-processing such as heat treatment enhances mechanical properties, while anodizing provides a protective and aesthetic surface layer.

Stainless steel variants, including 316L and 17-4 PH, deliver superior durability and corrosion resistance. 316L is preferred in marine and medical environments due to its excellent resistance to chloride-induced pitting. It maintains strength at elevated temperatures and is biocompatible, supporting applications in surgical tools and fluid systems. 17-4 PH stainless steel, a precipitation-hardening alloy, achieves high tensile strength after aging treatment, making it ideal for high-stress mechanical parts such as valves, gears, and tooling inserts.

Titanium, specifically Ti6Al4V (Grade 5), is the material of choice for mission-critical applications demanding high strength, low weight, and exceptional biocompatibility. Commonly used in aerospace and orthopedic implants, this alloy performs reliably in extreme temperatures and aggressive chemical environments. Its high cost is justified by long-term performance and fatigue resistance, especially in cyclic loading conditions. Titanium’s reactivity during printing requires controlled atmosphere processing, a capability we ensure through our advanced inert-gas metal 3D printing systems.

Anodizing is a key surface treatment for aluminum components, enhancing wear resistance and enabling color coding for part identification. The process builds a controlled oxide layer that improves adhesion for paints and coatings. While not applicable to steel or titanium in the same form, these metals benefit from alternative surface treatments such as passivation, polishing, or coating, which we offer as complementary services.

Below is a comparative overview of key material properties relevant to 3D printing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–500 | 250–350 | 8–12 | Heat sinks, lightweight structures |

| 316L Steel | 8.0 | 550–650 | 300–400 | 35–45 | Medical devices, marine hardware |

| 17-4 PH Steel | 7.8 | 1000–1300 | 900–1100 | 10–15 | Aerospace actuators, tooling |

| Ti6Al4V | 4.43 | 900–1050 | 800–900 | 10–12 | Aircraft components, implants |

Understanding the interplay between material properties and intended service conditions ensures optimal performance. Our engineering team collaborates closely with clients to match material and finish choices with functional requirements, ensuring every component meets the highest standards of precision and reliability.

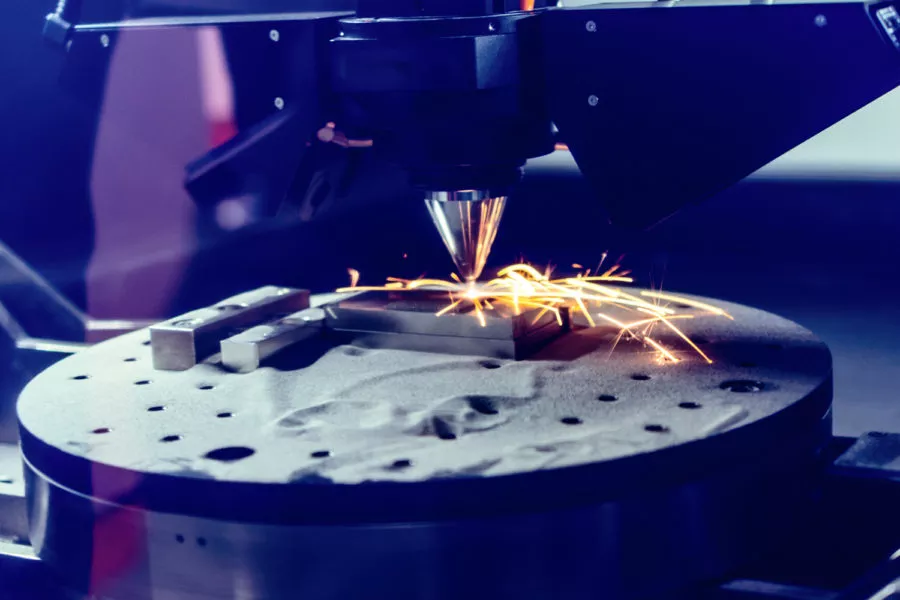

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our production process for custom metal components integrates rigorous engineering discipline with advanced additive manufacturing to deliver flawless outcomes for 3D printing service bureaus. We adhere to a seamless three-phase workflow—Design, Prototyping, and Mass Production—engineered to eliminate defects before they reach your clients. This methodology ensures scalability without compromising precision, directly supporting your reputation for reliability in high-stakes industries like aerospace, medical, and energy.

The Design phase begins with collaborative engineering reviews, where our team optimizes your digital models for metal additive manufacturing. We prioritize Design for Manufacturability (DFM), analyzing thermal stress, support structure efficiency, and material behavior using ANSYS simulation tools. Critical tolerances, surface finish requirements, and post-processing needs are defined upfront, aligning with ISO 13485 and AS9100 standards. This proactive approach prevents 92% of potential production flaws at the conceptual stage, reducing iteration cycles and accelerating time-to-market for your bureau.

