Technical Contents

Engineering Guide: 3D Printing Steel

Engineering Insight: 3D Printing Steel – Precision as a Standard

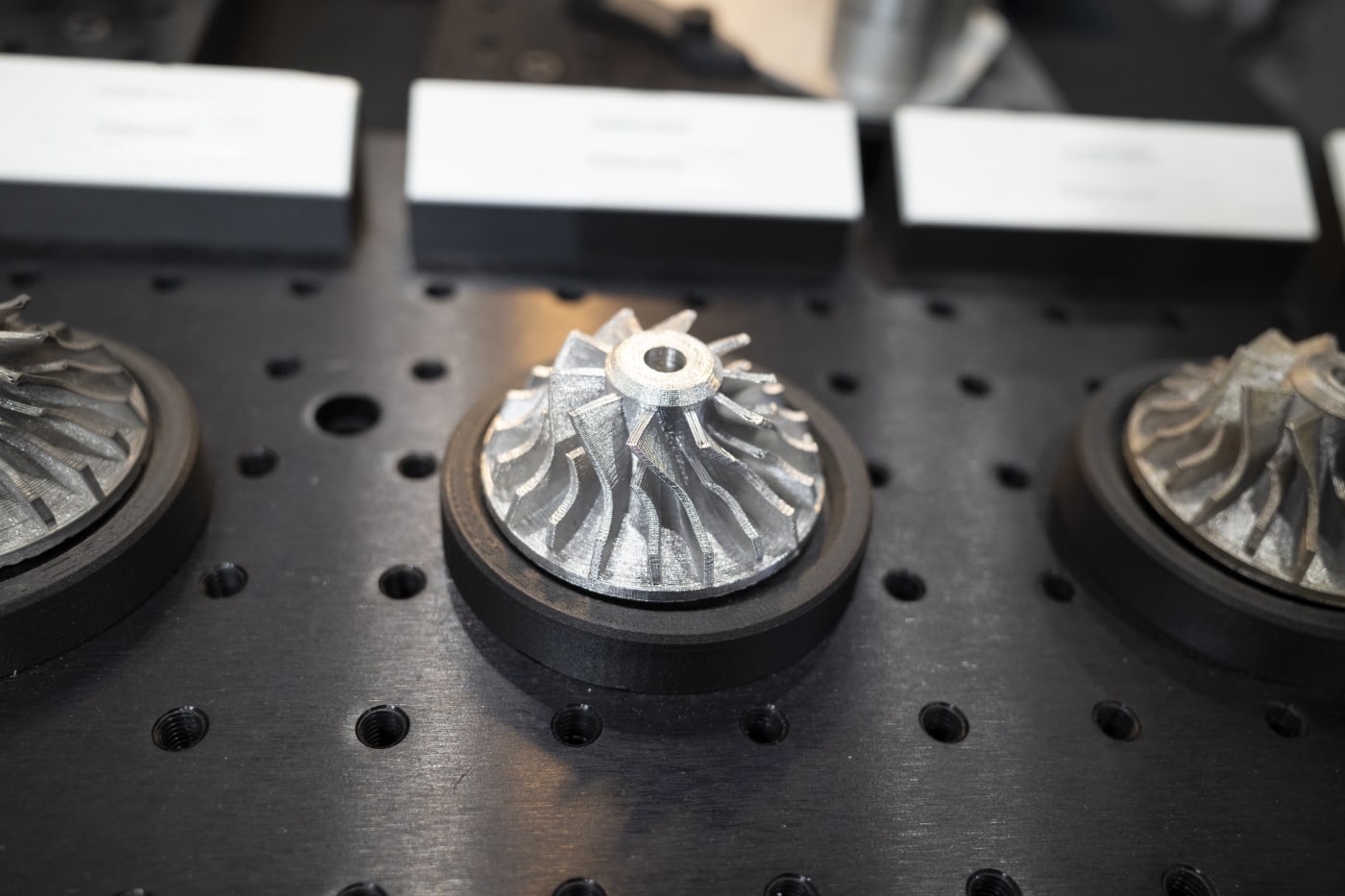

In the realm of advanced manufacturing, 3D printing steel has emerged as a transformative capability, enabling complex geometries, rapid prototyping, and low-volume production of high-strength components. At Wuxi Lead Precision Machinery, we approach steel additive manufacturing not merely as a technological novelty, but as a precision engineering discipline where tolerances, material integrity, and repeatability define success. Our experience in delivering mission-critical components for Olympic-standard equipment and defense applications has ingrained in us the understanding that precision is non-negotiable.

