Technical Contents

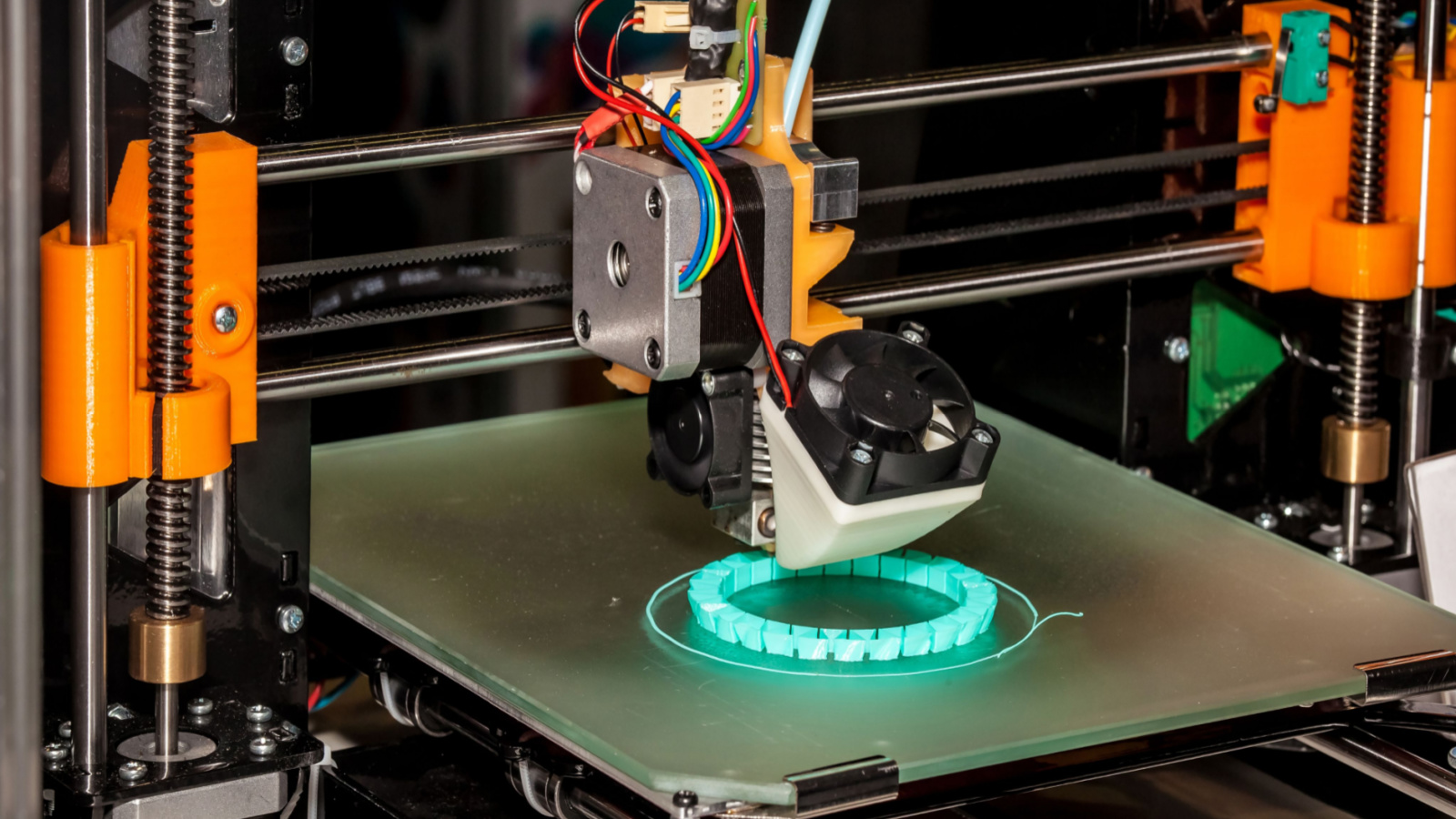

Engineering Guide: 3D Printing Service California

Engineering Insight Precision Imperatives in California Metal 3D Printing Services

