Technical Contents

Engineering Guide: China Machining Services

Precision Engineering: The Non-Negotiable Foundation of Advanced Manufacturing

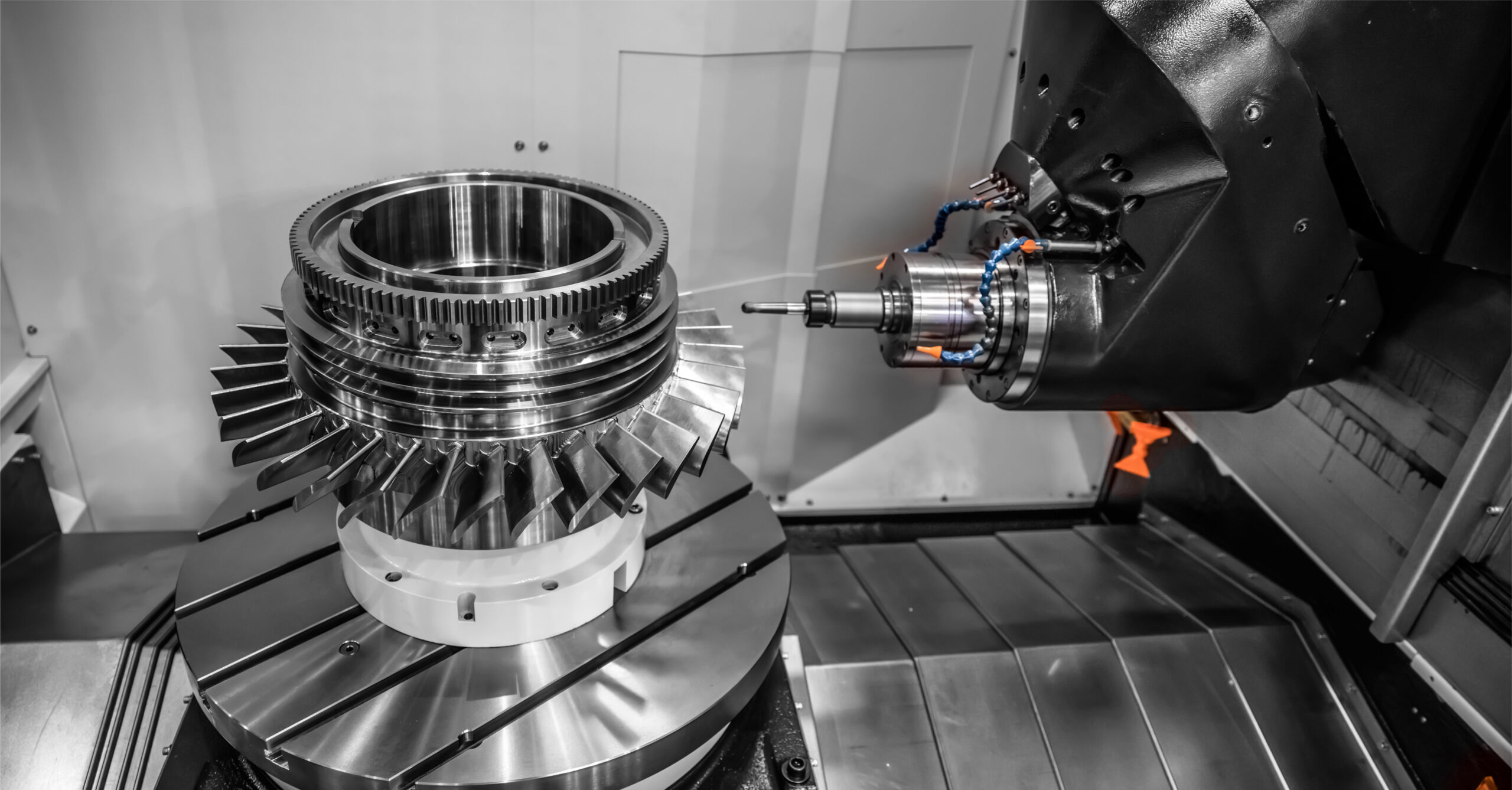

In high-stakes industrial applications, precision machining transcends mere dimensional accuracy; it is the bedrock of system reliability, performance longevity, and operational safety. Tolerances measured in microns directly impact component fatigue life, assembly integrity, and overall system efficiency. Sub-micron deviations in aerospace turbine blades can induce catastrophic harmonic vibrations, while inconsistent thread profiles in hydraulic manifolds lead to critical fluid leaks under pressure. The cost of inadequate precision extends far beyond scrap rates—it manifests in field failures, warranty liabilities, and reputational damage that erodes market position. True precision engineering requires marrying cutting-edge technology with deep metallurgical understanding and process physics, ensuring every micron of tolerance serves a functional purpose within the final assembly.

Wuxi Lead Precision Machinery operates at this critical convergence point. Our engineering discipline is forged through decades of delivering mission-critical components where zero-defect performance is non-negotiable. This includes structural elements for Olympic venue construction demanding flawless load distribution under extreme dynamic stresses, and precision-guided munition components requiring micron-level consistency across thousands of production units for military applications. These projects instilled rigorous protocols: full material traceability from certified mills, real-time in-process metrology with temperature-compensated CMMs, and adaptive machining strategies that account for microstructural anisotropy in exotic alloys. Our facility maintains ISO 9001 and AS9100 certifications not as paperwork exercises, but as operational frameworks ensuring every spindle rotation adheres to the tightest functional requirements.

