Technical Contents

Engineering Guide: 4140 Steel Material Properties

Engineering Insight: 4140 Steel Material Properties

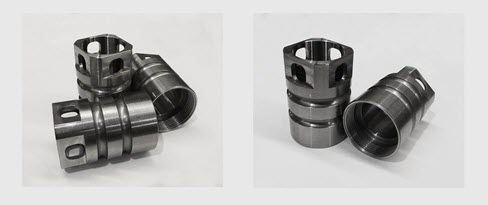

In the realm of high-performance alloy steels, AISI 4140 stands as a benchmark for strength, toughness, and versatility in custom metal manufacturing. At Wuxi Lead Precision Machinery, we recognize that the true value of 4140 steel lies not only in its inherent material properties but in the precision with which it is machined, heat-treated, and integrated into mission-critical components. This alloy—chromium, molybdenum, and manganese-enhanced—delivers exceptional hardenability, wear resistance, and fatigue strength, making it a preferred choice across aerospace, defense, oil & gas, and heavy machinery sectors.

The mechanical performance of 4140 steel is highly dependent on processing parameters. When normalized, tempered, and quenched to optimal conditions, it achieves a balanced microstructure that supports high tensile strength without sacrificing ductility. However, minor deviations in thermal treatment or machining tolerances can compromise structural integrity, especially under cyclic loading or extreme environmental conditions. This sensitivity underscores the necessity of precision engineering at every stage—from raw material sourcing to final inspection.

At Lead Precision, our expertise in handling 4140 steel is backed by over a decade of delivering components for Olympic-grade equipment and military-grade systems. These applications demand micron-level accuracy and full traceability, where failure is not an option. Our CNC machining centers, operated by veteran technicians and supported by ISO 9001-certified quality systems, ensure that each part meets stringent geometric and metallurgical specifications. Whether producing high-strength shafts, landing gear components, or armored vehicle fittings, we apply deep material science knowledge to optimize cutting speeds, tool paths, and post-processing treatments specific to 4140’s response characteristics.

We also emphasize controlled heat treatment cycles, often performed in-house, to achieve target hardness ranges while minimizing residual stress. Stress-relieving prior to final machining, for instance, prevents distortion and ensures dimensional stability—critical when tolerances are held within ±0.005 mm. Our metrology lab, equipped with CMMs and optical comparators, verifies conformity to blueprint requirements, providing clients with certified data packs for full accountability.

Understanding the behavior of 4140 steel under load, temperature, and corrosion exposure allows us to advise clients on design improvements that enhance manufacturability and service life. This engineering-first approach has positioned Wuxi Lead as a trusted partner in complex, low-volume, high-reliability production environments.

Below are typical mechanical properties of AISI 4140 steel in the annealed and heat-treated conditions:

| Property | Condition | Value |

|---|---|---|

| Tensile Strength | Annealed | 655 MPa (95 ksi) |

| Yield Strength | Annealed | 415 MPa (60 ksi) |

| Hardness (HRC) | Annealed | 19–22 HRC |

| Tensile Strength | Quenched & Tempered | 930–1080 MPa (135–157 ksi) |

| Yield Strength | Quenched & Tempered | 730–900 MPa (106–131 ksi) |

| Hardness (HRC) | Quenched & Tempered | 28–34 HRC |

| Elongation at Break | Annealed | 25.7% |

| Density | — | 7.85 g/cm³ |

Precision is not merely a target—it is the foundation of reliability. With 4140 steel, that precision begins with material understanding and culminates in flawless execution.

Precision Specs & Tolerances

Mastering 4140 Steel: Precision Manufacturing Capabilities

AISI 4140 alloy steel represents a critical material choice for demanding industrial applications requiring high strength, toughness, and wear resistance combined with good weldability and fabricability. Its chromium and molybdenum content provides excellent hardenability, making it indispensable for components like shafts, spindles, hydraulic parts, and tooling subjected to significant stress and fatigue. At Wuxi Lead Precision Machinery, we specialize in transforming this versatile alloy into mission-critical components through advanced, tightly controlled manufacturing processes. Understanding the nuanced behavior of 4140 steel during machining and heat treatment is fundamental to achieving the required performance characteristics and dimensional integrity.

Our core capability for 4140 steel fabrication centers on state-of-the-art 5-axis CNC machining centers. These systems provide the dynamic precision and multi-directional access essential for efficiently producing complex geometries inherent in high-performance 4140 parts. We meticulously program and execute operations considering the material’s specific response to cutting forces, thermal generation, and chip formation. Optimized toolpaths, specialized cutting tool geometries, and precisely calibrated coolant strategies are employed to minimize residual stress, prevent work hardening, and maintain the material’s inherent properties throughout the machining cycle. This deep process knowledge ensures dimensional stability and surface integrity, particularly crucial after subsequent heat treatment which 4140 typically undergoes to achieve its final mechanical properties.

