Technical Contents

Engineering Guide: 3D Printing Services Houston

Engineering Insight Precision as the Non-Negotiable Foundation in Industrial 3D Printing Services Houston

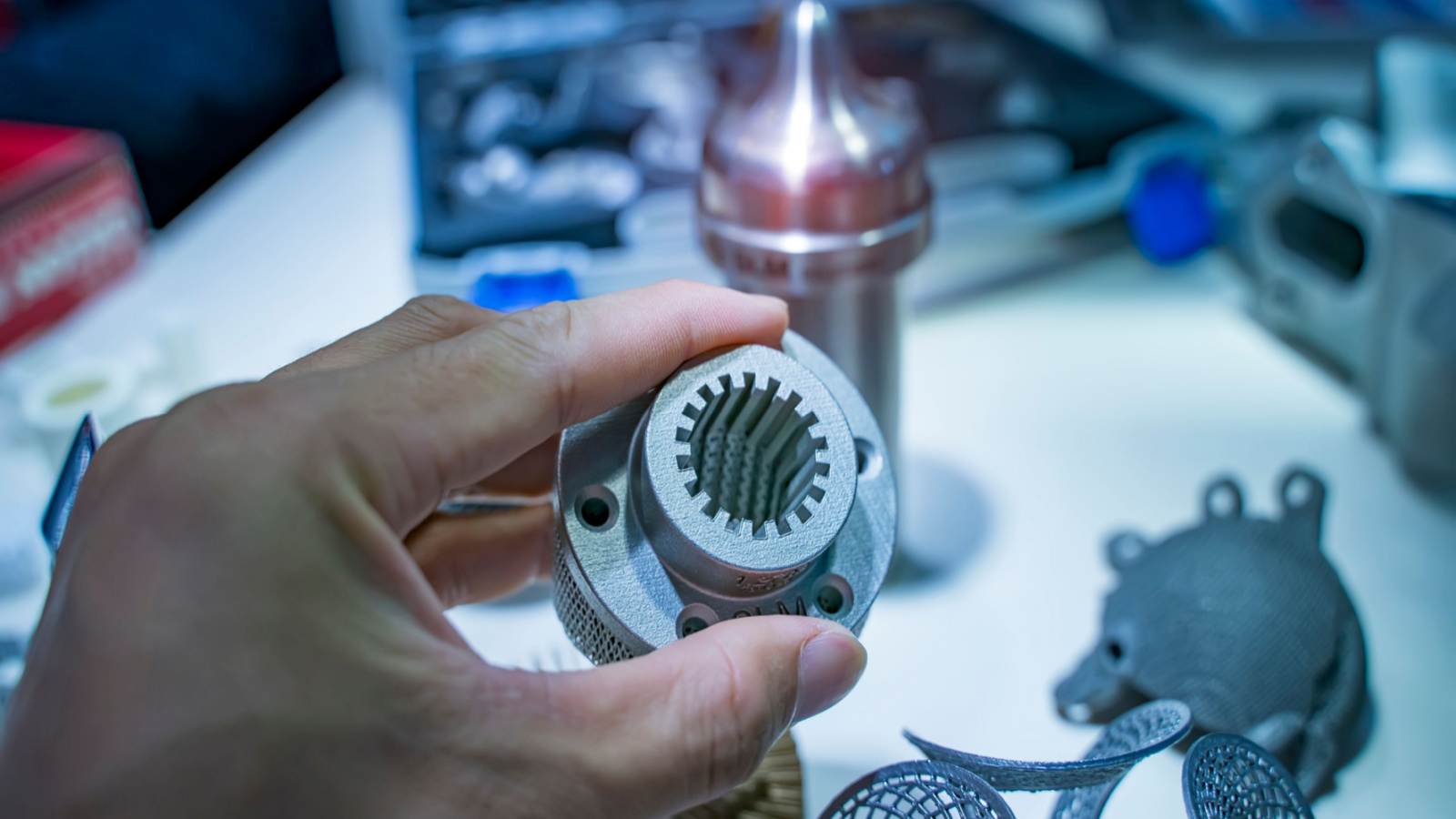

In the demanding landscape of Houston’s industrial sector—spanning energy, aerospace, and advanced manufacturing—the term precision transcends marketing rhetoric. It is the absolute cornerstone of viable metal additive manufacturing. When procuring 3D printing services Houston providers offer, dimensional accuracy, surface integrity, and material consistency are not merely desirable attributes; they are fundamental requirements dictating component functionality, safety, and regulatory compliance. Sub-millimeter deviations in turbine blades, downhole tooling, or aerospace brackets can cascade into catastrophic system failure or costly field recalls. True industrial 3D printing demands metrology-grade repeatability, not just prototyping capability. This is where the distinction between standard service bureaus and engineering-driven manufacturers becomes critically apparent.

Wuxi Lead Precision Machinery operates at this elevated precision threshold. Our engineering team possesses deep expertise in translating complex design intent into physically flawless metal components through additive processes. This rigor is forged through direct experience delivering mission-critical parts where failure is not an option. We have engineered and manufactured precision components for Olympic track cycling systems demanding aerodynamic perfection and structural integrity under extreme loads. Similarly, our facility has produced certified military-grade actuators and housings requiring strict adherence to MIL-STD specifications for dimensional stability and metallurgical properties under harsh operational environments. This background instills a culture where every build undergoes stringent in-process monitoring and final inspection protocols far exceeding typical service bureau standards.

The technical capability to achieve this level of precision is rooted in advanced hardware, controlled environments, and deep process mastery. Our dedicated metal additive systems operate within ISO Class 8 cleanrooms, minimizing particulate contamination that compromises part density and surface finish. Sophisticated in-situ monitoring tracks melt pool dynamics and thermal profiles layer by layer, enabling real-time adjustments to ensure geometric fidelity and