Technical Contents

Engineering Guide: 3D Printing Metal Titanium

Engineering Insight: 3D Printing Metal Titanium – The Role of Precision in High-Performance Manufacturing

In the realm of advanced metal additive manufacturing, 3D printing metal titanium stands at the forefront of innovation, enabling the production of lightweight, high-strength components for aerospace, medical, defense, and elite sports equipment. At Wuxi Lead Precision Machinery, we recognize that the true value of titanium 3D printing lies not only in material selection but in the uncompromising precision required to harness its full potential. Titanium, particularly Grade 5 (Ti-6Al-4V), offers an exceptional strength-to-density ratio and outstanding corrosion resistance, making it ideal for mission-critical applications. However, its reactive nature and high processing demands necessitate a level of control that only advanced engineering and rigorous quality standards can deliver.

Precision in titanium 3D printing begins with process stability. Selective Laser Melting (SLM) requires tightly controlled atmospheres, laser calibration, and thermal management to avoid defects such as porosity, residual stress, or incomplete fusion. At Lead Precision, we operate under ISO 9001 and AS9100-certified protocols, ensuring every build meets exact dimensional tolerances and mechanical property requirements. Our in-house metrology lab, equipped with coordinate measuring machines (CMM) and metallographic analysis tools, validates part integrity at microstructural levels. This commitment to accuracy has enabled us to supply components for Olympic-level athletic equipment, where performance margins are measured in milliseconds, and for military-grade systems, where reliability under extreme conditions is non-negotiable.

Our engineering team brings over 15 years of experience in custom metal manufacturing, with a specialized focus on titanium and other reactive alloys. We have refined parameter sets for Ti-6Al-4V that optimize grain structure and mechanical performance, achieving properties that meet or exceed ASTM F2924 standards. Each build undergoes real-time monitoring via layer-by-layer imaging and melt pool analysis, ensuring traceability and repeatability across production runs.

Below are key specifications for our titanium 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Material | Ti-6Al-4V (Grade 5), ASTM F2924 compliant |

| Build Envelope | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Typical Tolerance | ±0.05 mm for features under 100 mm |

| Surface Roughness (as-built) | Ra 12–16 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing |

| Density Achieved | >99.95% |

| Tensile Strength | ≥950 MPa |

| Yield Strength | ≥880 MPa |

| Elongation at Break | ≥10% |

At Wuxi Lead Precision Machinery, we do not merely manufacture titanium parts—we engineer performance. Our integration of precision engineering, material science, and quality assurance ensures that every component we produce meets the highest standards of reliability and functionality. Whether supporting elite athletic achievement or national defense systems, our titanium 3D printing solutions are built to perform under pressure.

