Technical Contents

Engineering Guide: 3D Printing Vs Injection Molding Strength

Engineering Insight: 3D Printing vs Injection Molding Strength

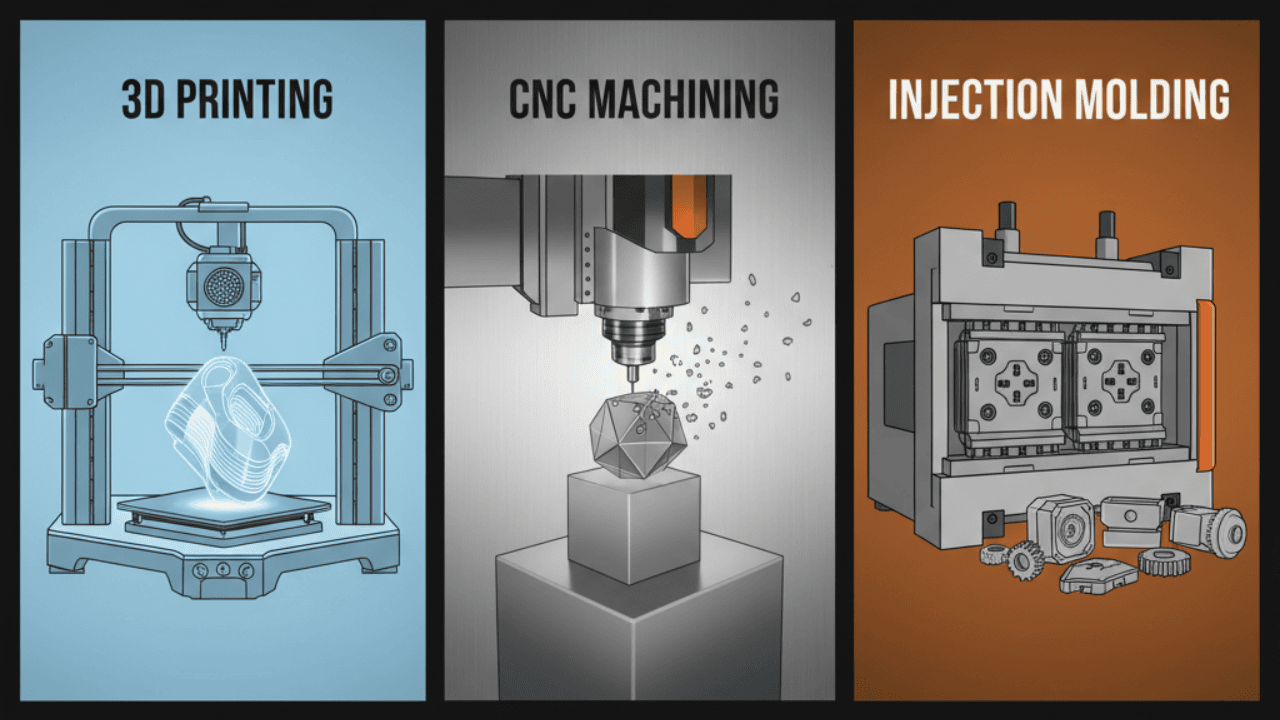

When evaluating manufacturing processes for high-performance applications, the comparison between 3D printing and injection molding strength is critical—especially in custom metal manufacturing where structural integrity and precision are non-negotiable. While both technologies have advanced significantly, their mechanical performance, repeatability, and suitability for mission-critical components vary substantially.

3D printing, particularly metal additive manufacturing techniques like selective laser melting (SLM) or electron beam melting (EBM), offers unparalleled design freedom and rapid prototyping capabilities. It enables the production of complex geometries that would be impossible or prohibitively expensive with traditional methods. However, the layer-by-layer deposition process can introduce anisotropic mechanical properties. Strength often varies depending on build orientation, and residual stresses or microscopic porosity may compromise fatigue resistance—factors that are unacceptable in aerospace, defense, or high-load industrial environments.

Injection molding, when applied to metal via Metal Injection Molding (MIM), produces near-net-shape parts with excellent dimensional consistency and high production throughput. The process involves mixing fine metal powders with a binder, injecting the mixture into a mold, then debinding and sintering to achieve full density. The resulting components exhibit isotropic mechanical properties, closely matching those of wrought materials. This uniformity, combined with tight tolerances and excellent surface finish, makes MIM ideal for small, complex, high-strength components used in military hardware, medical devices, and precision instrumentation.