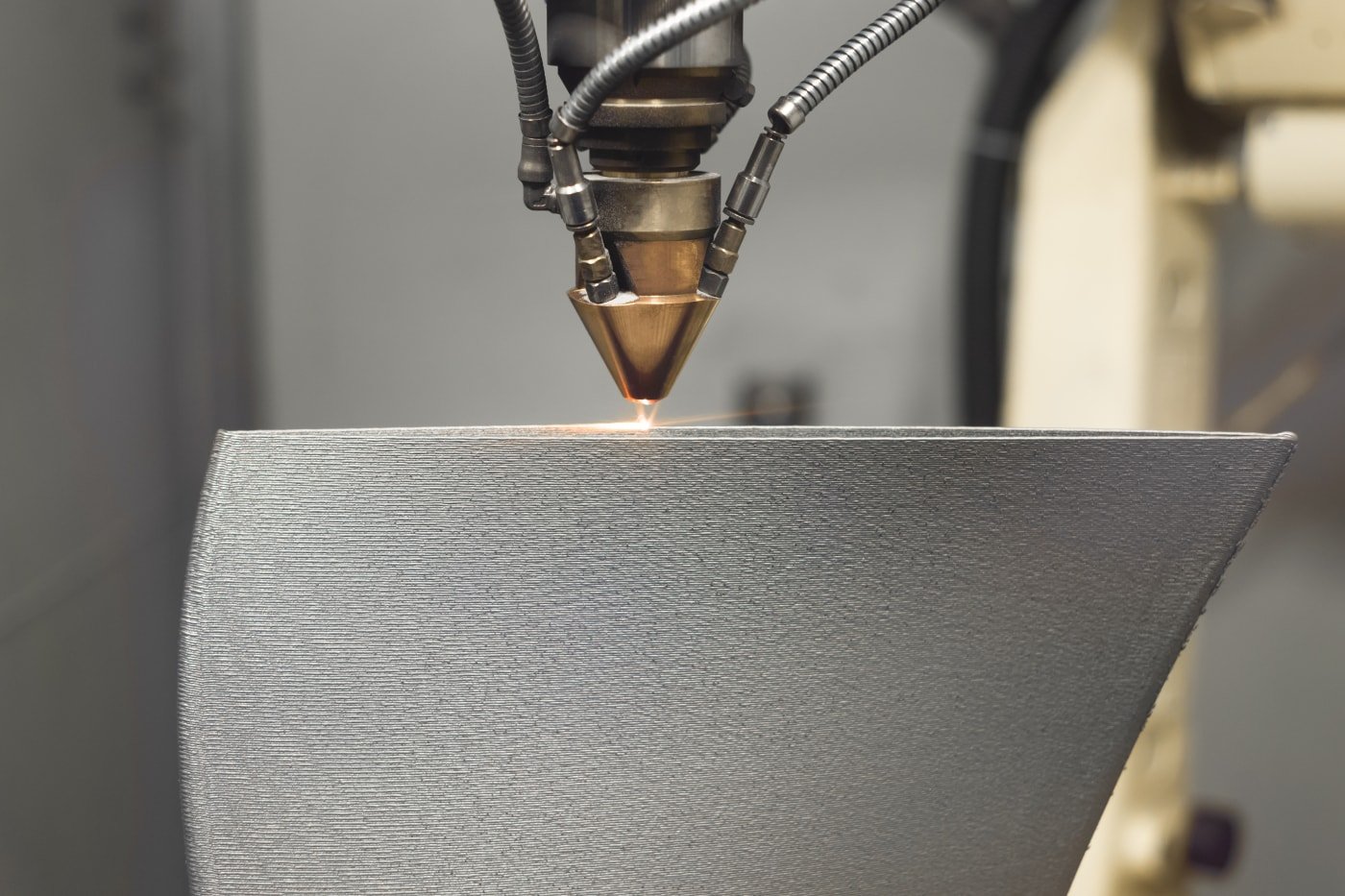

Steel, as a material, presents unique challenges in additive processes. Its high melting point, thermal conductivity, and susceptibility to residual stress demand meticulous control over laser parameters, chamber environment, and post-processing protocols. Even minor deviations in layer thickness or scanning speed can result in porosity, warping, or anisotropic mechanical behavior—defects that are unacceptable in high-load or safety-critical applications. At Lead Precision, we employ industrial-grade laser powder bed fusion (LPBF) systems with real-time melt pool monitoring and closed-loop calibration to ensure dimensional accuracy down to ±0.03 mm.

