Technical Contents

Engineering Guide: 3D Printing Online Shop

Engineering Insight Precision in Metal Additive Manufacturing

In high-stakes industrial applications, precision defines success or failure. For B2B buyers sourcing metal 3D printed components online, tolerances measured in microns directly impact part functionality, safety, and lifecycle costs. Generic online platforms often prioritize speed over accuracy, resulting in components that fail during assembly, under operational stress, or in regulated environments. True precision demands rigorous process control—from laser calibration to thermal management—ensuring dimensional stability, material integrity, and repeatability across every build. At Wuxi Lead Precision Machinery, we treat tolerances as non-negotiable engineering commitments, not marketing claims.

Our facility operates at the intersection of aerospace-grade standards and scalable production. Having delivered mission-critical components for the Beijing 2022 Winter Olympics ice resurfacing systems and certified military-grade brackets for defense contractors, we understand how microscopic deviations cascade into systemic failures. These projects required ISO 2768-m2 tolerances, zero porosity in Ti-6Al-4V aerospace alloys, and full traceability from powder lot to finished part. Such rigor stems from our dual-certified AS9100D and ISO 13485 quality management systems, which govern every parameter in our additive workflow.

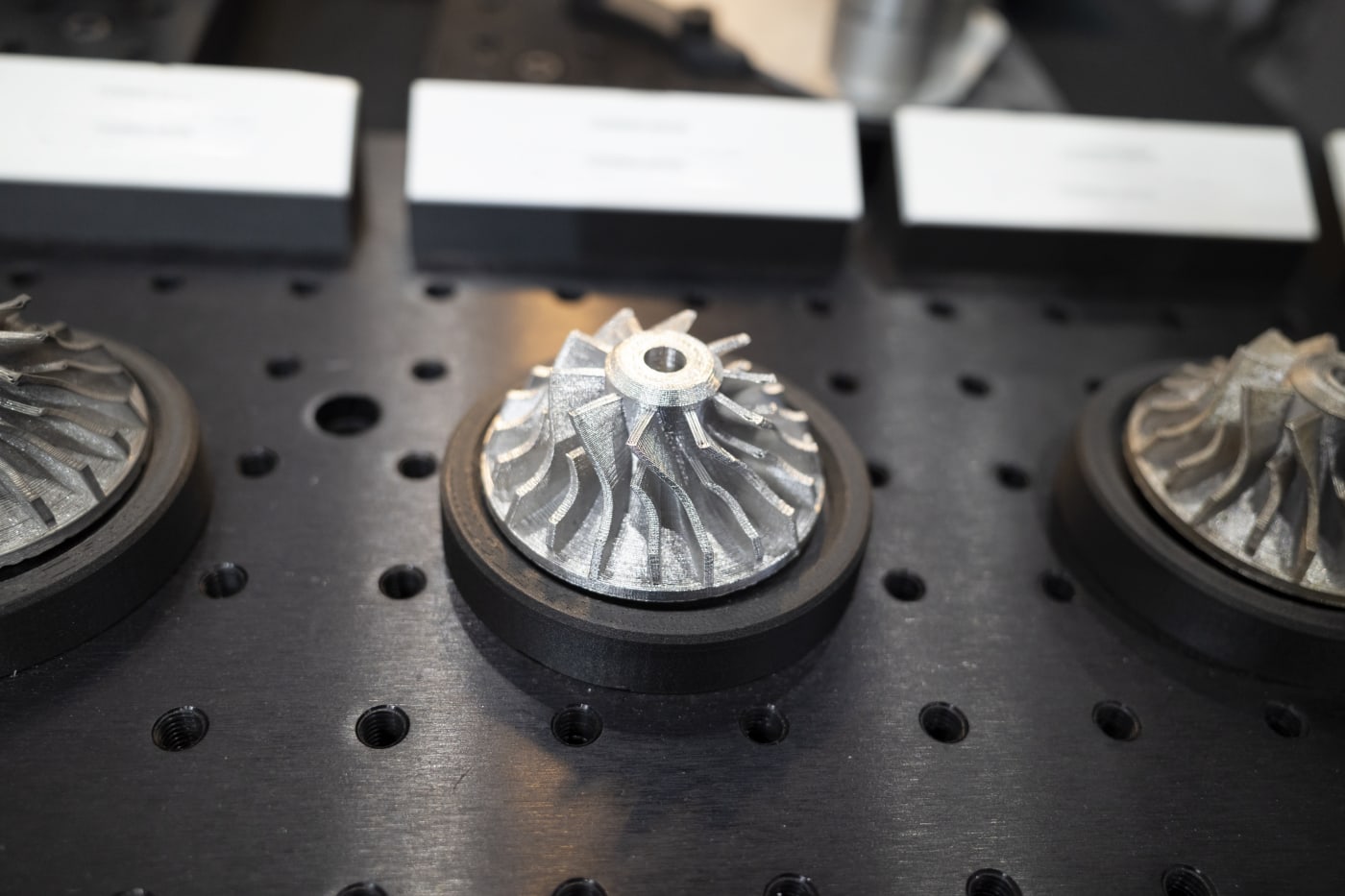

Unlike commercial 3D printing shops, we integrate precision metrology directly into production cycles. Each build undergoes in-situ laser monitoring, followed by post-process validation using Zeiss coordinate measuring machines (CMM) and micro-CT scanning. This eliminates guesswork, ensuring components meet geometric dimensioning and tolerancing (GD&T) specifications critical for hydraulic manifolds, turbine blades, or medical implants. When your application involves high-pressure systems or human safety, ±0.05mm tolerance isn’t optional—it’s existential.

Below are key precision metrics achievable through our industrial metal additive process:

| Parameter | Capability | Industry Standard Comparison |

|---|---|---|

| Layer Thickness | 20–60 μm | Typical: 30–100 μm |

| Dimensional Accuracy | ±0.02 mm per 100 mm | Typical: ±0.1 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm | Typical: Ra 15–25 μm |

| Material Density | >99.95% (non-porous) | Typical: 98–99.5% |

| Build Volume | 500 x 500 x 500 mm | Typical: 250 x 250 x 300 mm |

Wuxi Lead’s engineering team collaborates with clients during design validation to preempt precision risks—such as residual stress in overhangs or support-induced surface defects—before the first layer prints. We specialize in materials like Inconel 718, Maraging Steel 300, and aluminum AlSi10Mg, all processed under argon-controlled chambers to eliminate oxidation. Our post-processing suite includes stress-relief annealing, precision machining, and vibratory finishing to achieve mirror finishes where required.