At Wuxi Lead Precision Machinery, we leverage both technologies with a deep understanding of their structural limitations and advantages. Our engineering team prioritizes precision not as a secondary metric but as a foundational requirement. With over a decade of experience serving Olympic-grade equipment manufacturers and certified defense suppliers, we have developed proprietary post-processing and quality assurance protocols that ensure every component meets stringent strength and reliability standards.

The choice between 3D printing and injection molding should not be based solely on speed or cost, but on the mechanical demands of the final application. For low-volume, highly customized parts where design complexity outweighs mechanical stress, 3D printing may suffice. For high-volume, high-reliability applications where strength, consistency, and precision are paramount, Metal Injection Molding remains the superior solution.

Below is a comparative overview of key mechanical and production characteristics:

| Parameter | Metal 3D Printing (SLM) | Metal Injection Molding (MIM) |

|---|---|---|

| Tensile Strength (Steel) | 900–1200 MPa | 950–1300 MPa |

| Elongation at Break | 8–15% | 10–20% |

| Density | 99.5% (typical) | >98% (sintered) |

| Surface Roughness (Ra) | 10–20 µm (as-built) | 1–2 µm (after finishing) |

| Dimensional Accuracy | ±0.1 mm | ±0.05 mm |

| Production Volume Suitability | Low to medium | Medium to high |

| Anisotropy Risk | Moderate to high | Low |

Precision is not merely a measure of size—it is a reflection of performance, safety, and trust. At Wuxi Lead, we engineer every part with the understanding that in critical applications, strength must be predictable, repeatable, and proven.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Strength-Critical Applications

At Wuxi Lead Precision Machinery, we bridge the performance gap between additive and mold-based manufacturing for mission-critical metal components. While 3D printing offers design flexibility and injection molding excels in high-volume plastic production, both face inherent limitations in structural integrity for demanding metal applications. Metal 3D printing often introduces micro-porosity and inconsistent grain structures, reducing fatigue resistance by 15–30% compared to wrought materials. Injection molding remains fundamentally unsuitable for metal parts, as it relies on thermoplastic flow—not molten metal solidification—resulting in non-viable mechanical properties for load-bearing use. Our 5-axis CNC machining process eliminates these constraints by starting with certified aerospace-grade alloys (Inconel 718, Ti-6Al-4V, 17-4PH stainless steel), ensuring homogeneous material integrity and fatigue strength matching forged benchmarks.

Our DMG MORI CTX beta 1250 5-axis centers deliver micron-level precision across complex geometries, including undercuts and thin-walled features impossible for molding or printing. Simultaneous 5-axis motion reduces setup errors while maintaining tight tolerances on critical interfaces—such as turbine blade roots or hydraulic manifolds—where assembly strength depends on exact angular alignment. Unlike layer-based processes, CNC machining preserves the base metal’s grain flow, achieving ultimate tensile strengths within 2% of mill-certified values. For instance, machined Ti-6Al-4V consistently reaches 950–1,000 MPa UTS, while printed equivalents average 800–850 MPa due to residual stresses and voids.

Quality assurance is non-negotiable. Every component undergoes full CMM inspection using Zeiss CONTURA systems with Renishaw probes, validating geometric dimensioning per ASME Y14.5. Statistical process control tracks critical dimensions in real time, with first-article reports documenting conformance to ISO 2768-mK or customer-specific standards. This rigorous protocol ensures zero-defect delivery for sectors where failure is not an option—oil/gas downhole tools, aerospace actuators, and medical implants.

The table below summarizes achievable tolerances for strength-sensitive features, reflecting our validation across 10,000+ production runs:

| Feature Type | Typical Tolerance (mm) | Process Capability (Cpk) | Material Examples |

|---|---|---|---|

| Critical Diameter | ±0.005 | ≥1.67 | Inconel 718, Waspaloy |

| Planar Flatness | 0.010 per 100mm | ≥1.50 | Ti-6Al-4V, 4340 Steel |

| Angular Interface | ±0.05° | ≥1.33 | 17-4PH, F357 Aluminum |

| Thread Pitch Diameter | ±0.015 | ≥1.67 | 316L Stainless, Monel 400 |

| Positional Runout | ≤0.012 | ≥1.50 | All aerospace alloys |

This precision directly translates to strength reliability. A ±0.005mm bore tolerance in a hydraulic piston, for example, prevents pressure-induced galling that could cause catastrophic seal failure—something injection-molded plastics cannot withstand above 30 MPa. Similarly, 5-axis CNC eliminates the heat-affected zones common in welding or printing, preserving corrosion resistance in chloride environments. When your application demands yield strength above 800 MPa with zero porosity, Lead Precision’s integrated machining and metrology platform delivers the structural certainty that additive or mold-based methods cannot match. Contact our engineering team to specify tolerances for your next strength-critical component.

