Technical Contents

Engineering Guide: 3D Printing Plastic Parts

Engineering Insight Precision in Industrial 3D Printing for Plastic Parts

In high-stakes manufacturing environments, the perception of 3D printed plastic parts as merely prototyping tools fundamentally misunderstands modern industrial capability. True precision engineering demands dimensional stability, material integrity, and repeatability that meet rigorous functional requirements – not just aesthetic approximation. At Wuxi Lead Precision Machinery, we treat plastic additive manufacturing with the same uncompromising standards applied to our custom metal components. Our experience delivering mission-critical parts for Olympic Games infrastructure and classified military programs underscores that tolerances below ±0.05mm and certified material performance are non-negotiable, even in polymer-based production.

The critical distinction lies in process control. Consumer-grade or standard industrial printers often prioritize speed over stability, yielding parts susceptible to warpage, layer delamination, or inconsistent mechanical properties under thermal or load stress. Industrial-scale additive systems require closed-loop environmental monitoring, calibrated material drying, and post-processing protocols that mirror CNC machining rigor. For instance, producing a flight-certified drone housing or a precision fluid manifold demands not only geometric accuracy but also validated isotropic strength and chemical resistance – achievable only through controlled build parameters and traceable material batches.

Wuxi Lead integrates additive capabilities within our end-to-end precision ecosystem. Every plastic part undergoes the same GD&T validation, CMM inspection, and thermal cycling tests as our titanium or aluminum components. This holistic approach ensures seamless integration of printed elements into metal assemblies – a necessity for complex systems where thermal expansion coefficients or load paths must align perfectly across material boundaries. Our Beijing 2022 Winter Olympics project required polymer brackets maintaining ±0.03mm flatness across -40°C to 80°C ranges; similarly, military communication housings we produced withstand 50G shocks while preserving RF shielding integrity.

Material selection and process validation are equally vital. The table below reflects the engineering-grade polymers we deploy under controlled conditions, far exceeding generic PLA or ABS specifications:

| Material | Tolerance (mm) | Max Temp (°C) | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|

| ULTEM 9085 | ±0.05 | 150 | 72 | Aerospace ducting, brackets |

| PEEK 450G | ±0.03 | 250 | 90 | Medical implants, seals |

| Nylon 12 CF | ±0.04 | 120 | 55 | Automotive load-bearing parts |

| Accura Extreme | ±0.05 | 80 | 58 | Fluidic systems, jigs |

Precision in plastic additive manufacturing is not an aspiration – it is a measurable, auditable outcome. For OEMs integrating printed components into high-reliability assemblies, partnering with a manufacturer that enforces aerospace-grade process discipline across all materials is essential. Wuxi Lead’s convergence of metal machining heritage and polymer science expertise delivers parts where geometry, function, and longevity converge. When your application demands more than a prototype, demand certified precision. Contact our engineering team to discuss validated additive solutions meeting AS9100 and ISO 13485 standards.

