Technical Contents

Engineering Guide: 3D Printing Service Quote

Engineering Insight Precision in Metal Additive Manufacturing Quoting

In metal additive manufacturing, the quotation process transcends a simple cost calculation. It represents the critical first engineering checkpoint where project viability, technical feasibility, and ultimate part performance are rigorously assessed. For high-integrity applications demanding micron-level accuracy and material consistency, the precision embedded within the quoting phase directly dictates downstream success. A superficial quote risks costly iterations, compromised functionality, or outright project failure, particularly when components interface with legacy systems or operate under extreme conditions. True precision quoting requires deep material science understanding, advanced process simulation capabilities, and a proven methodology for anticipating and mitigating inherent challenges like thermal distortion and residual stress.

At Wuxi Lead Precision Machinery, our quoting process is engineered with the same rigor applied to the Olympic-grade track cycling components and mission-critical military hardware we manufacture. We do not merely accept CAD files; we conduct a comprehensive engineering review. This involves analyzing geometric complexity, identifying potential support structure requirements, simulating build orientation for optimal density and minimal distortion, and selecting the precise laser parameters and inert gas environment necessary for the specified alloy. Our decades of experience in high-stakes precision manufacturing inform every parameter evaluated during this stage. We understand that a tolerance of ±0.05mm on a turbine blade bracket isn’t just a number—it’s the difference between seamless integration and catastrophic vibrational failure.

This level of scrutiny ensures the quote reflects not just machine time, but the engineered solution required to achieve the specified performance. It prevents under-quoting based on optimistic assumptions and eliminates hidden costs arising from unanticipated rework. Clients receive a transparent, technically validated cost projection aligned with achievable outcomes, fostering trust and enabling accurate project budgeting from inception. The precision of our quote is the foundation of the precision in your final component.

Our core metal additive capabilities supporting this precision-focused quoting and production are detailed below:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Materials | 316L, 17-4PH, Ti6Al4V | Inconel 718, AlSi10Mg, Custom Alloys |

| Build Volume | 250 x 250 x 300 mm | 500 x 500 x 500 mm |

| Layer Thickness | 20-50 µm | 20-30 µm (Optimized) |

| Dimensional Accuracy | ±0.1% (min ±0.1 mm) | ±0.05 mm (Verified) |

| Surface Roughness (as-built) | Ra 12-25 µm | Ra 8-15 µm (Process Controlled) |

| Post-Processing | Stress Relief, HIP, Machining | Precision CMM Verification, Micro-Machining |

The precision demanded by aerospace, defense, and elite sporting goods programs we support—where components bear Olympic medals or ensure operational readiness—shapes our fundamental approach. Every quote we generate is an engineering commitment, validated by our ISO 9001:2015 and AS9100D certified processes. It signifies that the final part will not only meet but be demonstrably traceable to the exacting specifications outlined at the project’s outset. Partnering with Lead Precision means your metal additive project begins with an engineering foundation built for uncompromising performance.

Precision Specs & Tolerances

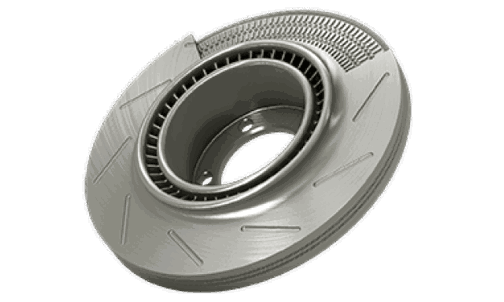

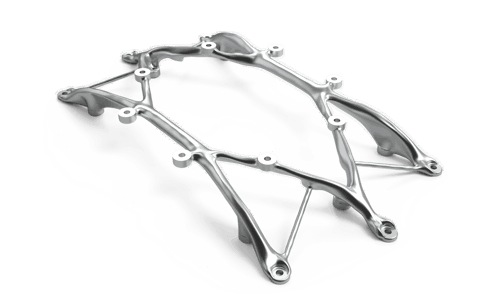

At Wuxi Lead Precision Machinery, our advanced 3D printing service delivers precision-engineered metal components tailored to the exacting demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. Our additive manufacturing capabilities are fully integrated with complementary precision processes, ensuring that every part not only meets but exceeds functional and dimensional expectations. We specialize in producing complex geometries that are difficult or impossible to achieve through traditional machining, while maintaining structural integrity and material consistency.