material homogeneity. Post-processing, including precision stress-relieving, HIP (Hot Isostatic Pressing), and CNC finishing, is integral to meeting final dimensional tolerances and surface roughness requirements. For Houston clients, this means receiving flight-certifiable aerospace brackets or high-pressure valve components with guaranteed performance characteristics, not just printed forms requiring extensive rework.

The following table outlines the core precision capabilities inherent to our industrial metal additive manufacturing platform, directly applicable to Houston’s high-stakes projects.

| Parameter | Capability Range | Relevance to Houston Industry Applications |

|---|---|---|

| Build Volume | Up to Ø350 x 400 mm | Suitable for critical aerospace brackets, tooling inserts, sensor housings |

| Layer Thickness | 20 – 60 µm | Enables fine features in fluid dynamics components, medical implants |

| Dimensional Tolerance | ±0.05 mm typical (after finishing) | Meets ASME Y14.5 standards for oil & gas valve parts |

| Surface Roughness (As Built) | Ra 8 – 15 µm | Reduces post-processing time for hydraulic components |

| Key Materials | Inconel 718, Ti-6Al-4V, 17-4PH SS, AlSi10Mg | Matches requirements for downhole tools, turbine parts, marine hardware |

| In-Process Monitoring | Full melt pool & thermal imaging | Ensures defect-free builds for safety-critical military/aerospace parts |

Partnering with a provider possessing this engineering depth and proven track record in high-consequence applications mitigates risk for Houston manufacturers. It ensures that the 3D printing services Houston offers are not just a fabrication step, but a certified, reliable extension of your own precision manufacturing capability—delivering parts ready for integration, not just inspection. Precision isn’t an add-on; it is the essential engineering foundation.

Precision Specs & Tolerances

Technical Capabilities in Precision Metal Manufacturing

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to meet the exacting demands of high-performance industries. Specializing in complex, high-precision components, our facility integrates state-of-the-art 5-axis CNC machining with comprehensive quality assurance protocols to ensure every part meets stringent technical and dimensional requirements. Our engineering expertise supports clients across aerospace, energy, medical, and industrial automation sectors, where reliability and repeatability are non-negotiable.