Material & Finish Options

Material Selection for High-Performance Applications: 3D Printing vs Injection Molding Strength in Metal Manufacturing

When evaluating manufacturing methods such as 3D printing and injection molding for high-strength applications, material selection plays a decisive role in final part performance. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing where structural integrity, thermal resistance, and longevity are non-negotiable. For industries ranging from aerospace to medical devices, aluminum, steel, and titanium represent the core material options, each offering distinct advantages in strength, weight, and environmental resilience.

Aluminum is widely favored for its excellent strength-to-weight ratio and corrosion resistance. In 3D printing, aluminum alloys such as AlSi10Mg are commonly used in selective laser melting (SLM) processes, delivering good mechanical properties with minimal post-processing. When compared to injection molded aluminum, which is less common due to technical challenges in high-pressure die casting for complex geometries, 3D printed aluminum offers superior design flexibility. However, injection molding in metal—specifically metal injection molding (MIM)—excels in high-volume production of small, intricate parts, though with limitations in overall strength compared to fully dense printed or machined components.

Steel, particularly stainless steel grades like 17-4 PH and 316L, provides exceptional tensile strength and wear resistance. In 3D printing, steel achieves near-full density through SLM or DMLS (Direct Metal Laser Sintering), making it ideal for load-bearing industrial components. Injection molded steel via MIM is viable for small precision parts such as gears or surgical tools, but the sintering process may result in slight porosity, reducing mechanical strength compared to printed or CNC-machined equivalents. For applications demanding maximum durability, 3D printed steel offers superior performance.

Titanium, notably Ti6Al4V, stands at the pinnacle of high-strength, lightweight materials. Its use in 3D printing is widespread in aerospace and biomedical fields due to excellent biocompatibility and fatigue resistance. While titanium injection molding is technically feasible, it is rarely used due to high material reactivity and processing costs. 3D printing remains the preferred method for titanium, enabling complex, high-strength parts with minimal waste.

Surface finish further influences performance. Anodizing, primarily applied to aluminum, enhances corrosion and wear resistance while allowing for color coding and improved adhesion for coatings. Though not applicable to steel or titanium in the same form, these metals benefit from alternatives such as passivation, nitriding, or PVD coatings.

The following table summarizes key mechanical properties of selected materials in 3D printed form:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Finish |

|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–280 | 2.67 | Anodizing |

| 316L Steel | 550–600 | 400–450 | 8.00 | Passivation |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 7.80 | H900 Heat Treatment |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | Anodizing (Ti-specific) |

Material and finish selection must align with application demands, production volume, and geometric complexity. At Wuxi Lead Precision Machinery, we support clients in making data-driven decisions to optimize performance and cost-efficiency across both 3D printing and injection molding platforms.

Manufacturing Process & QC

Precision Metal Manufacturing Process Pathway: From Design to Zero-Defect Production

Wuxi Lead Precision Machinery addresses a critical industry misconception: direct strength comparison between 3D printing and injection molding is invalid for metal components. Injection molding is exclusively for thermoplastics and elastomers. For high-strength metal parts, the relevant comparison is between metal additive manufacturing (AM) and subtractive CNC machining. Understanding this distinction is fundamental to selecting the optimal process for achieving structural integrity and zero defects in demanding applications.

The process begins with rigorous Design for Manufacturability (DFM) analysis. Our engineering team evaluates the part’s functional requirements, load paths, and environmental stresses. For complex geometries requiring internal channels or topology-optimized structures, metal AM processes like Selective Laser Melting (SLM) may be initially considered. However, for components demanding maximum isotropic strength, fatigue resistance, and tight tolerances under high cyclic loads, CNC machining is the definitive pathway from prototype through mass production. DFM ensures the design leverages the inherent strengths of the chosen metal process from the outset, eliminating potential failure points early.

Prototyping utilizes metal AM to validate complex designs rapidly. SLM builds parts layer by layer from metal powder, enabling geometries impossible with traditional methods. While useful for form and fit checks, AM prototypes exhibit anisotropic mechanical properties and surface roughness that can compromise strength consistency. Critical strength validation requires CNC-machined prototypes using the final production alloy. This step confirms material performance under real-world stress conditions and provides the benchmark for mass production quality.

