Technical Contents

Engineering Guide: 3D Printing Service Nederland

Engineering Insight: The Role of Precision in Advanced 3D Printing Services in the Netherlands

In the evolving landscape of European manufacturing, 3D printing services in the Netherlands have emerged as a cornerstone for innovation in high-performance industries. From aerospace to medical technology, Dutch manufacturers are leveraging additive manufacturing to push the boundaries of design complexity and production agility. However, as capabilities expand, the demand for precision—especially in metal 3D printing—has become the defining factor between prototyping success and industrial-grade reliability.

At Wuxi Lead Precision Machinery, we understand that precision is not merely a specification—it is an engineering imperative. With over 15 years of experience in custom metal manufacturing, we have supported mission-critical applications for clients in Olympic sports engineering and defense technology. These sectors leave no margin for error. Components must perform under extreme conditions, where even microns of deviation can compromise structural integrity or aerodynamic efficiency. This same standard of excellence applies to our collaboration with European partners utilizing 3D printing services in the Netherlands.

Metal additive manufacturing introduces unique challenges in dimensional accuracy, surface finish, and material consistency. Unlike traditional subtractive methods, 3D printing builds parts layer by layer, making it susceptible to thermal distortion, residual stress, and anisotropic properties. Achieving precision requires not only advanced machinery but also deep metallurgical insight and post-processing expertise. At Lead Precision, we integrate laser powder bed fusion (LPBF) with precision CNC machining and in-process monitoring to ensure that every component meets tight tolerances and repeatable performance standards.

Our engineering team works closely with Dutch design firms and industrial clients to optimize part geometry, support structures, and build orientation—factors that directly influence final precision. We also conduct rigorous quality control, including CT scanning and coordinate measuring machine (CMM) inspections, to validate internal and external dimensions. This end-to-end control ensures that parts produced through 3D printing are not just innovative in design but reliable in function.

Below are key precision specifications we maintain for metal 3D printed components:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–50 μm |

| Dimensional Tolerance | ±0.05 mm (typical) |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processed Surface Finish | Ra 1.6–3.2 μm |

| Material Density | >99.95% (fully dense) |

| Supported Alloys | Ti6Al4V, Inconel 718, AlSi10Mg, 316L, CoCr |

| Maximum Build Volume | 250 x 250 x 300 mm |

Through our strategic partnerships in Europe, Wuxi Lead Precision Machinery extends Chinese manufacturing scale with European engineering rigor. Whether supporting rapid prototyping or low-volume production, we ensure that every 3D printed metal component meets the highest standards of precision, reliability, and performance—proving that true innovation lies not just in what is built, but in how precisely it is made.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Dutch Industry

