Technical Contents

Engineering Guide: 3D Printing Service Uk

Engineering Insight: The Role of Precision in 3D Printing Services in the UK

In the evolving landscape of advanced manufacturing, 3D printing services in the UK have become a cornerstone for industries demanding rapid prototyping, complex geometries, and low-volume production runs. However, as adoption grows across aerospace, defence, and high-performance engineering sectors, the true differentiator lies not merely in the ability to print metal parts, but in the precision, repeatability, and material integrity achieved throughout the additive manufacturing process.

At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is engineered. Our experience delivering mission-critical components for Olympic-standard equipment and military-grade systems has instilled a culture where tolerances are not just met, they are guaranteed. When UK-based manufacturers partner with Lead Precision, they gain access to a process framework refined through years of supplying components where failure is not an option.

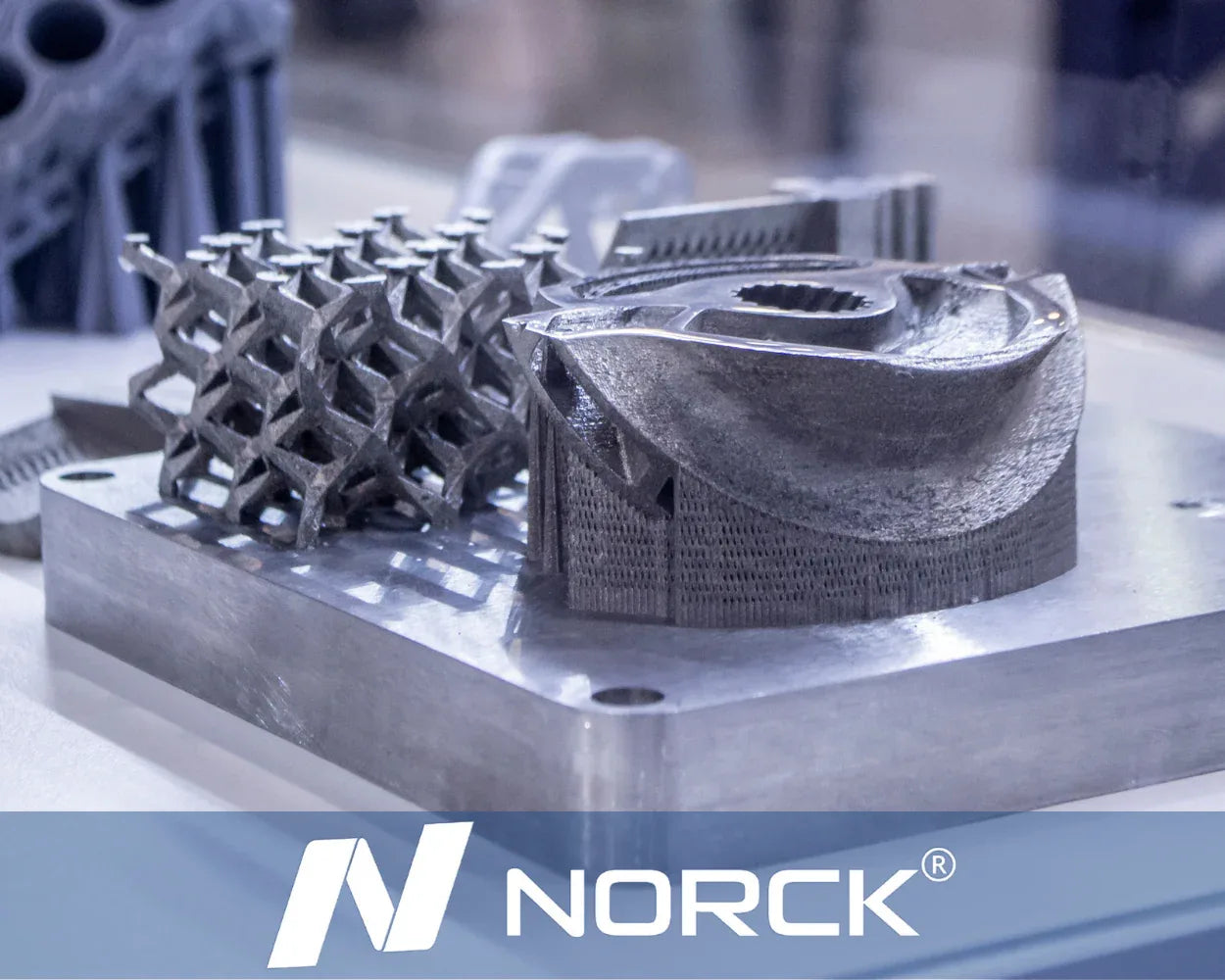

Metal 3D printing, particularly using technologies such as selective laser melting (SLM) and direct metal laser sintering (DMLS), allows for the creation of parts with internal channels, lattice structures, and topology-optimized forms impossible through traditional machining. Yet without stringent process control, these advantages can be undermined by residual stress, porosity, or dimensional drift. Our approach integrates in-situ monitoring, post-process heat treatment, and precision CNC finishing to ensure every part meets the exacting standards required by UK engineering leaders.

We collaborate closely with UK design engineers to optimize part orientation, support structures, and build parameters—ensuring that as-printed components not only match CAD specifications but also perform reliably under real-world loads and thermal cycles. This level of engineering insight is born from our work on high-stakes projects, including lightweight titanium assemblies for high-speed motion systems and corrosion-resistant Inconel components for extreme environments.

For UK manufacturers seeking a trusted offshore partner, Lead Precision offers more than advanced machinery—we offer proven expertise in transforming digital designs into certified, precision-engineered metal components. Our facility in Wuxi operates under ISO 9001 and AS9100 standards, with full traceability from powder to finished part.

Below are key specifications demonstrating our 3D printing capabilities relevant to UK industrial demands.

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–60 microns |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing |

| Materials Available | Ti6Al4V, Inconel 718, Stainless Steel 316L, AlSi10Mg, CoCr, Tool Steel (Maraging) |

| Quality Certification | ISO 9001, AS9100, Material Test Reports (MTR) |

