Technical Contents

Engineering Guide: 3D Printing Service Los Angeles

Engineering Insight: The Role of Precision in Advanced 3D Printing Services – A Global Perspective

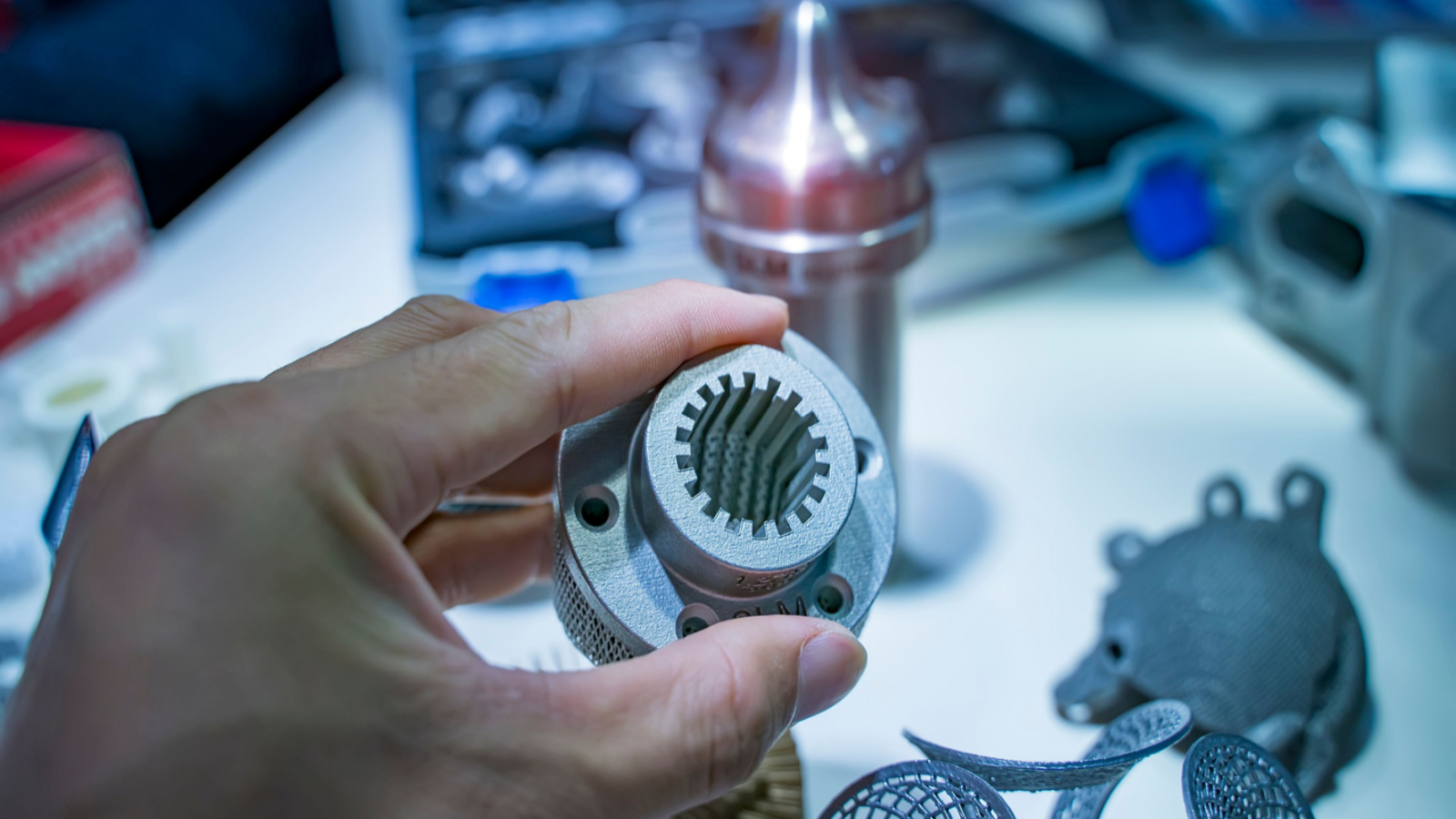

In the rapidly evolving landscape of custom metal manufacturing, 3D printing services in Los Angeles have become a cornerstone for innovation in aerospace, defense, medical, and high-performance industrial sectors. While local capabilities continue to expand, the true differentiator in additive manufacturing is not just access to technology—but the mastery of precision engineering that ensures repeatability, structural integrity, and compliance with mission-critical standards. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is a disciplined process embedded in every phase of production.

