Technical Contents

Engineering Guide: 3D Printing Services Nyc

Engineering Insight Precision Imperatives in NYC 3D Printing Services

New York City’s manufacturing ecosystem demands parts that perform flawlessly under exacting conditions. While accessibility to 3D printing services is high locally, true precision engineering remains scarce. Many providers prioritize speed over dimensional stability, leading to costly downstream failures in assembly or performance. For critical applications in aerospace, medical devices, or high-performance tooling, tolerances beyond ±0.1mm are non-negotiable. Thermal management during printing, residual stress control, and post-processing validation separate prototyping-grade output from production-ready components. NYC-based innovators require partners who treat precision as a systemic engineering discipline—not an afterthought.

At Wuxi Lead Precision Machinery, we engineer metal additive solutions where microns define success. Our work supporting Olympic infrastructure projects required titanium components with surface finishes under Ra 1.6µm and geometric tolerances holding ±0.025mm across 500mm spans—standards exceeding typical NYC service bureau capabilities. Similarly, military subcontractor engagements demanded certified repeatability for flight-critical assemblies, validated through rigorous NADCAP-accredited metrology. This heritage translates directly to NYC clients: we understand that a 0.05mm deviation in a hydraulic manifold or surgical guide can cascade into system failure. Our process integrates real-time melt pool monitoring, adaptive thermal compensation algorithms, and in-house 5-axis CNC finishing to ensure first-article compliance.

Material integrity is equally pivotal. Substandard powder handling or inconsistent inert gas environments introduce porosity that compromises fatigue life. We deploy ASTM F3055-compliant workflows with full material traceability, from vacuum-atomized Ti-6Al-4V to Inconel 718, ensuring mechanical properties match forged equivalents. Consider the specifications below as benchmarks for mission-critical work:

| Parameter | Capability Range | Industry Standard Comparison |

|---|---|---|

| Dimensional Tolerance | ±0.025mm to ±0.05mm | Typical: ±0.1mm to ±0.2mm |

| Surface Roughness (As-Built) | Ra 8–12µm | Typical: Ra 15–25µm |

| Surface Roughness (Post-Processed) | Ra 0.8–1.6µm | Typical: Ra 3.2–6.3µm |

| Max Build Volume | 500 x 500 x 500 mm | Common NYC Service: ≤300mm |

| Certified Materials | Ti-6Al-4V, Inconel 718, 17-4PH, AlSi10Mg | Limited to 1–2 alloys locally |

NYC’s competitive edge relies on manufacturing partners who merge local responsiveness with global-grade precision engineering. Wuxi Lead bridges this gap: our Chinese production infrastructure delivers Olympic-proven quality at scalable volumes, while dedicated US engineering teams provide seamless collaboration for NYC innovators. When your design demands zero-compromise accuracy, the true cost of 3D printing isn’t the machine hour—it’s the risk of tolerances that undermine your product’s purpose. Partner with engineers who measure success in microns, not just millimeters.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industries requiring precision, reliability, and consistency. As a trusted provider of high-end machining services, we specialize in complex part production using state-of-the-art 5-axis CNC machining technology. Our capabilities are engineered to meet the stringent demands of aerospace, medical, energy, and industrial automation sectors, where dimensional accuracy and material integrity are non-negotiable.

Our 5-axis CNC machining centers enable simultaneous multi-directional cutting, allowing for intricate geometries and tight tolerances that are unattainable with conventional 3-axis systems. This advanced machining process reduces setup times, improves surface finish, and ensures exceptional part accuracy by minimizing the need for repositioning. We work with a wide range of metals, including titanium, stainless steel, aluminum, Inconel, and tool steels, supporting both prototyping and high-volume production runs.

Every component undergoes a rigorous quality control protocol, anchored by comprehensive CMM (Coordinate Measuring Machine) inspection. Our metrology lab is equipped with high-precision CMM systems that verify critical dimensions, geometric tolerances, and surface characteristics against customer CAD models and engineering drawings. This closed-loop inspection process ensures full traceability and compliance with ISO 9001 standards, AS9100 for aerospace, and other industry-specific requirements.

Our technical team combines deep manufacturing expertise with digital engineering tools to optimize toolpaths, material utilization, and process efficiency. From initial design review to final inspection, we maintain continuous oversight to deliver parts that meet exact specifications. In addition to machining, we offer secondary services such as heat treatment, surface finishing, and precision assembly to provide fully finished components ready for integration.