Precision in 3D printing is not accidental. It is the result of disciplined engineering, rigorous validation, and a commitment to excellence—values that define both UK manufacturing and Wuxi Lead Precision Machinery.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding UK Applications

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions specifically engineered for the stringent requirements of UK industries including aerospace, medical device, and high-performance automotive sectors. While additive manufacturing holds niche value, our core expertise and investment focus on precision subtractive processes where dimensional accuracy, material integrity, and surface finish are non-negotiable. We specialize in complex, high-value metal components where 5-axis CNC machining provides the optimal balance of precision, repeatability, and material performance over alternative methods for critical applications.

Our production floor is anchored by state-of-the-art DMG MORI CTX beta 1250 and DMC 1035 V linear 5-axis CNC machining centers. These platforms enable the complete machining of intricate geometries in a single setup, eliminating cumulative error from multiple fixtures and significantly enhancing positional accuracy. Capable of handling materials from aerospace-grade titanium alloys (Ti-6Al-4V) and Inconel 718 to medical stainless steels (316L, 17-4PH) and high-strength aluminum alloys, our machines achieve exceptional surface finishes down to Ra 0.4 µm while maintaining micron-level tolerances across complex contours. The integrated high-precision spindles and thermal compensation systems ensure stability during extended production runs, critical for UK customers requiring batch consistency.

Rigorous quality control is inseparable from our manufacturing process. Every critical component undergoes comprehensive verification using Zeiss CONTURA G2 coordinate measuring machines (CMM). Our certified metrology lab performs full geometric dimensioning and tolerancing (GD&T) analysis, surface roughness validation, and material verification per ISO 17025 standards. This data is fully traceable and provided in detailed inspection reports, offering UK clients complete confidence in part conformance to their engineering specifications and regulatory requirements such as AS9100 or ISO 13485. We implement statistical process control (SPC) methodologies throughout production to proactively manage variation.

Material selection and process optimization are guided by decades of application-specific experience. We collaborate closely with UK engineering teams during the design for manufacturability (DFM) phase to identify potential challenges early, recommend optimal material grades for the operational environment, and suggest geometric refinements that enhance machinability without compromising function. This proactive engineering partnership minimizes lead times and ensures the final component meets the exact performance demands of its end-use application, whether a fuel system manifold for a regional aircraft or an implantable orthopedic device.