California’s advanced manufacturing ecosystem demands more than additive novelty; it requires engineered precision as a non-negotiable foundation. For sectors like aerospace, medical device production, and high-performance automotive, the transition from prototyping to certified end-part production hinges on dimensional accuracy, material integrity, and process repeatability. Standardized 3D printing services often fall short when tolerances dip below 0.1mm or when complex geometries intersect with stringent fatigue requirements. At Wuxi Lead Precision Machinery, we recognize that California clients invest in additive manufacturing not for speed alone, but for the ability to achieve geometries impossible via traditional methods—without sacrificing the precision their safety-critical applications demand. This necessitates integrated metrology, closed-loop process control, and materials expertise exceeding typical service bureau capabilities.

Our approach integrates decades of precision engineering heritage directly into metal additive workflows. Consider turbine components for renewable energy systems supplied to California partners: achieving the required surface finish for aerodynamic efficiency while maintaining internal cooling channel integrity demands layer-by-layer thermal management criticality. Similarly, our production of titanium cranial implants for US medical device firms required not only biocompatible material certification but sub-50-micron dimensional repeatability across complex organic shapes—validated through in-house CT scanning. This level of execution stems from direct experience delivering Olympic-level performance parts, such as titanium structural components for competitive cycling teams where gram-level weight savings intersect with absolute fatigue life requirements, and military-grade drone subsystems operating under extreme vibration profiles. These projects conditioned our systems to treat every build as a mission-critical output, not merely a printed object.

The following specifications represent our baseline capabilities for demanding California projects, reflecting the rigor applied across all production runs:

| Parameter | Capability | Industry Relevance |

|---|---|---|

| Material Systems | Ti-6Al-4V, Inconel 718, 17-4PH | Aerospace, Medical, Oil & Gas |

| Layer Thickness | 20–50 μm | Surface finish & detail capture |

| Dimensional Tolerance | ±0.05 mm per 100 mm | Assembly-critical interfaces |

| Build Volume | Ø250 x 325 mm | Mid-size industrial components |

| Post-Processing | Stress relief, HIP, 5-axis milling | Certification compliance |

California’s innovation engine thrives on partners who understand that additive manufacturing’s true value emerges only when precision is engineered into every process layer. Wuxi Lead Precision Machinery bridges China’s advanced manufacturing scale with the uncompromising standards required by West Coast innovators. We do not merely operate printers; we engineer validated outcomes where material science, geometric complexity, and metrological certainty converge. For your next high-stakes metal additive project, demand the precision pedigree proven in Olympic arenas and defense applications—contact our engineering team to discuss certified production pathways.

