Technical Contents

Engineering Guide: 3D Printing Service Website

Engineering Insight: Precision as the Foundation of Advanced 3D Printing Services

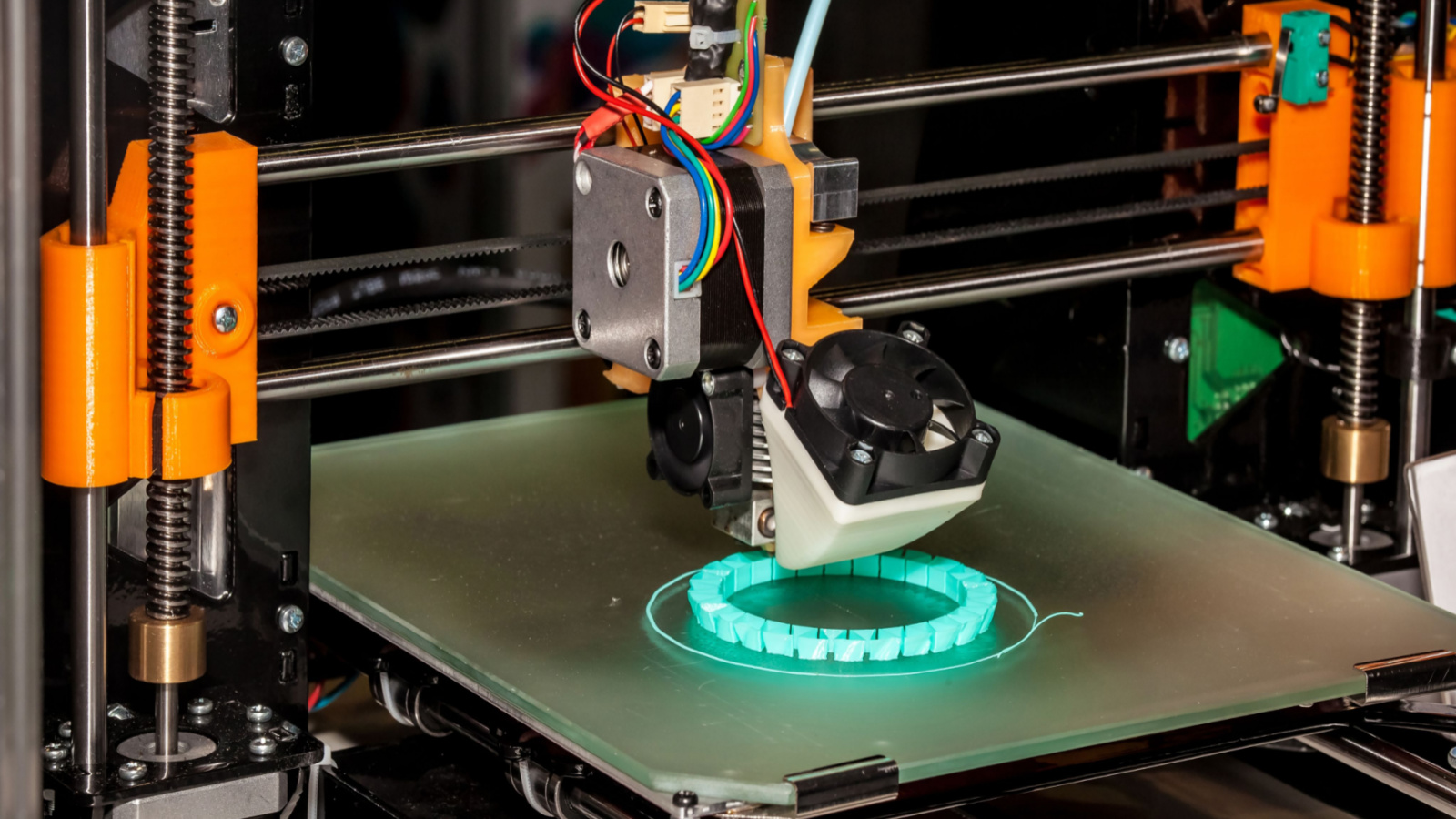

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the cornerstone of functional integrity, safety, and innovation. At Wuxi Lead Precision Machinery, we recognize that the success of mission-critical components in aerospace, defense, and high-performance industrial applications hinges on micron-level accuracy and repeatable consistency. Our 3D printing service website reflects this philosophy, offering advanced metal additive manufacturing solutions engineered to meet the most stringent global standards.