Los Angeles stands at the forefront of American innovation, hosting R&D centers and engineering firms that demand rapid prototyping and low-volume production with uncompromising quality. However, achieving micron-level tolerances, optimal surface finishes, and consistent material properties requires more than advanced printers. It demands decades of metallurgical expertise, rigorous process validation, and a deep understanding of post-processing techniques such as heat treatment, HIP (Hot Isostatic Pressing), and precision CNC finishing. These are the hallmarks of true industrial-grade additive manufacturing.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-precision metal manufacturing, serving clients in Olympic equipment development and military defense systems where failure is not an option. Our work on components for high-stress environments—such as titanium structural elements for aerospace applications and corrosion-resistant alloys for naval systems—has honed our ability to control every variable in the 3D printing process. From powder quality assurance to build orientation and residual stress management, our engineering protocols ensure that each part meets or exceeds ASTM, ISO, and MIL-STD requirements.

Our integration of 3D printing with traditional precision machining allows us to deliver hybrid-manufactured components that combine design freedom with functional accuracy. This is particularly critical for Los Angeles-based partners who require not only rapid iteration but also certification-ready outputs for regulated industries.

Below are key specifications that define our 3D printing and post-processing capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | Titanium (Ti6Al4V), Inconel 718, Stainless Steel 316L, Aluminum AlSi10Mg, Tool Steel (Maraging) |

| Build Volume | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20–50 µm |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10–15 µm; down to Ra 0.8 µm post-polishing |

| Post-Processing | Stress Relieving, HIP, CNC Machining, Shot Peening, Passivation |

| Quality Standards | ISO 9001:2015, ASTM F273-16, MIL-STD-883 |

Precision in 3D printing is not merely about resolution—it is about reliability, traceability, and performance under real-world conditions. As Los Angeles continues to drive technological advancement, Wuxi Lead Precision Machinery remains committed to supporting global innovation with engineering excellence forged in the most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

Wuxi Lead Precision Machinery delivers elite custom metal manufacturing solutions, specifically engineered for industries requiring uncompromising accuracy and repeatability. While the Los Angeles market frequently seeks 3D printing services for prototyping, our core expertise targets high-integrity end-use metal components where precision, material properties, and surface finish are non-negotiable. For critical aerospace, medical, and industrial applications requiring tight tolerances in solid metal, subtractive manufacturing via multi-axis CNC machining consistently outperforms additive methods in dimensional stability, fatigue resistance, and regulatory compliance. Our facility in Wuxi, China, operates as a seamless extension of your engineering team, providing certified precision that meets or exceeds stringent Western aerospace and medical standards.

Our technical foundation centers on advanced 5-axis CNC machining centers, enabling single-setup production of complex geometries with exceptional accuracy. This eliminates cumulative errors from multiple fixtures, ensuring critical feature relationships are maintained across intricate contours. We machine a comprehensive range of materials including titanium alloys (Ti-6Al-4V), Inconel 718, 17-4PH stainless steel, aluminum 7075-T6, and cobalt-chrome medical alloys. Full-process control spans from raw material certification through heat treatment oversight to final inspection, guaranteeing material integrity throughout production.

Quality assurance is non-optional in mission-critical components. Every part undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machines (CMM) with sub-micron resolution. Our CMM protocols follow ASME Y14.5 standards, providing full GD&T validation and comprehensive first-article inspection reports (FAIR). Statistical process control (SPC) data is integrated into production runs, enabling real-time adjustments to maintain capability indices (Cp/Cpk) above 1.67. This systematic approach ensures every component shipped from Wuxi meets the exact specifications demanded by Los Angeles-based engineering teams.

The following table details our standard achievable tolerances for machined metal components, reflecting our process capability under controlled production conditions:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Surface Finish (Ra) |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) | 0.4 µm (16 µin) |

| Hole Diameter | ±0.008 mm (±0.0003″) | ±0.003 mm (±0.00012″) | 0.8 µm (32 µin) |

| Positional Tolerance | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) | N/A |

| Angular Tolerance | ±0.005° | ±0.002° | N/A |

| Flatness | 0.010 mm per 100 mm | 0.005 mm per 100 mm | 0.2 µm (8 µin) |

Why this precision matters for Los Angeles clients: When your application demands certified mechanical properties, fatigue life, or biocompatibility in metal, our CNC-first approach delivers parts ready for immediate integration into flight-critical systems or surgical implants. We eliminate the post-processing uncertainties inherent in metal 3D printing, providing dimensionally stable components with documented traceability. Partner with Wuxi Lead to transform your most challenging metal part designs into certified reality, backed by ISO 9001:2015 and AS9100D quality systems. Our engineering team collaborates directly with your Los Angeles facility to optimize designs for manufacturability, ensuring on-time delivery without compromising the tolerances your project requires.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

Selecting the appropriate material is critical when producing precision-engineered metal components through additive manufacturing. For industries ranging from aerospace to medical devices and high-end automotive, the choice between aluminum, steel, and titanium directly impacts performance, durability, weight, and cost. At Wuxi Lead Precision Machinery, we specialize in custom metal 3D printing services that leverage advanced materials to meet exacting engineering standards.