Precision Specs & Tolerances

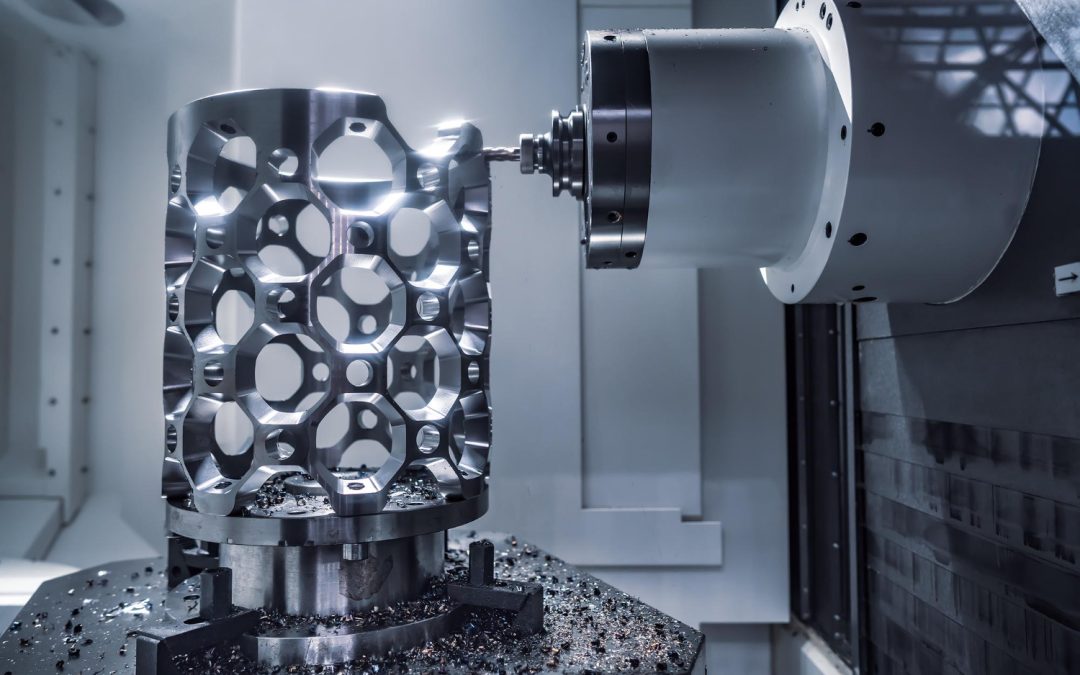

Advanced Technical Capabilities in Precision Metal Manufacturing

Wuxi Lead Precision Machinery delivers high-performance custom metal manufacturing solutions engineered for mission-critical industries including aerospace, medical, energy, and advanced automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, which enable the production of complex geometries with exceptional accuracy and surface finish. These multi-axis platforms allow simultaneous movement across five planes, significantly reducing setup time and part handling while maintaining tight tolerances across intricate features. This level of precision is essential for components requiring organic contours, undercuts, deep cavities, or asymmetric profiles—geometries often encountered in advanced 3D printed metal components requiring post-processing or hybrid manufacturing routes.

All machining operations are supported by a robust digital workflow, integrating CAD/CAM systems with real-time tool monitoring and adaptive control technologies. This ensures consistent material removal rates, minimized tool wear, and optimal surface integrity. Our facility utilizes high-rigidity CNC platforms equipped with automatic tool changers, high-speed spindles, and sealed probing systems for in-process verification. These systems are maintained under strict environmental controls to eliminate thermal drift and ensure repeatability across long production runs.

Quality assurance is integral to every stage of production. Each component undergoes comprehensive inspection using a Zeiss DuraMax and CONTURA G2 Coordinate Measuring Machine (CMM), enabling micron-level verification of dimensional accuracy, geometric tolerances, and form deviations. The CMM system is programmed to follow ISO 10360 standards, with full traceability and digital reporting for every inspection cycle. This metrology-grade validation ensures compliance with AS9100, ISO 13485, and other industry-specific quality frameworks.

Our technical team combines decades of machining expertise with deep knowledge of advanced alloys, including titanium (Ti6Al4V), Inconel 718, stainless steels (316L, 17-4 PH), aluminum 7075, and tool steels. This enables us to tailor cutting strategies, fixturing, and finishing processes to the unique behavior of each material—particularly critical when supporting hybrid manufacturing workflows where 3D printed metal parts require precision CNC finishing.

The following table outlines the standard precision tolerances achievable across our machining and inspection processes:

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Geometric Tolerances | ±0.02 mm | ±0.008 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 3.2 μm | 0.4 μm | Profilometer |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Air Gauges, CMM |

| Positional Accuracy | ±0.02 mm | ±0.008 mm | CMM, Vision System |

| Angular Features | ±0.05° | ±0.01° | CMM, Sine Bar with Gauge Blocks |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for clients seeking precision metal components, whether produced entirely via CNC or as part of a hybrid 3D printing and finishing workflow. Our commitment to technical excellence ensures every part meets the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision Metal 3D Printing: Aluminum, Steel, Titanium & Finishes

Material selection is paramount in metal additive manufacturing, directly influencing part performance, longevity, and cost-effectiveness for demanding California industries like aerospace, medical, and high-performance automotive. At Wuxi Lead Precision Machinery, our expertise ensures optimal material pairing with your application’s mechanical, thermal, and environmental requirements. Understanding the core properties of Aluminum, Steel, and Titanium alloys is the critical first step in leveraging 3D printing’s full potential.