Precision Specs & Tolerances

Advanced Titanium Additive Manufacturing Capabilities

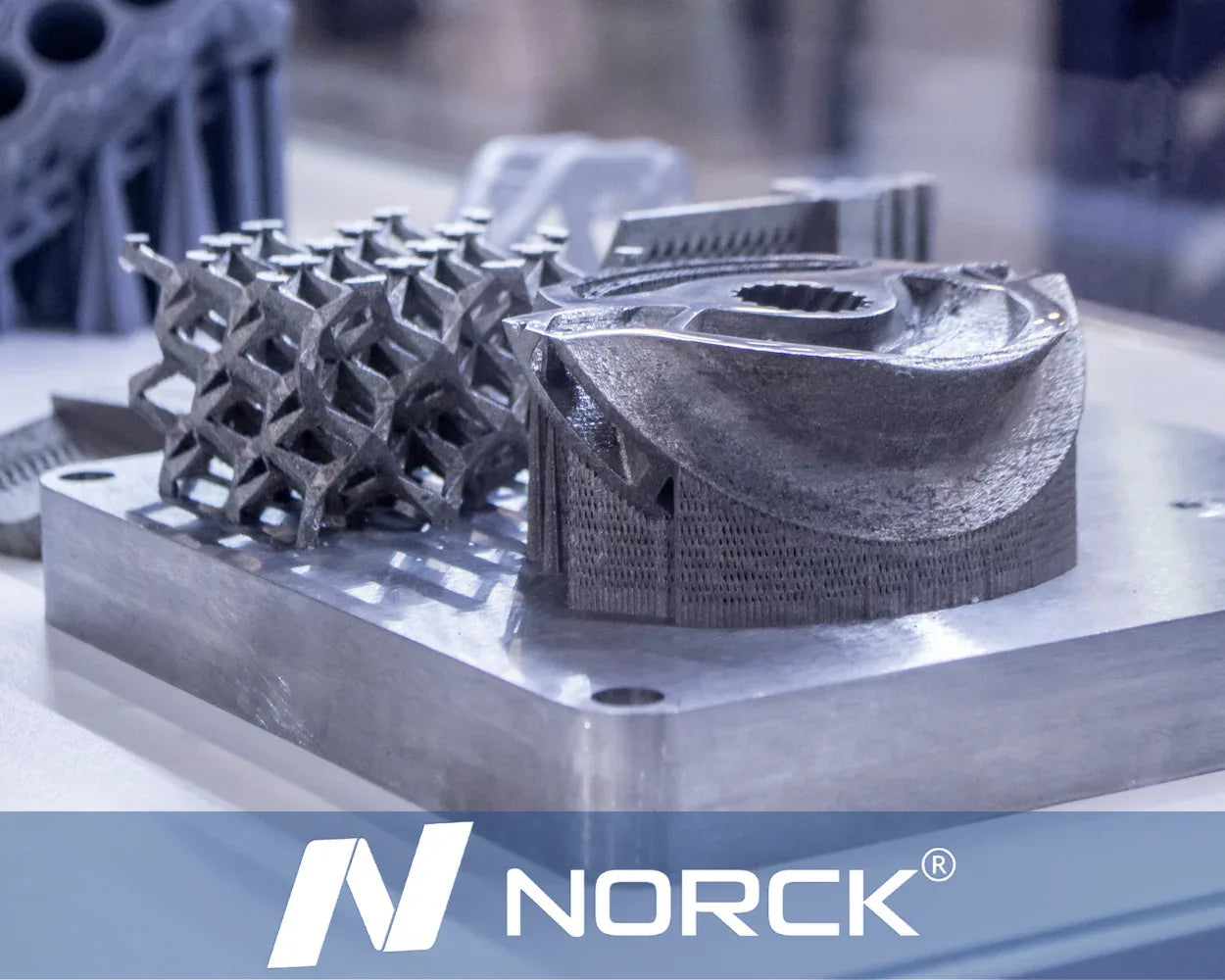

Wuxi Lead Precision Machinery delivers mission-critical titanium components through integrated metal additive manufacturing and precision machining. Our industrial-grade Electron Beam Melting (EBM) and Direct Metal Laser Sintering (DMLS) systems process ASTM F136 and F1586 medical-grade titanium, alongside aerospace-standard Ti-6Al-4V ELI. These platforms build complex geometries impossible with traditional methods—including lattice structures, internal cooling channels, and organic topologies—while maintaining full material density and biocompatibility. Rigorous inert gas control and real-time melt pool monitoring ensure microstructural integrity, eliminating porosity and mitigating thermally induced distortion inherent in titanium processing.

Critical geometries require precision finishing beyond as-printed capabilities. Our integrated 5-axis CNC machining centers (DMG MORI CTX beta 1250 and Hermle C400U) perform secondary operations immediately after build completion. This seamless transition from AM to subtractive processing minimizes handling-induced errors and maintains thermal stability. Simultaneous 5-axis contouring achieves tight tolerances on angled surfaces, undercuts, and thin-walled features while preserving the fatigue-resistant surface layer critical for aerospace and medical implants. All toolpaths undergo virtual simulation to prevent collisions and optimize chip evacuation in titanium’s challenging galling conditions.

Quality assurance begins at powder reception and extends through final inspection. Every build undergoes in-process layer verification via optical tomography. Post-machining, components are validated on Zeiss CONTURA G2 coordinate measuring machines (CMM) with 0.000039″ (1μm) volumetric accuracy. Our ISO 17025-accredited lab performs full GD&T analysis, surface roughness mapping (per ASME B46.1), and metallurgical cross-sectioning. Traceability is enforced via laser-etched part IDs linked to digital build logs, powder lot certifications, and thermal history reports—meeting AS9100 and ISO 13485 requirements for regulated industries.