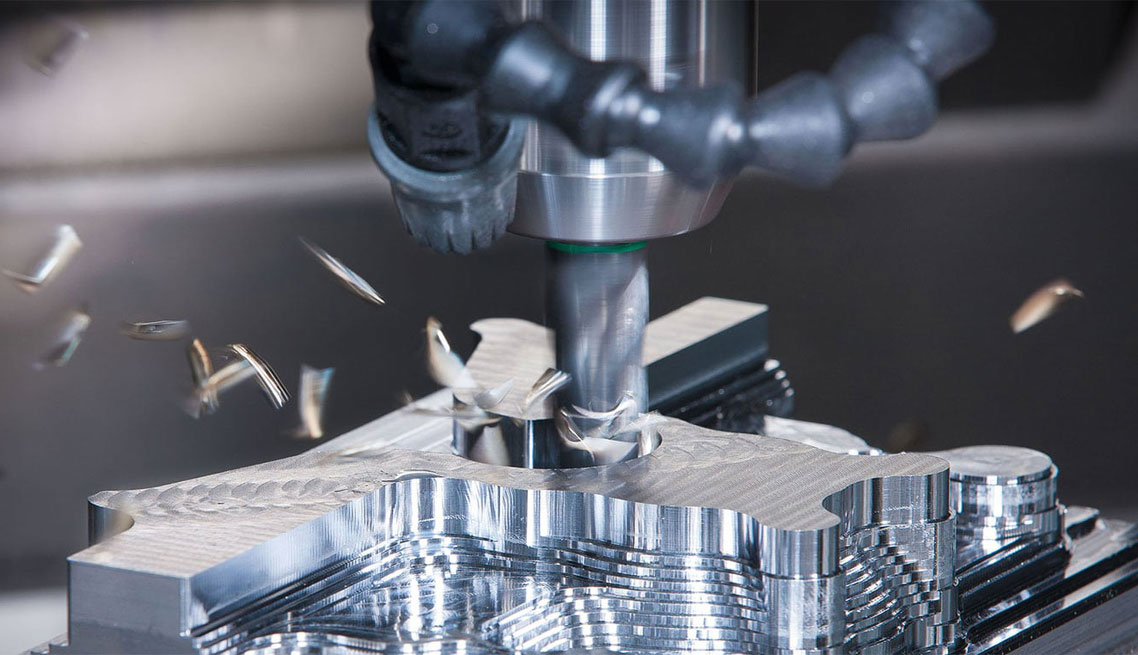

At the core of our production capabilities is a modern fleet of 5-axis CNC machining centers. These systems enable simultaneous multi-directional cutting, allowing for the efficient production of geometrically intricate parts in a single setup. This reduces cumulative error, improves surface finish, and significantly shortens lead times compared to traditional 3-axis methods. Our machines are optimized for a wide range of engineering metals, including titanium, Inconel, aluminum alloys, stainless steel, and tool steels. Whether producing low-volume prototypes or high-volume production runs, our machining processes maintain consistency and precision across all batches.

To ensure dimensional integrity, every critical component undergoes rigorous post-machining inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems are calibrated to international standards and operated by certified metrology technicians. This allows for full 3D verification of complex geometries, positional tolerances, and surface profiles. Data from CMM reports are documented and traceable, providing clients with full transparency and compliance with ISO 9001 and AS9100 quality management systems.

Our commitment to precision is reflected in the tight tolerances we consistently achieve across diverse part types and materials. The following table outlines our standard and advanced tolerance capabilities based on feature type and manufacturing process.

| Feature Type | Standard Tolerance | Advanced Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed/precision bored |

| Positional Tolerance | ±0.02 mm | ±0.005 mm | Relative to datum |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machined; polished upon request |

| Angular Features | ±0.05° | ±0.01° | 5-axis simultaneous control |

| Form Tolerance (Flatness) | 0.02 mm/m | 0.005 mm/m | Critical sealing surfaces |

All manufacturing workflows are supported by integrated CAD/CAM systems and digital process planning, ensuring seamless transition from design to delivery. Our technical team collaborates directly with clients to optimize part design for manufacturability, reducing cost and enhancing performance. With a focus on precision, repeatability, and quality assurance, Wuxi Lead Precision Machinery provides a trusted extension of your advanced manufacturing needs—delivering excellence from concept to final inspection.