Aluminum alloys, particularly AlSi10Mg, dominate applications requiring an exceptional strength-to-weight ratio and thermal conductivity. This material is ideal for lightweight structural components, heat exchangers, and drone parts where weight savings are non-negotiable. Its inherent machinability post-print also facilitates achieving tight tolerances on critical features. Steel variants, especially Stainless Steel 316L and 17-4 PH, deliver superior strength, hardness, and wear resistance. These are the go-to choices for functional prototypes, tooling inserts, hydraulic components, and parts requiring high durability in corrosive or high-stress environments. Titanium Grade 5 (Ti6Al4V) stands unmatched for extreme conditions. Its combination of very high strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility makes it essential for aerospace brackets, medical implants, and marine components exposed to saltwater or aggressive chemicals.

Surface finish significantly impacts both aesthetics and functional performance. Anodizing is the primary post-processing finish applied to aluminum 3D printed parts. This electrochemical process creates a durable, corrosion-resistant oxide layer that can be dyed various colors for identification or branding. Hard anodizing (Type III) provides an even thicker, harder surface crucial for wear resistance in moving parts. It is vital to note that anodizing is specific to aluminum; steel and titanium require alternative finishes like passivation, electropolishing, or specialized coatings which we also provide.

The following table summarizes key properties of the most prevalent metal 3D printing alloys used in precision manufacturing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 2.67 | 400 – 450 | Good | Lightweight structures, heat sinks, UAV parts |

| Stainless Steel 316L | 7.98 | 550 – 650 | Excellent | Marine components, chemical handling, medical tools |

| Titanium Ti6Al4V | 4.43 | 900 – 1000 | Outstanding | Aerospace fixtures, surgical implants, high-performance racing |

Selecting the right material and finish requires meticulous analysis of the operational environment and functional demands. Wuxi Lead Precision Machinery combines deep metallurgical knowledge with advanced metal 3D printing capabilities and ISO-compliant post-processing in our certified facilities. We partner with California clients to navigate these critical choices, ensuring the final part meets the highest standards of precision, reliability, and performance, delivered with the supply chain consistency global manufacturers require. Let our engineering team guide your next high-value project.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless metal manufacturing begins with precision engineering during the design phase. Our team collaborates directly with clients to interpret technical requirements, functional constraints, and end-use conditions. Using advanced CAD software such as SolidWorks, Autodesk Inventor, and Siemens NX, we convert conceptual ideas into detailed 3D models with exact geometric specifications. Every design undergoes rigorous simulation using finite element analysis (FEA) to validate structural integrity, thermal performance, and fatigue resistance. This digital validation ensures that potential failure points are identified and corrected before physical production begins. Tolerance analysis and manufacturability reviews are conducted in alignment with ISO 2768 and ASME Y14.5 standards, guaranteeing that each component is optimized for both performance and production efficiency.

Prototyping: Validating Performance with Zero Compromise

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art metal 3D printing technologies, including Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). These additive processes enable the creation of complex geometries that are unachievable through traditional machining, while maintaining material properties comparable to forged metals. Prototypes are produced in the same high-performance alloys intended for mass production—such as Inconel 718, titanium Ti-6Al-4V, and aluminum AlSi10Mg—ensuring accurate evaluation of mechanical behavior. Each prototype undergoes comprehensive metrology testing using coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.02 mm. Functional testing, including stress load cycles and environmental exposure, is performed to confirm real-world performance. This iterative validation process ensures design readiness and mitigates risk before scaling to full production.