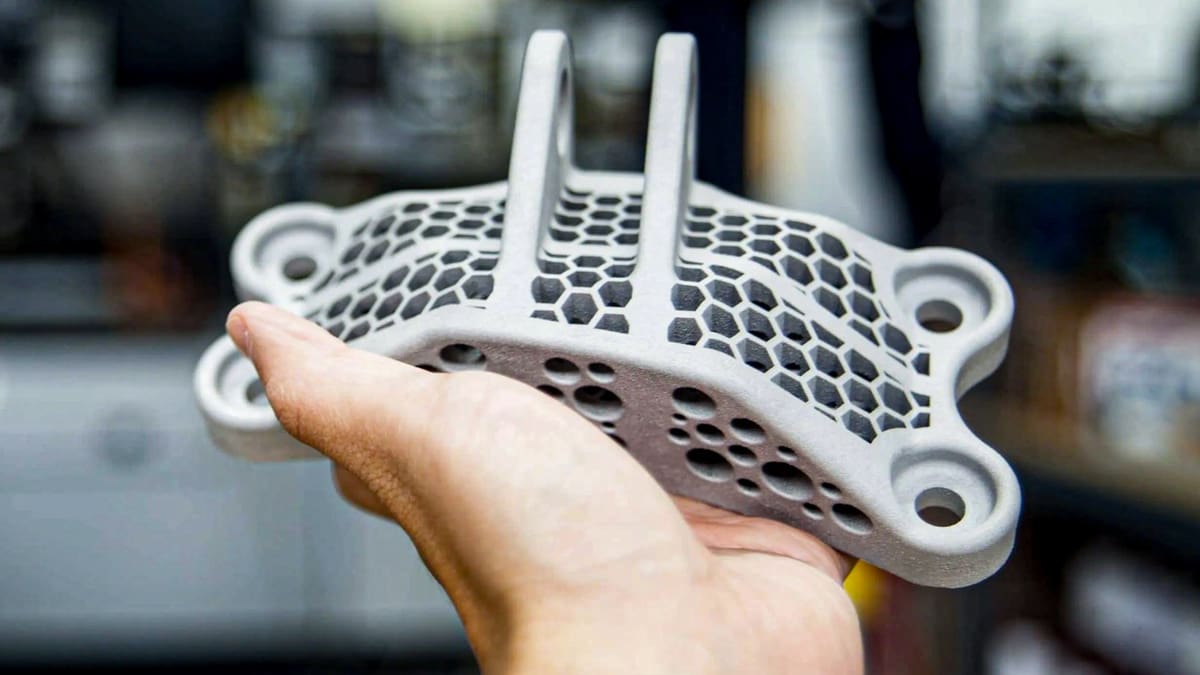

Our metal 3D printing process utilizes state-of-the-art laser powder bed fusion (LPBF) technology, compatible with a range of high-grade alloys including stainless steel (316L, 17-4 PH), titanium (Ti6Al4V), aluminum (AlSi10Mg), and Inconel (718, 625). Each build is optimized using expert support structure design and thermal simulation to minimize residual stress and distortion, ensuring superior part quality and repeatability. Layer resolution as fine as 20 microns enables intricate internal features, lattice structures, and conformal cooling channels—ideal for performance-driven applications.

Post-processing is a critical phase in our workflow, and we maintain full in-house control to guarantee consistency. All printed components undergo stress relief, heat treatment, and, where required, hot isostatic pressing (HIP) to eliminate internal porosity. Machining of critical interfaces and sealing surfaces is performed on our 5-axis CNC centers, which provide ±0.005 mm positional accuracy and exceptional surface finish control. This hybrid approach—combining additive freedom with subtractive precision—ensures that final components meet tight tolerance requirements and functional performance standards.

Quality assurance is embedded at every stage. Each production run is supported by comprehensive first-article inspection reports and material certifications. Our coordinate measuring machine (CMM) laboratory conducts full geometric dimensioning and tolerancing (GD&T) verification, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Additionally, we perform metallurgical analysis, hardness testing, and density verification to validate material properties.

The following table outlines our standard technical specifications and achievable tolerances for metal 3D printed components:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 300 mm |

| Layer Thickness | 20 – 60 μm |

| Typical Surface Roughness | Ra 6.3 μm (as-built), Ra 1.6 μm (machined) |

| Dimensional Tolerance | ±0.1 mm for first 100 mm, +0.05 mm per additional 100 mm |

| Feature Resolution | Minimum wall thickness: 0.4 mm, Hole diameter: ≥0.5 mm (drilled post-process) |

| Supported Materials | Stainless Steel 316L, 17-4 PH; Titanium Ti6Al4V; Aluminum AlSi10Mg; Inconel 718, 625 |

| Post-Processing Capabilities | Stress relieving, HIP, CNC machining, polishing, anodizing, passivation |

| Inspection Standards | CMM, GD&T, CT scanning (on request), material test reports (MTRs) |

By combining cutting-edge 3D printing technology with precision CNC finishing and rigorous quality control, Wuxi Lead Precision Machinery delivers metal components that meet the highest standards of performance, reliability, and repeatability.

