Technical Contents

Engineering Guide: 3D Printing Design Service

Engineering Insight Precision in Metal Additive Manufacturing Design

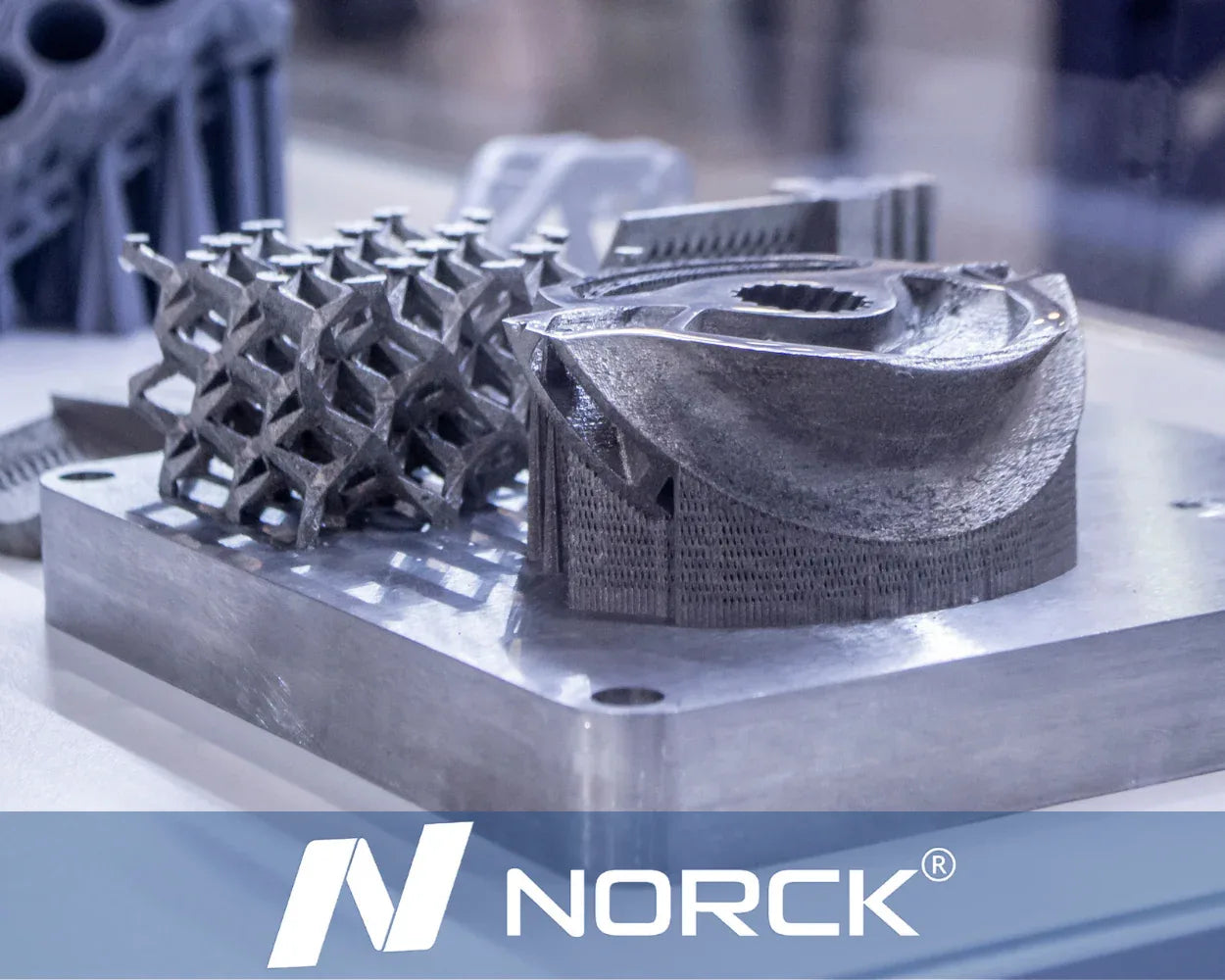

Achieving functional integrity in metal 3D printed components demands far more than translating a CAD model into a printable file. Precision is the non-negotiable foundation, governing every phase from initial design through post-processing. In high-stakes applications like aerospace, medical implants, or advanced tooling, microscopic deviations in geometry, surface finish, or internal material structure can cascade into catastrophic part failure. The inherent complexities of metal additive processes—thermal distortion during layer fusion, residual stress accumulation, support structure interaction, and powder removal challenges—require proactive design strategies. Ignoring these factors results in parts that fail dimensional inspection, exhibit compromised mechanical properties, or necessitate costly, time-consuming rework. True precision begins at the design stage, where anticipating and mitigating process-induced variables is paramount.

Wuxi Lead Precision Machinery leverages over 15 years of specialized expertise in mission-critical metal additive manufacturing to solve these complex precision challenges. Our engineering team possesses deep, practical knowledge of how design choices directly impact manufacturability and final part performance. This expertise is rigorously validated through demanding projects, including the production of zero-defect ceremonial components for the Olympic Games and precision-critical subsystems for advanced military platforms. These applications demanded absolute adherence to micron-level tolerances, flawless surface integrity, and uncompromised material properties under extreme operational conditions. We understand that precision isn’t merely a specification sheet metric; it is the culmination of integrated design-for-additive thinking, meticulous process control, and rigorous quality validation protocols developed through real-world, high-consequence manufacturing.