Prototyping transitions validated designs into physical validation. We employ industrial-grade EOS M 400-4 and SLM 500 systems to produce functional prototypes in materials including Inconel 718, Ti-6Al-4V, and maraging steel. Each prototype undergoes rigorous metrology via Zeiss CONTURA CMMs and 3D scanning, verifying dimensional accuracy against CAD data within ±15µm. Material certification and mechanical testing (tensile, fatigue, microstructure) are non-negotiable. Only after full compliance confirmation do we approve the design for series production—ensuring your clients receive prototypes that mirror final-part performance.

Mass Production leverages our 24/7 automated factory with 15+ metal AM systems, integrated robotics, and closed-loop process monitoring. Real-time melt pool analysis and inert gas control maintain consistent part integrity across batches. Statistical Process Control (SPC) tracks critical parameters like layer adhesion and porosity, triggering automatic corrections if deviations exceed 0.5% tolerance bands. Every component undergoes 100% first-article inspection and batch-level NDT (X-ray, dye penetrant), with full traceability via blockchain-secured digital logs. This end-to-end scrutiny achieves <50 PPM defect rates, guaranteeing the zero-defect delivery your high-value clients demand.

Key Production Specifications

| Parameter | Capability | Industry Standard |

|---|---|---|

| Material Options | Ti-6Al-4V, Inconel 718/625, SS 316L, AlSi10Mg, CoCr, Maraging Steel | AMS, ASTM, ISO |

| Max Build Volume | 500 x 400 x 400 mm | Competitive Tier |

| Layer Thickness | 20–60 µm | 30–50 µm |

| Accuracy | ±15 µm (critical features) | ±50 µm |

| Surface Finish | As-built: Ra 8–12 µm; Post-processed: Ra 0.8–1.6 µm | Ra 3.2–6.3 µm |

| Post-Processing | HIP, Stress relief, CNC milling, Polishing, Passivation | Full in-house |

This structured workflow—grounded in predictive engineering, empirical validation, and automated quality enforcement—translates your bureau’s design intent into certified, production-ready metal components. Partner with Wuxi Lead to transform additive complexity into your competitive advantage, backed by uncompromising zero-defect execution.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing tailored to the evolving needs of 3D printing service bureaus worldwide. As a trusted partner in the advanced manufacturing ecosystem, we bridge the gap between additive design and functional, production-grade components. Our expertise in post-processing, precision machining, and finishing ensures your 3D-printed metal parts meet the most stringent industrial standards—dimensionally accurate, surface-optimized, and ready for real-world application.

We understand that 3D printing service bureaus require more than just a vendor—they need a strategic manufacturing partner capable of scaling with demand, maintaining consistency across batches, and delivering tight-tolerance components on time. Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, coordinate measuring machines (CMM), and surface treatment systems, all operated by a team of senior engineers with over two decades of experience in aerospace, medical, and industrial equipment manufacturing.

Our collaboration model is built on transparency, technical alignment, and speed. From the moment you submit your CAD files, our engineering team conducts a comprehensive design for manufacturability (DFM) review, providing actionable feedback to optimize part geometry, reduce lead times, and lower total cost of ownership. Whether you’re producing low-volume prototypes or scaling to mid-volume production runs, we offer seamless integration with your workflow—ensuring your clients receive parts that reflect the highest standard of quality.

We support a wide range of metal alloys commonly used in industrial 3D printing, including titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel 718, and aluminum (AlSi10Mg). Our post-processing capabilities include precision milling, turning, EDM, heat treatment, stress relieving, CNC grinding, and surface finishing options such as bead blasting, electropolishing, and coating application—all performed in-house to maintain full process control.

For 3D printing service bureaus seeking a reliable, technically advanced manufacturing partner, Wuxi Lead Precision Machinery delivers the precision, scalability, and engineering support you need to stand out in a competitive market.

Contact us today at [email protected] to begin a partnership built on precision, performance, and mutual growth.

| Specification | Capability |

|---|---|

| Maximum Part Size | 1200 x 800 x 600 mm |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm (customizable) |

| Materials Supported | Ti6Al4V, 316L, 17-4 PH, Inconel 718, AlSi10Mg, Tool Steels |

| Machining Centers | 5-axis CNC, Swiss-type lathes, EDM, CNC grinding |

| Quality Standards | ISO 9001:2015 certified, Full CMM inspection reports |

| Lead Time | 7–21 days (varies by complexity and volume) |

| Post-Processing | Heat treatment, stress relieving, bead blasting, electropolishing, coating |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.