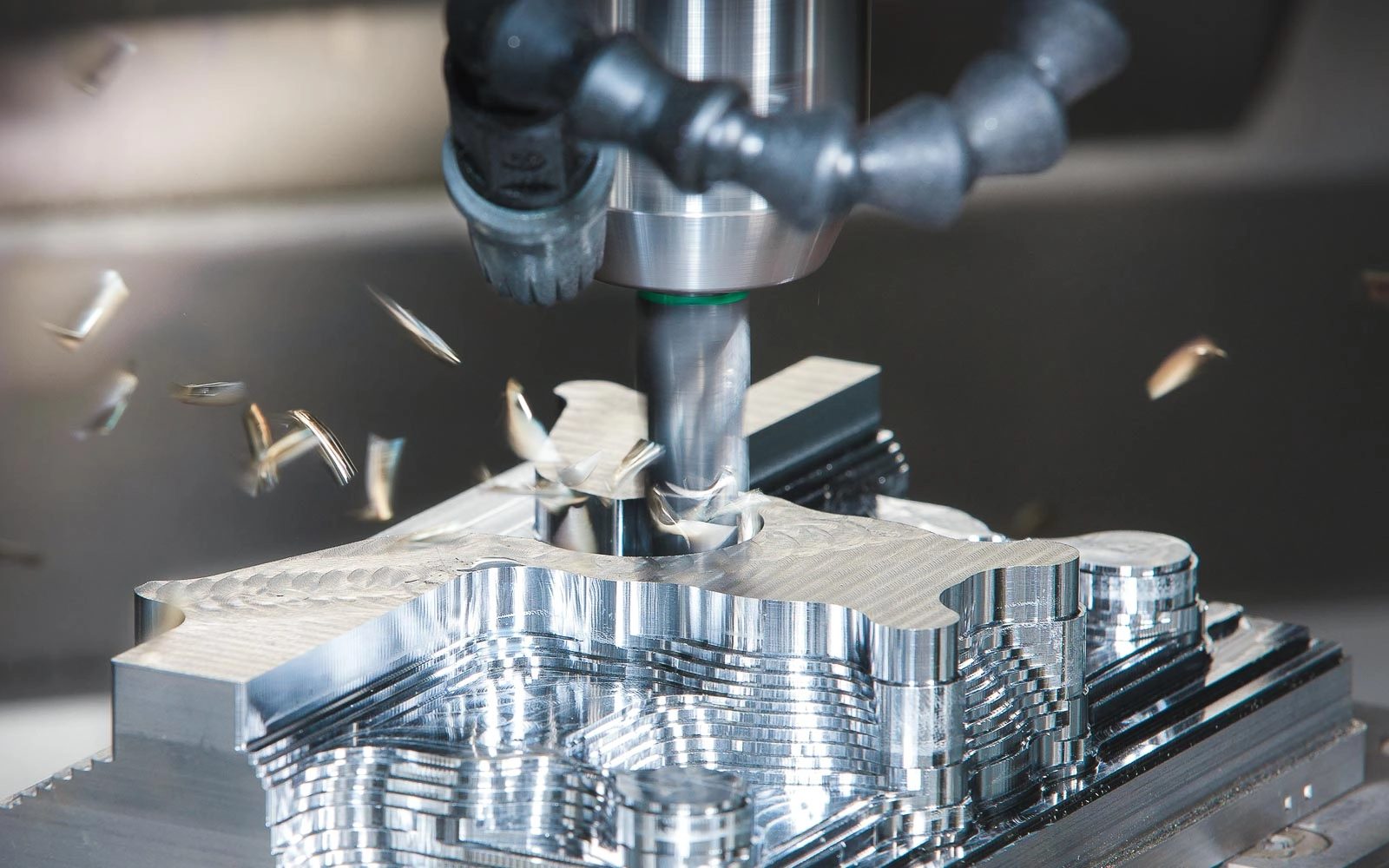

Wuxi Lead Precision Machinery delivers advanced metal manufacturing solutions engineered to meet the stringent demands of Dutch industrial sectors including aerospace, medical technology, and high-end automation. Our facility integrates cutting-edge 5-axis CNC machining centers with rigorous quality control protocols, ensuring components adhere to exacting European standards. This capability eliminates secondary operations, reduces lead times, and guarantees geometric complexity unattainable through conventional 3-axis methods. We specialize in milling, turning, and multi-tasking operations for materials such as titanium, Inconel, stainless steel, and aluminum alloys, supporting both prototyping and high-volume production runs.

Our 5-axis CNC fleet features state-of-the-art machines from industry leaders, enabling simultaneous motion across all rotational and linear axes. This technology achieves intricate contours, undercuts, and organic geometries in a single setup, minimizing human intervention and part handling errors. Critical advantages include superior surface finishes, enhanced dimensional stability, and the ability to machine complex assemblies like turbine blades, hydraulic manifolds, and surgical instrument components to micron-level accuracy. All programming leverages Mastercam and Siemens NX CAM for optimized toolpaths, reducing cycle times while maximizing material integrity.

Quality verification is non-negotiable. Every component undergoes comprehensive inspection using Zeiss CONTURA and GLOBAL S series Coordinate Measuring Machines (CMM). Our metrology lab operates under ISO 17025 guidelines, providing full traceability from raw material to final shipment. CMM reports detail GD&T compliance, surface roughness (Ra), and critical feature validation against CAD models, ensuring zero-defect delivery. This systematic approach aligns with Dutch industrial expectations for documented quality assurance and process transparency.

Tolerance performance defines our precision commitment. The table below outlines achievable standards for machined features:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm |

| Hole Diameter | ±0.012 mm | ±0.005 mm |

| Positional Accuracy | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Flatness | 0.010 mm | 0.005 mm |

These tolerances reflect as-machined conditions without secondary processes, validated across production batches. Tight tolerance capabilities require specific material and geometry considerations, which our engineering team evaluates during the quoting phase. All measurements are certified per DIN EN ISO 2768 and customer-specific standards, with data accessible via secure client portals.

