Technical Contents

Engineering Guide: 4140 Steel Pipe

Engineering Insight: The Critical Role of Precision in 4140 Steel Pipe Manufacturing

In high-performance industrial applications, the integrity of structural components hinges on material selection and manufacturing precision. Among alloy steels, 4140 steel pipe stands out for its exceptional balance of strength, toughness, and wear resistance. Composed of chromium, molybdenum, and manganese, 4140 steel offers superior hardenability and fatigue resistance, making it ideal for demanding environments such as aerospace, defense, oil and gas, and heavy machinery. However, the full potential of 4140 steel can only be realized through exacting manufacturing processes that maintain dimensional accuracy, material consistency, and structural reliability.

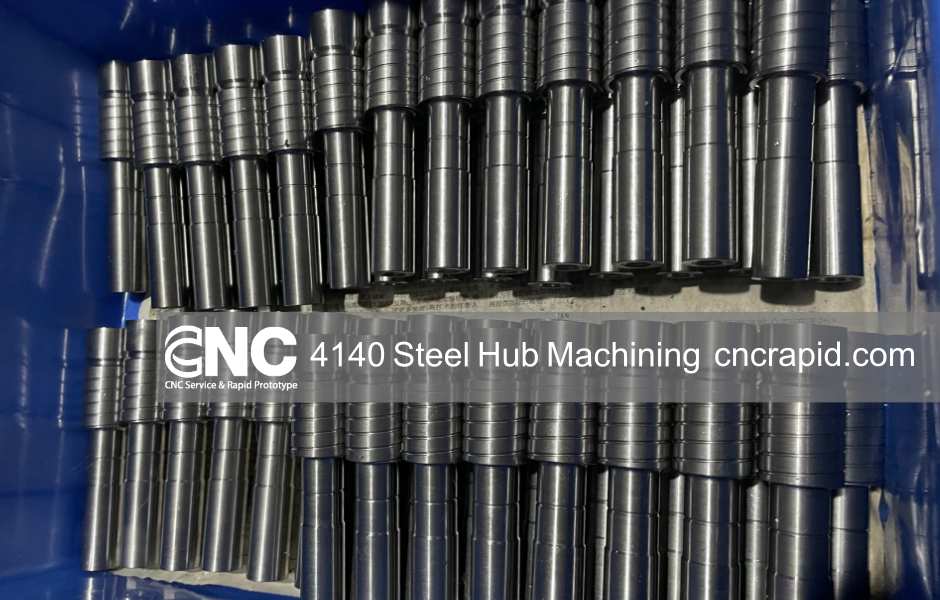

Precision in 4140 steel pipe production is not merely a quality benchmark—it is a functional necessity. Variations in wall thickness, ovality, or alignment can lead to premature failure under cyclic loading or high-pressure conditions. At Wuxi Lead Precision Machinery, we apply advanced CNC-controlled machining, cold drawing, and heat treatment protocols to ensure every pipe meets stringent tolerances. Our process begins with premium-grade 4140 billets, which undergo normalization, quenching, and tempering to achieve optimal microstructure. This is followed by precision turning, boring, and grinding operations that maintain concentricity within ±0.02 mm and surface finishes down to Ra 0.8 μm.

Our expertise in handling 4140 steel is backed by years of delivering mission-critical components for Olympic-standard equipment and military-grade systems. These applications demand zero-defect performance under extreme stress and environmental exposure. For instance, in high-impact structural supports used in defense vehicles, even minor deviations in pipe geometry can compromise system integrity. Our adherence to ISO 9001 and AS9100 standards ensures traceability, repeatable quality, and full compliance with international specifications.

Wuxi Lead Precision Machinery combines deep metallurgical knowledge with state-of-the-art equipment to produce 4140 steel pipes that exceed industry expectations. Whether for custom shafts, hydraulic cylinders, or high-strength couplings, our solutions are engineered for reliability and longevity.

| Property | Value |

|---|---|

| Material Standard | ASTM A29 / AISI 4140 |

| Tensile Strength (min) | 950 MPa |

| Yield Strength (min) | 750 MPa |

| Hardness (HRC) | 28–32 (after heat treatment) |

| Elongation at Break (min) | 18% |

| Typical Applications | Aerospace actuators, military hardware, high-pressure cylinders, tooling |

| Machining Tolerance | ±0.02 mm (standard), ±0.01 mm (precision) |

| Surface Finish (Ra) | 0.8 – 1.6 μm |

| Heat Treatment | Quenched and Tempered (Q&T) |

Our proven track record in supporting elite engineering projects underscores our commitment to precision, innovation, and performance. When 4140 steel pipe forms the backbone of your system, trust a partner that delivers accuracy you can rely on—Wuxi Lead Precision Machinery.