Mass Production: Consistency Through Advanced Automation

With design and prototype approval, we transition seamlessly into high-volume manufacturing using a hybrid approach that integrates metal 3D printing, CNC machining, and automated post-processing. Our production lines are monitored in real time through IoT-enabled sensors and statistical process control (SPC) systems, ensuring every parameter—from laser power to chamber atmosphere—remains within strict tolerances. Each component is traceable via a digital twin, recording all process data for full auditability. In-process inspections occur at critical stages, supported by automated vision systems and non-destructive testing (NDT) methods such as X-ray and ultrasonic inspection. Final parts are subjected to 100% dimensional verification and surface finish analysis to meet aerospace, medical, and industrial certification requirements.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Alloys | Stainless Steel 316L, Inconel 718, Ti-6Al-4V, AlSi10Mg, Tool Steel (Maraging) |

| Layer Thickness | 20–50 μm |

| Build Volume (Max) | 250 × 250 × 325 mm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (As-Built) | Ra 8–12 μm; Ra <1.6 μm after polishing |

| Post-Processing Options | Heat Treatment, HIP, CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001, AS9100, ISO 13485 (medical-grade) |

Through this rigorously controlled process—design, prototyping, and mass production—Wuxi Lead ensures zero-defect delivery, making us a trusted partner for high-end metal manufacturing needs, including advanced 3D printing service in California and global markets.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Metal Additive Manufacturing Solution for California

When California’s most demanding aerospace, medical, and defense innovators face geometrically complex metal components beyond traditional manufacturing limits, they require a partner with uncompromising precision and engineering depth. Wuxi Lead Precision Machinery delivers this capability from our ISO 9001:2015 and AS9100D certified facility in China, engineered specifically for U.S. high-stakes applications. We bridge the gap between ambitious design and flawless execution, eliminating the compromise between innovation and reliability. Our direct collaboration model ensures your California-based engineering team receives factory-direct expertise without intermediaries, accelerating time-to-market while maintaining stringent U.S. quality standards.

Our metal additive manufacturing services leverage state-of-the-art Direct Metal Laser Sintering (DMLS) systems, producing flight-certifiable parts with material properties matching wrought equivalents. We specialize in mission-critical alloys including Ti-6Al-4V, Inconel 718, 17-4 PH stainless steel, and aluminum AlSi10Mg, processed under rigorously controlled atmospheres to achieve near-net-shape accuracy. Unlike conventional California-based 3D printing services constrained by legacy equipment or limited material science expertise, Lead Precision integrates full metallurgical analysis, hot isostatic pressing (HIP), and precision CNC post-processing under one roof. This vertical integration guarantees dimensional stability and fatigue performance required for FAA Part 21 or FDA Class III applications.

Critical Performance Specifications for Mission-Critical Applications

| Parameter | Capability | Industry Standard | Lead Precision Advantage |

|---|---|---|---|

| Minimum Feature Size | 0.3 mm | 0.5 mm | Enables micro-cooling channels |

| Dimensional Tolerance | ±0.02 mm per 100 mm | ±0.05 mm | Eliminates secondary machining |

| Surface Roughness (As-Built) | Ra 8–12 μm | Ra 15–20 μm | Reduces post-processing time |

| Material Density | >99.95% (HIP processed) | 99.8% | Matches wrought fatigue life |

| Max Build Volume | 250 x 250 x 325 mm | 200 x 200 x 250 mm | Accommodates larger assemblies |

Material integrity is non-negotiable in California’s regulated sectors. Every build undergoes real-time melt pool monitoring, full build chamber oxygen control below 100 ppm, and comprehensive post-build validation including CT scanning and mechanical testing per ASTM F3301/F3318. Our engineers collaborate with your team from DfAM optimization through first-article inspection, ensuring designs leverage additive advantages without sacrificing certification pathways. With 72-hour rapid quoting and dedicated U.S. time zone engineering support, we eliminate the latency typically associated with offshore manufacturing.

For California projects where failure is not an option, partner with an additive manufacturer that treats your specifications as engineering mandates. Contact our technical sales team at [email protected] to initiate an engineer-to-engineer consultation. Provide your part geometry, material requirements, and certification needs—we will deliver a validated manufacturing strategy within 48 hours. Lead Precision Machinery: Precision Engineered, Globally Delivered. Your innovation deserves nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.