The following table details our standard achievable tolerance capabilities under controlled production conditions for common materials. Specific project requirements may allow for tighter control through enhanced process validation.

| Feature Type | Standard Capability | Typical Capability | Best Achievable (Controlled Conditions) |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | ±0.005 mm |

| Geometric Tolerances | ±0.025 mm | ±0.012 mm | ±0.005 mm |

| Hole Diameter | ±0.020 mm | ±0.010 mm | ±0.003 mm |

| Positional Accuracy | ±0.030 mm | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | 0.4 µm |

Wuxi Lead Precision Machinery provides UK manufacturers with a reliable, high-precision alternative for mission-critical metal components where the performance guarantees of CNC machining are essential. Our technical capabilities are backed by robust quality systems and a commitment to engineering collaboration, ensuring your specifications are met with unwavering consistency.

Material & Finish Options

Material Selection in Custom Metal 3D Printing: A Guide for Precision Engineering

Selecting the appropriate material and finish is critical in high-performance metal 3D printing applications, particularly within aerospace, automotive, and medical manufacturing sectors. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal components using advanced additive manufacturing technologies. Our expertise ensures optimal material performance, dimensional accuracy, and surface integrity tailored to demanding industrial environments.

Aluminum alloys, particularly AlSi10Mg, are widely used in lightweight structural applications where strength-to-density ratio is paramount. This material offers excellent thermal conductivity, good corrosion resistance, and high fatigue performance, making it ideal for complex geometries in drone components, heat exchangers, and automotive brackets. Its compatibility with selective laser melting (SLM) enables intricate internal channels and topology-optimized designs not feasible with traditional machining.

Stainless steel variants such as 316L and 17-4 PH provide superior mechanical strength, wear resistance, and durability in aggressive environments. 316L is preferred for marine and chemical processing equipment due to its outstanding corrosion resistance, while 17-4 PH delivers high tensile strength through precipitation hardening, suitable for valve parts, molds, and high-stress fixtures. Both steels exhibit excellent weldability and long-term stability under thermal cycling.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands at the forefront of high-end additive manufacturing. Renowned for its exceptional strength-to-weight ratio and biocompatibility, it is the material of choice for aerospace structural components, medical implants, and performance racing parts. Ti-6Al-4V maintains mechanical integrity at elevated temperatures and resists oxidation and saltwater corrosion, ensuring reliability in extreme operational conditions.

Post-processing surface treatments further enhance component functionality. Anodizing, commonly applied to aluminum parts, increases surface hardness and corrosion resistance while allowing for color coding and improved adhesion for coatings. Type II and Type III (hardcoat) anodizing are available depending on application requirements, with hardcoat offering superior abrasion resistance for high-wear environments.

Below is a comparative overview of key materials used in our metal 3D printing services:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 2.67 | Heat exchangers, lightweight frames | Anodizing, bead blasting |

| 316L Stainless Steel | 550–600 | 400–450 | 8.00 | Marine components, chemical valves | Passivation, polishing |

| 17-4 PH Steel | 900–1000 | 750–850 | 7.80 | Molds, aerospace fixtures | HVOF coating, polishing |

| Ti-6Al-4V | 900–950 | 800–850 | 4.43 | Medical implants, jet engine parts | Anodizing, plasma spraying |

Material selection must align with functional requirements, environmental exposure, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through material testing, DfAM optimization, and full traceability documentation. Our ISO-certified processes ensure every component meets stringent international standards, whether produced for UK markets or global deployment.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our production process for custom metal components—delivered to exacting UK engineering standards—integrates advanced additive manufacturing with rigorous quality control. We eliminate defects at every stage through a disciplined sequence: Design Validation, Prototyping & Iteration, and Scalable Mass Production. This methodology ensures your final parts meet aerospace, medical, and industrial performance requirements without compromise.

The process begins with comprehensive Design for Additive Manufacturing (DfAM) analysis. Our engineers collaborate with your team to optimize geometry, material selection, and support structures specifically for metal 3D printing. We simulate thermal stresses and build orientation using certified software, identifying potential weaknesses before the first layer is deposited. Critical tolerances, surface finishes, and post-processing needs are defined collaboratively, ensuring the digital model aligns with functional intent and regulatory demands. This phase prevents costly downstream errors and accelerates time-to-market.

Prototyping transforms the validated design into physical reality. Using our industrial-grade metal AM systems (primarily selective laser melting with stainless steel 316L, Inconel 718, and Ti6Al4V), we produce functional prototypes matching production material properties. Each prototype undergoes full metrological validation against CAD data. Dimensional accuracy, mechanical properties, and assembly fit are verified. We provide detailed inspection reports, enabling data-driven refinements. This iterative loop—typically 1-3 cycles—de-risks the design and confirms manufacturability before committing to volume production.