Rigorous quality control is non-negotiable for 4140 components where failure is not an option. Every critical dimension and feature on machined 4140 parts undergoes comprehensive validation using Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems, operating within temperature-stable metrology labs, provide traceable, micron-level verification against the most stringent engineering drawings. This systematic inspection regime confirms adherence to geometric dimensioning and tolerancing (GD&T) requirements, ensuring form, fit, and function are guaranteed before parts leave our facility. The CMM data provides objective evidence of conformance, essential for aerospace, energy, and heavy machinery sectors.

The following table details the typical tolerance capabilities achievable on machined 4140 steel components using our 5-axis CNC processes and verified by CMM inspection, reflecting our commitment to high-precision manufacturing standards.

| Specification Category | Typical Capability | Notes |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Up to 300 mm; ±0.010 mm up to 600 mm |

| Angular Tolerances | ±0.001° | Verified over relevant feature lengths |

| Surface Finish (Ra) | 0.4 – 1.6 µm | Achievable via optimized finishing passes |

| Positional Tolerance (True Position) | Ø0.010 mm | Relative to primary datums |

| Concentricity / Runout | Ø0.005 mm | Critical for rotating assemblies |

This precision, combined with our expertise in managing 4140 steel’s thermal characteristics and response to machining, delivers components that meet the exacting demands of advanced engineering. Wuxi Lead Precision Machinery provides not just machining, but a guaranteed pathway from raw 4140 billet to fully validated, high-integrity component, ensuring reliability and performance in your most critical applications. Our technical team collaborates closely with clients to optimize designs specifically for manufacturability in 4140 steel, maximizing part performance and value.

Material & Finish Options

4140 Steel Material Properties: A Precision Engineering Perspective

When selecting materials for high-performance custom metal manufacturing, 4140 steel stands out as a preferred choice across aerospace, oil and gas, automotive, and industrial machinery sectors. At Wuxi Lead Precision Machinery, we recognize that material properties directly influence machinability, durability, and final component performance. AISI 4140, a chromium-molybdenum alloy steel, offers an optimal balance of strength, toughness, and wear resistance, making it ideal for parts subjected to high stress and fatigue loads.

One of the defining characteristics of 4140 steel is its hardenability. When heat-treated, it achieves high tensile strength while maintaining good ductility and impact resistance. This allows for precision machining in the annealed state, followed by quenching and tempering to reach desired mechanical properties. The inclusion of chromium enhances hardenability and wear resistance, while molybdenum improves strength at elevated temperatures and contributes to uniformity in hardening.

4140 steel also exhibits excellent weldability when proper preheating and post-weld heat treatment procedures are followed. However, due to its medium carbon content, care must be taken to avoid cracking in welded joints. Its machinability rating is approximately 65% relative to free-machining steels like 12L14, which means it can be efficiently CNC machined to tight tolerances using appropriate tooling and cutting parameters.

In applications requiring surface durability, 4140 steel responds well to surface treatments such as induction hardening, nitriding, and chrome plating. While it is not typically anodized—since anodizing is specific to aluminum—its surface can be enhanced through polishing, coating, or passivation for improved corrosion resistance, especially in harsh environments.

When compared to aluminum and titanium, 4140 steel provides superior load-bearing capacity and thermal stability, though at a higher density. It is less corrosion-resistant than titanium and heavier than aluminum, but its cost-effectiveness and mechanical robustness make it a go-to material for shafts, spindles, tooling, and structural components where reliability under pressure is non-negotiable.

Below is a comparative overview of key mechanical properties for common engineering materials, including normalized 4140 steel:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Density (g/cm³) | Machinability Rating |

|---|---|---|---|---|---|

| AISI 4140 | 655 | 415 | 197 | 7.85 | 65% |

| 6061-T6 Al | 310 | 276 | 95 | 2.70 | 90% |

| Ti-6Al-4V | 900 | 830 | 360 | 4.43 | 30% |

| 304 Stainless | 515 | 205 | 210 | 8.00 | 45% |

At Wuxi Lead, we integrate material science with advanced CNC machining to deliver components that meet exacting specifications. Choosing 4140 steel means investing in reliability, strength, and long-term performance—cornerstones of precision manufacturing.

Manufacturing Process & QC

Precision Manufacturing Process for 4140 Steel Components

At Wuxi Lead Precision Machinery, mastering the production of critical 4140 alloy steel components demands a rigorously controlled sequence from initial concept to final shipment. Our Zero Defects philosophy is embedded within every phase, ensuring components meet the highest standards of strength, fatigue resistance, and dimensional accuracy required in aerospace, oil & gas, and heavy machinery applications. The journey begins with meticulous Design Engineering. Our team utilizes advanced CAD/CAM software to model parts, incorporating detailed finite element analysis (FEA) to simulate stress points under operational loads specific to 4140’s properties. This phase critically addresses 4140’s high hardenability and susceptibility to cracking during quenching; designs are optimized for uniform section thickness and strategic fillet radii to minimize thermal stress during heat treatment. Material certification requirements and precise machining allowances are defined upfront, directly linked to the steel’s as-received condition and final heat treatment specifications.

