Technical Contents

Engineering Guide: 4140 Steel Sheet

Engineering Insight: 4140 Steel Sheet – The Role of Precision in High-Performance Manufacturing

In the realm of custom metal manufacturing, few materials command the respect and versatility of 4140 steel sheet. Known for its balanced combination of strength, toughness, and hardenability, 4140 alloy steel is a mainstay in critical applications across aerospace, defense, oil and gas, and high-performance automotive industries. However, the true potential of 4140 steel is only fully realized through precision engineering and exacting manufacturing control. At Wuxi Lead Precision Machinery, we understand that material excellence must be paired with process mastery to deliver components that meet the most stringent operational demands.

4140 steel, a chromium-molybdenum alloy, offers superior wear resistance and fatigue strength when properly heat-treated. Its ability to be quenched and tempered to high tensile strengths makes it ideal for structural and load-bearing applications. Yet, this same responsiveness to thermal processing demands absolute consistency in machining, forming, and finishing. Even minor deviations in tolerances or heat treatment parameters can result in part failure under stress, particularly in mission-critical environments.

This is where precision becomes non-negotiable. At Lead Precision, our CNC machining centers operate within micron-level tolerances, ensuring dimensional accuracy across complex geometries. Our thermal processing protocols are calibrated to ASTM and MIL-STD standards, guaranteeing uniform microstructure and mechanical properties. Whether producing custom 4140 steel sheets for structural chassis in military vehicles or high-integrity components for Olympic-grade sporting equipment, our process control ensures repeatability and reliability.

Our experience in delivering precision parts for Olympic and military-grade applications underscores our commitment to excellence. These projects demand not only adherence to specifications but also rigorous documentation, traceability, and quality assurance. Every 4140 steel component we produce undergoes comprehensive inspection, including ultrasonic testing and hardness profiling, to validate performance under real-world loads.

The following table outlines key mechanical and physical properties of normalized and heat-treated 4140 steel sheet, typical of the material forms we process:

| Property | Condition | Value |

|---|---|---|

| Tensile Strength | Annealed | 655 MPa (95 ksi) |

| Yield Strength | Annealed | 415 MPa (60 ksi) |

| Hardness (HRC) | Quenched & Tempered | 28–32 |

| Elongation at Break | Annealed | 25.7% |

| Density | — | 7.85 g/cm³ |

| Modulus of Elasticity | — | 205 GPa (29.7×10⁶ psi) |

| Machinability Rating | Annealed | 65% (relative to AISI 1212) |

At Wuxi Lead Precision Machinery, we do not merely fabricate 4140 steel sheets—we engineer performance. Our integration of advanced CNC technology, decades of metallurgical expertise, and a proven track record in high-stakes manufacturing ensures that every component meets the highest standards of precision and durability. When failure is not an option, our clients trust Lead Precision to deliver.

Precision Specs & Tolerances

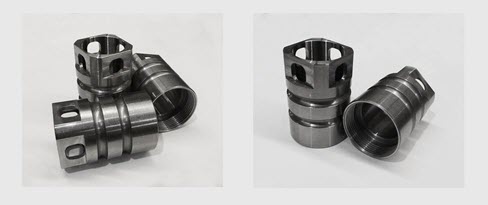

Precision Manufacturing of 4140 Steel Sheet Components

Wuxi Lead Precision Machinery delivers uncompromising quality for critical 4140 chromium-molybdenum alloy steel sheet applications. Our technical capabilities address the inherent challenges of machining this high-strength, heat-treatable material, which demands exceptional control over thermal stability, residual stress, and dimensional repeatability. 4140 steel’s superior fatigue resistance and toughness make it indispensable for aerospace landing gear, defense components, and heavy industrial tooling, yet its machinability requires specialized expertise to prevent distortion and maintain tight tolerances post-heat treatment.

Our dedicated 5-axis CNC machining centers form the core of this capability. Utilizing DMG MORI CTX beta 2500 and Makino D200Z platforms, we achieve complex geometries in a single setup, minimizing handling-induced errors and ensuring optimal part alignment. These machines feature high-torque spindles, rigid cast-iron bases, and integrated thermal compensation systems critical for maintaining accuracy during extended 4140 machining cycles. Advanced toolpath strategies, including high-efficiency roughing and finish milling with polycrystalline diamond (PCD) tooling, mitigate work hardening while optimizing surface integrity. All processes adhere to strict material traceability protocols, with full lot certification and documented heat treatment verification prior to machining.

