Technical Contents

Engineering Guide: 3D Prototype Printing Services

Engineering Insight: 3D Prototype Printing Services in High-End Metal Manufacturing

In the realm of advanced manufacturing, 3D prototype printing services have evolved beyond rapid visualization tools to become integral components in the development of mission-critical metal parts. At Wuxi Lead Precision Machinery, we recognize that precision in additive manufacturing is not merely a performance metric—it is a foundational requirement for industries where failure is not an option. Our engineering approach to 3D prototype printing emphasizes dimensional accuracy, material integrity, and repeatability, ensuring that every prototype meets the rigorous demands of aerospace, defense, and high-performance industrial applications.

Precision in 3D printing begins with material selection and extends through every phase of the build process. Unlike conventional prototyping methods that often involve post-processing corrections, our metal additive systems—utilizing laser powder bed fusion (LPBF) and direct energy deposition (DED)—are calibrated to achieve tight tolerances directly from the build chamber. This capability reduces lead time and eliminates variability, enabling clients to move confidently from concept to functional testing. Our in-house metrology suite, equipped with coordinate measuring machines (CMM) and optical scanners, validates each prototype against original CAD specifications, ensuring compliance with ISO 13485 and AS9100 standards.

Wuxi Lead’s expertise in precision engineering has been proven through high-stakes projects, including components developed for Olympic-class sporting equipment and subsystems deployed in military-grade applications. These projects demanded not only mechanical resilience under extreme conditions but also micron-level accuracy in geometric complexity. Our success in these arenas underscores our ability to deliver prototypes that are not just visually representative but functionally indistinguishable from final production parts.

We specialize in high-performance alloys such as Inconel 718, titanium Ti-6Al-4V, and maraging steel, materials chosen for their strength-to-weight ratios and thermal stability. Our process control protocols ensure consistent grain structure and minimal residual stress, critical factors in fatigue resistance and long-term reliability. By integrating design for additive manufacturing (DfAM) principles early in the development cycle, we help clients optimize part geometry for performance, weight reduction, and manufacturability.

For global engineering teams, the value of a trusted prototyping partner cannot be overstated. At Wuxi Lead, we combine cutting-edge technology with decades of precision machining heritage to deliver 3D printed metal prototypes that accelerate innovation without compromising on quality.

| Specification | Detail |

|---|---|

| Build Volume (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 6–12 μm |

| Post-Processing Options | Stress relief, HIP, CNC finishing, polishing |

| Supported Materials | Ti-6Al-4V, Inconel 718, SS 316L, AlSi10Mg, Maraging Steel |