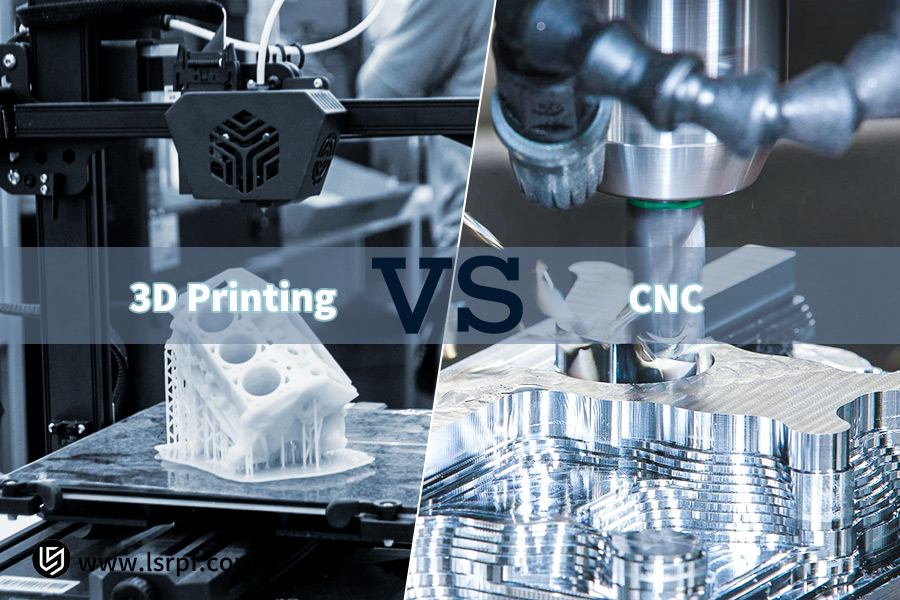

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities in custom metal manufacturing are engineered to meet the most demanding specifications in high-precision industries such as aerospace, medical devices, automotive, and industrial automation. While our expertise is rooted in metal fabrication, our integrated approach to advanced manufacturing allows us to support hybrid production workflows, including the finishing, post-processing, and precision integration of 3D printed plastic components into complex metal assemblies. Our 5-axis CNC machining centers play a pivotal role in this process, enabling us to achieve superior surface finishes, tight tolerances, and complex geometries that complement additive manufacturing outputs.

Our 5-axis CNC machining systems are equipped with high-speed spindles, automated tool changers, and real-time monitoring software, ensuring consistent accuracy and efficiency. These machines allow for simultaneous multi-axis movement, reducing setup times and eliminating the need for multiple fixtures. This capability is particularly valuable when machining hybrid components or creating precision metal housings, mounts, or interfaces for 3D printed plastic parts. The integration of 5-axis technology ensures that even the most intricate contours and undercuts are machined with micron-level precision.

Quality control is embedded into every stage of production. We employ a comprehensive inspection protocol using state-of-the-art Coordinate Measuring Machines (CMM) to verify dimensional accuracy and geometric conformity. Each component undergoes full-spectrum metrology, including first-article inspection and in-process checks, to ensure compliance with international standards such as ISO 9001 and AS9100. Our CMM systems are calibrated to traceable standards and operated by certified metrology technicians, guaranteeing repeatable and reliable results across production batches.

The following table outlines the standard tolerances we maintain across our machining operations, reflecting our commitment to precision and consistency:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Angular Dimensions | ±0.1° | ±0.05° | Measured via CMM |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | GD&T compliant |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined, polish optional |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Verified on granite surface plate |

| Thread Accuracy | 6H/6g | 4H/4g | ISO metric standards |

These tolerances are achievable across a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and high-performance alloys. While 3D printing enables rapid prototyping and complex internal structures in plastics, our machining and inspection capabilities ensure that final assemblies—especially those combining plastic and metal elements—meet the rigors of functional performance and regulatory compliance. Wuxi Lead Precision Machinery delivers not just parts, but precision-engineered solutions backed by advanced technology and rigorous quality assurance.

Material & Finish Options

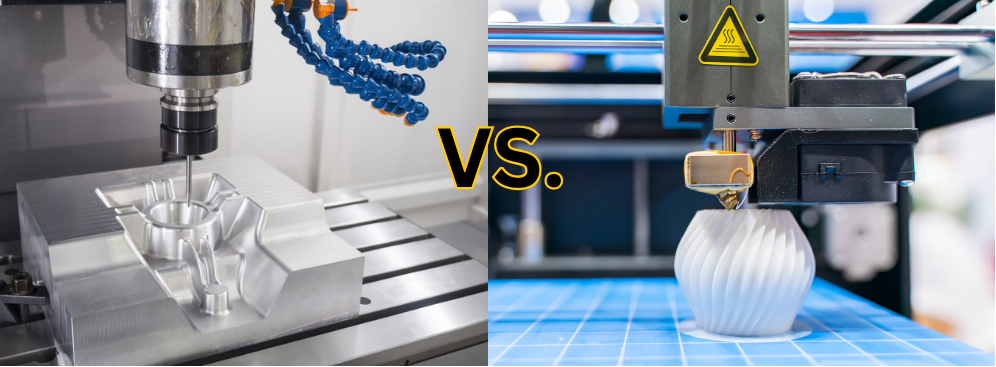

Material Selection for Precision Metal Components: Beyond Plastic 3D Printing Realities