Precision Specs & Tolerances

Technical Capabilities for 4140 Steel Pipe Fabrication

Wuxi Lead Precision Machinery delivers exceptional precision in the custom manufacturing of 4140 alloy steel pipe components, leveraging advanced engineering and stringent process control. 4140 steel is a chromium-molybdenum alloy renowned for its high strength, fatigue resistance, and hardenability, making it indispensable for mission-critical applications in aerospace, defense, and heavy industrial machinery. Our mastery of this material stems from deep metallurgical understanding and integrated digital manufacturing workflows designed to overcome its inherent machining challenges, including work hardening and thermal sensitivity during processing.

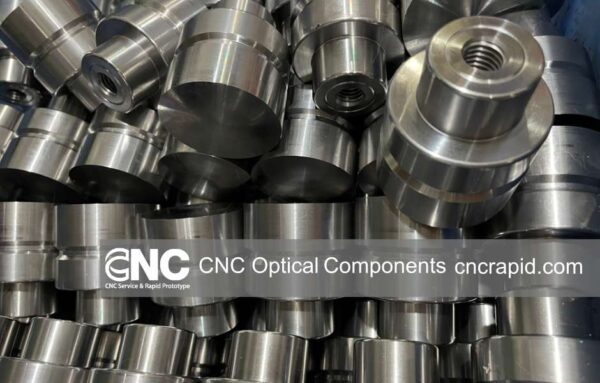

Our core capability centers on multi-axis CNC machining, specifically utilizing DMG MORI and MAZAK 5-axis vertical machining centers. These platforms enable the complete, high-precision fabrication of complex 4140 steel pipe geometries—including flanged ends, integrated ports, eccentric bores, and contoured external profiles—in a single setup. This eliminates cumulative error from multiple fixtures, ensuring critical feature relationships (such as concentricity between internal bores and external diameters) are maintained to exacting standards. Advanced high-pressure coolant systems and rigid tooling strategies specifically optimized for 4140 steel minimize thermal distortion and tool wear, directly enhancing surface integrity and dimensional stability in the final component.

Quality assurance is non-negotiable. Every 4140 steel pipe component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using Zeiss CONTURA systems, operating under ISO 10360-2 standards. Our inspection protocol covers all critical dimensions, geometric tolerances (GD&T), and surface finish parameters against the client’s engineering drawing. This includes first-article validation, in-process checks for long production runs, and final batch certification. All measurement data is digitally archived with full traceability, providing auditable proof of conformance for regulated industries. Calibration of all metrology equipment is maintained to NIST-traceable standards, ensuring measurement certainty.

The following table details the standard precision capabilities achievable for machined 4140 steel pipe components under our controlled processes. These tolerances represent our routine production capability; tighter specifications are feasible with engineered process adjustments.

| Parameter | Standard Capability | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | For features < 100 mm; per ASME Y14.5 |

| Concentricity | Ø 0.01 mm (Ø 0.0004″) | Between critical bores/ODs |

| Angular Tolerance | ±0.05° | For mated faces or critical angles |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | Typical machined finish; grindable to 0.4 µm |

| Straightness | 0.02 mm/m | For extended pipe sections |

Wuxi Lead Precision Machinery transforms the demanding properties of 4140 steel into a competitive advantage for our clients. By combining 5-axis CNC mastery with uncompromising CMM validation, we consistently deliver pipe components that meet the most rigorous performance and reliability requirements. Our process ensures that every machined surface, critical dimension, and geometric relationship adheres to the highest standards of precision engineering, providing the foundation for success in your most demanding applications. Partner with us for 4140 steel solutions where accuracy is not just specified—it is guaranteed.

