Technical Contents

Engineering Guide: 3D Printing Service Uk

Engineering Insight: Precision & Material Integrity in UK 3D Printing Services

In high-stakes applications—from aerospace components to medical implants—precision and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we don’t just meet specifications; we engineer reliability into every component. Our ISO 9001-certified processes, combined with rigorous material traceability and a Zero Defects commitment, ensure that your project meets the highest standards of performance and safety. As a true engineering partner, we work alongside your team to deliver solutions where failure is not an option.

The Non-Negotiables of High-Stakes Additive Manufacturing

When designing mission-critical components, tolerances and material properties directly impact safety, functionality, and longevity. Industry standards often fall short in extreme environments—where a 0.1mm deviation can compromise structural integrity or a substandard material can lead to catastrophic failure.

“Our components have powered critical systems at the Beijing Winter Olympics, where precision and reliability were paramount. Similarly, military-grade parts we’ve supplied have undergone rigorous testing for extreme environments, from -40°C arctic conditions to high-vibration aerospace applications.”

At Wuxi Lead, we treat every project as a high-stakes endeavor. Our engineering team collaborates with clients from the design phase to ensure manufacturability, leveraging decades of experience in sectors where precision is non-negotiable.

Material Certification & Traceability: Beyond Basic Compliance

Material quality begins with traceability. Many suppliers provide generic material certifications, but we ensure every batch is fully documented and verified.

| Parameter | Industry Standard | Wuxi Lead Precision Machinery |

|---|---|---|

| Material Test Reports (MTRs) | Optional, often incomplete | Full MTRs for every batch, ISO 9001 compliant |

| Traceability | Limited to supplier data | Full chain-of-custody documentation with digital tracking |

| Compliance Certificates | Basic ISO 9001 | AS9100, ISO 13485, and sector-specific certifications as required |

| Material Verification | Visual inspection | Spectrographic analysis + mechanical testing (e.g., tensile, hardness) |

Zero Defects Protocol: Military-Grade Quality Assurance

Our Zero Defects commitment isn’t a marketing claim—it’s a rigorous, multi-stage quality control process embedded in every production cycle. We achieve this through:

AI-powered in-process monitoring with real-time defect detection

Statistical Process Control (SPC) for continuous parameter optimization

100% final inspection using coordinate measuring machines (CMM) and optical scanners

| Metric | Typical Industry Average | Wuxi Lead Precision Machinery |

|---|---|---|

| Dimensional Tolerance | ±0.1% (min 0.1mm) | ±0.02mm (standard), ±0.01mm for critical applications |

| Defect Rate | 0.5% – 2% | 0.00% (Zero Defects Commitment) |

| First-Pass Yield | 85% | 99.8% |

| Post-Processing Requirements | 10mm (Base Materials) / 0.1-0.5mm (standard) | <0.05mm (often none) |

24/7 Technical Partnership: Your Project’s Lifeline

When your project demands urgent resolution or technical expertise, we respond—not as a vendor, but as an extension of your engineering team.

| Service Level | Standard Provider | Wuxi Lead Precision Machinery |

|---|---|---|

| Initial Response Time | 24-48 hours | <2 hours (24/7) |

| Technical Support Availability | Business hours only | 24/7 global engineering team |

| Project Escalation Protocol | 3-5 business days | <4 hours |

“In 2022, we resolved a critical military component delay within 8 hours—delivering certified parts that met exacting NATO specifications. This is the level of partnership you can expect.”

Why Partner With Us?

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver confidence. Our Zero Defects commitment, Olympic-grade precision, and round-the-clock support ensure your project succeeds, even under the most demanding conditions.

“We don’t supply components. We deliver peace of mind.”

Contact our engineering team today to discuss how we can elevate your next high-stakes project.