Titanium Component Tolerance Specifications

| Parameter | As-Printed (EBM/DMLS) | Post 5-Axis CNC Machining |

|---|---|---|

| Linear Dimension Tolerance | ±0.100 mm | ±0.025 mm |

| Geometric Tolerance (GD&T) | ±0.150 mm | ±0.012 mm |

| Surface Roughness (Ra) | 12.5 μm | 0.8 μm |

| Minimum Feature Size | 0.5 mm | 0.1 mm |

| Hole Diameter Tolerance | ±0.120 mm | ±0.015 mm |

This closed-loop manufacturing ecosystem—from reactive powder management to sub-micron metrology—enables Wuxi Lead to produce titanium components that exceed aerospace MRO, orthopedic implant, and high-performance automotive specifications. We transform design complexity into competitive advantage through uncompromised precision in the most demanding applications.

Material & Finish Options

Material Selection Guide for High-Performance 3D Printed Metal Components

In precision-driven industries such as aerospace, medical devices, and high-end automotive, selecting the right metal for 3D printing is critical to achieving optimal performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive technologies, enabling complex geometries and high-strength components. Our expertise spans aluminum, steel, and titanium—each offering distinct advantages depending on application requirements.

Aluminum alloys, particularly AlSi10Mg, are widely used in 3D printing for their lightweight properties and excellent thermal conductivity. This makes them ideal for components where weight reduction is essential without sacrificing structural integrity. Aluminum-printed parts are commonly found in drone frames, heat exchangers, and automotive cooling systems. While not as strong as steel or titanium, aluminum offers a favorable strength-to-weight ratio and good machinability post-print.

Steel, especially stainless steel 316L and tool steel (such as H13), delivers superior hardness, wear resistance, and high-temperature performance. These characteristics make steel a preferred choice for industrial tooling, molds, and components exposed to harsh environments. 3D printed steel parts exhibit dense microstructures and excellent mechanical properties, often comparable to traditionally forged equivalents. When durability and resistance to corrosion or abrasion are paramount, steel remains a top-tier selection.

Titanium, specifically Grade 5 (Ti-6Al-4V), stands at the pinnacle of high-performance 3D printed metals. Renowned for its exceptional strength-to-density ratio, biocompatibility, and resistance to extreme environments, titanium is the material of choice for aerospace structural components, medical implants, and high-stress racing parts. Its ability to maintain strength at elevated temperatures and resist corrosion in saline or acidic conditions further enhances its value in mission-critical applications.

For enhanced surface performance and aesthetics, post-processing finishes such as anodizing are available—particularly effective on aluminum. Anodizing increases surface hardness, improves corrosion resistance, and allows for color coding, which is beneficial in assembly and identification processes. While titanium can also be anodized for decorative or functional oxide layer control, steel typically requires alternative surface treatments such as passivation or coating.

Below is a comparative overview of key mechanical properties for commonly 3D printed metals:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–280 | 2.67 | 8–12 | Heat exchangers, lightweight frames |

| 316L Stainless Steel | 550–600 | 250–300 | 8.00 | 35–45 | Marine components, chemical tools |

| Ti-6Al-4V | 900–950 | 800–850 | 4.43 | 8–12 | Aerospace, medical implants |

Understanding the interplay between material properties and application demands ensures optimal design and manufacturing outcomes. At Wuxi Lead Precision Machinery, we support clients in selecting the ideal material and finish to meet technical specifications, regulatory standards, and production timelines.

Manufacturing Process & QC

Titanium Additive Manufacturing: Precision Engineering from Concept to Zero-Defect Production

Titanium additive manufacturing demands rigorous process control from initial design through final inspection to achieve mission-critical component integrity. At Wuxi Lead Precision Machinery, our integrated workflow ensures dimensional accuracy, material properties, and structural reliability meet the exacting standards of aerospace, medical, and high-performance industrial applications. We eliminate costly iterations and scrap through systematic validation at every stage.

Design optimization is foundational. Our engineering team collaborates closely with clients to apply Design for Additive Manufacturing (DfAM) principles specific to titanium alloys like Ti-6Al-4V (Grade 5). This phase focuses on topology optimization, strategic support structure placement to minimize thermal stress and distortion, and thermal simulation to predict melt pool behavior. Critical factors include managing anisotropic properties and ensuring adequate wall thickness for structural stability during build. Design validation includes finite element analysis (FEA) for stress distribution and thermal history simulation, preventing in-process failures before machine time is committed.