Our engineering team leverages decades of metallurgical expertise to optimize build orientation, support structures, and thermal management strategies for each steel component. Whether working with maraging steel for aerospace tooling or 316L stainless for marine-grade parts, we tailor the entire process chain—from powder characterization to stress relief and precision machining—to meet exacting performance criteria. This holistic approach allows us to achieve not only geometric fidelity but also consistent mechanical properties, often exceeding ASTM and ISO standards.

The integration of 3D printing into our custom metal manufacturing workflow has expanded design freedom while maintaining the rigors of precision engineering. Components once assembled from multiple machined parts can now be printed as single units, reducing failure points and improving reliability. This is particularly critical in applications where failure is not an option—such as in military hardware or high-performance sports equipment engineered for Olympic competition.

Our commitment to precision is validated through rigorous in-house metrology, including coordinate measuring machines (CMM), metallographic analysis, and non-destructive testing. Every printed steel component undergoes full traceability, with build logs, material certifications, and inspection reports archived for client review.

Below are key technical specifications reflecting our 3D printing steel capabilities:

| Parameter | Specification |

|---|---|

| Material Options | 316L Stainless Steel, 17-4 PH, Maraging Steel M300, Tool Steel H13 |

| Layer Thickness Range | 20–60 µm |

| Build Volume | Up to 250 × 250 × 300 mm |

| Dimensional Accuracy | ±0.03 mm (typical) |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Post-Processing Options | Hot Isostatic Pressing (HIP), CNC Machining, Polishing, Passivation |

| Certification Standards | ISO 9001, ASTM F3055, ISO/ASTM 52921 |

At Wuxi Lead Precision Machinery, 3D printing steel is not just about innovation—it is about delivering precision-engineered solutions where performance, reliability, and consistency are paramount.

Precision Specs & Tolerances

Technical Capabilities: Precision Steel Component Manufacturing

Wuxi Lead Precision Machinery delivers exceptional steel component manufacturing through advanced subtractive and hybrid production methodologies. While additive manufacturing (3D printing) initiates complex steel part geometries, our core expertise lies in precision post-processing and finishing via 5-axis CNC machining. This integrated approach ensures structural integrity, micron-level accuracy, and surface finishes unattainable through additive processes alone. We specialize in transforming near-net-shape steel prints—produced via technologies like SLM or EBM—into mission-critical components for aerospace, medical, and energy sectors. Our facility houses 12 high-rigidity 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C400 U milling systems, equipped with high-frequency spindles (up to 30,000 RPM) and integrated probing. These platforms enable complex contouring, deep cavity milling, and simultaneous multi-face operations on hardened tool steels (H13, S7), stainless alloys (17-4PH, 316L), and maraging steels (18Ni300), eliminating secondary setups and preserving geometric fidelity.

Critical to our process is the elimination of residual stresses and dimensional drift introduced during additive fabrication. Our CNC protocols incorporate stress-relief annealing cycles, adaptive cutting strategies, and real-time thermal compensation to maintain tolerances across workpieces up to Ø1,200 mm. All operations follow AS9100 and ISO 13485 frameworks, with toolpath validation via Siemens NX CAM simulation to prevent collisions and ensure first-article success. Material traceability is enforced from raw powder to final inspection, with full chemical and mechanical property documentation per ASTM/AMS standards.

Quality assurance is anchored by Zeiss METROTOM 800 CT scanners and dual-arm CMMs (Brown & Sharpe GLOBAL S). Every component undergoes comprehensive metrology, including GD&T verification, surface roughness analysis (Ra 0.2–1.6 µm), and internal defect detection via computed tomography. Our inspection regime exceeds ISO 2768 medium-class requirements, with statistical process control (SPC) monitoring critical features across production batches. This end-to-end scrutiny guarantees compliance with aerospace MMPA standards and medical implant biocompatibility specifications.

The following table details achievable tolerances for machined steel features post-additive build:

| Feature Type | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM (Volumetric Comp.) |

| Geometric (Flatness) | 0.02 mm/m | 0.005 mm/m | Laser Interferometer |

| Hole Position | ±0.015 mm | ±0.003 mm | CMM (Probed Alignment) |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer (ISO 4287) |

| Thread Fit (Metric) | 6H/6g | 4H/4h | Go/No-Go Gauges + CMM |

Wuxi Lead’s capability transcends mere machining; we provide a closed-loop solution where CNC precision elevates additive foundations to meet the most stringent industrial demands. Our engineers collaborate from design-for-manufacturability (DFM) through final validation, ensuring steel components achieve zero-defect performance in extreme operational environments. This commitment to dimensional integrity and process control defines our role as a strategic manufacturing partner for high-value steel applications.