The following table outlines our standard technical capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finishes available) |

| Standard Tolerance (Machined) | ±0.010 mm |

| Geometric Tolerance (GD&T) | ±0.005 mm (per ASME Y14.5) |

| Minimum Wall Thickness | 0.5 mm (material-dependent) |

| Typical Lead Time | 7–15 days (varies by complexity and volume) |

All technical data is validated through continuous in-process and final inspections. Wuxi Lead Precision Machinery remains committed to pushing the boundaries of precision manufacturing, supporting innovation through advanced capabilities and uncompromising quality.

Material & Finish Options

Material Selection for High-Performance Metal 3D Printing in NYC Applications

Selecting the optimal material for metal additive manufacturing is critical for NYC-based clients in aerospace, medical, and precision engineering sectors. Material choice directly impacts part performance, regulatory compliance, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize alloys that balance printability, mechanical properties, and post-processing efficiency for demanding urban industrial environments. Aluminum, steel, and titanium dominate high-value applications, each serving distinct functional requirements.

Aluminum alloys—particularly AlSi10Mg and 7075—are ideal for weight-sensitive components requiring thermal conductivity and corrosion resistance. These materials excel in aerospace brackets, heat exchangers, and automotive prototypes where NYC firms prioritize rapid iteration. Aluminum’s lower density reduces shipping costs for international collaborations while maintaining structural integrity under cyclic loads. However, its lower melting point necessitates precise laser parameter control during printing to avoid porosity.

Stainless steel variants like 316L and 17-4 PH deliver superior strength, hardness, and chemical resistance for medical implants, fluid handling systems, and tooling. 316L’s biocompatibility meets ASTM F744 standards for NYC healthcare clients, while 17-4 PH achieves H900 heat-treated tensile strengths exceeding 1300 MPa for high-stress industrial fixtures. Steel’s versatility supports complex geometries but requires stress-relief annealing to mitigate residual stresses inherent in layer-by-layer fabrication.

Titanium Grade 5 (Ti-6Al-4V) remains the benchmark for mission-critical applications demanding exceptional strength-to-weight ratios and biocompatibility. NYC aerospace and biomedical innovators leverage its fatigue resistance for turbine blades and orthopedic implants. Titanium’s inertness ensures longevity in saline or high-temperature environments but demands inert gas shielding during printing to prevent oxygen embrittlement.

Key Material Properties for Metal 3D Printing

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|

| AlSi10Mg | 300-350 | 180-220 | 2.67 | Heat sinks, drone components |

| 316L Stainless | 550-650 | 200-300 | 8.00 | Surgical instruments, valves |

| 17-4 PH Steel | 1200-1400 | 1100-1300 | 7.75 | Molds, aerospace fittings |

| Ti-6Al-4V | 900-1000 | 800-850 | 4.43 | Implants, aircraft structural |

Anodizing transforms aluminum surfaces into durable, corrosion-resistant finishes essential for NYC’s humid coastal climate. Type II (sulfuric acid) anodizing provides decorative color options and moderate wear resistance for consumer-facing parts. For industrial applications, Type III (hardcoat) anodizing delivers 50-100 μm thickness with Rockwell C60 hardness—critical for hydraulic components exposed to abrasive urban debris. All anodizing processes are ASTM-compliant and enhance adhesion for secondary coatings.

Wuxi Lead Precision Machinery integrates material science expertise with end-to-end quality control, ensuring your NYC project specifications translate into certified, production-ready components. Contact our engineering team to discuss alloy selection validated through 200+ successful trans-Pacific collaborations.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The journey of every high-performance metal component begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we collaborate closely with clients to translate conceptual requirements into manufacturable, high-integrity designs. Our in-house engineering team leverages advanced CAD/CAM software and DFMA (Design for Manufacturing and Assembly) principles to optimize geometry, material selection, and tolerance specifications. Finite element analysis (FEA) and thermal stress modeling are applied where necessary to ensure structural reliability under operational conditions. This phase is critical for eliminating potential failure points before any physical production begins. Design validation includes comprehensive digital simulations and, when required, cross-compatibility checks with 3D printing services in NYC or other additive manufacturing partners to ensure seamless integration of hybrid manufacturing workflows.