For industries where failure is not an option, precision must be engineered, not assumed. Partner with a manufacturer that validates every micron through military-grade protocols and Olympic-caliber execution. Contact our engineering team to discuss your tolerance-critical application—we’ll deliver certified data, not just parts.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for industries demanding precision, reliability, and repeatability. At the core of our technical capabilities is our 5-axis CNC machining platform, enabling us to produce highly complex geometries with exceptional accuracy. This technology allows simultaneous movement across five axes, providing superior access to intricate part features and reducing the need for multiple setups. As a result, we achieve tighter tolerances, improved surface finishes, and greater consistency across both prototyping and high-volume production runs.

Our machining center is equipped with state-of-the-art 5-axis CNC machines capable of handling a wide range of metallic materials, including aluminum alloys, stainless steel, titanium, Inconel, and other high-performance alloys. These systems are operated by experienced CNC programmers and machinists who utilize advanced CAM software to optimize tool paths, minimize cycle times, and ensure maximum part integrity. The integration of high-speed machining techniques further enhances productivity without compromising precision.

Quality control is embedded into every stage of our manufacturing process. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional compliance with customer specifications. Our CMM system provides full 3D measurement capability with micron-level accuracy, allowing for detailed validation of complex contours, hole patterns, and geometric tolerances as defined in ASME Y14.5 standards. In addition to CMM inspection, we employ supplementary metrology tools such as optical comparators, surface roughness testers, and calibrated hand instruments to verify critical features.

We maintain a climate-controlled inspection environment to eliminate thermal variation, ensuring measurement stability and repeatability. Each production batch is accompanied by a full inspection report, available upon request, detailing key dimensions and conformance data. Our quality management system is aligned with ISO 9001 standards, reflecting our commitment to continuous improvement and customer satisfaction.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Positional Accuracy | ±0.01 mm | ±0.005 mm | Verified via CMM |

| Linear Dimensions | ±0.01 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter Tolerance | ±0.01 mm | ±0.005 mm | Reamed or precision bored |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm | Machined surfaces, achievable via fine tool paths |

| Geometric Tolerances | ±0.02 mm | ±0.01 mm | Includes flatness, perpendicularity |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom | Based on 5-axis machine capacity |

| Minimum Feature Size | 0.5 mm | 0.3 mm | Dependent on material and geometry |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance protocols to meet the demanding requirements of aerospace, medical, automation, and high-end industrial clients. Our technical capabilities are designed to support innovation while ensuring manufacturability, scalability, and compliance with international standards.