Material & Finish Options

Material Selection for Precision Metal 3D Printing

Selecting the optimal material is critical for achieving functional performance, cost efficiency, and manufacturability in metal additive manufacturing. At Wuxi Lead Precision Machinery, our engineering team evaluates your part’s mechanical requirements, environmental exposure, and post-processing needs to recommend the most suitable alloy. Aluminum, steel, and titanium each offer distinct advantages for demanding industrial applications, but require specific process parameters to ensure print success and final part integrity. Material choice directly impacts powder flow characteristics, laser interaction, residual stress development, and necessary support structures – factors our experienced technicians meticulously control.

Aluminum alloys, particularly AlSi10Mg, dominate lightweight structural applications requiring good thermal conductivity and moderate strength. This alloy is ideal for complex aerospace brackets, heat exchangers, and automotive components where weight reduction is paramount. While offering excellent castability in AM, aluminum parts typically require stress relief and may need precision machining for critical features. Steel variants provide the necessary backbone for high-strength, wear-resistant components. Maraging steel (e.g., 18Ni300) delivers exceptional toughness and fatigue resistance for tooling inserts and high-performance shafts, while stainless steels like 316L offer superior corrosion resistance for marine or chemical processing parts. Steel generally allows for high-density builds but necessitates careful thermal management to prevent cracking.

Titanium alloys, especially Ti6Al4V (Grade 5), represent the pinnacle for strength-to-weight ratio and biocompatibility in extreme environments. This material is indispensable for aerospace structural components, medical implants, and high-performance motorsport parts exposed to high temperatures or corrosive elements. Processing titanium demands stringent inert atmosphere control throughout printing and handling due to its reactivity, a capability we ensure with our dedicated argon-purged systems. All metal AM parts benefit from appropriate surface finishing to meet functional or aesthetic specifications.

Anodizing is a vital post-processing step primarily for aluminum components. This electrochemical process creates a durable, corrosion-resistant oxide layer that can be dyed for identification. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with color options, suitable for general industrial use. For applications demanding maximum surface hardness and abrasion resistance, such as hydraulic components or fixtures, Type III (hard coat) anodizing is essential. Our integrated finishing capabilities ensure seamless transition from printing to anodizing, maintaining tight tolerances and consistent quality.

The following table summarizes key properties of common metal AM materials we process:

| Material Type | Common Alloys | Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 290 – 350 | 8 – 12 | 2.67 | Lightweight structures, heat exchangers, automotive |

| Steel | 18Ni300, 316L | 1200 – 1800 (Maraging) | 10 – 15 | 7.9 – 8.0 | Tooling, high-strength shafts, corrosion-resistant parts |

| Titanium | Ti6Al4V | 900 – 1050 | 10 – 15 | 4.43 | Aerospace components, medical implants, high-temp parts |

Collaborate with our application engineers early in the design phase. We provide detailed material datasheets and conduct feasibility analysis to ensure your selected material aligns with both performance goals and manufacturability within our advanced metal 3D printing systems, optimizing your path from quote to certified production part.

Manufacturing Process & QC

Design: The Foundation of Precision Manufacturing

At Wuxi Lead Precision Machinery, every successful manufacturing journey begins with a meticulously engineered design phase. Our engineering team collaborates closely with clients to analyze 3D CAD models, ensuring geometric integrity, material suitability, and manufacturability. We conduct comprehensive Design for Manufacturing (DFM) reviews to identify potential weaknesses, optimize wall thickness, support structures, and thermal behavior—critical parameters in metal additive manufacturing. Finite Element Analysis (FEA) is employed to simulate stress distribution and thermal deformation, ensuring the final component meets exact performance criteria. This phase is not merely conceptual; it is a rigorous technical validation that aligns the digital model with real-world physical demands. All design iterations are documented and approved through a secure digital workflow, ensuring traceability and compliance with ISO 9001 standards.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to produce high-fidelity metal prototypes using state-of-the-art laser powder bed fusion (LPBF) technology. These prototypes are not mockups—they are fully dense, functionally tested components built from the same materials and processes as final production parts. We utilize materials such as Inconel 718, titanium Ti6Al4V, stainless steel 316L, and aluminum AlSi10Mg, all processed in controlled inert atmospheres to eliminate contamination. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM), microstructure analysis, and, when required, non-destructive testing (NDT) such as industrial CT scanning. Functional testing—including pressure, fatigue, and fit-check evaluations—confirms performance under real operating conditions. This stage serves as the final gate before mass production, ensuring that design intent, material behavior, and process stability converge without compromise.