Prototyping: Validating Performance Before Scale

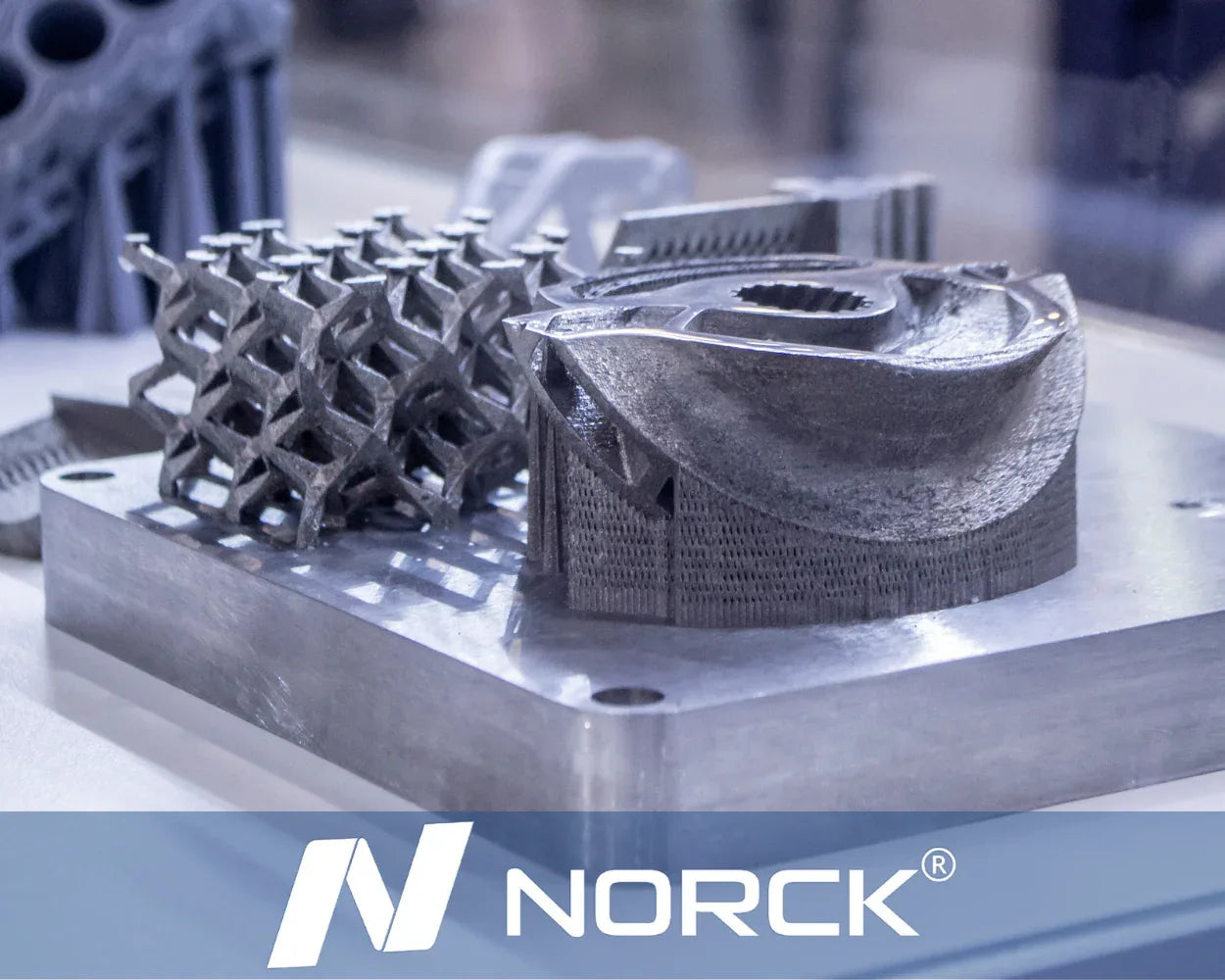

Once the design is finalized, we proceed to rapid prototyping using precision CNC machining and selective laser melting (SLM) technologies. This stage allows for functional testing, fit checks, and performance validation under real-world conditions. Unlike conventional prototyping services, our process maintains full production-grade material properties and surface integrity, ensuring that prototypes are not just visual models but true representations of the final part. Iterations are managed efficiently through digital feedback loops, reducing time-to-refinement. For clients integrating with 3D printing services in NYC, we provide certified material test reports and dimensional inspection data to ensure consistency across manufacturing platforms. Every prototype undergoes first-article inspection (FAI) per AS9102 standards, with full GD&T verification to confirm compliance.