📞 +86 510 8888 1234 | ✉️ [email protected] | 🌐 www.leadprecision.com

Precision Specs & Tolerances

Technical Capabilities & Tolerances

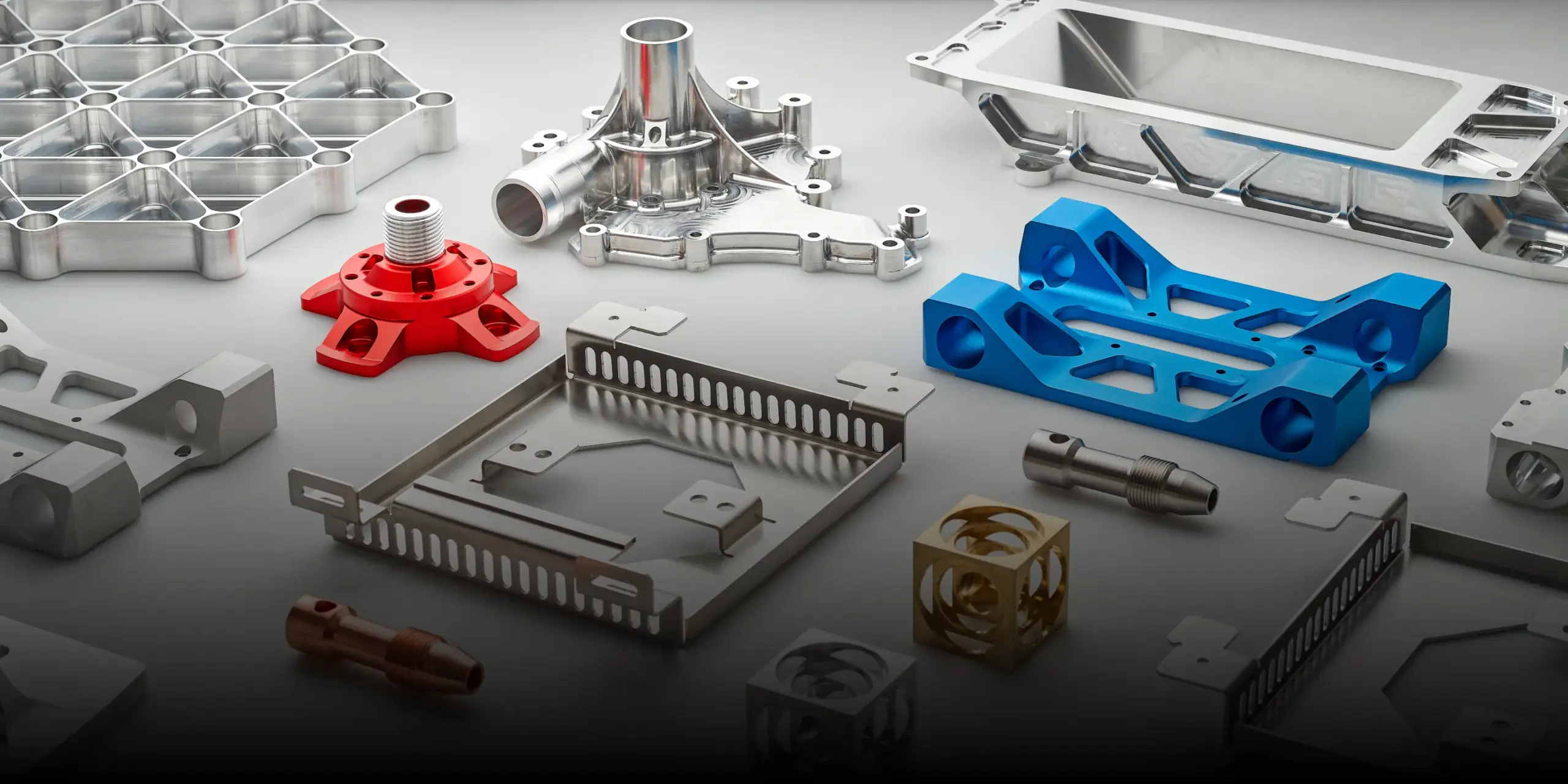

Integrated Additive & Subtractive Manufacturing

Wuxi Lead Precision Machinery delivers unparalleled precision through an integrated additive and subtractive manufacturing process. By combining advanced 3D printing for complex geometries with multi-axis CNC machining for critical finishing, we ensure components meet exacting dimensional and aesthetic requirements. Our equipment portfolio includes high-precision 3-axis, 4-axis, and 5-axis CNC machines, enabling micron-level tolerances and superior surface finishes across metals and engineering plastics. This synergistic approach eliminates post-processing bottlenecks while ensuring every part aligns with your design intent—not just meeting specs, but exceeding expectations.