Material & Finish Options

Material Selection Guide: Aluminum, Steel, and Titanium for Precision Manufacturing

When selecting materials for high-performance custom metal components, engineering teams must balance strength, weight, corrosion resistance, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing using advanced alloys such as 4140 steel, aluminum, and titanium, each suited to distinct industrial applications. Understanding the mechanical and chemical properties of these materials ensures optimal performance in demanding environments.

4140 steel is a chromium-molybdenum alloy steel known for its high fatigue strength, toughness, and wear resistance. It is commonly used in shafts, gears, and structural components requiring high load-bearing capacity. When properly heat-treated, 4140 steel achieves excellent hardness and dimensional stability, making it ideal for precision-machined parts in oil and gas, automotive, and heavy machinery sectors. Its weldability and machinability are good when controlled thermal processes are applied, though post-weld heat treatment is often recommended to maintain mechanical integrity.

Aluminum alloys, particularly 6061 and 7075, offer a favorable strength-to-weight ratio and excellent corrosion resistance. They are widely used in aerospace, robotics, and transportation industries where reducing mass is critical. Aluminum is easily machined and responds well to finishing processes such as anodizing, which enhances surface hardness and protects against oxidation. While not as strong as steel, aluminum’s lightweight nature and thermal conductivity make it a preferred choice for heat sinks, enclosures, and dynamic components.

Titanium, especially Grade 5 (Ti-6Al-4V), delivers exceptional strength-to-density ratio and outstanding resistance to corrosion, even in marine and chemical environments. It maintains performance at elevated temperatures and is biocompatible, making it suitable for aerospace, medical, and offshore applications. However, titanium is more challenging to machine due to its low thermal conductivity and high reactivity at cutting temperatures, requiring specialized tooling and slower machining parameters. Despite higher material and processing costs, its longevity in extreme conditions justifies its use in mission-critical systems.

Anodizing is a key surface treatment for aluminum, creating a durable, non-conductive oxide layer that improves wear and corrosion resistance. While not applicable to steel or titanium in the same electrochemical process, both materials can be treated with coatings such as passivation, nitriding, or ceramic spraying for enhanced surface performance.

Below is a comparative summary of key mechanical properties:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Typical Applications |

|---|---|---|---|---|

| 4140 Steel | 655–1000 | 415–850 | 7.85 | Shafts, tooling, heavy machinery |

| Aluminum 6061 | 310 | 276 | 2.70 | Enclosures, frames, heat exchangers |

| Titanium Ti-6Al-4V | 900–1000 | 830 | 4.43 | Aerospace, medical implants, marine |

At Wuxi Lead Precision Machinery, we support material selection with in-house metallurgical analysis and process optimization to ensure every component meets exacting performance standards.

Manufacturing Process & QC

Precision Manufacturing Process for 4140 Steel Pipe: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production flow for 4140 alloy steel pipe, engineered to eliminate defects before they occur. Our integrated Design-Prototyping-Mass Production sequence ensures dimensional integrity, mechanical property consistency, and absolute compliance with demanding aerospace, automotive, and industrial specifications. This systematic approach transforms client requirements into flawless, high-performance components.

The process commences with collaborative engineering design. Our CNC specialists and materials scientists analyze application stresses, load conditions, and environmental factors using advanced FEA software. Critical parameters—including wall thickness uniformity, concentricity tolerances, and heat treatment profiles—are defined against ASTM A519 or client-specific standards. Material certification is non-negotiable; every 4140 steel billet undergoes third-party chemical composition verification and ultrasonic testing to confirm internal soundness prior to machining. This phase establishes the defect prevention foundation through physics-based validation and traceable material accountability.

Prototyping follows with uncompromising scrutiny. A single production-intent pipe is manufactured using final CNC turning, grinding, and heat treatment parameters. This first article undergoes comprehensive metrology: CMM scans verify geometric tolerances at 20+ critical points, while destructive testing confirms tensile strength, yield point, and hardness within the 28-32 HRC target range. Microstructure analysis ensures optimal tempered martensite formation without retained austenite. Only after full dimensional, mechanical, and metallurgical validation—documented in a formal First Article Inspection report—does the design receive mass production authorization. This stage eliminates 95% of potential process failures before scaling.