Aluminum alloys, particularly AlSi10Mg, are widely used for applications requiring a high strength-to-weight ratio and excellent thermal conductivity. This material is ideal for lightweight structural components, heat exchangers, and complex geometries where weight reduction is a priority. Its good fatigue resistance and moderate strength make it suitable for dynamic loading environments. While not as strong as steel or titanium, aluminum offers significant cost advantages and is highly machinable post-printing.

Stainless steel, especially grades like 316L and 17-4 PH, delivers superior strength, corrosion resistance, and temperature tolerance. These properties make it a preferred choice for industrial tooling, fluid system components, and parts exposed to harsh environments. 316L stainless steel is particularly valued for its excellent weldability and resistance to chemical corrosion, making it suitable for marine and chemical processing applications. 17-4 PH, a precipitation-hardening steel, can be heat-treated to achieve very high tensile strength, bridging the gap between standard steel and more exotic alloys.

Titanium, specifically Ti6Al4V (Grade 5), stands at the pinnacle of performance materials in metal 3D printing. Renowned for its exceptional strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosion, titanium is the material of choice for aerospace, defense, and medical implant applications. Its ability to maintain structural integrity under high stress and elevated temperatures makes it indispensable in mission-critical components. While more expensive and challenging to process, titanium’s long-term performance justifies its use in high-value systems.

Following printing, post-processing finishes further enhance component functionality. Anodizing is a common surface treatment for aluminum parts, improving wear resistance, corrosion protection, and aesthetic quality. Type II and Type III (hard coat) anodizing offer increasing levels of durability, with hard anodizing suitable for components subjected to abrasion or high mechanical loads. While anodizing is not applicable to steel or titanium in the traditional sense, these materials benefit from alternative finishes such as passivation, polishing, or coating technologies tailored to specific operational demands.

Below is a comparative overview of key material properties for common 3D printed metals.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–500 | 250–300 | 2.67 | 8–12 | Lightweight structures, heat sinks |

| 316L Stainless Steel | 550–650 | 300–400 | 8.0 | 30–45 | Chemical processing, marine components |

| 17-4 PH Steel | 1000–1300 | 900–1100 | 7.8 | 10–15 | Aerospace, tooling, high-strength parts |

| Ti6Al4V | 900–1050 | 800–900 | 4.43 | 8–12 | Aerospace, medical implants, defense |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle expectations. Wuxi Lead Precision Machinery provides expert consultation to ensure optimal material pairing and post-processing for your 3D printed components.

Manufacturing Process & QC

Precision Metal Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we transform Los Angeles innovators’ complex metal part concepts into flawless, high-volume reality through a rigorously controlled additive manufacturing process. Our integrated workflow eliminates traditional production bottlenecks while guaranteeing zero-defect delivery, critical for aerospace, medical, and defense sectors where failure is not an option. This disciplined approach bridges the gap between rapid prototyping and scalable production without compromising on the stringent quality standards demanded by Southern California’s advanced manufacturing ecosystem.

The journey begins with collaborative design optimization. Our engineering team works directly with your Los Angeles-based designers to refine geometries specifically for metal additive manufacturing, ensuring structural integrity, minimizing support structures, and optimizing for the final application’s thermal and mechanical loads. We utilize advanced simulation software to predict potential stress points and material behavior, preventing issues before the first layer is deposited. This phase is not merely file preparation; it is a critical engineering validation step that sets the foundation for defect-free outcomes.

Prototyping transitions seamlessly into our production environment using identical industrial-grade equipment and parameters planned for mass production. Unlike competitors who prototype on different machines, we eliminate process variability by utilizing the same EOS M 400-4 or SLM Solutions S500 systems for both stages. This ensures dimensional stability and material properties remain consistent from the first part to the ten-thousandth. Each prototype undergoes comprehensive metrology, including CT scanning and metallurgical analysis, verifying internal integrity and microstructure against your specifications.