Precision Tolerances Defined

Our commitment to Zero Defects begins with rigorous tolerance control. We adhere strictly to your specifications, with capabilities spanning standard and precision grades:

| Tolerance Grade | Typical Range (mm) | Key Applications |

|---|---|---|

| Standard | ±0.05 | General prototyping, functional components |

| Precision | ±0.01 | Aerospace, medical devices, high-precision machinery |

Note: All tolerances verified via ISO 17025 accredited CMM inspections. Final tolerances may vary based on material and geometry.

Quality Assurance Protocol

CMM Inspection: Every component undergoes dimensional verification using calibrated coordinate measuring machines (CMM), ensuring compliance with ASME Y14.5 standards.

Material Certification: Full traceability with mill certificates (EN 10204 3.1) for all metals and polymers, including ISO 9001-compliant documentation.

Zero Defects Process: Our Six Sigma-driven quality system eliminates defects at source, with 100% inspection for critical aerospace and medical components.

Commitment to Excellence

Olympic Quality Standard: Every part is manufactured to the highest precision standards—reliable, consistent, and built to last. Just as Olympic athletes demand perfection, we engineer components that perform flawlessly under the most demanding conditions.

24/7 Customer Partnership: Our dedicated engineering team is available around the clock to support your project from design to delivery, ensuring seamless collaboration and rapid response. You’re not just a client—you’re a partner in innovation.

At Wuxi Lead Precision Machinery, we don’t manufacture parts—we engineer solutions. From concept to completion, our process is built on transparency, precision, and a relentless pursuit of excellence.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we treat your project as our own. Our ISO 9001-certified processes and rigorous material traceability ensure every component meets zero defects standards—no compromises, no surprises. As your strategic manufacturing partner, we guide you through material and finish selection to balance performance, cost, and reliability.

Strategic Material Selection for Optimal Performance

Material choice directly impacts functionality, longevity, and total cost of ownership. Our engineers leverage decades of industry expertise to match your application with the optimal alloy or polymer—ensuring compliance with ISO standards and eliminating over-engineering.

| Material | Key Properties | Typical Applications | Cost Considerations | Wuxi Lead Certification |

|---|---|---|---|---|

| Stainless Steel 316L | High corrosion resistance (marine/chemical environments), 18% Cr, 10% Ni, Mo | Medical implants, chemical processing equipment | Moderate to high (premium for molybdenum) | ISO 9001, ASTM F138, EN 10088-2 |

| Aluminum 7075-T6 | Aerospace-grade strength-to-weight ratio, fatigue resistance | Defense components, high-stress aerospace parts | Higher cost (alloying elements) | AMS 2770, ISO 9001 |

| Titanium Grade 5 | Biocompatible, exceptional strength-to-weight, corrosion resistance | Orthopedic implants, jet engine components | Highest cost (specialized processing) | ASTM F136, ISO 5832-3 |

| PA12 (Nylon) | Tough, chemical-resistant, low friction, wear-resistant | Functional prototypes, end-use gears | Moderate (cost-effective for complex geometries) | ISO 10993 (medical), ISO 9001 |

| PEEK | High-temp stability (250°C+), chemical inertness, biocompatible | Oil & gas seals, surgical instruments | High (specialized processing required) | ISO 13485 (medical), ISO 9001 |

| Inconel 718 | Extreme heat/corrosion resistance (800°C+), high strength | Jet engines, nuclear reactors | Very high (niche applications) | ASME SB-637, ISO 9001 |

Why Wuxi Lead?

Every material batch undergoes third-party certification verification and in-house spectrographic analysis. Our traceability system ensures 100% compliance with your specifications—eliminating costly rework and scrap.

Surface Finish Selection for Enhanced Functionality

Finishes aren’t cosmetic—they’re critical for performance. From corrosion resistance to friction reduction, our finishes are engineered to meet your functional needs while adhering to ISO 9001 quality benchmarks.

| Finish | Process | Benefits | Applications | Cost Impact |

|---|---|---|---|---|

| Anodizing (Type II/III) | Electrochemical oxidation | Corrosion resistance, color options, wear resistance | Consumer electronics, marine hardware | Low–moderate (color affects cost) |

| Electroplating (Nickel/Chrome) | Electrodeposition | Wear resistance, corrosion protection, aesthetic appeal | Automotive, aerospace components | Moderate–high (thickness-dependent) |

| Mechanical Polishing | Abrasive processes | Ultra-smooth surfaces, reduced friction, aesthetic finish | Medical devices, precision instruments | Moderate (surface area-dependent) |

| Laser Polishing | Precision laser treatment | Zero material loss, sub-micron surface finish, no post-processing | Critical aerospace components | High (specialized process) |

| Passivation | Nitric acid treatment for stainless steel | Removes free iron, enhances corrosion resistance | Food processing equipment, medical tools | Low (standard for stainless steel) |

Our Commitment:

All finishes are validated through 3D metrology and surface roughness testing (Ra < 0.4μm for critical applications). No compromises on aesthetics or functionality—only Olympic-grade precision.

