Technical Contents

Engineering Guide: 3D Printing Service Germany

Engineering Insight Precision Imperatives in German 3D Printing Services

German industrial manufacturing sets the global benchmark for dimensional accuracy and functional reliability. When sourcing metal 3D printing services within Germany or internationally, achieving micron-level precision is not merely desirable—it is a non-negotiable requirement for aerospace, automotive, and medical applications. German engineers demand components that perform identically in serial production as they do in prototype form, with zero deviation from CAD specifications under operational stress. Tolerances exceeding ±0.05mm or inconsistent surface finishes directly impact assembly integrity, fatigue life, and regulatory compliance. This precision culture stems from decades of engineering excellence where a single micron can determine system failure or success. Partnering with a service provider possessing deep metrology expertise and rigorous process validation is therefore critical, especially for mission-critical components.

Wuxi Lead Precision Machinery operates at this exacting standard, serving German clients through our ISO 13485 and AS9100 certified facilities. Our engineers understand that German quality expectations extend beyond print completion to encompass material traceability, in-process inspection, and final part certification. This commitment is validated through direct experience delivering components for Olympic timing systems requiring sub-10-micron repeatability and certified military aerospace subsystems where failure is not an option. We implement closed-loop laser calibration, real-time melt pool monitoring, and post-process CMM validation against German DIN standards, ensuring every printed part meets the stringent Geometrical Product Specification (GPS) requirements inherent to German engineering workflows. Our German-speaking technical team collaborates directly with client engineering departments to align on critical-to-quality characteristics before production begins.

The following table outlines key precision capabilities relevant to German high-end manufacturing demands:

| Specification Category | Capability Range | Industry Standard Alignment |

|---|---|---|

| Dimensional Tolerance | ±0.02mm to ±0.05mm | DIN ISO 2768-mK / GD&T ASME Y14.5 |

| Surface Roughness (as-built) | Ra 3.2μm to Ra 6.3μm | DIN 4762 / ISO 1302 |

| Repeatability (Batch) | ±0.03mm across 10 units | VDA 5 Compliant |

| Critical Feature Accuracy | ±0.015mm with metrology feedback | Customer-specific GPS |

| Material Certification | Full EN 10204 3.1 traceability | EN 10025 / AMS 4928 |

German procurement teams increasingly recognize that precision manufacturing excellence transcends geography when backed by verifiable process control. At Lead Precision, we bridge the gap between Chinese production scale and German engineering rigor through documented quality systems, transparent inspection data sharing, and engineering collaboration. Our track record with Tier 1 German suppliers proves that when precision is paramount, proven capability and certified processes define value—not just location. We enable German innovation by delivering metal AM components that integrate seamlessly into high-performance assemblies, certified to perform exactly as designed.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industries requiring precision, reliability, and repeatability. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries and high-integrity components that meet the rigorous demands of aerospace, medical, automotive, and industrial sectors. With a focus on dimensional accuracy and surface finish, our machining centers operate with dynamic multi-directional cutting paths, minimizing setup changes and ensuring optimal part consistency.

Our 5-axis CNC systems are equipped with high-speed spindles and advanced control units, allowing for simultaneous motion across all five axes. This capability supports the production of intricate contours, deep cavities, and organic forms that are unattainable with conventional 3-axis machines. The integration of tilt and rotary axes enables tool access from multiple angles, reducing the need for secondary operations and significantly improving geometric accuracy. Materials commonly processed include titanium alloys, stainless steels, aluminum alloys, Inconel, and other high-performance metals used in mission-critical applications.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Our CMM systems provide full 3D metrology data, verifying critical dimensions, positional tolerances, and form characteristics with micron-level precision. This data is documented and provided with each production batch, offering full traceability and audit readiness for our clients.

We maintain strict environmental controls in our production facility to minimize thermal drift and vibration, further enhancing machining accuracy. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, offering technical feedback to optimize part geometry, reduce lead times, and lower overall production costs. This proactive approach ensures manufacturability without compromising performance or quality.

The table below outlines the standard tolerances achievable across common machining operations, reflecting our commitment to precision and consistency.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, Micrometers |

| Hole Diameter | ±0.05 mm | ±0.012 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | CMM |

| Flatness | 0.05 mm | 0.01 mm | CMM, Surface Plate |

| Perpendicularity | 0.05 mm | 0.02 mm | CMM, Dial Indicator |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Surface Roughness Tester |

All tolerances are achievable on parts up to 800 mm in length, depending on geometry and material. Custom inspection plans can be developed for applications requiring even tighter control or specialized testing. Wuxi Lead Precision Machinery remains committed to delivering precision-engineered metal components that meet the highest standards of quality and performance, supporting global innovation in advanced manufacturing.