Material & Finish Options

Material Selection for High-Performance Metal 3D Printing in Houston Applications

Selecting the optimal material and finish is critical for Houston-based industrial projects demanding precision, durability, and environmental resilience. Wuxi Lead Precision Machinery provides expert guidance on metal additive manufacturing materials and post-processing, ensuring your 3D printed components meet stringent oil and gas, aerospace, and medical device requirements prevalent in the Gulf Coast region. Understanding the core properties of aluminum, steel, and titanium alloys, coupled with appropriate surface treatments like anodizing, directly impacts part functionality, lifespan, and total cost of ownership.

Aluminum alloys, particularly 6061 and 7075, offer an exceptional strength-to-weight ratio ideal for weight-sensitive applications such as drone components or automotive fixtures. They provide good thermal conductivity and moderate corrosion resistance but require surface enhancement for harsh Houston environments. Stainless steel variants, especially 17-4 PH and 316L, deliver superior strength, excellent corrosion resistance against salt air and chemicals, and high-temperature stability crucial for downhole tools or marine hardware. Titanium Grade 5 (Ti6Al4V) stands unmatched for extreme strength-to-weight ratio, exceptional biocompatibility, and outstanding resistance to corrosion and high temperatures, making it indispensable for critical aerospace structural parts and medical implants where failure is not an option. Material choice must align precisely with the operational stresses, environmental exposure, and regulatory standards of your specific Houston project.

The following table details key performance characteristics for common metal 3D printing alloys:

| Material Category | Key Alloys | Typical Tensile Strength (MPa) | Max Continuous Use Temp (°C) | Primary Houston Applications |

|---|---|---|---|---|

| Aluminum | AlSi10Mg, 6061 | 300 – 400 | 150 – 200 | Lightweight fixtures, heat sinks |

| Stainless Steel | 17-4 PH, 316L | 900 – 1100 | 300 – 400 | Valves, pumps, marine components |

| Titanium | Ti6Al4V (Gr 5) | 900 – 1000 | 400 – 600 | Aerospace brackets, medical implants |

Anodizing is a vital post-processing step for aluminum components produced via metal 3D printing. This electrochemical process significantly enhances surface hardness, wear resistance, and corrosion protection—essential for parts exposed to Houston’s humid, saline atmosphere or industrial chemicals. Type II (sulfuric acid) anodizing provides a good balance of corrosion resistance and dyeability for identification, while Type III (hardcoat) anodizing delivers maximum abrasion resistance for high-wear applications like jigs and tooling. Proper anodizing also seals the inherently porous surface of 3D printed aluminum, preventing fluid ingress and ensuring long-term reliability. Wuxi Lead Precision Machinery integrates certified anodizing processes within our comprehensive finishing suite, guaranteeing consistent, high-quality results that meet ASTM B580 and AMS 2469 standards.

Partnering with Wuxi Lead ensures your Houston project leverages the right material science and surface engineering from print to final part. Our engineering team collaborates closely with your design and manufacturing staff to select the optimal alloy and finish combination, mitigating risk and maximizing component performance in demanding Gulf Coast operations. Contact our technical sales group for a detailed material suitability assessment on your next critical metal additive manufacturing project.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of every successful manufacturing project begins with a rigorous design phase. For clients seeking advanced 3D printing services in Houston, our engineering team collaborates closely with design inputs to ensure every component meets exact functional, dimensional, and material requirements. Utilizing advanced CAD software and simulation tools, we translate conceptual sketches or 3D models into manufacturable designs optimized for metal additive manufacturing. Finite element analysis (FEA) and thermal stress modeling are applied to predict performance under real-world conditions, minimizing the risk of failure. Design for manufacturability (DFM) principles are embedded throughout, ensuring geometry compatibility with laser powder bed fusion (LPBF) processes and eliminating unnecessary support structures or post-processing complexities.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using our high-precision metal 3D printing systems. This stage is critical for clients in aerospace, medical, and energy sectors who demand zero-defect outcomes. Prototypes are produced in the same material intended for mass production—typically Inconel 718, titanium Ti-6Al-4V, stainless steel 316L, or aluminum AlSi10Mg—ensuring accurate representation of mechanical properties and surface behavior. Each prototype undergoes comprehensive inspection, including coordinate measuring machine (CMM) verification, microstructure analysis, and non-destructive testing (NDT) such as X-ray computed tomography. Feedback from this phase is integrated into final design adjustments, ensuring full compliance with performance and regulatory standards before transitioning to full-scale production.