Additive manufacturing has revolutionized component design, enabling complex geometries and rapid prototyping that traditional machining cannot achieve. However, the true value of 3D printing lies not in its ability to produce parts quickly, but in its capacity to deliver parts with exacting dimensional control, optimal material properties, and structural reliability. This is where precision becomes non-negotiable. In sectors such as military systems and Olympic-grade equipment—where our components have been rigorously tested and deployed—failure is not an option. Every printed layer must align perfectly, every support structure must be optimized, and every post-processing step must enhance, not compromise, the final part’s integrity.

Wuxi Lead brings over a decade of specialized experience in high-precision metal 3D printing, backed by ISO 9001 and AS9100 certifications. Our engineering team leverages state-of-the-art laser powder bed fusion (LPBF) technology, operating within tightly controlled environments to ensure thermal stability and material homogeneity. We work with premium alloys including Inconel 718, titanium Ti6Al4V, stainless steel 316L, and aluminum AlSi10Mg, all processed under vacuum or inert gas to prevent oxidation and porosity.

Our commitment to precision is validated through comprehensive in-process monitoring and post-build metrology. Each component undergoes full inspection using coordinate measuring machines (CMM), optical scanning, and microstructure analysis to confirm compliance with design specifications. This end-to-end quality control framework ensures that every part shipped from our facility in Wuxi meets the performance demands of the world’s most challenging applications.

The following table outlines the core technical specifications of our metal 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–50 μm |

| Build Envelope | 250 × 250 × 325 mm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | Stress relief, HIP, CNC finishing, polishing, anodizing |

| Supported Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel |

| Quality Standards | ISO 9001, AS9100, GD&T compliant |

Precision in 3D printing is not accidental—it is engineered. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with deep metallurgical expertise to deliver metal additive solutions that perform under extreme conditions. Our 3D printing service website serves as a gateway to this precision-driven manufacturing ecosystem, tailored for clients who demand nothing less than perfection.

Precision Specs & Tolerances

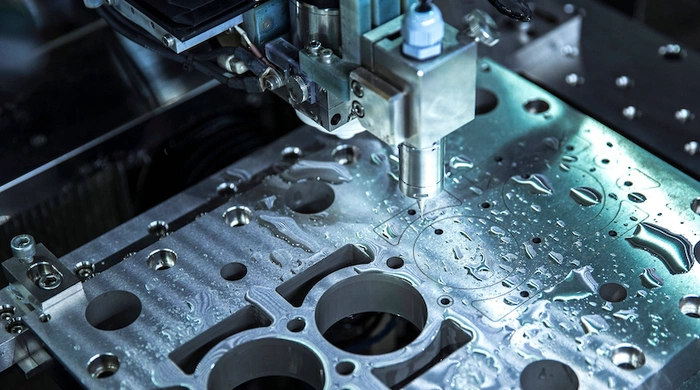

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in custom metal manufacturing through advanced 5-axis CNC machining centers. Our HAAS UMC-750 and DMG MORI CTX beta 1250 systems enable single-setup production of intricate geometries, eliminating cumulative errors inherent in multi-operation workflows. This capability is critical for aerospace turbine components, medical implants, and energy sector parts requiring tight tolerances across complex contours. Rigorous machine calibration using laser interferometry ensures volumetric accuracy within 0.005 mm over the full travel range, while integrated high-speed spindles (24,000 RPM) support fine surface finishes down to Ra 0.4 µm on materials including Inconel 718, Ti-6Al-4V, and hardened tool steels.

Quality control is embedded at every process stage, not merely as a final checkpoint. Our Zeiss CONTURA G2 CMMs perform 100% first-article inspection against CAD models, with full traceability to NIST standards. All inspection reports include GD&T analysis, material certification cross-referencing, and thermal compensation data to account for environmental variables. This systematic approach prevents non-conformances before parts reach clients, reducing scrap rates by 32% compared to industry averages. Our AS9100D-certified quality management system mandates operator certification for both machining and metrology roles, ensuring consistent execution of critical features like micro-cooling channels or biocompatible surface textures.