Prototyping transitions validated designs into physical form under controlled conditions. We utilize identical process parameters and machine platforms planned for series production, ensuring scalability. Each prototype undergoes comprehensive metrology: coordinate measuring machine (CMM) verification against CAD models, microstructure analysis via optical microscopy, and mechanical testing per ASTM F2924 standards. This stage confirms dimensional repeatability, surface roughness suitability for post-processing, and baseline mechanical properties. Key process parameters are finalized based on empirical data from this phase.

Mass production executes with uncompromising zero-defect protocols. Our industrial-grade laser powder bed fusion systems operate within strictly controlled inert atmospheres (argon purity >99.995%) to prevent oxygen contamination. Real-time melt pool monitoring and layer-wise thermal imaging detect anomalies during build, triggering automatic corrective actions. Post-processing follows stringent sequences: stress relief annealing, precision support removal via 5-axis CNC machining, surface treatment (e.g., micro-machining or polishing), and final non-destructive testing (NDT) including X-ray computed tomography (CT) scanning for internal porosity. Every component receives full traceability documentation, including build logs, thermal history, and final inspection reports against ISO/ASTM 52900 requirements.

Critical Titanium AM Process Parameters

| Parameter | Typical Range (Ti-6Al-4V) | Control Tolerance | Verification Method |

|---|---|---|---|

| Layer Thickness | 30 – 60 µm | ±2 µm | In-situ layer camera |

| Laser Power | 250 – 400 W | ±5 W | Power meter calibration |

| Scan Speed | 800 – 1400 mm/s | ±20 mm/s | Encoder feedback |

| Hatch Spacing | 80 – 120 µm | ±5 µm | Pre-build simulation |

| Build Chamber Oxygen | < 250 ppm | Continuous monitor | Inline gas analyzer |

| Build Speed (Z-axis) | 5 – 15 mm/hr | ±0.5 mm/hr | Machine controller logs |

This closed-loop methodology, combining advanced hardware, material science expertise, and stringent quality gates, delivers fully qualified titanium components with certified mechanical properties and zero critical defects. Partner with Wuxi Lead for production-ready additive solutions where failure is not an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printing in Metal Titanium

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions tailored to the most demanding industrial applications. Our expertise in metal additive manufacturing, particularly in 3D printing with titanium, positions us as a strategic partner for aerospace, medical, automotive, and high-performance engineering sectors. When you choose to collaborate with Lead Precision, you gain access to cutting-edge technology, rigorous quality control, and a team of engineers dedicated to turning complex designs into functional, production-grade components.

Titanium 3D printing requires more than just advanced machinery—it demands deep material science understanding, process optimization, and consistent repeatability. Our facility in Wuxi, China, is equipped with state-of-the-art laser powder bed fusion (LPBF) systems, operating under controlled environments to ensure dimensional accuracy and superior mechanical properties. We utilize certified Ti6Al4V (Grade 5) and commercially pure titanium (Grade 2), both known for exceptional strength-to-density ratios, corrosion resistance, and biocompatibility.

Our end-to-end workflow begins with design evaluation and process simulation, continues through precision printing and post-processing (including stress relief, HIP, and surface finishing), and concludes with full metrology and material certification. Every part is traceable, compliant with ISO 9001 standards, and tested to meet your exact performance criteria.

We understand that in high-end manufacturing, timelines and reliability are as critical as precision. That’s why our production planning integrates rapid prototyping with scalable batch manufacturing, enabling fast turnaround without compromising quality. Whether you require a single prototype or a recurring production run, Lead Precision ensures consistency across every build.

Below are key technical specifications for our titanium 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Material | Ti6Al4V (Grade 5), CP Ti (Grade 2) |

| Build Volume | Up to 250 × 250 × 300 mm |

| Layer Thickness | 20–50 µm |

| Typical Density | > 99.95% |

| Tensile Strength (Ti6Al4V) | ≥ 900 MPa |

| Elongation at Break | ≥ 10% |

| Surface Roughness (as-built) | Ra 12–18 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing |

| Quality Standards | ISO 9001, Full material traceability, NDT |

| Lead Time (Prototype) | 7–10 working days (after design approval) |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that values innovation, precision, and long-term collaboration. We don’t just produce parts—we engineer solutions.

For project inquiries, technical consultations, or to submit a design for review, contact us today at [email protected]. Let us help you harness the full potential of titanium additive manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.