Technical Contents

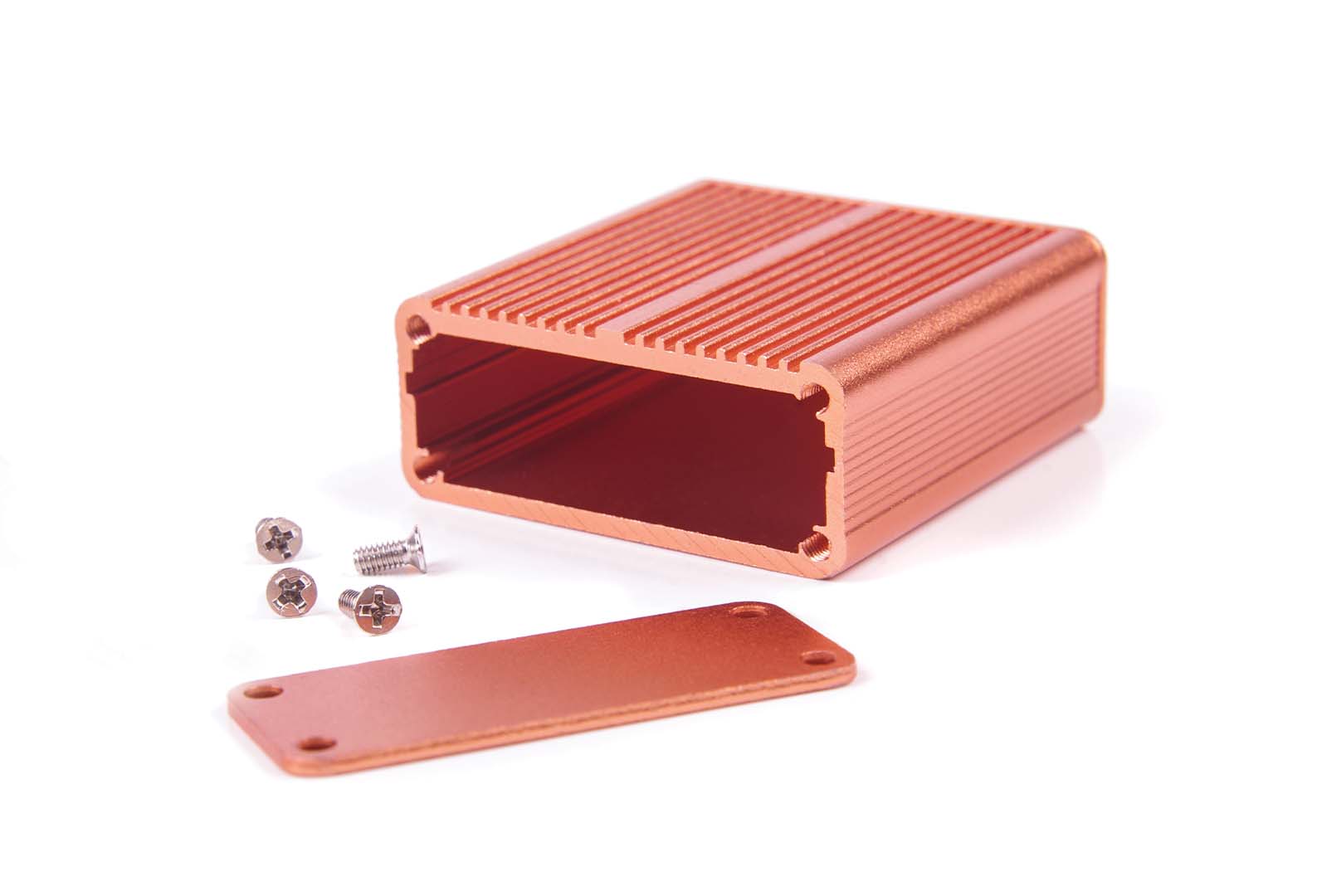

Engineering Guide: 3D Printing Electronics Enclosure

Engineering Insight Precision in 3D Printed Electronics Enclosures

Achieving functional integrity in 3D printed electronics enclosures demands uncompromising precision engineering. While additive manufacturing offers design freedom, the critical performance factors—thermal management, electromagnetic interference (EMI) shielding, and environmental sealing—are fundamentally governed by dimensional accuracy and surface quality. Minor deviations in wall thickness, mating surface flatness, or vent geometry directly compromise thermal dissipation pathways and EMI containment. A tolerance stack-up of mere tenths of a millimeter can prevent effective gasket compression, leading to ingress protection failure or signal leakage in sensitive applications. At Wuxi Lead Precision Machinery, we treat these enclosures not as prototypes, but as mission-critical components where precision is non-negotiable.

