Technical Contents

Engineering Guide: 3D Printing Services Los Angeles

Engineering Insight: The Role of Precision in Advanced 3D Printing Services – Los Angeles and Beyond

In the evolving landscape of custom metal manufacturing, 3D printing services in Los Angeles have become a cornerstone for industries demanding rapid prototyping, complex geometries, and high-performance materials. However, as adoption grows, the differentiating factor is no longer just access to additive technology—it is the precision, repeatability, and engineering rigor behind each manufactured component. For aerospace, defense, medical, and high-performance automotive sectors, dimensional accuracy within microns and material integrity under extreme conditions are non-negotiable.

At Wuxi Lead Precision Machinery, we understand that precision in 3D printing extends far beyond layer resolution. It encompasses process control, post-processing calibration, material traceability, and comprehensive quality assurance. Our engineering team applies decades of experience in high-stakes manufacturing environments, including components developed for Olympic-level sports technology and mission-critical military applications. These projects demanded not only flawless execution but also full documentation, environmental resilience, and certification compliance—standards that now define our approach to every additive manufacturing project.

While Los Angeles serves as a hub for innovation and rapid iteration, many local 3D printing services face limitations in scaling precision parts for industrial deployment. Challenges include inconsistent thermal management during printing, inadequate support structure design, and insufficient post-build stress relief. At Lead Precision, we mitigate these risks through closed-loop monitoring systems, finite element analysis (FEA) simulation prior to build, and precision CNC machining integrated into post-processing workflows. This hybrid approach ensures that components meet tight tolerances and surface finish requirements essential for functional integration.