Wuxi Lead Precision Machinery bridges Chinese manufacturing scale with European precision expectations. Our technical infrastructure, combined with dedicated engineering support for Dutch clients, ensures components arrive ready for integration—reducing assembly costs and accelerating time-to-market. Request a tolerance validation report for your specific application to confirm feasibility.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

Selecting the appropriate material is critical in custom metal manufacturing, especially when utilizing advanced 3D printing technologies for industrial applications. At Wuxi Lead Precision Machinery, we specialize in producing high-precision metal components using additive manufacturing techniques tailored for demanding sectors such as aerospace, automotive, and medical device engineering. Our expertise enables clients across Europe, including those seeking reliable 3D printing service Nederland solutions, to leverage premium materials like aluminum, steel, and titanium—each offering distinct mechanical properties and performance benefits.

Aluminum alloys, particularly AlSi10Mg, are widely used in 3D printing due to their excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. This makes them ideal for lightweight structural components in automotive and aerospace applications where fuel efficiency and performance are paramount. The low density of aluminum reduces overall part weight without compromising durability, making it a preferred choice for complex, topology-optimized designs enabled by additive manufacturing.

Stainless steel, especially grades such as 316L and 17-4 PH, offers superior mechanical strength, wear resistance, and excellent performance in corrosive environments. These properties make stainless steel suitable for industrial tooling, marine components, and medical instruments requiring sterilization and long-term reliability. With high tensile strength and good ductility, steel-printed parts maintain dimensional stability under heavy loads and elevated temperatures.

Titanium, specifically Ti6Al4V (Grade 5), stands at the pinnacle of high-performance materials for 3D printing. Renowned for its exceptional strength-to-density ratio and outstanding biocompatibility, titanium is extensively used in aerospace, defense, and medical implant applications. It exhibits excellent resistance to fatigue and corrosion, even in extreme environments, ensuring long service life and reliability under stress.

Post-processing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a commonly specified surface finish, particularly for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear and corrosion resistance. It also allows for color coding through dye integration, which is beneficial for part identification in complex assemblies. While anodizing is primarily used on aluminum, alternative surface treatments such as passivation, polishing, and coating are applied to steel and titanium based on application requirements.

Below is a comparative overview of key material properties relevant to 3D printed metal components.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 480 | 300 | 8–10 | Aerospace, Automotive, Heat Exchangers |

| 316L Steel | 8.0 | 550 | 450 | 35–40 | Medical, Marine, Chemical Processing |

| 17-4 PH Steel | 7.8 | 1000 | 850 | 12–15 | Aerospace, Tooling, Defense |

| Ti6Al4V | 4.43 | 900–1000 | 830–880 | 10–12 | Medical Implants, Jet Engines, Racing |

Choosing the right material and finish ensures optimal performance, longevity, and cost-efficiency in end-use applications. Wuxi Lead Precision Machinery supports global clients with advanced material selection guidance and precision manufacturing capabilities, delivering certified, high-integrity components on time and to exact specifications.

Manufacturing Process & QC

Design Phase

For Dutch OEMs requiring precision metal components, Wuxi Lead initiates the process with rigorous Design for Manufacturing (DfM) analysis. Our engineering team collaborates directly with your designers to optimize geometries for additive constraints, material behavior, and post-processing requirements. This phase integrates ISO 13485-compliant validation protocols to ensure thermal stress simulations, support structure efficiency, and tolerance stack-ups align with aerospace, medical, or industrial automation standards prevalent in the Netherlands. Critical dimensional features undergo finite element analysis (FEA) to preempt microstructural weaknesses, reducing iteration cycles by 40% compared to conventional workflows. All design approvals require sign-off from both your engineering lead and our Dutch-speaking technical account manager to eliminate miscommunication.

