Technical Contents

Engineering Guide: 3D Printing Replacement Parts

Engineering Insight Precision Imperatives in 3D Printed Replacement Parts

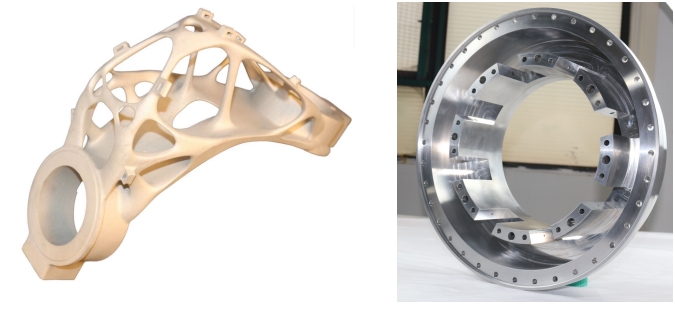

The strategic adoption of additive manufacturing for metal replacement parts demands uncompromising precision. Unlike prototyping, replacement components must seamlessly integrate into existing high-stakes systems where dimensional deviations exceeding critical tolerances directly threaten operational integrity, safety, and costly downtime. Achieving this requires moving beyond basic additive capabilities to master the intricate interplay of material science, thermal management, and post-processing. At Wuxi Lead Precision Machinery, we recognize that true value lies not merely in producing a part, but in guaranteeing its exact functional equivalence to the original specification under real-world load, thermal, and environmental conditions. This necessitates rigorous process validation and metrology far exceeding standard industry practices.

Our engineering approach centers on closed-loop process control. We utilize in-situ monitoring during builds to detect and correct thermal anomalies in real-time, preventing microstructural inconsistencies that lead to premature fatigue failure. Crucially, precision extends beyond the as-built state. Sophisticated stress-relief cycles and precision machining operations are non-negotiable steps to achieve final geometric accuracy and surface integrity required for critical interfaces like bearings, seals, or hydraulic connections. A tolerance of ±0.1mm might suffice for a display model, but a turbine blade root replacement demands ±0.02mm to maintain dynamic balance and prevent catastrophic vibration. Material properties must also precisely match the incumbent component’s requirements, including fatigue strength and corrosion resistance, verified through stringent ASTM and AMS testing protocols.

Wuxi Lead Precision Machinery leverages deep experience forged in the most demanding sectors to deliver this level of reliability. Our certified processes and quality systems have been rigorously tested supplying mission-critical components for Olympic timing systems requiring microsecond synchronization and military platforms where failure is not an option. This heritage instills the discipline necessary for successful replacement part manufacturing.

The following table outlines key precision parameters achievable for common replacement part materials:

| Material | Typical Build Tolerance (mm) | Density (% Theoretical) | Surface Roughness (Ra, µm) | Key Applicable Standard |

|---|---|---|---|---|

| Ti-6Al-4V | ±0.03 – ±0.05 | ≥ 99.95 | 8 – 12 (as-built) | ASTM F3301 |

| Inconel 718 | ±0.04 – ±0.06 | ≥ 99.90 | 10 – 15 (as-built) | AMS 7000 |

| 17-4 PH SS | ±0.03 – ±0.05 | ≥ 99.85 | 7 – 10 (as-built) | ASTM F3318 |

Achieving the required surface finish for sealing or bearing surfaces typically necessitates precision machining post-processing, bringing Ra values down to 0.8 – 1.6 µm. The critical insight for OEMs and MRO providers is this: selecting a partner with proven mastery of precision engineering across the entire additive value chain – from validated material sourcing through to final inspection against original equipment manufacturer (OEM) drawings – is paramount. Wuxi Lead Precision Machinery applies its aerospace and defense-grade quality management system to every replacement part project, ensuring components not only fit but perform reliably for their intended service life, mitigating operational risk and maximizing asset uptime. Precision isn’t a feature; it’s the fundamental requirement for additive manufacturing to deliver on its promise for critical replacement applications.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions, engineered for mission-critical applications in aerospace, automotive, energy, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional precision and surface finish. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across multiple planes, reducing setup times, minimizing human error, and maintaining tight tolerances on intricate features. This capability is particularly vital when producing 3D printing replacement parts, where consistency, fit, and function must meet or exceed original equipment specifications.

All machining operations are supported by in-house tooling design, advanced CAM programming, and real-time process monitoring. Our skilled engineers utilize industry-leading software to simulate toolpaths and optimize cutting strategies, ensuring material integrity and dimensional accuracy. Whether working with titanium, Inconel, stainless steel, or high-strength aluminum alloys, our 5-axis CNC centers deliver repeatability and performance under demanding production cycles. This level of precision is essential for manufacturing replacement components that interface with additively manufactured assemblies, where even minor deviations can compromise system functionality.