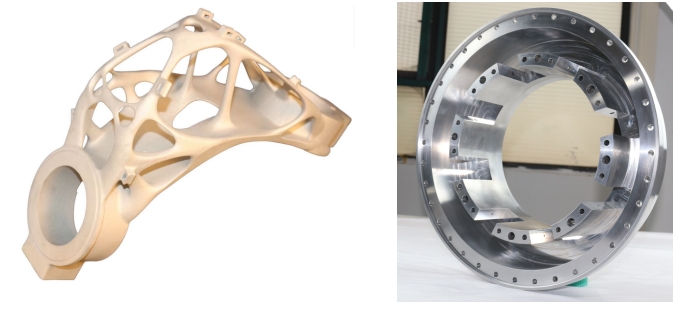

Wuxi Lead Precision Machinery addresses a critical industry clarification: while 3D printing plastic parts serves specific prototyping or low-stress applications, high-performance end-use components in demanding sectors like aerospace, medical, and automotive fundamentally require precision metal manufacturing. Plastic 3D printing cannot meet the structural integrity, thermal stability, wear resistance, or regulatory standards mandated for critical metal parts. Our expertise lies in transforming metal alloys through CNC machining, not plastic additive processes. Selecting the optimal metal substrate is therefore the indispensable foundation for performance, longevity, and cost-effectiveness in precision engineering.

Material choice directly impacts manufacturability, functional lifespan, and total cost of ownership. Aluminum alloys offer an exceptional strength-to-weight ratio and excellent machinability, making them ideal for aerospace structures, heat sinks, and housings where weight savings are paramount. Steel variants, particularly hardened tool steels and stainless grades, deliver superior strength, wear resistance, and dimensional stability under high loads and temperatures, essential for tooling, hydraulic components, and surgical instruments. Titanium alloys provide the ultimate in strength-to-weight ratio combined with outstanding corrosion resistance and biocompatibility, justifying their use in critical aerospace components and permanent medical implants despite higher material and machining costs. Consideration must extend beyond initial part function to include production volume, secondary operations, and environmental exposure.

The following table provides key comparative specifications for common precision machining alloys:

| Material Family | Typical Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310-570 | Moderate (varies) | Excellent (A) | Aerospace frames, heat exchangers, consumer electronics housings |

| Steel | 4140, 17-4PH, 304/316 Stainless | 7.8-8.0 | 655-1300+ | Good (Stainless: Excellent) | Good to Fair (B-C) | Tooling, shafts, valves, medical instruments, structural fittings |

| Titanium | Ti-6Al-4V (Grade 5) | 4.4 | 900-1000 | Excellent | Poor (D) | Aircraft engine components, surgical implants, marine hardware |

Surface finishing, particularly anodizing for aluminum, is not merely cosmetic but a critical performance enhancer. Type II (Sulfuric Acid) anodizing provides robust corrosion resistance and a base for dyeing, while Type III (Hardcoat) anodizing delivers extreme surface hardness (up to 60-70 HRC), superior wear resistance, and electrical insulation for high-abrasion environments. Proper anodizing thickness and sealing are vital for meeting aerospace (AMS 2469, AMS 2471) or medical (ASTM F2004) specifications. For steel and titanium, alternatives like passivation, plating, or specialized coatings address specific corrosion or wear challenges.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to guide clients through this complex selection matrix. We analyze your functional requirements, environmental conditions, regulatory constraints, and production volumes to recommend the optimal alloy and finishing process. This strategic approach minimizes risk, ensures regulatory compliance, and maximizes component value over its operational life. Trust our precision metal manufacturing capability to transform your most demanding designs into reliable, high-performance reality. Contact our engineering team for a material selection consultation specific to your application.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Reality

The foundation of flawless 3D printed plastic part production begins with meticulous design engineering. At Wuxi Lead Precision Machinery, our design phase integrates advanced CAD modeling with deep materials science expertise to ensure every component meets exact functional, thermal, and mechanical requirements. Engineers collaborate directly with clients to evaluate load conditions, environmental exposure, and dimensional tolerances, applying design-for-additive-manufacturing (DfAM) principles to optimize part geometry, minimize material waste, and eliminate stress concentrations. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations are routinely employed to validate structural integrity and performance under real-world conditions. This proactive approach ensures that design flaws are identified and corrected before any physical prototype is produced, significantly reducing downstream risk and accelerating time to market.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to high-fidelity prototyping using industrial-grade 3D printing technologies such as Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) with engineering thermoplastics. These prototypes are not merely visual models—they are fully functional parts used for fit checks, assembly validation, and performance testing under operational loads. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy against the original CAD file. Material properties, including tensile strength, heat deflection temperature, and chemical resistance, are tested in accordance with international standards. Feedback from this phase is systematically incorporated into final design refinements, ensuring that what moves into mass production is a proven, reliable design.