Mass production leverages the perfected process parameters from prototyping within a controlled, ISO 9001-certified environment. Production builds are monitored in real-time via melt pool sensors and inert gas analytics. Every component undergoes 100% first-article inspection, followed by statistically significant in-process checks using coordinate measuring machines (CMM) and optical comparators. Critical features are verified at defined intervals throughout the build run. Post-processing—including heat treatment, precision machining, and surface finishing—adheres to documented procedures with calibrated equipment. Final inspection confirms all specifications are met, with full traceability from raw material certificates to finished part documentation.

Our commitment to Zero Defects is operationalized through embedded quality gates and advanced metrology. The table below details our core inspection capabilities for UK-bound components:

| Inspection Parameter | Equipment Used | Capability Range | Accuracy/Tolerance | Traceability Standard |

|---|---|---|---|---|

| Dimensional Accuracy | Zeiss CONTURA CMM | 0.001 mm – 1000 mm | ±(2.5 + L/300) µm | NIST-traceable |

| Surface Roughness | Mitutoyo SJ-410 Profilometer | Ra 0.05 µm – 12.5 µm | ±5% of reading | NIST-traceable |

| Material Composition | Bruker Q4 Fluorescence | ppm to 100% | ±0.01% for key elements | Certified Reference |

| Internal Defect Detection | Nikon XT H 225 CT Scanner | Up to Ø300 mm parts | 50 µm resolution | ASTM E1000 compliant |

This integrated approach—grounded in engineering collaboration, empirical validation, and closed-loop quality control—guarantees that every metal component shipped from Wuxi Lead to the UK performs reliably in your most demanding applications. We deliver not just parts, but documented confidence in every shipment.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printing Services in the UK

When precision, reliability, and scalability define your manufacturing needs, partnering with Wuxi Lead Precision Machinery ensures access to world-class metal 3D printing services tailored for high-performance industries. As a leading provider of custom metal manufacturing solutions from China, we specialize in delivering complex, high-integrity components to clients across aerospace, medical, automotive, and energy sectors—directly supporting UK engineering firms with seamless cross-border collaboration.

Our state-of-the-art metal additive manufacturing capabilities are built on a foundation of precision engineering, advanced materials science, and rigorous quality control. Whether you require rapid prototyping, low-volume production, or full-scale serial manufacturing, our team in Wuxi integrates seamlessly with your design and engineering workflows to deliver parts that meet exact technical specifications and regulatory standards.

We understand the unique demands of UK-based manufacturers—especially in industries where component failure is not an option. That’s why every part produced through our 3D printing service undergoes comprehensive inspection, including dimensional verification, metallurgical analysis, and non-destructive testing when required. Our certifications align with international quality benchmarks, ensuring traceability and compliance across every production run.

Our metal additive processes support a broad range of high-performance alloys, enabling the production of lightweight, topology-optimized, and functionally integrated parts that are difficult or impossible to achieve through traditional machining. From Inconel turbine blades to titanium medical implants, our technology delivers superior geometric freedom and material efficiency.

Below are key specifications of our metal 3D printing capabilities:

| Specification | Detail |

|---|---|

| Technology | Selective Laser Melting (SLM) |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–60 μm |

| Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Inconel (625, 718), Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Surface Roughness | As-built: 10–15 μm Ra; Post-processed: <3 μm Ra |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Post-Processing | Stress relieving, HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), NDT compliance (UT, PT, RT) |

Collaborating with Lead Precision means more than just sourcing parts—it means gaining a strategic manufacturing partner committed to innovation, speed, and technical excellence. Our engineering team provides full DfAM (Design for Additive Manufacturing) support, helping UK clients optimize designs for performance, cost, and manufacturability from the earliest stages.

For UK businesses navigating supply chain complexity and rising production demands, our direct communication channels, rapid turnaround times, and scalable infrastructure offer a competitive edge. We manage logistics efficiently, ensuring timely delivery to your facility with full documentation and quality reports.

Contact us today to discuss your next project. Send your CAD files, material requirements, and production goals to [email protected] and receive a detailed technical and commercial proposal within 24 hours. Let Wuxi Lead Precision Machinery become your trusted partner in advanced metal 3D printing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.