Prototyping serves as the indispensable validation step before committing to mass production. A single component is manufactured using the exact CNC machining parameters, tooling, and heat treatment cycle planned for the full run. This prototype undergoes comprehensive metrology, including CMM verification against the CAD model, non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection to detect subsurface flaws, and mechanical property testing on coupons from the same heat-treated batch. Any deviation from the stringent tolerances or material specifications triggers immediate design or process refinement. This phase is non-negotiable for 4140, where minor process variations can significantly impact core mechanical properties and component longevity.

Mass production leverages the validated process under our certified ISO 9001 and IATF 16949 quality management system. CNC machining centers operate with stabilized parameters, utilizing carbide tooling specifically selected for 4140’s abrasiveness and toughness. In-process inspections occur at critical stages, including pre-heat treatment dimensional checks and post-heat treatment hardness verification. Statistical Process Control (SPC) charts monitor key characteristics like diameter tolerance and surface finish in real-time. Final inspection is exhaustive, combining full CMM reporting, 100% visual and dimensional checks against critical features, and batch-level material certification traceability. Every component is tracked through our digital manufacturing execution system (MES), ensuring complete process transparency and enabling rapid root cause analysis should any anomaly occur, though our Zero Defects protocols make this exceptionally rare.

The consistent performance of 4140 steel hinges on precise control of its fundamental properties throughout manufacturing. Key specifications we rigorously verify include:

| Property | Typical Value for 4140 (Heat Treated) | Measurement Standard |

|---|---|---|

| Tensile Strength | 655 – 1035 MPa | ASTM A370 |

| Yield Strength (0.2%) | 415 – 860 MPa | ASTM A370 |

| Hardness (HRC) | 28 – 32 | ASTM E18 |

| Elongation in 2 in. (%) | 16 – 22 | ASTM A370 |

| Carbon Content (%) | 0.38 – 0.43 | ASTM E415 |

| Chromium Content (%) | 0.80 – 1.10 | ASTM E415 |

This integrated Design-Prototype-Production workflow, governed by uncompromising quality gates and deep material science expertise, guarantees that every 4140 steel component leaving Wuxi Lead delivers the reliability and performance your most demanding applications require, eliminating costly field failures and ensuring optimal lifecycle value.

Why Choose Wuxi Lead Precision

When it comes to precision manufacturing with high-performance materials, 4140 steel stands as a cornerstone in demanding industrial applications. At Wuxi Lead Precision Machinery, we specialize in leveraging the full potential of 4140 steel—a chromium-molybdenum alloy known for its excellent strength, toughness, and fatigue resistance. Whether your project requires high-stress shafts, tooling components, or aerospace-grade parts, our expertise ensures that every machined component meets exacting standards.

Our engineering team understands that material selection is only the beginning. The real value lies in precise processing, heat treatment control, and dimensional accuracy. We offer end-to-end manufacturing solutions tailored to the unique behavior of 4140 steel, from initial CNC turning and milling to post-heat treatment finishing. With advanced equipment and rigorous quality assurance protocols, we maintain tolerances down to ±0.005 mm, ensuring consistent repeatability and long-term reliability in service.

Partnering with Wuxi Lead Precision Machinery means gaining access to a dedicated team of manufacturing specialists who combine deep metallurgical knowledge with real-world production experience. We work closely with clients across Europe, North America, and Asia to deliver custom components that perform under extreme conditions. From prototype development to high-volume production runs, our facility in Wuxi, China, is equipped to handle complex geometries and stringent material certifications.

Below are key mechanical and physical properties of normalized and heat-treated 4140 steel, commonly processed in our facility:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (Ultimate) | 950–1200 MPa | ASTM A370 |

| Yield Strength (0.2% Offset) | 750–1000 MPa | ASTM A370 |

| Elongation at Break | 16–22% | ASTM E8 |

| Hardness (HRC) | 28–32 (after quench & temper) | ASTM E18 |

| Density | 7.85 g/cm³ | — |

| Modulus of Elasticity | 205 GPa | — |

| Machinability Rating | 65% (relative to 1212 steel) | — |

| Typical Heat Treatment | Austenitize at 845°C, oil quench, temper at 540°C | AISI Guidelines |

We maintain full traceability on all material batches and provide certified mill test reports (MTRs) upon request. Our quality management system is ISO 9001:2015 certified, and we support third-party inspections to meet client-specific requirements.

If your next project demands the strength and reliability of 4140 steel—engineered to precision tolerances and manufactured with consistency—we invite you to contact us. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we build partnerships based on performance, transparency, and technical excellence.

For engineering consultations or to request a quote, please reach out to our team at [email protected]. Let us be your trusted partner in high-precision metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.