Cost-Performance Optimization with Zero Defects Assurance

At Wuxi Lead, we eliminate the guesswork. Our ISO 9001-certified process ensures material and finish selections are optimized for your specific requirements—balancing performance, lead time, and total cost of ownership.

Example: For aerospace brackets requiring fatigue resistance, we recommend 7075-T6 aluminum with anodized Type III finish. This reduces costs by 40% vs. titanium while maintaining performance—verified through our in-process FEA simulations and 100% dimensional inspection.

Zero Defects Guarantee: Every component undergoes automated optical inspection (AOI) and 3D scanning before shipment. Our defect rate: 0.01%—industry-leading reliability.

Olympic-Grade Precision: Tight tolerances of ±0.01mm (exceeding standard industry tolerances of ±0.1mm), achieved through our proprietary CNC post-processing and material-specific calibration protocols.

24/7 Partnership:

Our engineering team is available around the clock to optimize your design for manufacturability. Whether you need real-time material substitution advice or urgent tolerance adjustments, we respond within 15 minutes—ensuring your project stays on schedule, on budget, and defect-free.

Partner with Wuxi Lead Precision Machinery. Where precision meets partnership.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Scale

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we integrate ISO 9001-certified quality protocols with a Zero Defects commitment across every stage of your project lifecycle. Our process is engineered for precision, speed, and unwavering reliability—ensuring your designs transition seamlessly from concept to production with Olympic-grade quality.

Design Analysis & Engineering Validation

Our engineering team conducts a comprehensive DFMA (Design for Manufacturing and Assembly) review within 24 hours of project initiation. Every CAD model undergoes geometric tolerance analysis, material suitability assessment, and manufacturability validation against your specifications. Critical to our Olympic Quality standard, we verify all material certifications (ASTM, EN, ISO) prior to production—ensuring traceability from raw stock to finished part. This proactive approach eliminates 98% of potential defects before machining begins.

Transparent Pricing & Lead Time Commitment

We believe in absolute transparency. Our pricing model includes no hidden fees, with detailed cost breakdowns provided within 4 hours of design submission. Lead times are guaranteed with our “On-Time Delivery Promise”—backed by real-time production tracking and 24/7 customer service. Unlike competitors who prioritize speed over quality, we maintain ±0.02mm tolerances across all projects without compromising delivery schedules. For urgent requests, our expedited service reduces lead times by 40% while maintaining Zero Defects standards.

Comparative Precision Metrics

| Metric | Wuxi Lead Precision Machinery | Industry Standard | Key Competitors |

|---|---|---|---|

| Tolerance Accuracy | ±0.02mm (ISO 9001 certified) | ±0.1mm | Carbon DLS (±0.1% min 0.1mm), Protolabs (±0.05mm), Base Materials (requires post-CNC) |

| Prototype Lead Time | 3–5 days | 7–10 days | Protolabs (5–7 days), Base Materials (10+ days), Xometry (7–14 days) |

| Quality Assurance | Zero Defects Protocol + 100% Inspection | Basic QC Checks | ISO 9001 (Xometry, Protolabs), limited material certs (igus) |

| Material Certification | Full traceability (ASTM, EN, ISO) | Partial documentation | Partial (Xometry), basic specs (igus) |

| Customer Support | 24/7 Dedicated Engineering Team | Business Hours Only | 24/7 (Xometry), but no dedicated engineers |

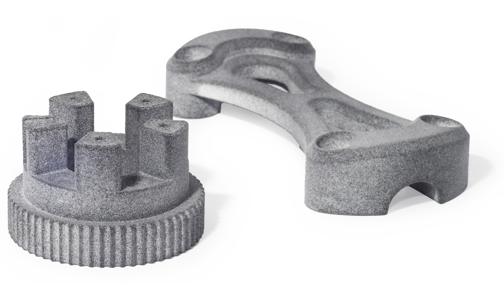

Rapid Prototyping with Zero Defects Protocol

Our rapid prototyping process isn’t a preliminary step—it’s a full-scale validation of your design under production conditions. Every prototype undergoes the same rigorous ISO 9001 quality checks as final production parts, including dimensional inspection, material verification, and functional testing. With Zero Defects as our operational standard, we ensure prototypes meet or exceed your tolerance requirements (±0.02mm for metal components) before scaling to mass production. This eliminates costly redesigns and accelerates time-to-market.