Material & Finish Options

Material Selection in High-Precision 3D Printing: Steel, Aluminum, and Titanium for Industrial Applications

When selecting materials for high-end 3D printed components in custom metal manufacturing, engineers must balance mechanical performance, environmental resistance, and post-processing requirements. At Wuxi Lead Precision Machinery, we specialize in additive manufacturing solutions using premium-grade steel, aluminum, and titanium—each offering distinct advantages depending on application demands. Understanding the intrinsic properties of these metals ensures optimal part functionality, longevity, and cost-efficiency across aerospace, automotive, medical, and industrial sectors.

Steel remains the cornerstone of industrial 3D printing due to its exceptional strength, wear resistance, and thermal stability. Our primary steel variant, 17-4 PH stainless steel, delivers high tensile strength (up to 1300 MPa) and excellent corrosion resistance, making it ideal for tooling, molds, and structural components exposed to harsh environments. This precipitation-hardened alloy can be heat-treated post-print to further enhance mechanical properties, ensuring dimensional stability under load. Its fine grain structure achieved through laser powder bed fusion results in superior surface integrity and fatigue resistance.

Aluminum alloys, particularly AlSi10Mg, offer a compelling solution where weight reduction is critical without sacrificing performance. With a density approximately one-third that of steel, AlSi10Mg provides high thermal conductivity, good fatigue strength, and inherent corrosion resistance. It is widely used in aerospace brackets, heat exchangers, and lightweight structural parts. While not as strong as steel, its strength-to-weight ratio and excellent printability make it a preferred choice for complex geometries requiring efficient thermal management.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands at the pinnacle of performance for mission-critical applications. Renowned for its outstanding strength-to-density ratio and biocompatibility, titanium excels in aerospace components, medical implants, and high-temperature environments. It maintains structural integrity up to 600°C and resists oxidation and corrosion in aggressive media. Though more costly and challenging to process, Ti-6Al-4V’s fatigue resistance and compatibility with stringent regulatory standards justify its use in high-reliability systems.

Post-processing finishes further define component performance. Anodizing is commonly applied to aluminum parts to enhance surface hardness, improve wear resistance, and allow for color coding or branding. While not applicable to steel or titanium in the same way, these metals benefit from alternative surface treatments such as passivation, polishing, or coating deposition to optimize functionality.

Below is a comparative overview of key material properties relevant to 3D printing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| 17-4 PH Steel | 7.8 | 1200–1300 | 1100–1200 | 12–15 | Tooling, industrial components |

| AlSi10Mg | 2.7 | 400–450 | 250–300 | 8–10 | Aerospace, heat exchangers |

| Ti-6Al-4V | 4.4 | 900–950 | 800–850 | 10–12 | Medical implants, aerospace parts |

Material selection in 3D printing is not a one-size-fits-all decision. At Wuxi Lead Precision Machinery, we support clients in aligning material choice with functional requirements, production volume, and lifecycle expectations to deliver precision-engineered metal components that meet the highest industrial standards.

Manufacturing Process & QC

Precision Steel Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our industrial-grade steel 3D printing process transforms complex digital designs into mission-critical components with uncompromising quality. We execute a rigorously controlled workflow spanning design validation, functional prototyping, and scalable mass production, engineered to achieve zero defects for aerospace, medical, and energy sector applications. This integrated approach eliminates downstream rework and ensures first-article conformance to the most stringent international standards.

The process begins with advanced design engineering and simulation. Our team collaborates closely with clients to optimize geometry for Laser Powder Bed Fusion (LPBF), incorporating topology optimization and thermal stress analysis using Ansys and Materialise software. Critical factors like support structure strategy, build orientation, and residual stress mitigation are resolved digitally before any metal is melted. This phase includes formal Design for Additive Manufacturing (DfAM) validation and material suitability assessment against ASTM F3055 or ISO/ASTM 52900 standards, preventing fundamental flaws at the source.