The tangible output of this methodology is reflected in our capability spectrum. Below is a comparison of industry-standard machining tolerances versus our validated production performance across critical parameters:

| Parameter | Typical Industry Standard | Wuxi Lead Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Tolerance | ±0.025 mm | ±0.003 mm | CMM (ZEISS CONTURA) |

| Geometric Tolerance | ±0.05 mm | ±0.005 mm | Laser Tracker (FARO) |

| Surface Roughness (Ra) | 1.6 µm | 0.2 µm | Profilometer (Mitutoyo) |

| Material Utilization | 65-75% | >88% | Nesting Software Analysis |

This performance stems from our integrated approach: Haas and DMG MORI 5-axis platforms operating within climate-controlled cells, coupled with proprietary vibration-dampening fixture systems. More critically, our engineers apply physics-based simulation to predict thermal drift and tool deflection before the first chip is cut, transforming tolerance stacks from theoretical exercises into guaranteed outcomes. For clients in energy, defense, and advanced robotics, this means components that integrate seamlessly into complex assemblies without costly rework—reducing time-to-market while eliminating field failure risks.

Precision at this level is not purchased; it is co-engineered through transparent collaboration. We partner with your design team during DFM stages to optimize manufacturability without compromising functional intent, turning dimensional challenges into competitive advantages. When your application demands performance where fractions of a micron define success, Wuxi Lead Precision Machinery delivers engineered certainty. Contact our engineering team to discuss how our Olympic-proven precision protocols can secure your next critical project.