Mass production executes under our Zero Defects Protocol, a multi-layered quality system embedded at every stage. Real-time melt pool monitoring and inert gas atmosphere control ensure perfect layer fusion. Every 50th layer is automatically inspected via integrated optical systems, with deviations triggering immediate process correction. Completed builds undergo 100% first-article inspection per AS9102 standards, followed by batch-level testing including tensile, fatigue, and chemical composition verification. Our ISO 13485 and AS9100 certified facility guarantees traceability from raw powder lot to finished component.

Critical production capabilities enabling this seamless transition are detailed below:

| Parameter | Prototyping Capability | Mass Production Capability | Material Compatibility |

|---|---|---|---|

| Build Volume | 250 x 250 x 325 mm | 400 x 400 x 400 mm | Titanium Ti6Al4V ELI, Inconel 718, 316L, AlSi10Mg, CoCr |

| Layer Thickness | 20-50 µm | 20-50 µm | Optimized per material/application |

| Dimensional Tolerance | ±0.05 mm | ±0.02 mm (post-process) | Verified via CMM & optical scanning |

| Surface Roughness | As-built: Ra 12-15 µm | As-built: Ra 10-12 µm | Optional polishing to Ra 0.4 µm |

| Lead Time (Typical) | 5-7 business days | 10-15 business days (100+ units) | Powder recycling validated per ASTM F3049 |

This closed-loop process delivers Los Angeles clients production-ready metal components with certified mechanical properties and absolute reliability. We eliminate the risk of scaling failures by treating prototyping as production validation, not a separate phase. Partner with Wuxi Lead to convert your Los Angeles engineering vision into zero-defect metal reality, backed by seamless trans-Pacific coordination and uncompromising quality control. Demand precision that performs—every part, every time.

Why Choose Wuxi Lead Precision

When your project demands precision, reliability, and advanced engineering in custom metal manufacturing, partnering with Wuxi Lead Precision Machinery ensures you’re working with a global leader in high-performance production solutions. While we are headquartered in Wuxi, China, our reach extends to key industrial markets worldwide—including Los Angeles—where innovation in 3D printing and advanced manufacturing continues to accelerate. Whether you are a design engineer, product developer, or procurement manager in aerospace, medical devices, automotive, or industrial equipment, our team delivers end-to-end metal manufacturing services tailored to your technical and operational requirements.

We understand that businesses in Los Angeles require more than just parts—they need strategic manufacturing partners who can scale with their growth, respond to tight deadlines, and maintain uncompromising quality. At Wuxi Lead Precision Machinery, we combine state-of-the-art metal 3D printing (additive manufacturing), CNC machining, and precision sheet metal fabrication under one roof. Our ISO 9001-certified facility is equipped with the latest in laser powder bed fusion (LPBF) and direct metal laser sintering (DMLS) technologies, enabling us to produce complex, high-strength components from materials such as titanium, stainless steel, Inconel, aluminum, and tool steel. Every part is manufactured to exacting tolerances, with full traceability, post-processing, and quality inspection.

Our collaborative approach begins the moment you reach out. We don’t just manufacture parts—we co-engineer solutions. From design optimization for additive manufacturing (DfAM) to rapid prototyping and low-to-mid volume production, our engineering team works closely with your design files to ensure manufacturability, cost-efficiency, and performance. We support a wide range of file formats and offer expert feedback on geometry, support structures, and material selection to maximize the value of your 3D printing investment.

For Los Angeles-based companies seeking a reliable offshore manufacturing partner with onshore-level quality, Wuxi Lead Precision Machinery offers competitive pricing, fast turnaround times, and seamless communication in English. We manage all logistics, customs documentation, and quality reporting, so you receive your parts on schedule and ready for integration.

Explore how we can support your next project with precision, speed, and engineering excellence.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Additive Processes | DMLS, SLM, LPBF |

| Materials | Titanium (Ti6Al4V), Stainless Steel (316L, 17-4PH), Inconel 718, Aluminum (AlSi10Mg), Tool Steel (Maraging, H13) |

| Build Envelope | Up to 250 x 250 x 325 mm (per machine) |

| Tolerance | ±0.05 mm typical |

| Surface Finish | As-built: Ra ≤ 15 µm; Post-processed: Ra ≤ 3.2 µm (polishing, machining) |

| Secondary Operations | CNC Machining, Heat Treatment, HIP, Surface Coating, CMM Inspection |

| Quality Standards | ISO 9001:2015, Full Material Certification, First Article Inspection Reports |

Contact us today at [email protected] to discuss your 3D printing service needs in Los Angeles. Let Wuxi Lead Precision Machinery be your trusted partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.