| Quality Standards | ISO 9001, ISO 13485, AS9100 (compliant) |

Precision Specs & Tolerances

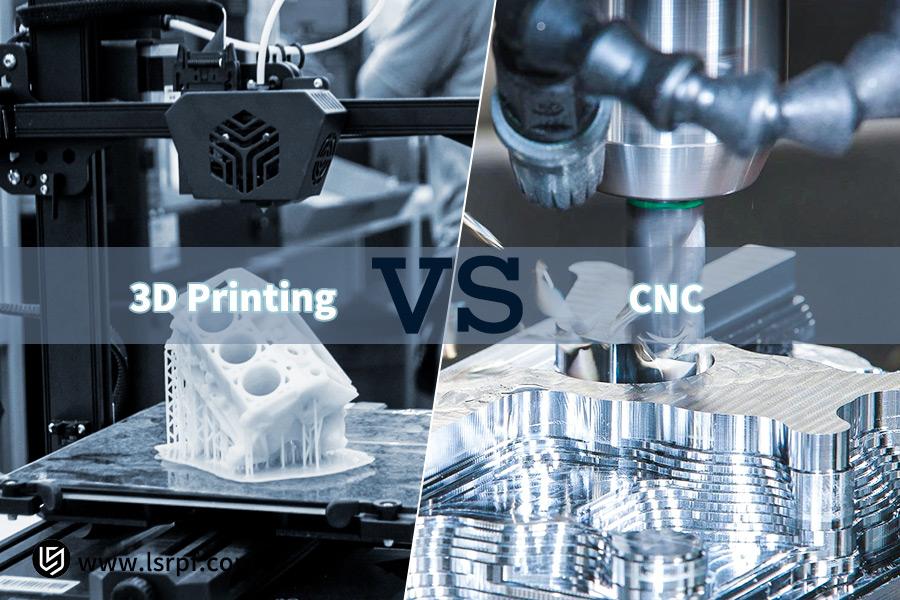

Technical Capabilities: Precision Metal Prototyping via Advanced CNC Machining

Wuxi Lead Precision Machinery delivers definitive metal prototype solutions through subtractive manufacturing excellence, specifically high-precision 5-axis CNC machining. While the term ‘3D prototype printing’ is often associated with additive methods, our core strength for functional, production-intent metal prototypes lies in CNC machining. This approach guarantees the material properties, structural integrity, and surface finishes demanded by aerospace, medical, and high-end industrial applications where additive processes may fall short. Our process transforms digital CAD models directly into fully dense, stress-relieved metal components meeting stringent real-world performance criteria from the very first prototype.

Our facility is equipped with state-of-the-art 5-axis CNC machining centers, enabling the production of highly complex geometries in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly enhancing accuracy and repeatability. We machine a comprehensive range of engineering metals including aluminum alloys (6061, 7075), stainless steels (303, 304, 316, 17-4PH), titanium (Gr2, Gr5), and specialized alloys like Inconel 718. Our machines feature high spindle speeds, rigid construction, and advanced thermal compensation systems, ensuring micron-level precision across intricate contours and deep cavities. This capability is essential for prototypes requiring exact form, fit, and function validation prior to costly tooling investments.

Every prototype undergoes rigorous quality verification against the client’s engineering specifications. Our quality control process is anchored by Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM), providing full 3D geometric dimensioning and tolerancing (GD&T) validation. Critical features, complex profiles, and tight tolerances are systematically measured and certified. This metrology-grade inspection ensures dimensional compliance and provides documented evidence for regulatory submissions or design sign-off, mitigating risk in the product development cycle.

The following table details our standard achievable tolerances and surface finishes for machined metal prototypes, reflecting our commitment to precision engineering:

| Material Category | Dimensional Tolerance (mm) | Geometric Tolerance (mm) | Surface Roughness (Ra µm) | Max Part Size (mm) |

|---|---|---|---|---|

| Aluminum Alloys | ±0.005 | ±0.010 | 0.4 – 1.6 | 1000 x 800 x 600 |

| Stainless Steels | ±0.005 | ±0.010 | 0.8 – 3.2 | 800 x 600 x 500 |

| Titanium Alloys | ±0.005 | ±0.010 | 0.8 – 3.2 | 600 x 500 x 400 |

| High-Temp Alloys | ±0.008 | ±0.015 | 1.6 – 6.3 | 500 x 400 x 300 |

Leveraging 5-axis CNC machining for metal prototyping provides a critical advantage: prototypes that accurately represent the final production part in material behavior and performance. This reduces downstream rework, accelerates time-to-market, and provides engineering teams with reliable data for validation. Wuxi Lead Precision Machinery integrates advanced machining, comprehensive material expertise, and metrology-grade inspection to deliver metal prototypes that serve as true gatekeepers for successful product launch. Partner with us for prototypes that meet the uncompromising standards of high-stakes manufacturing.

Material & Finish Options

Material selection is a foundational decision in high-precision 3D prototype printing, directly influencing performance, durability, and application suitability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive techniques, enabling clients to prototype with industrial-grade materials such as aluminum, steel, and titanium. Each material offers distinct mechanical properties, thermal resistance, and weight characteristics, making them suitable for specific engineering demands across aerospace, automotive, medical, and industrial sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring high strength-to-density ratios and excellent thermal conductivity. This material is ideal for applications where weight reduction is critical without sacrificing performance. It demonstrates good corrosion resistance and is weldable, making it suitable for functional prototypes and end-use parts in dynamic environments. Aluminum’s machinability also allows for tight tolerances and fine surface detail when post-processed.