Mass Production: Scalable Precision with Zero-Defect Assurance

Our mass production process leverages a fully integrated digital workflow, enabling consistent replication of validated prototypes across hundreds or thousands of units. Each build is monitored in real time using in-situ sensors that track melt pool stability, layer adhesion, and atmospheric conditions within the build chamber. Post-processing—including stress relief, heat treatment, support removal, CNC machining, and surface finishing—is performed under strict quality controls aligned with ISO 9001 and AS9100 standards. Automated optical inspection (AOI) and batch traceability systems ensure every component is fully documented and defect-free. With a focus on lean manufacturing and continuous improvement, Wuxi Lead maintains production yields exceeding 99.5% across high-volume runs.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Printing Technology | Laser Powder Bed Fusion (LPBF) |

| Layer Thickness | 20–60 μm |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Standard Materials | Inconel 718, Ti-6Al-4V, 316L, AlSi10Mg, Maraging Steel |

| Tolerance | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001, AS9100, NADCAP (for NDT) |

Through this disciplined progression from design to prototyping to mass production, Wuxi Lead delivers defect-free, mission-critical metal components to global clients—supporting innovation and reliability in every part we manufacture.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal 3D Printing Excellence in Houston’s Industrial Ecosystem

Houston’s industrial sector faces relentless pressure to innovate while maintaining stringent quality and delivery schedules. Local 3D printing providers often struggle with complex metal part production, limited material options, and extended lead times that disrupt critical operations in aerospace, energy, and defense. At Wuxi Lead Precision Machinery, we resolve these challenges through a globally integrated yet locally responsive manufacturing partnership. Our China-based facility operates as your dedicated offshore extension, engineered specifically for Houston’s high-stakes projects. We merge advanced metal additive capabilities with rigorous aerospace-grade quality control, eliminating supply chain bottlenecks without sacrificing precision.

Lead Precision delivers mission-critical components where others cannot. Our end-to-end process begins with collaborative design analysis to optimize for additive manufacturing, ensuring structural integrity and cost efficiency. We specialize in demanding alloys essential to Houston’s core industries, including Inconel 718 for downhole tools, Ti-6Al-4V for aerospace assemblies, and custom tool steels for high-wear applications. Every build undergoes in-process monitoring and full post-processing—including heat treatment, HIP, and precision CNC finishing—to meet AS9100 and NADCAP standards. This systematic approach guarantees parts that perform under extreme Houston operational conditions, from Gulf of Mexico drilling environments to rocket engine test stands.

Our technical capabilities are structured to exceed Houston’s engineering specifications:

| Specification | Capability | Industry Relevance |

|---|---|---|

| Materials | Ti-6Al-4V, Inconel 625/718, SS 316L, AlSi10Mg, Maraging Steel | Oil & gas, aerospace, medical |

| Build Volume | 250 x 250 x 325 mm | Complex assemblies, tooling |

| Layer Thickness | 20–50 µm | High-resolution features |

| Dimensional Accuracy | ±0.025 mm | Critical mating surfaces |

| Surface Finish (as-built) | Ra 8–12 µm | Reduced post-processing time |

| Lead Time | 7–10 days (standard orders) | Just-in-time production support |

This precision is backed by our ISO 9001-certified workflow and dedicated U.S. technical liaison team, ensuring seamless communication across time zones. We integrate directly with your engineering data systems, providing real-time build updates and full traceability from raw powder to certified component. Unlike regional vendors constrained by limited capacity, Lead Precision scales production to your volume needs—from single prototypes to batch runs of 500+ units—without compromising on NDT testing or metallurgical validation.

When Houston’s projects demand parts that must function flawlessly on the first try, our partnership becomes your strategic advantage. We absorb the complexity of advanced metal additive manufacturing so your engineering teams can focus on innovation, not supply chain firefighting. Contact us today to initiate an engineer-to-engineer consultation. Email [email protected] with your part specifications and timeline requirements. Our technical sales team will respond within 4 business hours with a feasibility assessment and competitive quotation. Let Lead Precision become your trusted source for metal 3D printing that meets Houston’s exacting standards—delivered faster, certified stronger, and engineered for success.