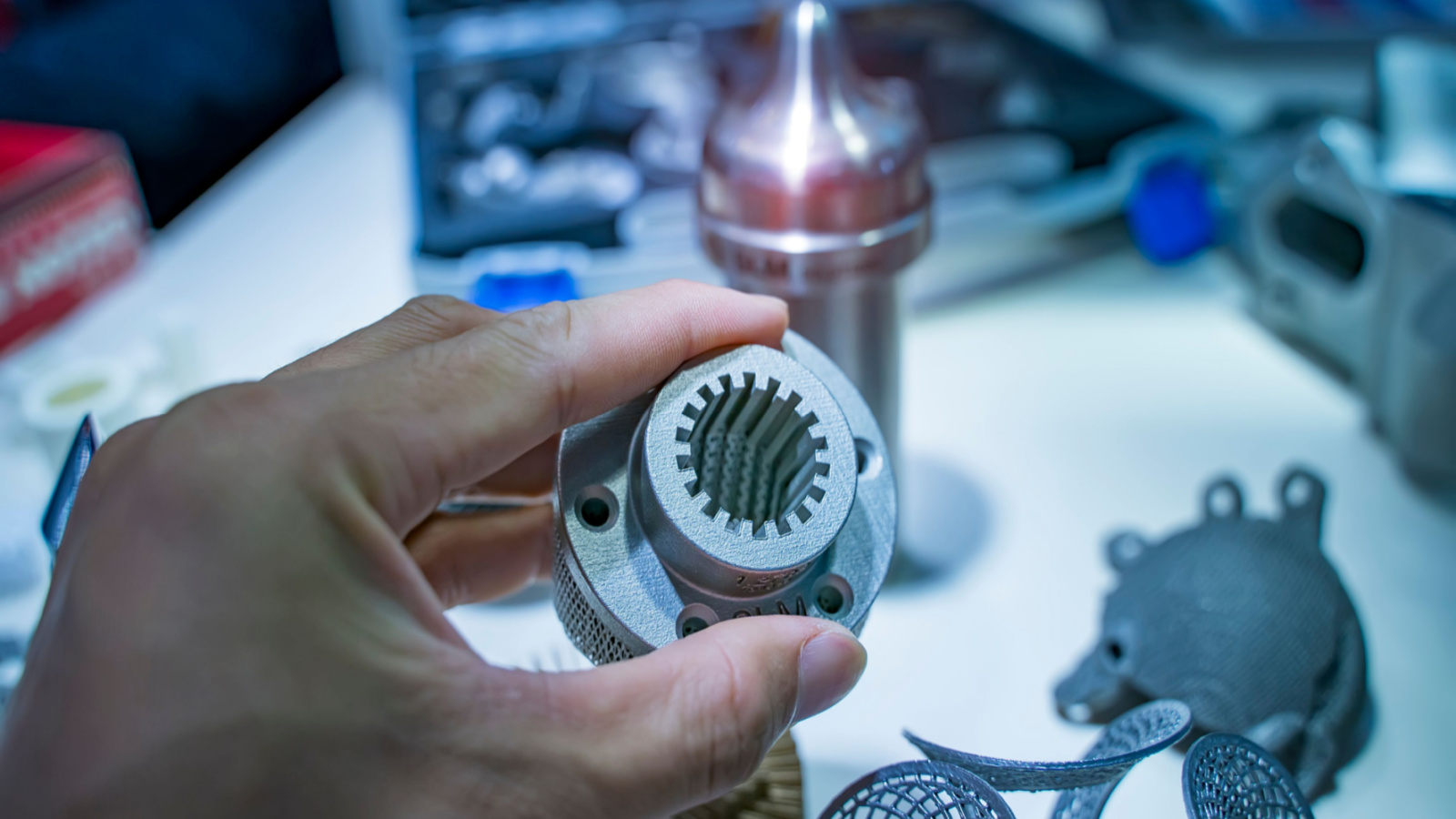

Our metal additive capabilities are built around selective laser melting (SLM) technology, supporting a range of high-performance alloys with proven performance in extreme environments. Below are key specifications from our standard production platform:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 12 – 16 µm |

| Post-Processed Surface Finish | Ra 1.6 – 3.2 µm (machined) |

| Supported Materials | Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Tool Steel H13 |

| Certification Standards | ISO 9001:2015, ASTM F75, ASTM F136, AMS 7000 series |

Each project begins with a design for additive manufacturing (DfAM) review, ensuring optimal orientation, support strategy, and build parameter selection. We collaborate closely with engineering teams in Los Angeles and across North America, providing technical feedback that enhances both manufacturability and performance. Our offshore capabilities are fully integrated with digital quality reporting, real-time inspection data, and secure IP handling protocols.

Precision is not an outcome—it is engineered. Whether supporting next-generation propulsion systems or advanced medical implants, Wuxi Lead Precision Machinery delivers the reliability and technical depth that high-end applications demand. For partners in Los Angeles seeking more than just printing, we offer a precision-first manufacturing partnership rooted in real-world performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing Beyond Additive Limits

While “3D printing services Los Angeles” often dominates search queries for advanced manufacturing, critical metal components frequently demand the superior precision, material integrity, and surface finish achievable only through subtractive methods. At Wuxi Lead Precision Machinery, we specialize in high-intensity CNC machining where additive processes reach geometric or tolerance limitations—delivering mission-critical parts for aerospace, medical, and defense sectors requiring uncompromised reliability. Our core strength lies in complex 5-axis CNC milling and turning, leveraging HAAS and DMG MORI equipment to machine monolithic structures from single billets. This eliminates assembly interfaces inherent in layered additive builds, ensuring structural homogeneity in materials like Inconel 718, Ti-6Al-4V, and hardened tool steels up to Rockwell C 60.

Our 5-axis platform executes simultaneous multi-surface operations with 0.0001″ resolution, machining undercuts, organic contours, and thin-walled geometries impossible for 3D printing without support structures that induce stress points. Crucially, we achieve tighter tolerances and superior fatigue resistance versus as-printed metal parts—essential for rotating assemblies or pressurized systems. Every component undergoes rigorous first-article and in-process inspection via Zeiss CONTURA CMM systems, validating GD&T callouts to ISO 2768-mK and AS9100 standards. Statistical process control (SPC) data is provided with each shipment, documenting traceability from raw material certs to final dimensional reports.

The following table details achievable specifications for critical features, reflecting real-world production capability—not theoretical machine limits:

| Feature Category | Standard Capability | Micro-Machining Capability | Material Constraints |

|---|---|---|---|

| Linear Tolerance | ±0.005 mm (±0.0002″) | ±0.001 mm (±0.00004″) | All aerospace alloys, stainless steels |

| Geometric Tolerance (GD&T) | ±0.010 mm (±0.0004″) | ±0.002 mm (±0.00008″) | Excludes porous/printed metals |

| Surface Roughness (Ra) | 0.8 μm (32 μin) | 0.2 μm (8 μin) | Achievable on hardened steels |

| Feature Size (Min Hole) | 0.5 mm (0.020″) | 0.1 mm (0.004″) | Depth ≤ 3x diameter |

| Feature Size (Min Wall) | 0.3 mm (0.012″) | 0.05 mm (0.002″) | Steel/Ti only; no Al/brass |