Mass Production: Scalable Precision with Zero Defects

Our transition to mass production is governed by a zero-defect manufacturing philosophy. Each build is executed on calibrated industrial-grade metal 3D printers with real-time melt pool monitoring and layer-wise optical inspection. Process parameters are locked based on validated prototypes, and every machine undergoes daily calibration and preventive maintenance. Post-processing—including stress relief, support removal, heat treatment, CNC machining, and surface finishing—is performed in-house under tightly controlled conditions. We implement Statistical Process Control (SPC) across all stages, with full lot traceability from raw powder to final inspection. Each component is inspected against the original CAD model using 3D scanning, ensuring geometric accuracy within ±0.05 mm.

Typical Production Specifications

| Parameter | Capability |

|---|---|

| Build Volume | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–50 µm |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-printed) | Ra 8–12 µm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Coating |

| Materials Available | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (scalable batch sizes) |

Through integrated design validation, prototyping rigor, and disciplined production control, Wuxi Lead ensures every component meets the highest standards of performance, reliability, and repeatability.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Strategy Through Engineering Partnership

At Wuxi Lead Precision Machinery, we transcend conventional 3D printing service providers by integrating deep metallurgical expertise with precision engineering. Our clients—global leaders in aerospace, medical device manufacturing, and energy systems—partner with us not for transactional quotes but for engineered solutions that resolve complex production challenges. When mission-critical metal components demand sub-50μm resolution, biocompatible integrity, or extreme-temperature resilience, our ISO 9001 and ISO 13485-certified processes deliver certified repeatability where others compromise. We initiate every engagement with collaborative Design for Additive Manufacturing (DFM) analysis, ensuring your geometry, material selection, and post-processing requirements align with industrial-scale performance standards from prototype to serial production.

Our technical capabilities are engineered for uncompromising applications. Below outlines core specifications governing our metal additive services:

| Parameter | Capability | Industrial Relevance |

|---|---|---|

| Materials | Inconel 718/625, Ti6Al4V ELI, 316L, AlSi10Mg, CoCrMo | Aerospace turbine components, medical implants, chemical processing |

| Accuracy | ±0.05 mm typical | Hydraulic manifolds, sealing surfaces, microfluidics |

| Build Volume | 250 x 250 x 325 mm (standard) | Consolidated assemblies, tooling inserts |

| Surface Finish | As-built Ra ≤ 12.5 μm; polished to Ra ≤ 0.8 μm | Fluid dynamics-critical parts, surgical interfaces |

| Post-Processing | HIP, stress-relief, precision CNC finishing, MPI | Fatigue-resistant structural components |

This precision stems from our strategic integration of EOS M400-4 and SLM Solutions S500 systems within a climate-controlled Class 8 cleanroom environment. Each build undergoes rigorous in-situ monitoring via melt pool analytics and post-build validation through our in-house metallurgical lab—equipped for ASTM E8 tensile testing, microstructure analysis, and CT scanning. Unlike volume-focused competitors, we prioritize dimensional stability and material homogeneity for parts operating under 1,000°C+ or cyclic fatigue loads. Our engineering team collaborates directly with your R&D staff to optimize support structures, orientation, and thermal management protocols, reducing lead times by 30% while eliminating costly rework.

Partnering with Lead Precision means accessing China’s most advanced metal additive ecosystem without sacrificing Western engineering rigor. Our Wuxi facility operates under AS9100-aligned quality management systems, with traceable material pedigrees and NADCAP-accredited post-processing. When your project demands more than a price-per-cubic-centimeter quote—when success hinges on material science expertise, regulatory compliance, and zero-defect delivery—our engineering-led workflow becomes your strategic advantage.

Initiate a technical dialogue that transforms your design constraints into manufacturing opportunities. Contact our additive engineering team directly at [email protected] with your part specifications, target application environment, and performance requirements. We will respond within 4 business hours with a preliminary DFM assessment and process validation roadmap—not a generic quotation. For time-sensitive projects requiring expedited build slots or material certification support, reference your target timeline in the subject line. Let us demonstrate how precision engineering, not just printing, defines the Lead Precision standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.