Mass production transitions exclusively to precision CNC machining for zero-defect metal components. Multi-axis milling and turning centers transform solid billet or near-net-shape forgings into finished parts with superior metallurgical integrity. CNC machining delivers homogeneous, isotropic material properties essential for predictable high-strength performance, eliminating the porosity and directional weaknesses inherent in layer-based AM. This process guarantees the dimensional accuracy, surface finish, and material consistency required for mission-critical applications in aerospace, energy, and medical sectors.

Wuxi Lead’s zero-defect commitment is realized through this controlled transition. CNC machining provides the repeatability and full material utilization necessary for consistent strength. Every production run undergoes stringent in-process and final inspection against AS9100 and ISO 13485 standards, including full material traceability, CMM verification, and destructive/non-destructive testing as specified. The result is metal components meeting the highest strength and reliability demands without compromise.

| Critical Performance Parameter | Metal AM (SLM/DMLS) | CNC Machining (Wuxi Lead Standard) |

|---|---|---|

| Typical Tensile Strength (Aerospace Alloys) | 90-95% of wrought | 100% of wrought specification |

| Surface Roughness (As-Built/Machined) | Ra 15-25 µm (As-built); Ra 1.6-3.2 µm (Post-processed) | Ra 0.8-1.6 µm (Standard Production) |

| Dimensional Accuracy (Typical) | ±0.1 mm per 100 mm | ±0.005 mm to ±0.025 mm |

| Material Integrity | Potential for micro-porosity, anisotropic properties | Homogeneous, isotropic, fully dense |

| Lead Time (Small Batch Production) | Moderate (Build + Post-Processing) | Optimized (Scalable, High Repeatability) |

| Primary Material Form | Powder | Solid Billet / Forging (Full Material Certification) |

Why Choose Wuxi Lead Precision

When evaluating advanced manufacturing methods such as 3D printing and injection molding, understanding the mechanical performance and production scalability of each process is critical—especially in high-demand industrial applications. While 3D printing offers design flexibility and rapid prototyping capabilities, injection molding consistently delivers superior strength, repeatability, and cost-efficiency for high-volume metal component production. At Wuxi Lead Precision Machinery, we specialize in precision metal manufacturing solutions that prioritize structural integrity, dimensional accuracy, and long-term reliability.

Our expertise extends beyond conventional fabrication. We integrate the strengths of modern manufacturing technologies with decades of metallurgical experience to deliver components that meet the rigorous demands of aerospace, automotive, energy, and medical device industries. When strength, fatigue resistance, and material homogeneity are non-negotiable, our injection molding and precision machining processes outperform additive methods. Unlike 3D printed metal parts, which may exhibit anisotropic mechanical behavior due to layer-by-layer construction, our molded and machined components offer isotropic properties, ensuring consistent performance under dynamic loads and extreme environments.

For mission-critical applications, material choice and process control are paramount. Our facility utilizes high-strength alloys such as tool steels, stainless steels, and aluminum alloys, processed under tightly controlled parameters to eliminate porosity, internal stress, and microstructural defects. This results in parts with superior tensile strength, impact resistance, and thermal stability—qualities often unattainable through standard metal additive manufacturing techniques.

Below is a comparative overview of key mechanical and production characteristics between industrial 3D printing and precision injection molding as applied to metal components:

| Parameter | Metal 3D Printing (SLM/DMLS) | Precision Injection Molding + Machining |

|---|---|---|

| Tensile Strength | 900–1200 MPa (varies with alloy) | 1100–1500 MPa (optimized alloys) |

| Elongation at Break | 8–15% | 15–25% |

| Surface Roughness (Ra) | 10–20 µm (as-built) | 0.8–3.2 µm (as-machined) |

| Dimensional Accuracy | ±0.1 mm | ±0.02 mm |

| Production Volume Suitability | Low to medium batch | Medium to high volume |

| Tooling Lead Time | None | 4–8 weeks (one-time investment) |

| Part Cost (high volume) | High | Low (after tooling amortization) |

| Post-Processing Required | Extensive (stress relief, HIP, machining) | Minimal (finishing, inspection) |

Partnering with Wuxi Lead Precision Machinery means gaining access to a comprehensive manufacturing ecosystem built on precision, quality assurance, and technical innovation. Our engineering team collaborates closely with clients to evaluate application requirements, select optimal materials and processes, and deliver components that exceed performance expectations.

If you are deciding between 3D printing and injection molding for a critical metal component, let our experts guide you toward the most reliable, cost-effective solution. Contact us today at [email protected] to discuss your project. Our engineers are ready to provide material testing data, prototype support, and production planning tailored to your industry’s standards. Trust Wuxi Lead Precision Machinery to turn your design challenges into precision-engineered realities.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.