Technical Contents

Engineering Guide: Pick Your Part Durham Car Parts

Engineering Insight: The Critical Role of Precision in Custom Automotive Components

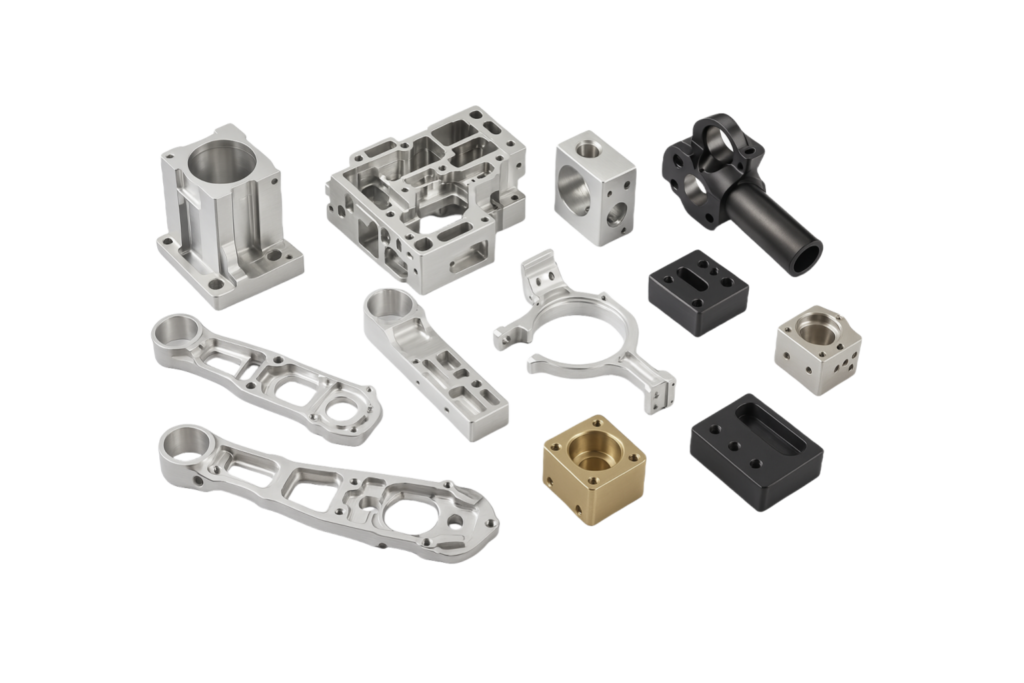

In the high-stakes world of automotive manufacturing, especially within performance, motorsport, and premium vehicle sectors, precision is not merely a quality target—it is a non-negotiable requirement. The phrase “pick your part Durham car parts” may evoke a modular, off-the-shelf approach to vehicle assembly, but behind the scenes, each selected component must meet exacting engineering standards to ensure safety, reliability, and peak performance. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in a machined part can lead to cascading failures under operational stress. This is why our custom metal manufacturing processes are built on a foundation of micron-level accuracy and rigorous quality control.

With over 15 years of experience serving global clients, Wuxi Lead has developed a reputation for delivering components where precision is paramount. Our expertise extends beyond commercial automotive applications into sectors where failure is not an option—Olympic-grade equipment and military defense systems. These industries demand materials and geometries that perform under extreme conditions, from sub-zero Arctic environments to high-G racing scenarios. The same standards we apply to aerospace actuators or tactical vehicle subsystems are brought to bear on every custom automotive component we produce.

Precision machining in automotive applications ensures optimal fit, function, and longevity. Whether manufacturing suspension arms, transmission housings, or custom engine brackets, tolerances within ±0.005 mm are routinely achieved using state-of-the-art CNC milling, turning, and multi-axis grinding technologies. Our facility utilizes real-time in-process metrology and post-production CMM (Coordinate Measuring Machine) verification to guarantee conformance across batches. This level of control is essential when clients “pick your part” from a catalog or configure-to-order system—each part must be functionally interchangeable without compromise.