Mass Production: Zero Defects Through Systematic Control

Transitioning to mass production, Wuxi Lead implements a zero-defect manufacturing framework built on statistical process control (SPC), real-time in-process monitoring, and 100% post-production inspection for critical features. Our ISO 9001 and IATF 16949-certified production lines utilize automated tool wear compensation, laser probing, and coordinate measuring machines (CMM) to maintain micron-level accuracy across batches. Each component is traceable through our ERP system, with lot-specific documentation including material certificates, process logs, and final inspection reports. This end-to-end traceability ensures full accountability and rapid root-cause analysis if anomalies arise.

Production Specifications

| Parameter | Capability | Tolerance Control | Quality Standard |

|---|---|---|---|

| Materials | Stainless Steel, Titanium, Inconel, Aluminum, Tool Steels | N/A | ASTM, AMS, ISO Certified |

| Dimensional Accuracy | Up to ±0.005 mm | Maintained via SPC & CMM | ISO 2768, AS9102 FAI |

| Surface Finish | Ra 0.4 µm to 3.2 µm (adjustable) | In-process metrology | Per customer specification |

| Batch Size | 1 – 100,000+ units | Scalable automation | Zero-Defect Target |

| Lead Time (Mass Prod) | 2–6 weeks (varies by complexity) | JIT and VMI options | On-time Delivery > 98% |

Through disciplined execution across design, prototyping, and production, Wuxi Lead ensures that every metal component meets the highest standards of precision and reliability—enabling seamless integration with advanced manufacturing ecosystems, including 3D printing services in NYC.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Additive Excellence

New York City’s advanced manufacturing sector demands precision, speed, and unwavering reliability—especially when prototyping or producing mission-critical metal components. While local 3D printing services offer convenience, they often face constraints in scalability, material expertise, and cost efficiency for complex industrial applications. Wuxi Lead Precision Machinery bridges this gap, delivering aerospace-grade metal additive manufacturing from our ISO 9001:2015 and AS9100D-certified facility in China, engineered specifically for discerning NYC enterprises. We eliminate the false choice between domestic proximity and global manufacturing excellence, providing NYC engineers with a strategic partner that combines cutting-edge technology, rigorous quality control, and transparent collaboration.

Our end-to-end metal AM workflow is built for industrial rigor. We specialize in Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) using premium materials including Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, and custom tool steels—validated for performance in aerospace, medical, and energy sectors. Unlike standard prototyping shops, we integrate precision CNC post-processing, heat treatment, and non-destructive testing within a single supply chain, ensuring dimensional accuracy and material integrity meet ASTM F3301 and AMS7000 standards. This holistic approach prevents the quality gaps common when outsourcing finishing to third parties.

Technical Capabilities for Demanding NYC Applications

| Capability | Specification | Relevance to NYC Engineering Teams |

|---|---|---|

| Build Volume | Up to Ø250 x 325 mm (DMLS) | Accommodates complex assemblies without segmentation |

| Dimensional Tolerance | ±0.05 mm for features < 50 mm | Critical for aerospace hydraulic components and medical implants |

| Surface Finish | As-built: Ra 12-25 μm; Post-CNC: Ra 0.8 μm | Meets stringent fluid dynamics and biocompatibility requirements |

| Material Certification | Full MTRs with chemical composition and mechanical properties | Ensures compliance for FAA/EASA and FDA-regulated projects |

| Lead Time | 72 hours for qualified prototypes | Accelerates NYC product development cycles without compromising quality |

Partnering with Lead Precision means gaining a responsive extension of your engineering team. We assign dedicated project managers fluent in English and technical standards to oversee every phase—from DfAM optimization and build simulation to final inspection reporting. Our digital workflow integrates seamlessly with NYC-based CAD systems (Siemens NX, SolidWorks, Creo), and we provide real-time build monitoring via secure cloud portals. This eliminates communication latency and ensures you retain full control, despite geographical distance.

For NYC manufacturers facing tight deadlines, complex geometries, or stringent material requirements, local 3D printing services often lack the industrial depth to deliver production-ready parts. We solve this by combining Chinese manufacturing scale with Western engineering discipline. Contact [email protected] today to discuss your project specifications. Include your target material, critical tolerances, and application for a confidential assessment within 24 business hours. Let us demonstrate how Lead Precision becomes your invisible advantage—turning ambitious NYC designs into certified, flight-ready, or implantable realities without supply chain compromise. Your next breakthrough deserves manufacturing precision that matches your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.