Precision Specs & Tolerances

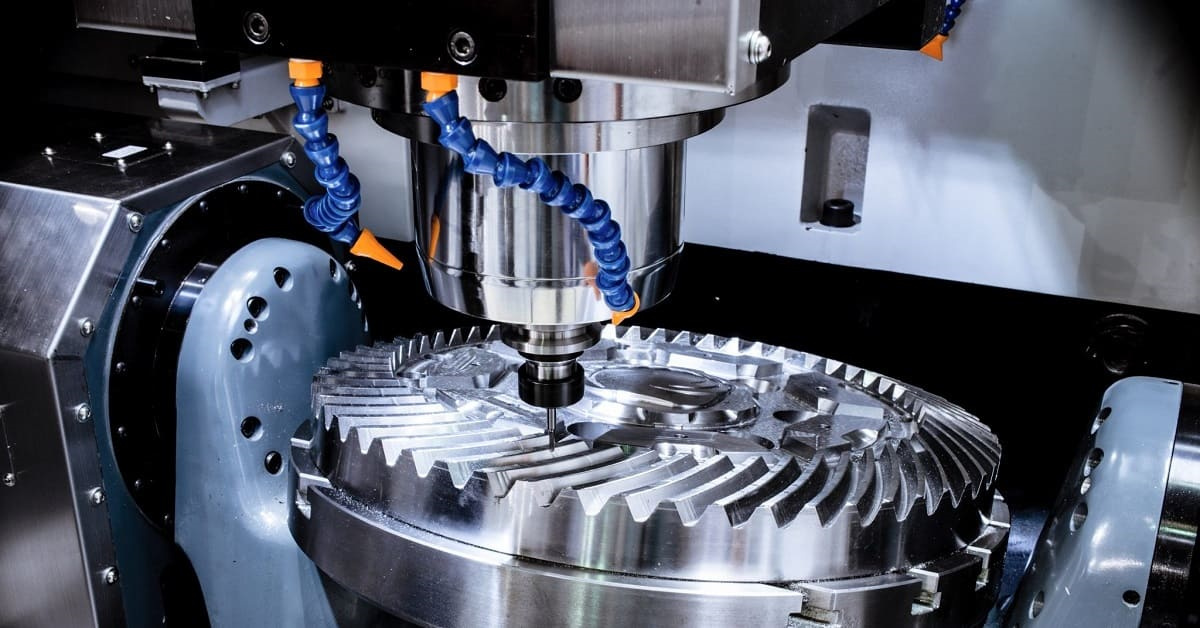

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions through state-of-the-art 5-axis CNC machining technology. Our technical capabilities are engineered to support high-complexity components across aerospace, medical, energy, and industrial automation sectors. With a focus on precision, repeatability, and material efficiency, our 5-axis CNC systems enable the production of intricate geometries that are unattainable with conventional 3-axis platforms. Simultaneous multi-axis motion allows for continuous part orientation, reducing setup cycles and improving dimensional accuracy across complex surfaces.

Our machining centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure optimal performance during extended production runs. We work with a broad range of metals, including aluminum alloys, stainless steel, titanium, Inconel, and specialty brass and bronze materials. The integration of 5-axis technology not only enhances geometric flexibility but also improves surface finish and tool life by maintaining optimal cutting angles throughout the machining process.

Quality control is embedded at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM) to verify compliance with design specifications. Our CMM system operates with sub-micron accuracy, providing full traceability and detailed metrology reports for each production batch. This ensures adherence to international standards such as ISO 9001 and AS9100, particularly in safety-critical applications where consistency and reliability are non-negotiable.

In addition to advanced hardware, our engineering team utilizes integrated CAD/CAM software to simulate toolpaths, optimize machining strategies, and detect potential collisions before physical machining begins. This digital-first approach minimizes errors, accelerates prototyping, and ensures seamless transition from design to final part. We support both low-volume prototypes and high-volume production runs with equal rigor, maintaining consistent quality regardless of order size.

The following table outlines our standard machining tolerances and inspection capabilities:

| Feature | Standard Tolerance | Precision Capability | Measurement Tool |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.02 mm | ±0.01 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | CMM |

| Flatness | 0.02 mm per 100 mm | 0.005 mm per 100 mm | Surface Plate, CMM |

| Surface Roughness | Ra 3.2 μm | Ra 0.4 μm | Profilometer |

| Angular Tolerance | ±0.1° | ±0.05° | CMM, Optical Comparator |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance protocols to deliver components that meet the most demanding engineering requirements. Our technical capabilities are designed to provide customers with a seamless, reliable, and high-precision manufacturing experience—ensuring performance, compliance, and long-term value.

Material & Finish Options

Material Selection Guide for Precision CNC Machining

Selecting the optimal material is critical for balancing performance, manufacturability, and cost in custom metal components. At Wuxi Lead Precision Machinery, we prioritize materials that align with your functional requirements while leveraging our CNC expertise to ensure precision and repeatability. Below we detail key considerations for aluminum, steel, and titanium alloys, along with essential anodizing finishes.