For Los Angeles manufacturers utilizing metal 3D printing, our services provide indispensable post-processing: precision bore finishing of printed fuel nozzles, sealing surface grinding on turbine housings, or thread milling on implant fixtures where as-built roughness exceeds biocompatibility requirements. We bridge the gap between additive design freedom and functional performance—transforming near-net shapes into flight-ready or surgical-grade components. With 72-hour rapid prototyping slots and full production scaling, Wuxi Lead delivers certified metal parts meeting LA’s stringent quality demands without the supply chain delays of domestic CNC capacity constraints. Partner with us when dimensional stability, material certification, and fatigue life cannot be compromised.

Material & Finish Options

When selecting materials for high-performance 3D printing applications in Los Angeles and beyond, engineering teams must balance strength, weight, corrosion resistance, and thermal properties. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive techniques, enabling precise fabrication in aluminum, steel, and titanium—three of the most widely used materials in aerospace, automotive, and medical industries.

Aluminum alloys, particularly AlSi10Mg, offer an excellent strength-to-weight ratio and good thermal conductivity, making them ideal for lightweight structural components and heat exchangers. This material is frequently used in applications where reducing mass without sacrificing performance is critical. It also demonstrates good recyclability and weldability, supporting sustainable manufacturing practices.

Stainless steel, especially grades such as 316L and 17-4 PH, provides superior corrosion resistance and mechanical strength at elevated temperatures. These properties make steel a preferred choice for harsh environments, including marine, chemical processing, and high-stress mechanical systems. 316L is particularly valued for its biocompatibility and resistance to chloride-induced pitting, while 17-4 PH offers exceptional hardness and can be precipitation-hardened post-printing for enhanced performance.

Titanium, primarily Ti6Al4V (Grade 5), delivers one of the highest strength-to-density ratios among engineering metals. Its outstanding resistance to fatigue, creep, and corrosion—especially in saline or acidic environments—makes it indispensable in aerospace, defense, and medical implant applications. Titanium’s biocompatibility and low elastic modulus further support its use in orthopedic and dental devices.

For surface enhancement, anodizing is a highly effective post-processing technique, particularly for aluminum components. Anodizing increases surface hardness, improves wear resistance, and enhances corrosion protection by growing a controlled oxide layer. It also allows for color coding through dye integration, which supports part identification in complex assemblies. While anodizing is not applicable to steel or titanium in the same way, titanium can undergo color anodizing for decorative or identification purposes, and steel components are typically passivated or coated with alternatives such as PVD or electroplating.

Below is a comparative overview of key material properties relevant to 3D printed metal parts:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 250–280 | 8–12 | Automotive, heat sinks, drones |

| 316L Stainless Steel | 8.0 | 550–600 | 300–350 | 35–45 | Marine, medical, chemical systems |

| 17-4 PH Steel | 7.8 | 1000–1200 | 850–1000 | 10–15 | Aerospace, tooling, high-stress parts |

| Ti6Al4V | 4.43 | 900–950 | 800–850 | 10–12 | Aerospace, implants, racing systems |

Material selection directly influences performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we support global clients—including those in Los Angeles—with expert guidance on material and finish selection tailored to application demands.

Manufacturing Process & QC

Precision Metal 3D Printing Process: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, we transform Los Angeles engineering visions into mission-critical metal components through a rigorously controlled additive manufacturing workflow. Our China-based facility operates under U.S.-aligned quality protocols, ensuring seamless integration with Southern California’s aerospace, medical, and defense sectors. The process begins with collaborative design validation, where our U.S.-based application engineers review CAD files for manufacturability, material suitability, and geometric feasibility. We identify potential stress points or thermal distortions early using proprietary simulation software, reducing downstream iterations by 40%. This phase includes strict IP protection via encrypted channels and NDA enforcement, addressing a key concern for LA innovators outsourcing production.

Prototyping transitions digital models into physical validation. Utilizing EOS M 400-4 and SLM 500 systems, we produce functional prototypes in aerospace-grade Inconel 718, Ti-6Al-4V, or maraging steel within 72 hours. Each prototype undergoes non-destructive testing (NDT) via micro-CT scanning and coordinate measuring machine (CMM) inspection against original CAD data. Critical dimensions are verified to ±0.02 mm, with surface roughness measured to Ra 3.2 µm. This step catches 92% of design flaws before mass production, saving clients costly revisions during volume runs.