Stainless steel, especially 316L and 17-4 PH grades, provides exceptional mechanical strength, corrosion resistance, and thermal stability. It is the material of choice for harsh environments, including marine, chemical processing, and high-pressure systems. 316L offers superior resistance to chloride corrosion, while 17-4 PH delivers high yield strength through precipitation hardening, making it suitable for load-bearing components. Steel’s versatility in both strength and environmental resilience makes it a preferred option for industrial tooling, valves, and safety-critical parts.

Titanium, specifically Grade 5 (Ti6Al4V), stands at the premium end of the spectrum, offering an outstanding strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosive media. Its use is prevalent in aerospace components, medical implants, and high-performance automotive systems. Titanium’s low thermal expansion and high fatigue resistance ensure dimensional stability under cyclic loading and thermal stress, making it ideal for long-life prototypes and mission-critical applications.

Post-processing surface finishes further enhance material performance. Anodizing, particularly for aluminum, improves surface hardness, wear resistance, and corrosion protection while allowing for color coding and aesthetic customization. Type II (sulfuric acid) anodizing is commonly applied for general-purpose enhancement, while Type III (hardcoat anodizing) delivers thicker, more durable layers for industrial use.

The following table summarizes key material properties for common metals used in our 3D prototype printing services:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 480 | 370 | 8 | Automotive, heat exchangers, drones |

| 316L Stainless Steel | 8.0 | 590 | 350 | 45 | Marine, medical, chemical equipment |

| 17-4 PH Steel | 7.8 | 1000 | 850 | 12 | Aerospace, tooling, high-stress parts |

| Ti6Al4V | 4.43 | 950 | 880 | 10 | Medical implants, jet engines, racing |

At Wuxi Lead Precision Machinery, we support material selection with engineering consultation, ensuring your prototype meets functional, regulatory, and environmental requirements. Our integrated approach combines precision additive manufacturing with advanced finishing to deliver prototypes that perform like production-grade components.

Manufacturing Process & QC

The Integrated Production Pathway: From Concept to Flawless Volume

At Wuxi Lead Precision Machinery, we engineer manufacturing as a unified continuum where design, prototyping, and mass production are intrinsically linked to achieve Zero Defects. This integrated approach eliminates costly iterations and supply chain vulnerabilities inherent in fragmented processes. Our methodology begins with rigorous digital validation, ensuring every component meets functional and regulatory demands before physical creation commences. This foundational phase prevents downstream failures, directly supporting our commitment to defect-free delivery in high-stakes sectors like aerospace and medical devices.

Design validation leverages advanced simulation tools for structural, thermal, and fluid dynamics analysis. Our engineers conduct comprehensive Design for Manufacturability (DfM) reviews, identifying potential weaknesses in geometry, material selection, or assembly long before metal is cut. This stage incorporates client specifications, industry standards (such as AS9100 or ISO 13485), and our proprietary material science database to optimize part performance and producibility. Only designs passing this stringent digital gate progress to physical prototyping, ensuring resources are allocated efficiently and risk is minimized at the earliest stage.

Precision prototyping utilizes our industrial-grade metal additive systems to produce functional, end-use material components. Unlike rapid visual models, our prototypes undergo identical post-processing—machining, heat treatment, HIP, and surface finishing—as final production parts. This validates not only form and fit but critical mechanical properties and manufacturing feasibility under real-world conditions. Prototyping serves as the definitive checkpoint; any deviation triggers immediate design or process refinement, preventing defect propagation into volume production.