Aluminum Alloys

Aluminum remains the most requested material for aerospace, automotive, and electronics due to its high strength-to-weight ratio, thermal conductivity, and corrosion resistance. 6061-T6 and 7075-T6 are industry standards; 6061 offers excellent weldability and moderate strength for structural frames, while 7075 delivers superior strength for high-stress applications like drone arms or aircraft fittings. Its low density reduces inertia in moving parts, but note that 7075’s zinc content increases machining complexity versus 6061. Aluminum’s softness enables high-speed machining with tight tolerances, though sharp tooling is essential to prevent burring.

Steel Alloys

Steel provides unmatched durability for load-bearing components. We commonly machine 303 stainless (free-machining) for hydraulic fittings and 17-4 PH stainless for aerospace actuators requiring high yield strength and corrosion resistance. Carbon steels like 1018 are cost-effective for non-corrosive environments but require protective finishes. Steel’s toughness demands rigid setups and slower feed rates versus aluminum, particularly with hardened grades. Always specify required hardness; 17-4 PH achieves 40 HRC via heat treatment, enhancing wear resistance but complicating post-machining processes.

Titanium Alloys

Titanium Grade 5 (Ti-6Al-4V) excels in medical implants and aerospace where extreme strength, biocompatibility, and corrosion resistance are non-negotiable. Its low thermal conductivity causes heat buildup during machining, necessitating specialized tooling, lower RPMs, and rigid coolant application to avoid work hardening. While 40% stronger than steel at half the weight, titanium’s cost and machining difficulty require careful justification. Avoid it for non-critical applications where aluminum or steel suffice.

Anodizing Finishes

Anodizing enhances aluminum’s surface properties. Type II (sulfuric acid) anodizing offers standard corrosion and wear resistance with dye options for identification. For critical wear surfaces like pistons or rails, specify Type III (hardcoat) anodizing, which yields a 50–70 µm thick, abrasion-resistant layer up to 60 HRC. Note that hardcoat increases lead time by 2–3 days and requires tighter dimensional allowances due to pore growth. Always confirm coating thickness requirements upfront to avoid rework.

Material Comparison Table

| Property | Aluminum 6061-T6 | Steel 17-4 PH | Titanium Ti-6Al-4V |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 1000 | 900 |

| Density (g/cm³) | 2.7 | 7.8 | 4.4 |

| Corrosion Resistance | Excellent | Excellent | Exceptional |

| Machinability Index | 90% | 55% | 20% |

| Typical Applications | Enclosures, brackets | Valves, shafts | Implants, aerospace |

Material choice directly impacts tool life, cycle time, and final part cost. Consult our engineering team early to optimize your design for manufacturability—whether selecting 6061 for rapid prototyping or titanium for mission-critical components. We provide material certification and in-process inspections to ensure compliance with ASTM/AMS standards.

Manufacturing Process & QC

Design: The Foundation of Precision Manufacturing

At Wuxi Lead Precision Machinery, the manufacturing journey begins with engineering excellence during the design phase. We collaborate closely with clients to translate concepts into manufacturable, high-precision metal components. Our team of senior CNC engineers and design analysts review 3D CAD models for structural integrity, material suitability, and manufacturability. Utilizing advanced simulation software, we perform tolerance analysis, thermal stress modeling, and toolpath optimization to preempt potential flaws. This proactive engineering approach ensures that every design is not only functional but optimized for repeatable accuracy in production. All design data is version-controlled and documented to meet ISO 9001 standards, forming a traceable foundation for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to precision prototyping—our critical validation step. Using state-of-the-art 5-axis CNC machining, wire EDM, and selective laser melting (SLM) for metal additive needs, we produce functional prototypes in the actual production-grade materials. These prototypes undergo rigorous in-house testing, including CMM inspection, surface roughness analysis, and dimensional verification against CAD models. We conduct fit, form, and function checks, often under simulated operational conditions, to ensure performance compliance. Client feedback is integrated at this stage, allowing for design refinements without impacting the production timeline. This iterative prototyping process reduces risk, confirms design intent, and certifies process readiness—ensuring that mass production begins with full confidence in quality and accuracy.