Our engineering approach integrates metrology-grade process control from the initial CAD model through post-processing. We prioritize controlled cooling rates and adaptive slicing strategies to minimize warpage and internal stress, ensuring geometric stability essential for consistent shielding effectiveness. Surface finishing protocols are tailored to achieve the required Ra values for optimal gasket adhesion and EMI gasket contact, directly impacting the enclosure’s ability to maintain a hermetic seal against dust, moisture, and electromagnetic noise. This level of control is not standard in generic 3D printing services; it requires deep materials science understanding and rigorous in-process verification.

The consequences of inadequate precision are severe in high-stakes environments. Consider thermal runaway in power electronics: a 0.1mm variance in internal fin spacing can elevate operating temperatures beyond safe limits, accelerating component degradation. Similarly, inconsistent wall density creates EMI leakage paths, jeopardizing signal integrity in communication systems. Our experience delivering enclosures for Olympic broadcast infrastructure and specialized military communication platforms underscores this reality. These applications demanded repeatability under extreme environmental stress—vibration, rapid temperature cycling, and exposure to corrosive elements—where failure was never an option. We engineered solutions meeting MIL-STD-810G vibration profiles and IP67 sealing requirements, validated through third-party environmental testing.

Precision manufacturing is our core competency, proven across sectors where reliability is paramount. Below are the critical specifications we consistently achieve for high-performance metal 3D printed enclosures:

| Critical Specification | Standard Capability | Mission-Critical Capability |

|---|---|---|

| Dimensional Tolerance (per feature) | ±0.05 mm | ±0.02 mm |

| Surface Roughness (Ra) | 6.3 µm | 1.6 µm (post-processed) |

| Material Density | >99.5% | >99.95% (void-free) |

These figures represent the baseline for functional enclosures. For applications like aerospace avionics or medical diagnostic equipment, we implement enhanced process windows and 100% geometric inspection to exceed standard benchmarks. The true value lies not just in hitting tolerances, but in the predictable, auditable process that guarantees every enclosure performs identically under operational load. Partner with Wuxi Lead Precision Machinery to transform your enclosure design from a printed part into a certified, reliable system component. Precision isn’t a feature we add—it’s the foundation we build upon.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance applications, including precision 3D printing electronics enclosures. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex, mission-critical components with exceptional accuracy and repeatability. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring and feature integration. This is particularly vital when manufacturing enclosures for 3D printing electronics, where internal cavities, mounting interfaces, shielding geometries, and thermal management features must align with exacting standards.

Our machining process supports a wide range of aerospace-grade aluminum alloys, stainless steels, titanium, and other conductive or EMI-shielded materials, ensuring compatibility with both mechanical and electrical performance requirements. The 5-axis platform minimizes setup changes, reduces human intervention, and maintains tight geometric consistency across high-precision features such as threaded inserts, grounding points, sensor cutouts, and flanged mounting surfaces. This capability ensures that every enclosure not only meets dimensional specifications but also supports optimal electronic function and environmental protection.

Quality assurance is integral to our production workflow. Every component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), which verifies critical dimensions, positional tolerances, flatness, and profile accuracy against CAD models. Our CMM system operates with sub-micron resolution, enabling traceable, repeatable validation for batch production and prototype runs alike. Data from inspections is documented and provided with each shipment, ensuring full compliance with ISO 9001 standards and customer-specific quality requirements.

We specialize in low-to-medium volume production runs where precision, material integrity, and design complexity are paramount. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce assembly steps, and enhance thermal and electromagnetic performance—all while maintaining manufacturability and cost efficiency.

The following table outlines our standard machining tolerances and inspection capabilities:

| Feature | Typical Tolerance | Inspection Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM, High-Precision Micrometers |

| Positional Tolerance | ±0.01 mm | CMM |

| Flatness | 0.01 mm per 100 mm | CMM, Surface Plate with Dial Indicator |

| Surface Finish | Ra 0.8 µm (standard), down to Ra 0.2 µm | Surface Roughness Tester |

| Angular Accuracy | ±0.05° | CMM, Optical Comparator |

| Hole Diameter (Drilled/Bored) | +0.01 mm / -0.00 mm | Air Gauges, CMM |

| Repeatability (Batch) | Cp ≥ 1.67, Cpk ≥ 1.33 | SPC-Controlled CMM Sampling |

With integrated 5-axis CNC machining and rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures that every 3D printing electronics enclosure meets the highest standards of precision, reliability, and performance in demanding industrial environments.