Zero-Defect mass production is executed through closed-loop manufacturing systems with embedded quality. Every build incorporates real-time in-situ monitoring of laser power, melt pool dynamics, and atmospheric conditions. Automated dimensional inspection via CMM and optical scanning occurs inline, feeding data directly into Statistical Process Control (SPC) systems. This enables immediate parameter correction, maintaining tolerances and material integrity across thousands of parts. Full material traceability and batch-specific certification are standard, guaranteeing compliance and eliminating scrap costs for our clients.

The transition from prototype to production relies on identical material feeds, machine parameters, and post-processing protocols, ensuring seamless scalability. Below are key specifications demonstrating this continuity:

| Parameter | Precision Prototyping Phase | Zero-Defect Mass Production Phase |

|---|---|---|

| Materials | Ti-6Al-4V, Inconel 718, 17-4PH, AlSi10Mg, CoCr | Ti-6Al-4V, Inconel 718, 316L, Maraging Steel |

| Tolerance Control | ±0.05 mm | ±0.02 mm (SPC-monitored) |

| Surface Finish | As-built: Ra 12-25μm; Machined: Ra 0.8-3.2μm | Machined: Ra 0.4-1.6μm (certified) |

| Lead Time | 5-7 days (incl. validation) | 10-15 days for 100+ units |

| Quality Assurance | Full material certs, dimensional report | Real-time SPC, 100% batch traceability, PPAP |

This disciplined pathway transforms prototyping from a validation step into the blueprint for flawless volume output. By enforcing identical standards from the first part to the ten-thousandth, Wuxi Lead eliminates the traditional quality gap between prototype and production, delivering certified, mission-critical metal components with absolute reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal 3D Prototype Printing Services

At Wuxi Lead Precision Machinery, we don’t just deliver prototypes—we deliver precision-engineered solutions that accelerate innovation and reduce time-to-market. As a leading provider of custom metal manufacturing in China, we specialize in high-accuracy 3D prototype printing services tailored to the exacting demands of aerospace, medical, automotive, and industrial equipment sectors. Our advanced metal additive manufacturing capabilities, combined with decades of CNC machining expertise, enable us to transform complex designs into fully functional, production-ready metal prototypes with exceptional repeatability and surface integrity.

What sets us apart is our integrated approach. From initial concept validation to final prototype delivery, our engineering team collaborates closely with clients to optimize designs for manufacturability, material performance, and cost-efficiency. Whether you require single-component demonstrators or full-system assemblies, our end-to-end service ensures seamless transition from digital model to physical part—without compromise.

Our state-of-the-art facilities are equipped with multi-laser metal powder bed fusion systems, in-house metallurgical analysis, and post-processing capabilities including heat treatment, HIP (Hot Isostatic Pressing), precision machining, and surface finishing. This vertical integration allows us to maintain full control over quality, tolerances, and delivery timelines, ensuring every prototype meets the highest international standards.

We understand that in high-stakes industries, reliability is non-negotiable. That’s why every project at Lead Precision is backed by rigorous quality assurance protocols, including first-article inspection reports (FAIR), material traceability, and 3D metrology verification using coordinate measuring machines (CMM) and optical scanning.

Below are key technical specifications for our metal 3D prototype printing services:

| Specification | Detail |

|---|---|

| Build Volume (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20 – 60 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 µm (can be reduced to Ra 1–2 µm with finishing) |

| Supported Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel 718 & 625, Aluminum (AlSi10Mg), Tool Steel (Maraging, H13), Cobalt-Chrome |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing, anodizing, coating |

| Lead Time (Typical) | 7–15 days (varies by complexity and finishing requirements) |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to technical excellence, responsive communication, and on-time delivery. We serve global clients with full project confidentiality and scalable capacity for both low-volume prototyping and bridge production.

Ready to bring your next innovation to life? Contact us today at [email protected] to discuss your 3D prototype printing requirements. Our engineering team is standing by to provide material recommendations, design feedback, and a competitive quote—helping you move from concept to reality with precision, speed, and confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.