Mass Production: Engineered for Zero Defects

With design and prototype approval, Wuxi Lead transitions seamlessly into high-volume manufacturing. Our production floor operates under strict process controls, with every CNC machine calibrated daily and monitored in real time using IoT-enabled sensors. We implement Statistical Process Control (SPC) to track critical dimensions and detect deviations before they affect output. Each component passes through automated inspection stations, including vision systems and coordinate measuring machines, ensuring 100% inspection on key features. Our lean manufacturing system minimizes waste and variation, while our traceability protocols log material batches, machine parameters, and operator data for every part produced. The result is consistent, high-yield production with zero-defect performance across runs of any scale.

Production Capabilities Overview

| Parameter | Specification |

|---|---|

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Tolerances | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm, customizable |

| Max Part Size | 1200 x 800 x 600 mm |

| Production Capacity | 50,000+ units/month |

| Key Equipment | 5-Axis CNC, CNC Turning, Wire EDM, CMM, SPC Systems |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP |

From concept to mass production, Wuxi Lead Precision Machinery delivers uncompromising quality through integrated engineering, precision prototyping, and disciplined manufacturing execution.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Manufacturing Excellence

In the high-stakes arena of custom metal manufacturing, your component quality directly impacts product performance, regulatory compliance, and market reputation. Wuxi Lead Precision Machinery stands as your strategic engineering partner, merging 15+ years of precision CNC expertise with rigorous quality systems to eliminate production risks. We specialize in mission-critical components for aerospace, medical device, and semiconductor sectors where tolerances below ±0.0002″ and zero-defect delivery are non-negotiable. Unlike commodity suppliers, we deploy dedicated engineering teams to co-develop solutions that optimize material yield, reduce assembly failures, and accelerate time-to-market—transforming complex design challenges into certified, production-ready outcomes.

Our integrated facility in Wuxi, China, operates under AS9100D and ISO 13485 certifications, ensuring every process—from raw material sourcing to final inspection—adheres to Tier 1 OEM standards. We invest in cutting-edge 5-axis milling, Swiss turning, and multi-tasking centers to handle exotic alloys like Inconel 718, Titanium Grade 5, and MP35N with sub-micron repeatability. This technical foundation, combined with our proprietary process validation protocols, guarantees dimensional stability across batches, eliminating costly rework and supply chain disruptions.

Critical capabilities driving your ROI include:

| Specification | Capability | Why It Matters for Your Project |

|---|---|---|

| Tolerance Control | ±0.0002″ (5µm) | Ensures seamless assembly in high-precision systems |

| Material Range | Titanium, Inconel, Hastelloy, PEEK | Supports extreme environment applications |

| Max Work Envelope | 1,200 x 800 x 600 mm | Accommodates complex monolithic structures |

| Lead Time | 15-25 days (complex prototypes) | Cuts development cycles by 30% vs. industry average |

| Quality Documentation | Full PPAP, FAI, CMM reports | Meets aerospace/medical audit requirements |

When you engage Lead Precision, you gain more than a vendor—you secure an engineering extension of your team. Our project managers initiate every collaboration with a Design for Manufacturability (DFM) review, identifying cost-saving opportunities without sacrificing integrity. We maintain real-time digital traceability from CAD model to shipped part, providing transparent access to inspection data and production milestones. This proactive approach has reduced client scrap rates by up to 40% while ensuring on-time delivery exceeding 98.7%.

The cost of inadequate manufacturing extends far beyond unit pricing—it risks recalls, delays, and brand erosion. Partner with an organization engineered to protect your most critical programs. Contact our engineering team today at [email protected] to schedule a confidential technical review. Include your project specifications and timeline, and we will deliver a detailed capability assessment within 24 business hours—including material optimization recommendations and a validated production schedule. Let Lead Precision become the unshakable foundation of your supply chain.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.