Material & Finish Options

Material Selection for High-Performance Metal 3D Printing: Aluminum, Steel, Titanium

Wuxi Lead Precision Machinery delivers precision-engineered metal AM components meeting stringent German industrial standards. Material selection is foundational to part performance, longevity, and cost-effectiveness. Understanding the distinct properties of Aluminum, Steel, and Titanium alloys is critical for optimizing your application within Germany’s demanding manufacturing landscape. We provide certified material traceability and process validation essential for aerospace, automotive, and medical sectors.

Aluminum alloys, particularly 7075 and 6061, offer an exceptional strength-to-weight ratio ideal for lightweight structural components. Aluminum 7075 achieves 570 MPa tensile strength, suitable for high-stress aerospace brackets and drone parts. Its thermal conductivity benefits heat exchangers, while inherent corrosion resistance reduces maintenance in automotive housings. Steel variants like 316L stainless steel provide superior corrosion resistance in harsh chemical or marine environments, essential for German pump manufacturers. Maraging steel 17-4PH delivers exceptional hardness (up to 44 HRC) and fatigue resistance for tooling inserts and high-wear transmission components. Titanium Grade 5 (Ti6Al4V) remains the benchmark for critical applications demanding biocompatibility and extreme strength-to-weight performance. Its 900 MPa tensile strength and outstanding corrosion resistance make it indispensable for aerospace landing gear, medical implants, and motorsport exhaust systems where weight savings directly impact efficiency.

Surface finish significantly influences functionality and durability. Anodizing is the premier post-processing solution for aluminum components. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification. Type III (hard coat) anodizing generates a thicker, harder ceramic layer (60-70 HRC) essential for high-abrasion environments like hydraulic manifolds or robotic arms. Both processes enhance adhesion for subsequent coatings while maintaining precise dimensional tolerances required by German OEMs. Critical steel components often utilize passivation or electropolishing to maximize corrosion resistance, while titanium typically requires specialized chemical etching or laser polishing for optimal biocompatibility.

Our German clients benefit from seamless integration of material science expertise with certified production. The table below summarizes key alloy properties for rapid evaluation:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Primary German Applications |

|---|---|---|---|---|

| Aluminum | 7075, 6061 | 2.8 | 500-570 | Lightweight structures, heat exchangers |

| Stainless Steel | 316L, 17-4PH | 7.9 | 550-1300 | Chemical pumps, tooling, marine hardware |

| Titanium | Ti6Al4V (Gr5) | 4.4 | 900-950 | Aerospace, medical implants, motorsport |

Material choice directly impacts manufacturability, lead time, and total cost of ownership. Wuxi Lead Precision Machinery collaborates with German engineering teams during the design phase to select optimal materials and finishes, ensuring components exceed performance expectations while adhering to DIN and ISO quality frameworks. Contact our engineering team for material-specific validation data and process capability studies tailored to your project.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with meticulous design engineering, ensuring that every component meets the exact functional and dimensional requirements of high-end industrial applications. Our engineering team collaborates closely with clients to analyze CAD models, perform design for manufacturability (DFM) reviews, and optimize geometries for metal 3D printing. This phase includes topology optimization, stress simulation, and thermal analysis using advanced software such as ANSYS and Siemens NX. The goal is to achieve maximum structural efficiency while minimizing material usage and weight—critical for aerospace, medical, and automotive sectors. All design iterations are documented and approved through a secure digital workflow, ensuring traceability and compliance with ISO 9001 standards.