Material selection further enhances performance. We work with high-strength alloys such as 7075 aluminum, 4140 steel, and titanium Grade 5, all processed under strictly controlled thermal and mechanical conditions. Surface treatments including anodizing, nitriding, and HVOF coating are applied where wear resistance or corrosion protection is critical.

Wuxi Lead’s engineering team collaborates directly with design partners to optimize part geometry for manufacturability without sacrificing performance. Through DFM (Design for Manufacturability) analysis and rapid prototyping, we reduce lead times and eliminate costly revisions—ensuring that when a customer selects a component, it arrives ready for integration.

The future of automotive manufacturing lies in the seamless integration of precision-engineered parts that perform reliably across diverse platforms. As modular and configurable systems grow in popularity, the demand for consistently accurate, high-integrity components will only increase. At Wuxi Lead Precision Machinery, we are committed to setting the benchmark in custom metal manufacturing for the global automotive industry.

Key Manufacturing Specifications

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.01 mm |

| Maximum Part Size | 1200 mm × 800 mm × 650 mm |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 1045), Stainless Steel (304, 316), Titanium (Gr5), Brass |

| Surface Finish (Ra) | 0.4 μm to 3.2 μm (adjustable per request) |

| Machining Processes | CNC Milling, CNC Turning, 5-Axis Machining, Grinding, EDM |

| Secondary Operations | Anodizing, Plating, Passivation, Welding, Heat Treatment |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, Full Traceability |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Automotive Component Integrity

Wuxi Lead Precision Machinery delivers the advanced manufacturing precision essential for the demanding requirements of the automotive remanufacturing and salvage sector, specifically addressing the critical needs of operations like Pick Your Part Durham. Our core competency lies in executing complex metal components to exacting standards, ensuring salvaged or remanufactured parts meet stringent OEM specifications for fit, function, and safety. This capability is foundational for integrating precision-machined elements back into the automotive supply chain with absolute reliability.

Our production backbone consists of state-of-the-art 5-axis CNC machining centers. These systems provide unparalleled flexibility and accuracy for machining complex geometries inherent in modern automotive components – from transmission housings and suspension knuckles to intricate engine brackets and sensor mounts. Simultaneous 5-axis movement eliminates the need for multiple setups, drastically reducing cumulative error and ensuring critical feature relationships are maintained within microns. We handle a wide spectrum of automotive-grade materials including aluminum alloys (e.g., 6061, 7075), cast irons, stainless steels (e.g., 304, 316), and specialty alloys, processing stock forms from billet to near-net forgings with consistent repeatability. Our machines achieve sub-micron level positioning accuracy and surface finishes critical for sealing surfaces and bearing interfaces.

Quality assurance is non-negotiable and integrated at every stage. Every critical dimension and geometric feature undergoes rigorous verification using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Mitutoyo CMMs provide full 3D metrology, generating detailed inspection reports traceable to international standards (ISO 17025 accredited processes). This systematic CMM inspection validates dimensional conformity against CAD models and engineering drawings, confirming that each machined part, whether a newly manufactured replacement or a precisely restored salvage component, adheres strictly to the required tolerances. This level of scrutiny is vital for ensuring parts function correctly within complex vehicle systems upon reinstallation.

The table below details our standard achievable tolerance capabilities, reflecting the precision achievable across typical production runs for automotive applications. Specific tolerances for individual features are always confirmed during the engineering review phase based on part geometry, material, and functional requirements.

| Feature Type | Standard Tolerance | Typical Machining Tolerance | Tight Tolerance Capability |

|---|---|---|---|

| Linear Dimensions | ±0.100 mm | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.075 mm | ±0.015 mm | ±0.003 mm |

| Positional Tolerance | ±0.100 mm | ±0.025 mm | ±0.008 mm |

| Flatness | 0.100 mm | 0.025 mm | 0.005 mm |

| Surface Roughness (Ra) | 3.2 µm | 1.6 µm | 0.4 µm |

This combination of advanced 5-axis CNC manufacturing and uncompromising CMM-based quality control provides Pick Your Part Durham and similar automotive recyclers with a definitive solution for producing or certifying components that meet the exacting demands of today’s vehicles. Wuxi Lead ensures dimensional integrity is never compromised, directly supporting your ability to supply reliable, high-performance parts to the aftermarket. Our precision engineering translates directly into reduced warranty claims and enhanced customer confidence in your offerings.