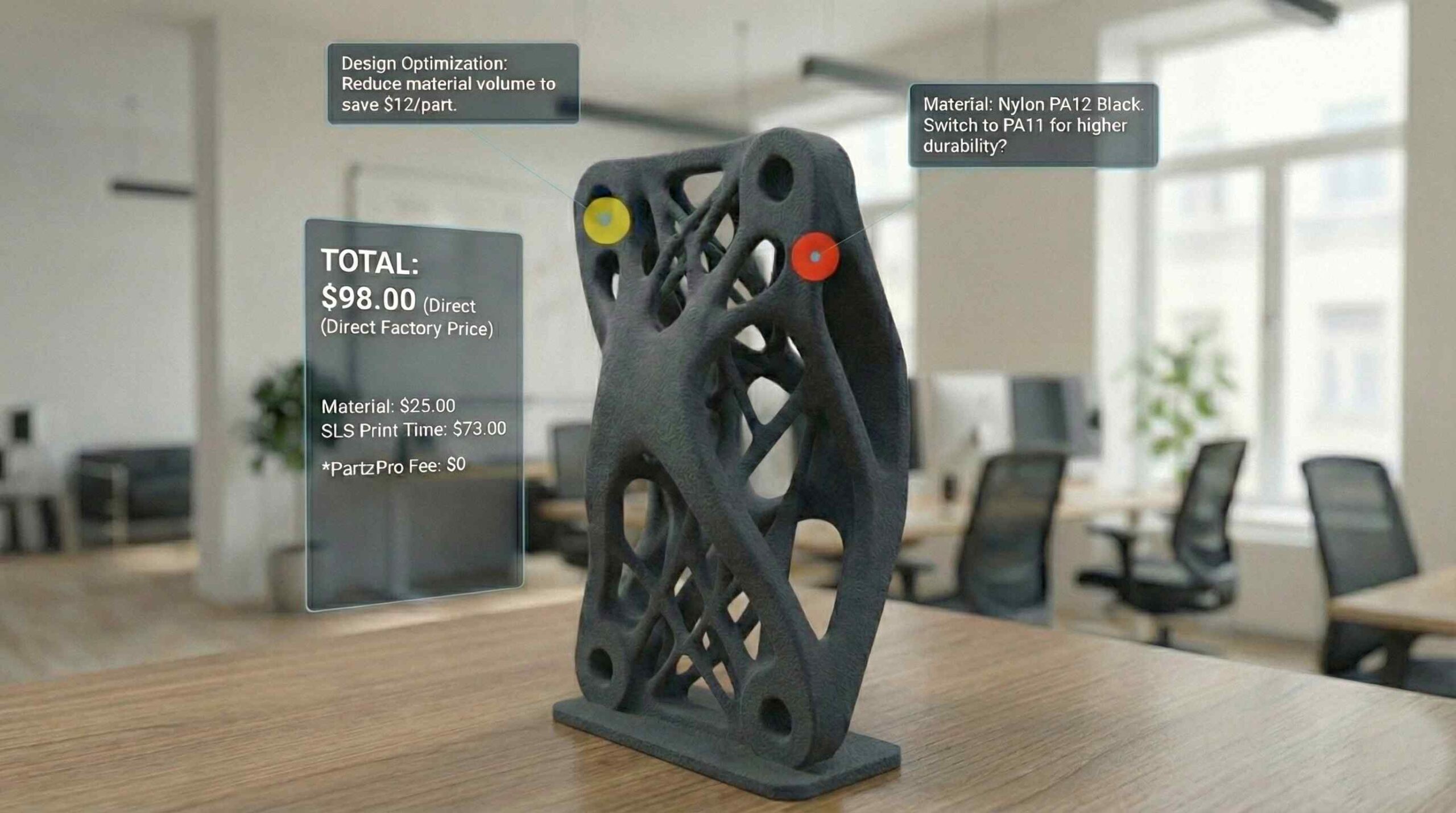

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.