Material & Finish Options

Material Selection for Precision 3D Printed Electronics Enclosures

Selecting the optimal material for 3D printed electronics enclosures is critical for performance reliability and longevity. While additive manufacturing enables complex geometries rapid prototyping it rarely delivers the final surface integrity dimensional accuracy or environmental resilience required for demanding electronic applications. Wuxi Lead Precision Machinery specializes in transforming 3D printed metal substrates through precision CNC machining and advanced finishing to meet stringent industrial specifications. The core material choice fundamentally dictates the enclosure’s thermal management EMI shielding structural integrity and environmental resistance. Aluminum stainless steel and titanium represent the primary high-performance alloys used in critical electronics housing applications each offering distinct advantages for specific operational demands.

Aluminum alloys particularly 6061-T6 dominate aerospace and telecommunications enclosures due to their exceptional strength-to-weight ratio excellent thermal conductivity and inherent corrosion resistance. This makes them ideal for heat-sensitive components requiring efficient thermal dissipation. Stainless steel 316L is the preferred solution for marine chemical processing or medical environments demanding superior corrosion resistance against chlorides acids and sterilization processes. Its higher density provides enhanced EMI shielding but requires careful thermal design. Titanium Grade 5 offers the ultimate strength-to-weight ratio and unparalleled corrosion resistance even in highly aggressive environments like offshore oil and gas or deep-sea applications. Its biocompatibility also suits high-end medical devices though it presents greater machining challenges and cost. The table below summarizes key comparative properties.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good | Aerospace Telecom Industrial Control |

| Stainless Steel 316L | 8.0 | 570 | Excellent | Marine Medical Chemical Processing |

| Titanium Grade 5 | 4.4 | 900 | Exceptional | Offshore Defense High-End Medical |

Surface finish is equally vital for functionality and durability. Anodizing is the industry-standard post-processing treatment for aluminum enclosures providing a hard wear-resistant oxide layer that significantly enhances corrosion protection. Type II (Sulfuric Acid) anodizing offers good general-purpose protection and dyeing capability for branding. For electronics enclosures demanding maximum durability chemical resistance and superior electrical insulation Type III (Hardcoat) anodizing is essential. It creates a much thicker denser oxide layer capable of withstanding harsh industrial environments and repeated handling without compromising the critical electrical isolation properties needed around sensitive circuitry. Wuxi Lead applies precise anodizing protocols with strict thickness and sealing control ensuring consistent performance and adherence to MIL-A-8625 standards.

Choosing the right base material combined with the appropriate anodized finish mitigates risks of thermal failure EMI interference or environmental degradation. At Wuxi Lead we integrate material science expertise with precision CNC post-processing and certified finishing to transform additive manufactured parts into mission-critical electronics enclosures. Consult our engineering team early in your design phase to optimize material selection and finishing strategy for your specific performance requirements and regulatory environment ensuring your enclosure delivers uncompromised protection and reliability.

Manufacturing Process & QC

The production process for custom 3D printed electronics enclosures at Wuxi Lead Precision Machinery follows a rigorous, phase-gated methodology designed to ensure zero defects and full compliance with high-end industrial standards. Our integrated workflow spans from initial design to prototyping and full-scale mass production, with precision engineering and quality control embedded at every stage.

Design begins with a collaborative engineering review, where our technical team works directly with client specifications to optimize enclosure geometry, material selection, thermal management, and electromagnetic shielding requirements. Using advanced CAD and simulation tools, we perform structural and thermal analysis to validate performance under real-world operating conditions. Design for manufacturability (DFM) principles are applied early to eliminate potential production risks, ensuring seamless transition to the next phase.

Prototyping is executed using high-precision metal 3D printing technologies, primarily selective laser melting (SLM), allowing for complex internal geometries and integrated features not possible with traditional machining. Each prototype is subjected to full dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy within ±0.02 mm. Functional testing, including fit checks, thermal cycling, and EMI performance, is conducted to validate design integrity. Feedback from this stage is incorporated into final design adjustments, ensuring the enclosure meets both mechanical and electrical requirements before entering mass production.