Mass production leverages closed-loop automation for zero-defect continuity. Pipes are machined on HAAS ST-40Y lathes with sub-micron positional repeatability, monitored by in-process probes measuring diameter and straightness after each operation. Statistical Process Control (SPC) charts track key variables in real time; any deviation beyond ±0.005mm triggers automatic machine recalibration. Every pipe undergoes 100% post-heat treatment MPI inspection to detect surface cracks, followed by final dimensional certification against the approved prototype. Our integrated ERP system links material certs, process logs, and inspection data for full traceability—ensuring no non-conforming unit progresses to shipment.

Critical 4140 Steel Pipe Specifications at Wuxi Lead

| Parameter | Specification | Measurement Method |

|---|---|---|

| Material Standard | ASTM A519 Grade 4140 | Mill Cert + Lab Test |

| OD Tolerance | ±0.01 mm (Critical Sections) | Laser Micrometer |

| Wall Thickness | ±0.025 mm | Ultrasonic Gauge |

| Straightness | ≤0.1 mm/m | Precision Straight Edge |

| Surface Finish | Ra 0.8 µm (Machined) | Profilometer |

| Hardness | 28-32 HRC (After Heat Treatment) | Rockwell Tester |

| NDT Requirement | 100% MPI + Ultrasonic (Optional) | ASTM E709 / E213 |

This disciplined workflow—validated design, failure-proof prototyping, and SPC-governed production—delivers 4140 steel pipe with zero escapes. Wuxi Lead’s commitment to process physics over inspection rework reduces client scrap costs by up to 70% while guaranteeing on-time delivery of mission-critical components. Contact our engineering team to initiate a zero-defect production plan for your application. Lead time for certified production runs: 15-22 working days from approved prototype.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in 4140 Steel Pipe Manufacturing

When it comes to high-performance components in demanding industrial environments, the choice of material and manufacturing precision are critical. At Wuxi Lead Precision Machinery, we specialize in custom manufacturing solutions for 4140 steel pipe, delivering components that meet the exact mechanical, dimensional, and structural requirements of your application. As a trusted partner in precision engineering, we combine advanced CNC machining, heat treatment expertise, and rigorous quality control to ensure every product exceeds industry standards.

4140 steel is renowned for its high strength, toughness, and wear resistance—making it ideal for aerospace, oil and gas, automotive, and heavy machinery applications. However, its performance potential can only be fully realized through precise fabrication and processing. Our team at Lead Precision brings decades of experience in working with alloy steels like 4140, ensuring optimal results from raw material selection through to final inspection. Whether you require seamless or welded pipe forms, precision turning, threading, or custom heat treatment, we have the capabilities to deliver.

Our manufacturing process is built on a foundation of advanced technology and strict adherence to international quality standards. We utilize state-of-the-art CNC lathes, milling centers, and induction hardening systems to maintain tight tolerances and consistent repeatability. Every 4140 steel pipe component undergoes comprehensive material testing, dimensional verification, and mechanical property validation to ensure reliability under extreme operating conditions.

We understand that no two industrial applications are the same. That’s why we offer fully customized solutions tailored to your technical specifications. From prototype development to large-scale production runs, our engineering team collaborates closely with clients to optimize design for manufacturability, reduce lead times, and improve cost-efficiency—without compromising performance.

Below are key specifications we routinely support for 4140 steel pipe components:

| Specification | Detail |

|---|---|

| Material Grade | AISI 4140, DIN 42CrMo4, JIS SCM440 |

| Outer Diameter Range | 20 mm – 600 mm |

| Wall Thickness | 3 mm – 80 mm |

| Length Tolerance | ±0.5 mm to ±5 mm (customizable) |

| Tensile Strength | 900 – 1200 MPa (quenched & tempered) |

| Hardness | 28 – 34 HRC (adjustable per application) |

| Surface Finish | Ra 0.8 – 6.3 µm (machined or ground) |

| Heat Treatment | Quenching & Tempering, Induction Hardening, Normalizing |

| Certifications | ISO 9001:2015, Material Test Reports (MTR), NDT available |

Partnering with Wuxi Lead Precision Machinery means gaining access to a dedicated team of engineers and production specialists committed to your success. We support global clients with end-to-end manufacturing, logistics, and technical consultation—all from our advanced facility in Wuxi, China.

For your next project involving 4140 steel pipe, contact us today at [email protected]. Let Lead Precision be your trusted partner in high-integrity metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.