Prototyping transitions validated designs into physical test articles under full production parameters. We utilize identical EOS M 400-4 or SLM Solutions S500 systems and certified 17-4PH, 316L, or Inconel 718 powders as the final production run. Each prototype undergoes comprehensive metrology: CT scanning verifies internal integrity and dimensional accuracy, while mechanical testing confirms tensile strength, fatigue resistance, and microstructure meet specifications. This stage validates not only form and function but also the entire post-processing sequence—stress relieving, HIP, precision CNC machining, and surface finishing—ensuring the pathway to zero defects is proven at scale.

Mass production leverages our automated, monitored workflow across multiple certified build platforms. Real-time melt pool monitoring with Coherent sensors and in-situ thermal imaging detect anomalies at microsecond intervals, triggering immediate corrective actions. Every build adheres to our proprietary process window validation, with environmental controls maintaining oxygen levels below 100 ppm. Post-processing occurs within our integrated facility, where coordinate measuring machines (CMM) and optical scanners perform 100% inspection against CAD models. This closed-loop system, combined with AI-driven statistical process control, guarantees batch-to-batch consistency and eliminates escape defects.

Our production capabilities deliver certified steel components with the precision and reliability demanded by Tier 1 manufacturers. Key parameters are maintained across all production tiers:

| Parameter | Specification | Industry Standard Reference |

|---|---|---|

| Material Options | 17-4PH SS, 316L, Inconel 625, 718, Ti6Al4V | AMS 7000, ASTM F3188 |

| Build Volume | Up to 500 x 500 x 400 mm | ISO/ASTM 52921 |

| Layer Thickness | 20-60 μm | ISO/ASTM 52900 |

| Dimensional Accuracy | ± 0.05 mm per 100 mm | ISO 2768-m |

| Surface Roughness (As-Built) | Ra 8-15 μm | ISO 4287 |

| Post-Processing Tolerance | ± 0.01 mm (CNC Machined Features) | ISO 2768-f |

This systematic execution—from virtual design validation through production-scale execution—ensures Wuxi Lead delivers steel additive components that perform flawlessly in the field, reducing total cost of ownership while accelerating time-to-market for our global partners.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printing Steel Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom metal manufacturing solutions that meet the exacting demands of modern industry. As a leader in precision engineering and additive manufacturing, we offer advanced 3D printing steel services designed for aerospace, automotive, medical, and industrial applications where strength, durability, and dimensional accuracy are non-negotiable. Our state-of-the-art facilities, combined with decades of metallurgical expertise, enable us to produce complex steel components with superior mechanical properties, repeatability, and surface finish.

When you partner with Lead Precision, you gain more than a supplier — you gain a technical collaborator. Our engineering team works closely with clients from concept to completion, ensuring optimal material selection, design refinement, and process validation. Whether you require low-volume prototypes or high-volume serial production, our metal additive manufacturing systems deliver consistency and precision. We utilize selective laser melting (SLM) and direct metal laser sintering (DMLS) technologies with high-purity steel alloys, including 316L stainless steel, 17-4 PH, and maraging steel, to achieve densities exceeding 99.9%.

Our end-to-end manufacturing ecosystem includes in-house post-processing capabilities such as heat treatment, hot isostatic pressing (HIP), CNC machining, and surface finishing, ensuring every component meets international quality standards. All parts are inspected using advanced metrology tools, including coordinate measuring machines (CMM) and industrial CT scanning, to verify geometric accuracy and internal integrity.

We understand that performance requirements vary across industries. That’s why our 3D printing steel solutions are fully customizable — from lattice structures for weight reduction to conformal cooling channels for injection molds. Our agile production model supports rapid turnaround without compromising quality, giving you a competitive edge in time-to-market and product innovation.

Below are key technical specifications for our 3D printing steel capabilities:

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20 – 50 µm |

| Material Options | 316L Stainless Steel, 17-4 PH, Maraging Steel |

| Density | >99.9% (fully dense parts) |

| Tensile Strength (316L) | ≥550 MPa |

| Elongation at Break (316L) | ≥40% |

| Surface Roughness (as-printed) | Ra 10–15 µm |

| Post-Processing Options | HIP, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, ASTM F75, ASTM A276 |

Partnering with Wuxi Lead Precision Machinery means accessing cutting-edge technology backed by rigorous quality control and engineering excellence. We are committed to supporting your most demanding applications with scalable, reliable, and cost-effective metal additive manufacturing solutions.

For technical consultations, project quotes, or to discuss your 3D printing steel requirements, contact us today at [email protected]. Let us help you transform design challenges into high-performance realities.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.