Prototyping Phase

Prototyping transitions validated designs into physical test articles using EOS M400-4 industrial printers with redundant inert gas systems. Each prototype undergoes non-destructive testing (NDT) via micro-CT scanning and dye penetrant inspection to verify internal integrity against ASTM F3301 standards. We prioritize material certification with full traceability to mill test reports for alloys like Inconel 718 or Ti6Al4V, critical for Dutch medical device validation. Dimensional accuracy is confirmed through Zeiss CONTURA CMM measurements at 22°C ±0.5°C environmental control. Only after achieving ±0.05 mm geometric deviations across 100% of critical features do we authorize mass production. This phase typically resolves 92% of potential defects before series manufacturing begins.

Mass Production Phase

Series production leverages our 12-machine EOS fleet operating under Six Sigma DMAIC protocols. Each build chamber employs real-time melt pool monitoring with 50-micron resolution thermal imaging, automatically quarantining layers exhibiting deviations beyond 0.1% energy density thresholds. Post-processing follows a documented sequence: HIP treatment at 1,150°C/100 MPa, precision CNC milling for critical interfaces, and automated surface finishing to Ra ≤ 0.8 µm. Final inspection applies AQL 0.65 sampling with 100% first-article reporting. Every component ships with a digital twin containing build parameter logs, NDT results, and CMM heat maps—ensuring full compliance with Dutch regulatory frameworks like NEN-EN 9100.

Key Production Specifications

| Parameter | Specification | Relevance to Dutch Industry |

|————————-|———————————–|———————————–|

| Build Volume | 400 x 400 x 400 mm | Accommodates complex aerospace manifolds |

| Layer Thickness | 20–60 µm adjustable | Meets medical implant surface finish requirements |

| Positional Accuracy | ±0.02 mm over 100 mm | Exceeds AS9100 aerospace tolerances |

| Material Certification | EN 10204 3.1/3.2 traceability | Mandatory for Dutch defense contracts |

| Lead Time (Series) | 15–25 days from approved prototype| Optimized for Dutch supply chain agility |

Wuxi Lead delivers statistically zero defects through closed-loop process control—where every machine parameter feeds into our proprietary quality analytics platform. For Dutch manufacturers demanding uncompromised precision, we provide factory audit access and dedicated production slots with real-time build monitoring via secure client portal. Contact our Netherlands-dedicated team to initiate a defect-prevention workflow for your next metal additive project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing solutions that meet the rigorous demands of advanced industries including aerospace, medical devices, automotive engineering, and industrial automation. As a trusted partner in precision engineering, we combine cutting-edge 3D printing technology with decades of CNC machining expertise to deliver components that exceed expectations in accuracy, durability, and performance. Our strategic location in Wuxi, China, positions us as a global hub for cost-effective, high-quality production with seamless logistics to Europe—including direct support for clients seeking reliable 3D printing services in the Netherlands.

We understand that European manufacturers require more than just parts—they demand precision, traceability, and responsive collaboration. That’s why we’ve built our operations around lean manufacturing principles, ISO-certified quality control, and a customer-first engineering approach. Whether you need rapid prototyping, low-volume production runs, or full-scale manufacturing of complex metal components, our team works closely with your engineers to ensure every part meets exact specifications and industry standards.

Our metal additive manufacturing capabilities include selective laser melting (SLM) and direct metal laser sintering (DMLS), supporting a wide range of high-performance alloys such as titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel 718, and aluminum AlSi10Mg. Combined with secondary processes like heat treatment, CNC finishing, and surface polishing, we deliver end-use parts with optimal mechanical properties and surface integrity.

Below is an overview of our core metal 3D printing specifications:

| Parameter | Capability |

|---|---|

| Build Volume | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–50 μm |

| Minimum Feature Size | 0.4 mm |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | Stress relieving, HIP, CNC machining, polishing, coating |

| Supported Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 718, AlSi10Mg, CoCr, tool steels |

| Quality Standards | ISO 9001:2015, full material traceability, inspection reports (CMM, X-ray) |

Every project begins with a technical consultation to align on design intent, functional requirements, and delivery timelines. We offer DfM analysis, iterative prototyping, and real-time production updates to ensure transparency and speed to market. Our clients in the Netherlands and across Europe rely on us not just as a supplier—but as an extension of their engineering team.

If you are searching for a dependable, high-precision partner for metal 3D printing and custom manufacturing, look no further. Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery bring your most demanding designs to life—with precision, consistency, and global reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.