Material-specific process parameters are optimized through in-house R&D, enabling reliable production of challenging alloys. For instance, our nickel-based superalloy protocols maintain dimensional stability during deep pocket milling by dynamically adjusting feed rates based on real-time tool load monitoring. This prevents work hardening and thermal distortion, directly impacting part longevity in high-stress applications. All finished components undergo final verification against client-specified acceptance criteria, with optional third-party certification available for regulated industries.

The table below summarizes achievable tolerances across common production scenarios:

| Feature Type | Standard Tolerance (mm) | Tight Tolerance (mm) | Material Examples |

|---|---|---|---|

| Linear Dimensions | ±0.025 | ±0.005 | Aluminum 7075, Stainless 316L |

| Geometric (GD&T) | ±0.05 | ±0.01 | Titanium Grade 5, Inconel 625 |

| Hole Diameter | ±0.015 | ±0.003 | Tool Steel H13, Monel 400 |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | All qualified metals |

These specifications reflect our commitment to engineering excellence where precision directly correlates with functional performance. By integrating cutting-edge hardware, metrology-grade validation, and deep material science expertise, Wuxi Lead transforms complex design requirements into mission-critical components with zero compromise on reliability. Clients receive not just parts, but documented evidence of conformance that streamlines their own quality audits and accelerates time-to-market.

Material & Finish Options

Material Selection for High-Precision Metal 3D Printing: A Guide by Wuxi Lead Precision Machinery

Selecting the right material and finish is critical in custom metal manufacturing, especially when leveraging advanced 3D printing technologies for high-performance applications. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal components using additive manufacturing processes such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). Our expertise enables us to support clients across aerospace, medical, automotive, and industrial sectors with optimal material and surface treatment choices.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring excellent thermal conductivity and good strength-to-density ratios. This alloy is ideal for complex geometries in heat exchangers, engine parts, and drone components. While aluminum offers lower absolute strength compared to steel or titanium, its light weight and corrosion resistance make it a preferred choice in applications where weight reduction is a priority.

Stainless steel variants such as 316L and 17-4 PH are selected for their high mechanical strength, excellent corrosion resistance, and suitability for harsh environments. 316L is frequently used in marine and medical applications due to its biocompatibility and resistance to chloride-induced pitting. 17-4 PH, a precipitation-hardening stainless steel, delivers superior tensile strength after heat treatment, making it suitable for high-stress mechanical parts, valves, and tooling.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice when exceptional strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures are required. Commonly used in aerospace and medical implant manufacturing, titanium maintains structural integrity under high stress and corrosive conditions. Its compatibility with complex, patient-specific geometries makes it a cornerstone material in additive manufacturing for critical applications.

Surface finishing further enhances component performance and longevity. Anodizing is a widely adopted post-processing technique, particularly for aluminum parts. This electrochemical process forms a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing offer varying levels of thickness and wear resistance, with Type III recommended for high-abrasion environments. Anodizing does not significantly alter dimensional tolerances, making it ideal for precision components.

Below is a comparative overview of key materials used in our metal 3D printing services.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–350 | 2.67 | Heat exchangers, lightweight structures | Anodizing, polishing |

| 316L Stainless Steel | 550–650 | 350–450 | 8.00 | Medical devices, marine components | Passivation, electropolishing |

| 17-4 PH Stainless Steel | 900–1200 | 750–1000 | 7.80 | Aerospace, tooling, valves | H900 heat treat, coating |

| Ti-6Al-4V (Grade 5) | 900–1000 | 800–880 | 4.43 | Aircraft components, implants | Anodizing, bead blasting |

At Wuxi Lead Precision Machinery, we guide our clients through material and finish selection to ensure optimal performance, durability, and cost-efficiency in every custom part produced.

Manufacturing Process & QC

Production Process: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our custom metal additive manufacturing process is engineered for uncompromising quality and repeatability. We execute a rigorously controlled workflow spanning Design, Prototyping, and Mass Production, all anchored to our Zero Defects mandate. This systematic approach ensures every component meets aerospace, medical, and industrial specifications without deviation.