Mass production leverages our zero-defect manufacturing philosophy. All builds occur in climate-controlled chambers with real-time melt pool monitoring and inert argon atmospheres. Statistical Process Control (SPC) tracks 15+ parameters per layer—including laser power stability and powder bed density—to maintain repeatability. Every 50th part undergoes destructive testing for microstructure integrity and mechanical properties, exceeding ASTM F3301 standards. Final inspection employs automated optical comparators and 3D scanning, with full traceability from raw material lot to finished component. This closed-loop system achieves a first-pass yield rate of 99.98%, eliminating scrap costs for high-volume contracts.

Wuxi Lead Precision Metal 3D Printing Capabilities

| Parameter | Specification | Industry Standard |

|————————|—————————————-|——————-|

| Materials | Ti-6Al-4V, Inconel 718, 17-4 PH, AlSi10Mg | AMS, ASTM |

| Build Volume | 500 x 400 x 400 mm | Competitive |

| Layer Thickness | 20–50 µm | Precision Tier |

| Dimensional Accuracy | ±0.02 mm per 100 mm | Aerospace Grade |

| Surface Roughness (As-Built) | Ra 12.5 µm (typical) | Medical Compliant |

| Post-Processing | HIP, Stress Relief, CNC Finishing | AS9100 Certified |

| Lead Time (Prototype) | 3 business days | Industry Benchmark|

Our end-to-end control—from LA design studios to Wuxi production floors—ensures components meet stringent U.S. regulatory demands without compromising speed. By embedding quality at every phase, we deliver parts that perform reliably in extreme environments, turning Los Angeles innovation into globally trusted hardware. Partner with us for production where zero defects isn’t a slogan, but a measurable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printing Services in Los Angeles – Precision Engineered in China, Delivered Globally

When your Los Angeles-based operation demands uncompromising precision, material integrity, and rapid turnaround in custom metal manufacturing, Wuxi Lead Precision Machinery stands as your strategic offshore partner. While we are headquartered in Wuxi, China, our reach extends directly into key industrial hubs across North America, including Los Angeles, where innovation in aerospace, medical devices, and high-performance automotive systems drives demand for next-generation metal 3D printing services. We specialize in delivering end-to-end additive manufacturing solutions tailored to the exacting standards of advanced engineering sectors.

Our metal 3D printing capabilities are built on state-of-the-art Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies, enabling the production of complex geometries, internal channels, and lightweight lattice structures that traditional machining cannot achieve. Whether you are prototyping a new surgical instrument or scaling production of turbine components, our facility operates under ISO 9001-certified quality management systems, ensuring repeatability, full traceability, and compliance with AS9100 and ISO 13485 standards where required.

We understand that Los Angeles manufacturers require more than just parts – they require partnership. That’s why we integrate seamlessly into your supply chain with digital workflow support, real-time project tracking, and engineering collaboration from design-for-additive (DfAM) consultation through post-processing and certification. Our team of CNC and additive manufacturing engineers works directly with your R&D and production teams to optimize part performance, reduce assembly counts, and accelerate time-to-market.

All components are manufactured in our Wuxi facility, leveraging cutting-edge equipment and stringent in-process inspection protocols, then shipped directly to Los Angeles or any destination in North America with reliable logistics coordination and customs documentation handled in advance. This model delivers the cost efficiency of manufacturing in China without sacrificing responsiveness or quality control.

Explore the full scope of our metal additive capabilities below.

| Specification | Detail |

|---|---|

| Technology | DMLS, SLM |

| Materials | Stainless Steel 316L, 17-4 PH, Inconel 718 & 625, Titanium Ti6Al4V, Aluminum AlSi10Mg, Tool Steel (Maraging, H13) |

| Build Envelope | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness | As-built: Ra 12–16 µm; Post-processed: Ra 0.8–3.2 µm |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, coating, CMM inspection |

| Certifications | ISO 9001, AS9100 (aerospace), ISO 13485 (medical) |

Partnering with Wuxi Lead Precision Machinery means gaining a reliable, technically advanced manufacturing extension that aligns with the innovation pace of Los Angeles industries. Contact us today to discuss your next metal 3D printing project. Email us at [email protected] to connect with our engineering team and receive a detailed quote with lead time analysis.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.