Mass Production: Zero Defects Through Process Control

Our transition to mass production is governed by a zero-defect manufacturing philosophy. Utilizing automated 3D printing cells with real-time monitoring, we maintain consistent layer adhesion, temperature control, and material feed accuracy across thousands of parts. Every build is supported by statistical process control (SPC), in-process inspections, and full traceability of materials and machine parameters. Post-processing—including annealing, machining, surface finishing, and coating—is performed under ISO 9001-certified procedures to ensure uniformity and durability. Final quality assurance includes 100% visual inspection and sampling-based metrology, with full documentation provided for each production batch.

| Parameter | Specification |

|---|---|

| Layer Resolution | 50 – 150 µm |

| Dimensional Accuracy | ±0.1 mm (standard), ±0.05 mm (precision) |

| Build Envelope (Max) | 700 x 500 x 600 mm |

| Supported Materials | PA12, PA6, ABS, PC, PEEK, ULTEM™ |

| Surface Finish | Ra 3.2 µm (as-printed), down to Ra 0.8 µm (polished) |

| Post-Processing Options | CNC machining, vapor smoothing, painting, anodizing (for hybrid metal-plastic assemblies) |

Through seamless integration of design intelligence, prototyping validation, and disciplined production execution, Wuxi Lead delivers 3D printed plastic components with uncompromising quality—engineered for performance, built for scale.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Integrated Metal Solutions in Your 3D Printing Workflow

While additive manufacturing excels at producing complex plastic prototypes and end-use parts, high-performance applications demand seamless integration with precision metal components. Wuxi Lead Precision Machinery specializes in bridging this critical gap. As your dedicated metal manufacturing partner, we transform your 3D printing projects from concept to fully functional, production-ready systems by delivering CNC-machined metal parts that meet the exacting standards plastic printing alone cannot achieve. Our expertise ensures structural integrity, thermal stability, and mechanical reliability where plastic falls short—essential for aerospace, medical devices, and industrial automation.

We understand that plastic 3D printing often requires complementary metal elements: custom housings, sensor mounts, load-bearing brackets, or wear-resistant interfaces. Lead Precision provides the precision metal backbone your assemblies need, with tolerances and material properties unattainable through additive methods. Our ISO 9001-certified facility leverages advanced 5-axis CNC milling, turning, and grinding technologies to produce components that integrate flawlessly with your printed plastics. This synergy eliminates assembly failures, reduces lifecycle costs, and accelerates time-to-market for complex multi-material systems.

Our technical capabilities are engineered to exceed industry benchmarks. The table below outlines core specifications for critical metal components supporting 3D printed plastic assemblies:

| Specification Category | Capability | Material Examples | Typical Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Aluminum 7075, Stainless Steel 316L, Titanium Ti-6Al-4V | Precision mounting interfaces for sensors, optical systems |

| Surface Finish | Ra 0.4 µm (as-machined) to Ra 0.05 µm (polished) | Hardened Steel, Inconel 718 | Sealing surfaces, hydraulic components, medical implants |

| Max Part Size | 1200 x 800 x 600 mm | Brass, Copper Alloys | Large structural frames, heat exchangers, robotic end-effectors |

| Critical Feature Accuracy | ±0.002 mm (GD&T compliant) | Magnesium Alloys, Tool Steels | Gear housings, bearing seats, high-torque transmission parts |

Beyond technical execution, we optimize your supply chain through concurrent engineering. Share your 3D printed plastic assembly designs early, and our engineering team will identify metal integration points, suggest cost-saving material substitutions, and validate manufacturability—reducing iterations and scrap. Our rapid prototyping services deliver metal validation parts in 5–7 days, ensuring your plastic-metal systems perform under real-world stress before full production.

Do not let material limitations compromise your innovation. Partner with Wuxi Lead Precision Machinery to unify additive and subtractive manufacturing into a single, streamlined workflow. Contact our engineering team directly at [email protected] to discuss how our precision metal solutions enhance the functionality, durability, and market readiness of your 3D printed plastic applications. Include your project specifications and timeline for a tailored capability assessment within 24 hours. Your next-generation product demands metal precision—let us deliver it.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.