Material & Finish Options

Material Selection Guide for Precision Metal Components

Selecting optimal materials is critical for performance, longevity, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, thermal, and environmental demands. Below, we detail key considerations for Aluminum, Steel, and Titanium alloys, alongside essential finishing processes like anodizing.

Aluminum Alloys dominate aerospace, automotive, and consumer electronics due to their exceptional strength-to-weight ratio and thermal conductivity. Grade 6061 offers weldability and moderate strength for structural frames, while 7075 delivers superior tensile strength for high-stress components like drone arms or bicycle forks. Aluminum’s natural corrosion resistance is further enhanced through anodizing, which creates a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with color options, whereas Type III (hard anodizing) achieves extreme surface hardness for military or hydraulic applications.

Stainless Steel Alloys are indispensable for medical, marine, and chemical processing equipment requiring robust corrosion resistance and sterilizability. 316L excels in saline or acidic environments due to molybdenum content, making it ideal for surgical implants and marine hardware. 17-4 PH offers precipitation-hardening capabilities for high-yield-strength applications like valve bodies or aerospace fittings. Note that stainless steel’s passive layer provides inherent corrosion resistance, but electropolishing or passivation may be specified to maximize performance in critical environments.

Titanium Alloys, particularly Ti-6Al-4V (Grade 5), deliver unmatched strength-to-weight ratios and biocompatibility for aerospace, medical implants, and motorsport components. Its exceptional resistance to fatigue, creep, and corrosion in chlorine or seawater environments justifies higher material costs for mission-critical applications. Titanium does not anodize conventionally; instead, we apply color anodizing for identification or aesthetic purposes via voltage-controlled oxide growth, or employ grit blasting for functional matte finishes.

Material Performance Comparison

| Property | Aluminum 7075 | Stainless Steel 316L | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.81 | 8.00 | 4.43 |

| Tensile Strength (MPa) | 572 | 580 | 900 |

| Corrosion Resistance | Good (enhanced by anodizing) | Excellent | Exceptional |

| Typical Applications | Aircraft fittings, racing parts | Surgical tools, marine valves | Jet engine components, prosthetics |

Finishing Considerations

Anodizing remains the premier finish for aluminum, directly impacting wear life and aesthetics. We strictly control electrolyte concentration, voltage, and temperature to meet MIL-A-8625 or ISO 7599 standards. For steel, anodizing is not applicable; instead, we recommend passivation per ASTM A967 or electropolishing for enhanced corrosion resistance. Titanium color anodizing follows ASTM F86 for medical traceability.

Partner with Wuxi Lead to navigate material complexities. Our engineering team evaluates your load requirements, environmental exposure, and regulatory constraints to prescribe the optimal alloy and finish—ensuring your components exceed performance benchmarks while minimizing total cost of ownership. Consult our experts for application-specific validation data and prototyping support.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production journey begins with meticulous design engineering, where functionality, manufacturability, and material performance converge. Our engineering team collaborates directly with clients to analyze 3D CAD models, ensuring geometric accuracy, tolerance stack-ups, and compliance with industry standards such as ISO 2768 and ASME Y14.5. Finite Element Analysis (FEA) and Design for Manufacturing (DFM) protocols are applied to optimize part geometry for structural integrity and efficient machining. This phase is critical in preventing downstream defects and ensuring seamless transition into prototyping. All design data is stored in a secure PLM system, enabling version control and traceability from concept to final delivery.

Prototyping: Validating Performance Before Scale

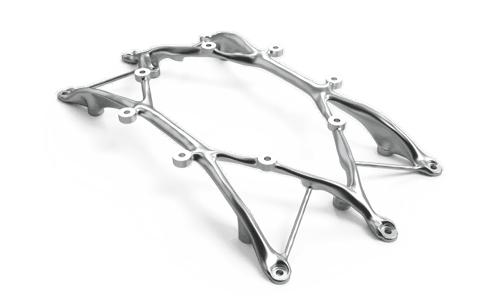

Prototyping serves as a functional checkpoint in our zero-defect strategy. Using advanced 5-axis CNC machining, metal 3D printing (SLM/DMLS), and precision sheet metal fabrication, we produce high-fidelity prototypes that mirror final production conditions. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface roughness analysis, and material property verification. Clients receive comprehensive inspection reports, first article inspection (FAI) documentation, and functional test results. Feedback loops are established to refine design or process parameters before mass production, minimizing risk and eliminating costly revisions at scale. This phase ensures that every component performs as intended under real-world conditions.