Quality assurance is non-negotiable. Every 4140 steel component undergoes comprehensive inspection via our Hexagon Leitz PMM-C 5-axis Coordinate Measuring Machine (CMM), calibrated to ISO 10360-2 standards. This system provides micron-level verification of critical features, including true position, profile, and geometric dimensioning and tolerancing (GD&T) callouts. Statistical process control (SPC) data is generated for every batch, enabling real-time adjustments and full traceability from raw material to final shipment. Our AS9100-certified quality management system ensures compliance with aerospace and defense sector requirements, with inspection reports detailing material certification, heat treatment parameters, and CMM results available upon request.

The following table details achievable tolerances for machined 4140 steel sheet components under controlled production conditions:

| Tolerance Type | Specification | Measurement Standard |

|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | ISO 2768-mK |

| Angular Features | ±0.001° | ISO 1101 |

| Surface Roughness | Ra 0.4 μm (16 μin) | ISO 1302 |

| Geometric Form (Flatness) | 0.010 mm per 100 mm | ISO 1101 |

| Positional Accuracy | ±0.008 mm (±0.0003″) | ASME Y14.5 |

Notes: Specifications assume stress-relieved material with uniform hardness (28-32 HRC). Tolerances may require adjustment based on part geometry complexity, feature aspect ratios, and customer-specified heat treatment sequencing. All values validated per CMM inspection with 95% confidence interval.

This integrated approach—combining advanced 5-axis machining, rigorous material science protocols, and metrology-grade validation—ensures that 4140 steel components meet the exacting demands of high-stress applications. We mitigate downstream assembly issues and extend component service life by controlling variables often overlooked in conventional manufacturing. Partner with Wuxi Lead to transform 4140 steel sheet into mission-critical parts where precision directly correlates with operational safety and longevity.

Material & Finish Options

Material Selection Guide: 4140 Steel, Aluminum, Titanium, and Surface Finishes

When selecting materials for precision manufacturing applications, understanding the mechanical properties, environmental resistance, and machinability of each option is critical. At Wuxi Lead Precision Machinery, we specialize in custom metal components using high-performance materials such as 4140 steel, aluminum alloys, and titanium. Each material offers distinct advantages depending on load requirements, operating environments, and cost considerations.

4140 steel is a chromium-molybdenum alloy steel known for its high strength, toughness, and excellent fatigue resistance. It is commonly used in aerospace, automotive, and heavy machinery applications where durability under stress is essential. In sheet form, 4140 steel can be precision machined, heat treated to achieve hardness levels between 28–32 HRC, and welded with proper pre- and post-weld heat treatments. Its moderate carbon content allows for good response to heat treatment while maintaining dimensional stability during machining.

Aluminum alloys, particularly 6061 and 7075, offer a high strength-to-weight ratio, making them ideal for lightweight structural components. They exhibit excellent corrosion resistance and are easily machined, making them suitable for high-volume production. However, aluminum lacks the wear resistance and hardness of 4140 steel, which limits its use in high-load or abrasive environments.

Titanium, especially Grade 5 (Ti-6Al-4V), provides exceptional strength-to-density ratio and outstanding resistance to corrosion, particularly in marine and chemical environments. While more expensive and challenging to machine than steel or aluminum, titanium is preferred in aerospace and medical applications where performance outweighs cost.

Surface finish selection further enhances material performance. Anodizing, primarily used for aluminum, creates a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. While 4140 steel cannot be anodized, alternative surface treatments such as zinc plating, black oxide, or nitriding improve wear and corrosion resistance. These finishes are selected based on environmental exposure and functional requirements.

Understanding the balance between mechanical performance, manufacturability, and cost ensures optimal part longevity and system efficiency. At Wuxi Lead, we support clients in selecting the right material and finish combination for mission-critical components.

Mechanical Properties Comparison

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HRC) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| 4140 Steel | 950–1200 | 750–900 | 28–32 | 7.85 | Shafts, gears, tooling |

| Aluminum 6061 | 310 | 275 | 15–20 | 2.70 | Enclosures, brackets |

| Aluminum 7075 | 570 | 505 | 18–22 | 2.81 | Aerospace structures |

| Titanium Ti-6Al-4V | 900–1000 | 830–860 | 36–40 | 4.43 | Aircraft components, implants |

Manufacturing Process & QC

Precision Manufacturing Process for 4140 Alloy Steel Components

Wuxi Lead Precision Machinery delivers zero-defect 4140 alloy steel components through a rigorously controlled three-phase production system. It is critical to note that 4140 is predominantly supplied as bar stock or plate; true “sheet” form is exceptionally rare due to the alloy’s hardenability and typical section size requirements for structural applications. Our process begins with comprehensive engineering design. Utilizing advanced CAD/CAM software, our engineers develop precise 3D models incorporating critical features, tolerances, and material specifications. Finite Element Analysis (FEA) validates structural integrity under operational loads, while CAM programming optimizes toolpaths for minimal stress induction during machining. This phase includes meticulous review of heat treatment requirements, as 4140’s performance hinges on proper quenching and tempering to achieve target mechanical properties without distortion.