Mass production leverages our automated SLM production cells, each equipped with in-situ monitoring systems that track laser power, melt pool stability, and layer consistency in real time. All builds occur in controlled argon environments to ensure material purity and mechanical consistency. Post-processing follows a standardized sequence: stress relief annealing, support removal via CNC milling, precision surface finishing (including micro-arc polishing for EMI-sensitive applications), and final cleaning in ultrasonic baths. Every unit undergoes 100% visual inspection and automated optical inspection (AOI) to detect surface anomalies. Batch traceability is maintained through laser-etched serial codes linked to digital production records.

Our zero-defect philosophy is enforced through ISO 13485 and IATF 16949-certified quality systems. Statistical process control (SPC) is applied across all critical parameters, with real-time data analytics enabling predictive corrections before deviations occur. First-article inspections (FAI) and production part approval processes (PPAP) are standard for new runs, ensuring consistency and compliance.

The following table outlines key production specifications for our 3D printed electronics enclosures:

| Parameter | Specification |

|---|---|

| Material Options | Aluminum AlSi10Mg, Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V |

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.02 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Surface Roughness (polished) | Ra 0.4–0.8 μm |

| Build Envelope | Up to 250 × 250 × 300 mm |

| Post-Processing | Stress relieving, CNC trimming, polishing, passivation |

| Quality Standards | ISO 9001, ISO 13485, IATF 16949 |

| Inspection Methods | CMM, 3D scanning, AOI, dye penetrant, X-ray |

From concept to delivery, Wuxi Lead ensures every 3D printed electronics enclosure meets the highest benchmarks in precision, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Electronics Enclosure Production with Integrated Precision

When developing high-performance electronics enclosures, 3D printing offers valuable prototyping and complex geometry capabilities. However, transitioning to volume production demands superior dimensional stability, thermal management, EMI shielding, and surface integrity that additive processes alone cannot consistently deliver. This critical gap is where Wuxi Lead Precision Machinery provides indispensable value. We specialize in seamlessly integrating precision CNC-machined metal components with your 3D printed assemblies, transforming prototypes into robust, market-ready solutions. Our engineering partnership ensures your enclosures meet rigorous industrial, medical, and aerospace standards where reliability is non-negotiable.

The inherent limitations of polymer-based 3D printing—such as thermal deformation under load, susceptibility to EMI interference, and inconsistent mechanical properties—become significant liabilities in demanding applications. Lead Precision bridges this performance chasm through advanced CNC milling, turning, and finishing of aerospace-grade aluminum alloys, stainless steels, and specialty metals. We manufacture critical sub-assemblies like mounting brackets, heatsinks, shielding cans, and precision-fit chassis interfaces that integrate flawlessly with your printed structures. This hybrid approach leverages the design freedom of additive manufacturing while embedding the thermal conductivity, structural rigidity, and electromagnetic compatibility only precision metal fabrication provides.

Our facility operates under strict ISO 9001:2015 and IATF 16949 quality management systems, guaranteeing repeatability from prototype to high-volume production. We manage the entire process under one roof: material sourcing, 5-axis CNC machining, anodizing or plating, precision sheet metal fabrication, and final assembly validation. This vertical integration eliminates supply chain vulnerabilities and accelerates time-to-market. Below are key specifications where our capabilities directly enhance 3D printed enclosure performance:

| Specification Category | 3D Printed Polymer Limitation | Lead Precision CNC Metal Solution |

|---|---|---|

| Dimensional Tolerance | ±0.2mm to ±0.5mm typical | ±0.005mm to ±0.01mm achievable |

| Thermal Conductivity | Low (0.1-0.5 W/m·K) | High (Aluminum: 160-220 W/m·K) |

| EMI Shielding Effectiveness | Minimal to none | 80-100 dB with proper design |

| Surface Finish (Ra) | 10-50 µm (as-printed) | 0.4-1.6 µm (machined), 0.1-0.8 µm (polished) |

| Material Options | Limited engineering polymers | Aluminum 6061-T6, 7075-T6, 304/316 Stainless Steel, Copper Alloys |

Partnering with Lead Precision means accessing China-based manufacturing excellence without compromising on Western engineering standards. Our technical team collaborates from the earliest design phase, providing DFM feedback to optimize both printed and machined elements for cost, performance, and assembly efficiency. We understand that electronics enclosures are functional components, not just housings—every thread, slot, and surface finish impacts system longevity and compliance.

Do not let enclosure limitations constrain your innovation or compromise field reliability. Contact our engineering team today to discuss how integrated metal solutions elevate your 3D printed electronics platforms. Submit your RFQ with technical drawings to [email protected] for a detailed capability assessment and precision manufacturing quotation within 24 business hours. Let Lead Precision be the foundation of your enclosure’s performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.