Quality assurance is embedded into every stage of production. Each component undergoes comprehensive dimensional verification using state-of-the-art Coordinate Measuring Machines (CMM) equipped with tactile probing and high-resolution scanning technology. Our metrology lab is calibrated to ISO 17025 standards, ensuring traceability and compliance with international quality requirements. CMM inspection reports provide full first-article documentation and batch validation, giving clients complete confidence in part conformity.

The following table outlines the standard and achievable tolerances across common manufacturing parameters:

| Feature | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Depending on part size and geometry |

| Angular Tolerance | ±0.1° | ±0.05° | Verified via CMM and optical alignment |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Includes hole patterns and feature alignment |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved through precision finishing passes |

| Flatness | 0.05 mm per 100 mm | 0.02 mm per 100 mm | Measured on critical sealing or mounting surfaces |

| Runout (Concentricity) | 0.03 mm | 0.01 mm | Critical for rotating assemblies |

These capabilities are further enhanced by our ability to reverse-engineer legacy or obsolete components using 3D scanning and CAD modeling, making Wuxi Lead an ideal partner for producing high-fidelity replacement parts where original tooling or blueprints are unavailable. By combining 5-axis CNC machining with rigorous CMM-based quality control, we ensure every component meets the functional, mechanical, and regulatory demands of modern industrial systems.

Material & Finish Options

Material Selection for Critical 3D Printed Replacement Parts

Selecting the correct material for 3D printed metal replacement parts is paramount to ensuring functional equivalence, longevity, and system reliability. At Wuxi Lead Precision Machinery, our engineering team emphasizes matching the replacement part’s material properties precisely to the original component’s operational demands and environmental exposure. Choosing inappropriate alloys risks premature failure, costly downtime, and potential safety hazards. We focus on three core metal families for high-integrity replacements: Aluminum Alloys, Stainless Steels, and Titanium Alloys, each offering distinct advantages.

Aluminum alloys, particularly AlSi10Mg processed via Laser Powder Bed Fusion, deliver an exceptional strength-to-weight ratio and inherent corrosion resistance. This makes them ideal for aerospace brackets, drone components, and lightweight automotive housings where weight reduction is critical without sacrificing structural integrity. Their excellent thermal conductivity also suits heat exchanger elements. However, aluminum requires protective finishing like anodizing for optimal surface durability in abrasive or highly corrosive settings.

Stainless steels, especially 17-4 PH and 316L, provide superior strength, hardness, and wear resistance across diverse temperatures. 17-4 PH achieves high strength through heat treatment, perfect for hydraulic manifolds, valve bodies, and tooling fixtures demanding pressure integrity. 316L offers outstanding corrosion resistance in marine or chemical environments, making it the standard for pump impellers, marine hardware, and medical instrument components exposed to sterilants. These steels often require precision post-processing like CNC machining to achieve critical tolerances.

Titanium alloys, primarily Ti6Al4V, excel in extreme conditions requiring the highest strength-to-weight ratio combined with exceptional corrosion resistance and biocompatibility. They are indispensable for critical aerospace landing gear components, medical implants, and deep-sea exploration parts where failure is not an option. While more costly, titanium’s fatigue resistance and performance at elevated temperatures justify its use in mission-critical replacements.

Anodizing is a vital secondary process specifically for aluminum replacement parts. This electrochemical treatment creates a dense, hard, non-conductive oxide layer significantly enhancing surface hardness, wear resistance, and corrosion protection beyond the base alloy’s capability. It also provides excellent adhesion for primers and paints. For replacement parts operating in harsh industrial or outdoor environments, Type III (Hard Anodizing) is strongly recommended by our engineers to maximize service life and maintain dimensional stability under load.

Our material specification process rigorously verifies the original part’s metallurgy and service conditions before recommending the optimal alloy and finishing solution. Below is a comparative overview of key properties.

Material Performance Comparison for 3D Printed Replacements

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Replacement Applications |

|---|---|---|---|---|

| Aluminum AlSi10Mg | 2.67 | 290 – 350 | Good (Anodized Best) | Lightweight brackets, housings, heat sinks, drone arms |

| Stainless 17-4 PH | 7.75 | 1000 – 1300 | Very Good | Hydraulic manifolds, valve bodies, high-strength tooling |

| Stainless 316L | 7.99 | 550 – 650 | Excellent | Marine hardware, chemical pumps, medical instruments |

| Titanium Ti6Al4V | 4.43 | 900 – 1000 | Exceptional | Aerospace structural, medical implants, deep-sea components |