Material & Finish Options

Material selection is a foundational step in precision metal manufacturing, directly influencing the performance, durability, and cost-efficiency of engineered components. For high-performance applications such as automotive, aerospace, and industrial systems, the choice between aluminum, steel, and titanium must align with mechanical requirements, environmental exposure, and production scalability. At Wuxi Lead Precision Machinery, we guide clients through this decision with engineering expertise and advanced processing capabilities, ensuring optimal material-to-application matching.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for components where weight reduction is critical, such as in performance automotive systems or heat dissipation units. The 6061 and 7075 aluminum alloys offer balanced mechanical properties and weldability, making them ideal for structural and load-bearing parts. When enhanced surface durability is required, aluminum can be treated with anodizing—a process that electrochemically forms a protective oxide layer. Type II (sulfuric acid) and Type III (hardcoat) anodizing improve wear resistance, enable color coding, and increase surface hardness up to 60 HRC in select cases.

Steel remains the standard for high-strength, high-wear applications. Alloy steels such as 4140 and 4340 provide exceptional toughness and fatigue resistance, ideal for drivetrain components, shafts, and tooling. Stainless steels, particularly grades 304 and 17-4 PH, offer corrosion resistance and maintain integrity in harsh environments. While steel does not anodize, surface treatments such as passivation, plating, and nitriding are employed to enhance longevity and performance. Steel’s versatility and cost-effectiveness make it a go-to choice for mission-critical mechanical systems.

Titanium, especially Grade 5 (Ti-6Al-4V), delivers outstanding strength-to-density performance and exceptional resistance to high temperatures and corrosive media. It is commonly used in aerospace and motorsport applications where extreme reliability under stress is non-negotiable. Though more challenging to machine and higher in cost, titanium’s longevity and performance in aggressive environments justify its use in premium engineering contexts. Surface treatments for titanium typically include acid etching or thermal oxidation, as it does not respond to anodizing in the same manner as aluminum.

Below is a comparative overview of key material properties to support informed selection.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Anodizing, Powder Coating | Brackets, Housings, Heat Sinks |

| Steel 4140 | 7.85 | 655 | Moderate | Nitriding, Zinc Plating | Shafts, Fasteners, Tooling |

| Stainless 17-4PH | 7.75 | 1000 | High | Passivation, Electropolish | Valves, Aerospace Components |

| Titanium Ti-6Al-4V | 4.43 | 950 | Very High | Thermal Oxidation, Etching | Engine Components, Racing Parts |

At Wuxi Lead Precision Machinery, we support material selection with in-house testing, prototyping, and full-scale production, ensuring every component meets exacting standards. By combining material science with precision CNC manufacturing, we deliver solutions engineered for performance and reliability.

Manufacturing Process & QC

Precision Manufacturing Process for Automotive Components

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for Pick Your Part Durham car parts, ensuring absolute compliance with automotive industry demands. Our methodology transforms conceptual designs into flawless, high-volume metal components through three integrated phases, all operating under our Zero Defects mandate certified to IATF 16949 standards.

The Design phase begins with collaborative engineering analysis. Our team dissects your CAD models and technical specifications, conducting comprehensive manufacturability reviews and tolerance stack-up analysis. We utilize advanced simulation software to predict material behavior under stress and thermal loads, identifying potential weaknesses before metal is cut. This digital twin validation ensures the design not only meets functional requirements but is optimized for efficient, repeatable CNC machining. Critical dimensions and geometric tolerances are locked down in alignment with ASME Y14.5 standards, forming the immutable baseline for all subsequent stages.