Subsequently, we execute a fully documented prototyping stage. A single component is manufactured using the finalized CNC programs on our high-rigidity machining centers, replicating the exact mass production environment. This prototype undergoes stringent dimensional verification via CMM and surface finish analysis. Crucially, it is subjected to the specified heat treatment cycle in controlled atmosphere furnaces, followed by comprehensive mechanical testing. Only upon validation of all geometric and material properties against the design intent does the process advance. This stage identifies and eliminates potential flaws in the manufacturing sequence before significant resource commitment.

Mass production leverages our certified ISO 9001:2015 quality management system with embedded zero-defect protocols. All 4140 material receives full mill certification verification upon receipt. Machining occurs on state-of-the-art CNC lathes and mills with real-time tool wear monitoring and in-process gauging. Heat treatment employs precisely calibrated furnaces with continuous atmosphere control to prevent decarburization, followed by mandatory stress relief where specified. Every component undergoes 100% dimensional inspection at critical features using automated optical comparators alongside periodic CMM spot checks. Statistical Process Control (SPC) charts track key parameters, enabling immediate corrective action. Final release requires documented conformance to all specifications, including non-destructive testing if mandated.

The critical mechanical properties achieved for properly processed 4140 alloy steel are:

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | 655 – 1000 MPa | ASTM A370 |

| Yield Strength (0.2%) | 415 – 850 MPa | ASTM A370 |

| Hardness (As Quenched & Tempered) | 24 – 36 HRC | ASTM E18 |

| Heat Treatment | Quench & Temper | ASTM A890 |

| CNC Machining Tolerance | ±0.005 mm (Typical) | ISO 2768-m |

This integrated approach, from validated design through prototype verification to statistically controlled mass production, ensures consistent delivery of 4140 components meeting the most demanding aerospace, automotive, and industrial performance criteria. Wuxi Lead’s commitment to process discipline eliminates latent defects, guaranteeing reliability and extended service life for your critical applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in 4140 Steel Sheet Fabrication

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision manufacturing solutions tailored to the demanding requirements of modern industrial applications. When working with 4140 steel sheet—a high-strength, low-alloy material known for its excellent toughness, wear resistance, and fatigue strength—precision, consistency, and technical mastery are non-negotiable. Our facility in Wuxi, China, is equipped with advanced CNC machining centers, laser cutting systems, and heat treatment capabilities, enabling us to produce complex components with tight tolerances and repeatable accuracy.

We understand that sourcing reliable 4140 steel sheet components is not just about cutting metal—it’s about ensuring material integrity, dimensional stability, and long-term performance under stress. That’s why our engineering team collaborates closely with clients from design through delivery, offering DFM (Design for Manufacturability) analysis, material certification, and in-process quality inspections. Whether you require prototype development or high-volume production runs, our integrated manufacturing ecosystem ensures faster lead times, reduced waste, and superior part quality.

Our commitment to excellence is reflected in every stage of production. From controlled atmosphere heat treatment to achieve precise hardness levels, to precision grinding and finishing operations, we maintain full traceability and compliance with international standards. We serve industries where failure is not an option—oil and gas, aerospace, heavy machinery, and automation—delivering components that perform reliably in extreme environments.

Below are key technical specifications we support for 4140 steel sheet processing:

| Specification | Capability |

|---|---|

| Material Grade | AISI 4140, 42CrMo4, SCM440 |

| Thickness Range | 3 mm – 150 mm |

| Tolerance (Machined) | ±0.02 mm |

| Surface Finish (Typical) | Ra 0.8 – 3.2 μm |

| Heat Treatment Options | Quenching & Tempering, Normalizing, Annealing |

| Hardness Range | 28 – 55 HRC (adjustable per requirement) |

| Maximum Part Dimensions | 2000 mm × 1000 mm × 800 mm |

| Certifications | ISO 9001:2015, Material Test Reports (MTR), PPAP, FAI |

We do not just manufacture parts—we engineer performance. At Wuxi Lead Precision Machinery, your project benefits from decades of metallurgical expertise, state-of-the-art equipment, and a customer-first approach that prioritizes reliability and responsiveness.

To discuss your 4140 steel sheet fabrication needs, contact us today at [email protected]. Our engineering team is ready to support your next high-performance application with precision, speed, and confidence. Partner with Lead Precision—where advanced manufacturing meets industrial excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.