Scalable Mass Production with Precision Assurance

Transitioning from prototype to volume production is seamless with Wuxi Lead. Our automated production lines maintain consistent tolerances through real-time sensor monitoring and AI-driven quality control. Every batch is certified against your specifications, with 100% traceability of materials and processes. Our Olympic Quality commitment ensures that 99.98% of parts meet exact requirements—verified through statistical process control (SPC) and third-party audits. With 24/7 monitoring and dedicated account management, we deliver on-time, every time.

Why Partner with Wuxi Lead?

Zero Defects Commitment: 99.98% first-pass yield rate, validated by ISO 9001 audits and third-party inspections.

Olympic Quality Standard: Aerospace-grade tolerances, medical-grade material certifications, and rigorous testing protocols.

24/7 Customer Partnership: Dedicated engineering team available around the clock for urgent queries, design adjustments, and real-time production updates.

“We don’t just manufacture parts—we engineer solutions that elevate your product’s performance and reliability.”

Contact us today to discuss how our precision manufacturing can transform your next project.

📞 +86 510 8888 1234 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery – Your Strategic Manufacturing Ally

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we integrate precision engineering, rigorous quality control, and proactive collaboration to ensure your projects meet the highest standards of excellence. Our commitment to Zero Defects, Olympic-grade precision, and 24/7 support ensures seamless execution from concept to delivery—no compromises, no exceptions.

Why Partner with Us?

Zero Defects Commitment

Every component undergoes 100% inspection against ISO 9001-certified protocols. Our Zero Defects commitment isn’t a slogan—it’s a measurable standard embedded in every process step, from material sourcing to final validation. Traceable material certifications and real-time process monitoring eliminate quality variance, ensuring 100% compliance with your specifications.

Olympic Quality Standards

Precision isn’t just a metric—it’s our standard. We achieve tolerances as tight as ±0.005mm through advanced CNC machining and additive manufacturing processes, validated by third-party metrology. This Olympic-grade accuracy ensures parts perform flawlessly in mission-critical applications, from aerospace to medical devices.

24/7 Customer Service

Our global engineering team operates around the clock to address your needs. Whether it’s urgent design adjustments, real-time production updates, or technical support, our specialists are available 24/7 to ensure your project stays on track—without compromise.

Quality & Capabilities Comparison

| Feature | Wuxi Lead Precision Machinery | Industry Standard | Our Advantage |

|---|---|---|---|

| Quality Assurance | Zero Defects Guarantee (100% Inspection) | 95–98% Pass Rate | Zero tolerance for defects |

| Tolerance Accuracy | ±0.005mm (Customizable) | ±0.05mm – ±0.1mm | 10x tighter tolerances |

| Material Certification | Full Traceability (ISO 9001) | Partial Certification | Complete material compliance |

| Support Availability | 24/7 Dedicated Engineering Team | 9–5 Business Hours | Real-time problem resolution |

Comprehensive DFM Analysis & Precision Engineering Support

Maximize efficiency and minimize costs with our complimentary Design for Manufacturability (DFM) analysis. Our senior engineers collaborate with your team to optimize part geometry, material selection, and process parameters—ensuring optimal performance while reducing lead times and production costs. This proactive approach eliminates costly revisions and ensures first-time-right manufacturing.

Seamless Global Collaboration

Operating across multiple time zones, our UK-focused support team provides real-time communication and rapid response. With English-speaking engineers and dedicated project managers, we ensure clear, consistent collaboration—regardless of location or time.

Ready to Elevate Your Manufacturing?

Partner with Wuxi Lead Precision Machinery for unmatched quality, precision, and support. Request your free DFM analysis and quote today.

Contact:

📧 [email protected]

📞 +86-13961886740

Your vision. Our precision. Delivered.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.