Prototyping transitions the validated design into physical reality under full production conditions. We machine initial samples using the exact alloys, tooling, and CNC programs designated for mass production. Each prototype undergoes exhaustive metrology: coordinate measuring machines (CMM) verify dimensional accuracy against the master CAD file, while surface profilometers confirm critical finish requirements. Material certifications and destructive testing reports are provided. This phase is not merely validation; it is the final stress test of the entire process flow, eliminating latent errors before committing to volume.

Mass Production deploys the perfected process with relentless quality vigilance. Our automated CNC cells operate under real-time statistical process control (SPC), continuously monitoring key parameters like tool wear and dimensional drift. Every component undergoes 100% critical feature inspection via automated vision systems or precision gauging at defined process checkpoints. Non-critical features are verified through rigorous sampling plans exceeding AQL 0.65. Final inspection includes comprehensive CMM reports for batch traceability and material verification. Any deviation triggers an immediate containment protocol and root cause analysis, ensuring non-conforming parts never leave our facility. This closed-loop system guarantees consistent output meeting the most stringent automotive safety and performance criteria.

Our core production capabilities supporting this workflow are detailed below:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Materials | Aluminum Alloys, Steel Alloys, Stainless Steel, Brass, Titanium | ASTM, SAE, EN |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ISO 2768-m, Custom GD&T |

| Surface Finish | Ra 0.4 µm to 3.2 µm (16 to 125 µin) | ISO 1302, Customer Specs |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) | – |

| Process Control | Real-time SPC, Full CMM Traceability | IATF 16949, PPAP Level 3 |

This disciplined progression from Design through Prototyping to Mass Production, underpinned by our Zero Defects culture and advanced metrology, delivers the consistent precision Pick Your Part Durham requires for critical automotive applications. We transform engineering intent into reliable, high-integrity metal components, mitigating your supply chain risk.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

In the competitive landscape of automotive component supply, precision, reliability, and responsiveness define success. For businesses like Pick Your Part Durham seeking high-performance car parts manufactured to exacting standards, partnering with Wuxi Lead Precision Machinery offers a strategic advantage. Based in China and serving global clients, Lead Precision specializes in custom metal manufacturing for the automotive, industrial, and transportation sectors. Our engineering-first approach ensures every component meets rigorous functional and dimensional requirements—on time, every time.

Our facility integrates advanced CNC machining, sheet metal fabrication, and precision turning with comprehensive quality control systems. From prototype development to high-volume production, we deliver complex metal parts with tight tolerances, superior surface finishes, and full documentation traceability. Whether you require engine brackets, transmission housings, suspension components, or custom fasteners, our team collaborates closely with your engineers to optimize design for manufacturability, reduce lead times, and lower total cost of ownership.

What sets Lead Precision apart is our end-to-end ownership of the manufacturing process. We control every stage—from raw material sourcing and in-house tooling to final inspection and logistics coordination. This vertical integration ensures consistency, faster iteration cycles, and full compliance with international standards including ISO 9001:2015 and IATF 16949. Our quality assurance protocols include first-article inspection reports (FAIR), coordinate measuring machine (CMM) validation, and material certification for every production batch.

We understand that automotive recyclers and suppliers like Pick Your Part Durham require durable, interchangeable parts that meet OEM specifications. Our custom manufacturing solutions are designed to support both direct replacement components and upgraded versions engineered for enhanced performance and longevity. With a responsive project management team fluent in English and backed by real-time production tracking, we ensure transparency and agility throughout the supply chain.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning, multi-tasking |

| Tolerances | ±0.005 mm (±0.0002″) |

| Materials | Aluminum alloys, stainless steel, carbon steel, brass, titanium |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Finishes | Anodizing, powder coating, passivation, plating, polishing |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS compliant |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by volume) |

Partnering with Lead Precision means gaining a manufacturer committed to precision, scalability, and long-term collaboration. We don’t just produce parts—we engineer solutions that drive your business forward.

Contact us today at [email protected] to discuss your custom metal manufacturing needs. Let our team support Pick Your Part Durham with OEM-grade components built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.