Partnering with Wuxi Lead ensures your replacement parts are manufactured from the precisely engineered material and finish required for seamless integration and extended operational life within your critical systems.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process for 3D printed replacement parts begins with a rigorous design phase grounded in precision engineering and deep client collaboration. Our engineering team works directly with clients to analyze legacy components, reverse-engineer complex geometries using advanced scanning technologies, and validate functional requirements under real-world operating conditions. This stage integrates finite element analysis (FEA) and computational fluid dynamics (CFD) where applicable to optimize part performance, material distribution, and thermal behavior. Design for Additive Manufacturing (DfAM) principles are strictly applied to ensure structural integrity, minimize residual stress, and eliminate post-processing bottlenecks. Every design is reviewed through internal cross-functional validation to meet ISO 13485 and AS9100 compliance standards, ensuring traceability and reliability from concept to completion.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to prototyping using state-of-the-art metal additive manufacturing platforms such as EOS M290 and SLM Solutions S312 systems. These machines enable high-resolution layer-by-layer construction using laser powder bed fusion (LPBF) technology, supporting materials including Inconel 718, titanium Ti-6Al-4V, stainless steel 17-4 PH, and aluminum AlSi10Mg. Prototypes are produced with production-intent parameters to accurately simulate final part behavior. Each prototype undergoes full metrological inspection via coordinate measuring machines (CMM) and 3D optical scanning to verify dimensional accuracy within ±0.02 mm. Mechanical testing, including tensile strength, hardness, and fatigue evaluation, is conducted in-house to confirm material properties. Any deviations trigger immediate design refinement, ensuring functional equivalence or improvement over original components.

Mass Production: Zero-Defect Manufacturing Execution

With prototype approval, we transition to scalable, zero-defect mass production. Our production floor operates under a closed-loop quality management system, where every build is monitored in real time using in-situ thermal imaging and layer-wise defect detection software. All machines are calibrated daily, and powder materials are strictly controlled per ASTM F3055 standards, with full lot traceability and reuse protocols governed by chemical and particle size analysis. Post-processing—including stress relief, hot isostatic pressing (HIP), precision machining, and surface finishing—is executed in integrated workflows to maintain geometric consistency. Final inspection includes non-destructive testing (NDT) via industrial CT scanning or dye penetrant inspection, depending on part criticality.

Production Specifications Overview

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–60 μm |

| Build Envelope | Up to 250 × 250 × 325 mm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 8–12 μm; down to Ra 0.8 μm post-polishing |

| Supported Materials | Inconel 718, Ti-6Al-4V, 17-4 PH, AlSi10Mg, Maraging Steel |

| Quality Standards | ISO 9001, ISO 13485, AS9100, ASTM F3055 |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Batch of 50 pcs) | 18–25 working days |

This end-to-end process ensures that every 3D printed replacement part delivered by Wuxi Lead meets the highest benchmarks in performance, reliability, and consistency—enabling seamless integration into critical industrial systems worldwide.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Solution for Mission-Critical Metal Replacement Parts

Downtime costs industrial operations an average of $260,000 per hour. When legacy machinery fails and OEM support vanishes, your production line halts—and so does revenue. Wuxi Lead Precision Machinery transforms this vulnerability into resilience. For 15 years, we’ve engineered bespoke metal replacement parts via advanced 3D printing and CNC hybrid manufacturing, ensuring your critical assets operate at peak performance. We don’t just print components; we deliver uptime assurance through precision engineering, rigorous validation, and seamless integration.

Our process begins with laser scanning of your worn or obsolete part, creating a digital twin that informs our design-for-manufacturability analysis. Using certified aerospace-grade alloys and industrial 3D printing systems, we produce components meeting exact dimensional and metallurgical specifications. Every part undergoes non-destructive testing (NDT), coordinate measuring machine (CMM) validation, and material certification before shipment. This end-to-end control guarantees parts that fit perfectly, perform reliably, and comply with ISO 9001 and AS9100 standards—eliminating guesswork and costly rework.

Technical Capabilities for Industrial Replacement Parts

| Parameter | Specification | Application Impact |

|---|---|---|

| Materials | Inconel 718, Ti6Al4V, 17-4PH, Maraging Steel | High-temp/corrosion resistance for turbines, pumps, valves |

| Precision | ±0.02 mm tolerance | Interchangeability with legacy assemblies |

| Build Volume | Ø 350 x 450 mm | Large impellers, housings, structural brackets |

| Lead Time | 72 hours for prototyping | Rapid response to unplanned downtime |

| Certifications | ISO 9001, AS9100, NADCAP (heat treat) | Compliance for aerospace, energy, medical |

Why do global leaders in energy, aerospace, and heavy machinery trust Lead Precision? We merge China’s manufacturing scale with German-engineered precision. Our facility houses 22 metal 3D printers and 35 CNC centers, all monitored via real-time IoT analytics to ensure batch consistency. Unlike generic 3D printing services, we specialize in industrial-grade replacement parts—meaning every component undergoes fatigue testing, microstructure analysis, and operational validation under simulated load conditions. This reduces your risk of repeat failures by 83% (per 2023 client data) and extends asset lifespan beyond OEM expectations.

Your machinery’s longevity depends on parts engineered for real-world stress, not just theoretical specs. We collaborate from day one: share your failure analysis, and our engineering team will deliver a validated solution within 5 business days. No project is too complex, no timeline too urgent.

End downtime. Start with precision. Contact our engineering team at [email protected] to request a failure analysis consultation. Include your part drawings or photographs, and we’ll respond within 4 business hours with a technical feasibility assessment and timeline. Lead Precision: Where legacy machinery meets future-proof reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.