Mass Production: Consistency Through Automation and Control

Once design and prototype validation are complete, we transition to high-volume manufacturing with a focus on repeatability and zero-defect output. Our automated production lines integrate CNC machining centers, robotic welding cells, and automated optical inspection (AOI) systems to maintain precision across thousands of parts. Each production batch follows standardized work instructions, with real-time process monitoring through IoT-enabled machines. Statistical Process Control (SPC) is employed to detect deviations before they affect quality. Every component is traceable via laser marking and batch-level documentation, supporting full supply chain transparency. Our quality management system is ISO 9001:2015 certified, with additional compliance for aerospace (AS9100D) and medical (ISO 13485) applications when required.

Production Specifications

| Parameter | Specification |

|---|---|

| Materials | Aluminum (6061, 7075), Stainless Steel (304, 316, 17-4PH), Titanium (Grade 5), Inconel 718, Brass, Tool Steels |

| Tolerances | ±0.005 mm (precision machining), ±0.05 mm (standard) |

| Surface Finish | Ra 0.8 µm (machined), Ra 1.6–3.2 µm (as-machined), up to Ra 0.2 µm (polished) |

| Max Part Size | 1200 x 800 x 600 mm (CNC), 250 x 250 x 300 mm (SLM) |

| Lead Time (Prototype) | 5–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

| Quality Standards | ISO 9001:2015, AS9100D, ISO 13485, RoHS, REACH |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures every metal component meets the highest standards of quality, performance, and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components

In the demanding landscape of high-performance manufacturing, your choice of precision metal partner directly impacts product integrity, time-to-market, and operational reliability. Wuxi Lead Precision Machinery stands as your strategic ally, engineered to deliver uncompromising quality for complex, low-to-medium volume metal components. We specialize in transforming intricate designs into reality through advanced CNC machining, serving global leaders in aerospace, medical device, semiconductor, and industrial automation sectors. Our ISO 9001:2015 certified facility in Wuxi, China, operates under rigorous quality management systems, ensuring every part meets or exceeds the most stringent international standards. We understand that your success hinges on partners who combine technical mastery with responsive collaboration, not just transactional fulfillment.

Lead Precision excels where tolerances are tight, materials are challenging, and failure is not an option. Our integrated engineering team works proactively during the design phase to optimize manufacturability, reduce costs, and mitigate risk – turning potential production hurdles into seamless execution. We manage the entire process in-house: from raw material sourcing and heat treatment coordination to precision machining, stringent metrology, and final assembly support. This vertical integration guarantees consistent quality control and eliminates the communication gaps inherent in multi-vendor supply chains. Our commitment extends beyond delivery; we provide comprehensive documentation, including First Article Inspection reports and material certifications, ensuring full traceability and compliance for your most critical applications.

Our technical capabilities are built on a foundation of modern, well-maintained equipment and deep metallurgical expertise. The table below outlines key specifications demonstrating our capacity to handle your most demanding projects:

| Capability | Specification | Application Impact |

|---|---|---|

| Machine Types | 3/4/5-Axis CNC Milling & Turning | Complex geometries, reduced setups |

| Max Work Envelope | 1000 x 600 x 500 mm (Milling) | Large, integrated components |

| Tolerance Capability | ±0.005 mm (Critical Features) | Precision fit, function, and reliability |

| Material Expertise | Titanium, Inconel, Stainless Steels, Aluminum Alloys, Tool Steels | Performance in extreme environments |

| Surface Finishes | Ra 0.4 µm to Ra 1.6 µm achievable | Optimal functionality and aesthetics |

| Quality Systems | ISO 9001:2015, CMM, Optical Comparators | Guaranteed conformance, full traceability |

When your project demands more than just a vendor – when it requires a true engineering extension of your team – Lead Precision delivers the precision, partnership, and proven results you need. We are positioned to become your trusted resource for overcoming the toughest metal fabrication challenges, ensuring your products perform flawlessly in the field. The next step towards securing a reliable, high-precision manufacturing partner is immediate and straightforward. Contact our engineering team directly at [email protected]. Provide your design specifications or project requirements, and expect a detailed technical and commercial proposal within 24 business hours. Let us demonstrate how Lead Precision Machinery becomes the decisive advantage in your supply chain. Reach out today to initiate a conversation focused solely on your success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.