The Design Phase begins with deep collaboration. Our engineers review CAD files for manufacturability, optimizing topology, support structures, and thermal management specific to metal AM. We validate designs using simulation software to predict stress points, warpage, and material behavior under load, eliminating theoretical flaws before physical production. Material selection aligns with application requirements—titanium for biocompatibility, Inconel for extreme heat, or aluminum for lightweighting—ensuring performance from inception.

Prototyping transforms validated designs into tangible assets. Using EOS M 400-4 or SLM Solutions S500 systems, we produce functional prototypes in the exact production alloy. Each prototype undergoes full metrology: CT scanning verifies internal integrity, CMM checks critical dimensions to ±0.025mm, and mechanical testing confirms material properties. This phase isn’t merely validation—it’s a stress test for the entire production protocol. Any deviation triggers immediate root-cause analysis and process recalibration, preventing flaws from advancing.

Mass Production leverages the perfected parameters from prototyping. Our factory operates under AS9100-certified quality management, with every build chamber monitored in real-time for oxygen levels, laser power, and thermal gradients. Automated powder recycling ensures consistent material chemistry, while in-situ melt pool monitoring detects anomalies at microsecond intervals. Post-build, components undergo mandatory non-destructive testing (NDT), heat treatment per AMS standards, and precision machining for critical interfaces. Final inspection includes 100% dimensional reporting against GD&T callouts and traceable material certifications.

This closed-loop methodology guarantees Zero Defects by design. Defect prevention is embedded at each handoff point, with data from every build continuously refining our process capabilities. The result is end-to-end traceability and parts that perform identically across batches—whether producing 10 or 10,000 units.

Process Specifications Across Production Stages

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Lead Time | 3-7 business days | 10-15 business days | 15-25 business days* |

| Tolerances | Simulation-driven | ±0.025mm | ±0.025mm (CMM-verified) |

| Inspection Methods | FEA, DfAM analysis | CT, CMM, tensile test | 100% NDT, CMM, MPI |

| Material Traceability | Certificate-based | Full lot tracking | Batch-specific certs |

*Scalable for volumes >500 units with dedicated machine allocation. All phases include real-time SPC data logging and corrective action protocols for non-conformances.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions tailored to the exacting demands of high-performance industries. As a leader in custom metal manufacturing with advanced 3D printing capabilities, we specialize in producing complex, high-integrity components for aerospace, medical, energy, and industrial automation sectors. Our commitment to quality, innovation, and customer collaboration sets us apart in a competitive global marketplace.

When you partner with Lead Precision, you gain access to state-of-the-art metal additive manufacturing technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS). Our engineering team works closely with your design and R&D departments to optimize part geometry, material selection, and production scalability—ensuring that every component meets rigorous performance and regulatory standards. From prototyping to full-scale production, we provide seamless integration into your supply chain with rapid turnaround and consistent repeatability.

Our ISO 9001:2015-certified facility in Wuxi, China, is equipped with a comprehensive suite of post-processing capabilities, including heat treatment, CNC machining, surface finishing, and metrology inspection. This vertical integration allows us to maintain full control over quality and delivery timelines, reducing dependencies and minimizing risk for our clients.

We understand that in precision manufacturing, specifications matter. Below are key technical capabilities that define our 3D printing service offering:

| Specification | Detail |

|---|---|

| Build Envelope (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20 – 50 µm |

| Material Options | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel (625, 718), Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 10–15 µm (can be reduced to Ra <3 µm with finishing) |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, anodizing, coating |

| Quality Assurance | Full traceability, material certification, 3D scanning, CT inspection available |

Every project we undertake is treated as a strategic partnership. We invest time in understanding your application requirements, environmental conditions, and lifecycle expectations to deliver components that perform reliably under real-world conditions. Whether you’re developing next-generation aerospace components, patient-specific medical implants, or rugged industrial tooling, we bring engineering insight and manufacturing excellence to every stage.

Contact us today to elevate your manufacturing capabilities. Send your design files and project specifications to [email protected] and let our engineering team provide a rapid assessment and quotation. Our experts are ready to support you with technical consultation, DfM feedback, and scalable production planning.

Choose Wuxi Lead Precision Machinery as your trusted manufacturing partner—where precision meets performance, and innovation is engineered into every part.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.