Prototyping: Validating Performance Before Scale

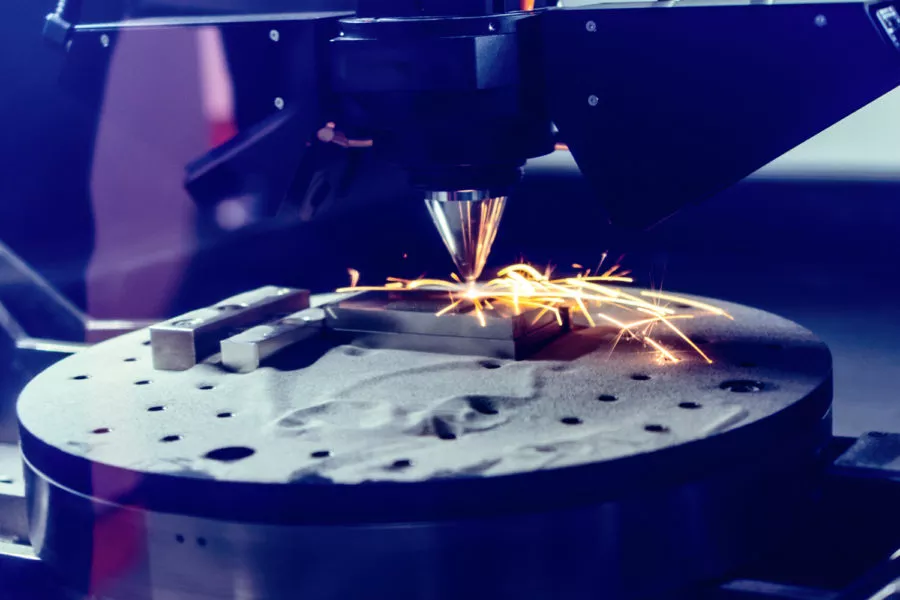

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art metal additive manufacturing systems, including SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering). These technologies allow us to produce fully dense, functional metal parts directly from 3D CAD data, using materials such as titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), Inconel 718, and aluminum alloys. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.02 mm. In addition, non-destructive testing (NDT), including micro-CT scanning and ultrasonic inspection, ensures internal integrity. Mechanical testing—tensile strength, hardness, and fatigue resistance—is conducted in-house to validate performance under real-world conditions. This stage not only confirms design intent but also establishes process parameters for full-scale production.

Mass Production: Industrial Scalability with Zero Defects

Transitioning to mass production, Wuxi Lead deploys a fully integrated, automated manufacturing cell designed for repeatability and quality consistency. Each build is monitored in real time via in-situ sensors that track laser power, melt pool dynamics, and layer adherence. Our production line supports batch manufacturing with serial traceability—each part assigned a unique QR code linked to its digital twin, recording all process data from powder lot to final inspection. Post-processing includes stress relief annealing, support removal via 5-axis CNC, precision machining, and surface finishing (polishing, bead blasting, or coating) as required. Final quality assurance involves 100% visual inspection, dimensional checks, and batch sampling for metallurgical analysis.

Material & Process Specifications

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–60 μm |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Dimensional Accuracy | ±0.02 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Post-Processed Finish | Ra 0.8–1.6 μm (machined/polished) |

| Supported Materials | Ti6Al4V, 316L, 17-4 PH, Inconel 718, AlSi10Mg |

| Heat Treatment Options | Stress relief, H900, H1150, Hot Isostatic Pressing (HIP) |

Through this rigorously controlled workflow—from precision design to defect-free mass production—Wuxi Lead ensures that every metal 3D printed component meets the highest standards of performance, reliability, and quality demanded by global industries.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for German-Grade Metal Additive Manufacturing

German engineering demands uncompromising precision, traceability, and reliability—especially in critical metal components for aerospace, medical, and industrial automation. While domestic 3D printing services in Germany offer local convenience, escalating costs and capacity constraints often lead to extended lead times and project bottlenecks. Wuxi Lead Precision Machinery bridges this gap, delivering German-standard metal additive manufacturing from China with seamless integration into your supply chain. We specialize in Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) for complex, high-integrity parts, certified to ISO 9001:2015 and AS9100D standards. Our German-speaking engineering team collaborates directly with your R&D and production units, ensuring technical alignment and eliminating communication barriers. Unlike generic offshore providers, we implement rigorous German-style quality protocols: full material traceability, in-process NDT inspections, and detailed PPAP documentation. This precision partnership reduces your time-to-market by 30% while maintaining the dimensional accuracy and mechanical properties your applications require.

Technical Capabilities for Demanding German Applications

| Parameter | Specification | Relevance for German Industry |

|---|---|---|

| Material Range | Inconel 718/625, Ti6Al4V, AlSi10Mg, 17-4PH SS | Meets EN/ASTM material certifications |

| Accuracy | ±0.05 mm per 100 mm | Compliant with DIN 2310 tolerances |

| Build Volume | 250 x 250 x 325 mm (EOS M 400) | Suitable for complex subsystem components |

| Certifications | ISO 9001:2015, AS9100D, Material Test Reports | Aligns with automotive/aerospace compliance |

| German Support | Dedicated project managers & engineers | Real-time collaboration in German/English |

Our facility operates under VDA 6.3 process audit frameworks, with every build monitored via real-time melt pool analytics and post-process CMM validation. For German OEMs, this means zero compromise on quality despite offshore production. We integrate directly with your PLM systems, provide digital twin validation reports, and adhere to German data security standards (GDPR-compliant). Whether prototyping turbine blades or producing serial medical implants, Lead Precision delivers the repeatability German engineering requires—without the premium costs of domestic German 3D printing services.

Choose a partner who understands Technische Präzision isn’t negotiable. We eliminate supply chain uncertainty with 12-week guaranteed lead times for DMLS production runs and transparent progress tracking via your preferred platform. Our engineers proactively optimize designs for additive manufacturing, reducing material waste by up to 40% while enhancing part performance. This is not outsourcing—it’s strategic collaboration engineered for German excellence. Contact our European team today to discuss your next high-integrity metal component project.

Elevate your manufacturing strategy with precision-built solutions. Contact [email protected] to initiate a technical consultation with our German-speaking engineering team. Specify your application requirements and receive a tailored capability assessment within 24 hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.