The capability to deliver this level of precision is anchored in our advanced production infrastructure. Below are the core specifications of our primary metal additive systems, engineered to meet the most stringent industrial requirements.

| Parameter | Specification | Significance for Precision |

|---|---|---|

| Build Volume | 250 x 250 x 325 mm | Enables large, complex single-piece builds reducing assembly errors |

| Layer Thickness | 20 – 60 µm adjustable | Direct control over surface finish and feature resolution |

| Positioning Accuracy | ± 25 µm over build volume | Ensures dimensional fidelity of intricate geometries |

| Laser Spot Size | 70 µm | Critical for fine feature definition and edge sharpness |

| Material Systems | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel | Consistent material properties validated for critical applications |

| Inert Atmosphere | < 100 ppm Oxygen | Prevents oxidation, ensuring material purity and mechanical integrity |

| Real-time Monitoring | Melt Pool Analysis, Thermal Imaging | Enables immediate process correction for defect prevention |

Partnering with Wuxi Lead means engaging engineers who translate precision from an abstract goal into a guaranteed outcome. We apply our hard-won experience from Olympic and defense projects to every client challenge, ensuring your 3D printed metal components meet not only your specifications but the uncompromising demands of real-world performance. Precision is not optional; it is the standard we engineer to from the first design iteration. Let our expertise secure the integrity of your most demanding metal additive projects.

Precision Specs & Tolerances

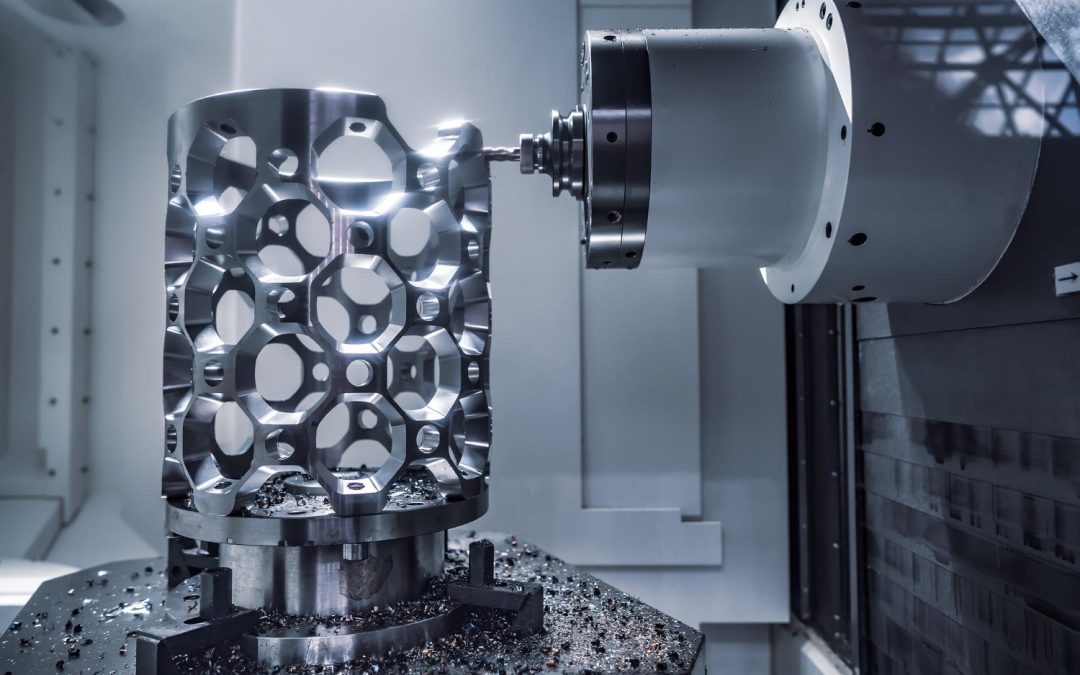

Wuxi Lead Precision Machinery delivers advanced 3D printing design services integrated with high-precision metal manufacturing capabilities, enabling complex, mission-critical components for aerospace, medical, automotive, and industrial applications. Our technical expertise bridges innovative additive design with subtractive precision, ensuring that every part meets stringent performance and compliance standards. Central to our capabilities is the seamless integration of 5-axis CNC machining, which allows for the precise finishing of 3D printed metal components, achieving geometries and surface finishes unattainable through additive processes alone.

Our 5-axis CNC machining centers provide simultaneous multi-directional tool movement, enabling the production of highly intricate features with minimal fixturing. This capability is essential for post-processing 3D printed parts, where internal channels, undercuts, and organic forms require accurate material removal and edge definition. With a focus on metals such as titanium, Inconel, stainless steel, and aluminum alloys, our machining systems ensure dimensional stability and repeatability across both prototyping and high-volume production runs.

Quality assurance is embedded at every stage of manufacturing. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM systems provide micron-level accuracy in verifying form, position, and surface integrity, supporting AS9100 and ISO 13485 quality standards. This metrology-backed validation is critical for clients requiring full traceability and first-article inspection reports.

The synergy between our 3D printing design services and precision CNC finishing allows Wuxi Lead to deliver components that meet the most demanding engineering specifications. From initial design optimization for additive manufacturing (DfAM) to final inspection, we maintain tight control over tolerances and material properties. Our engineering team collaborates directly with clients to refine part geometry, reduce weight, improve thermal or fluid dynamics, and enhance structural performance — all while ensuring manufacturability and cost efficiency.

Below is a summary of our standard achievable tolerances across key manufacturing processes:

| Feature | 5-Axis CNC Machining | Metal 3D Printing (as-built) | 3D Printing + CNC Post-Processing |

|---|---|---|---|

| Linear Tolerance | ±0.005 mm | ±0.1 mm | ±0.01 mm |

| Geometric Tolerance (GD&T) | ±0.01 mm (typical) | ±0.2 mm | ±0.02 mm |

| Surface Roughness (Ra) | 0.8 – 1.6 µm | 10 – 15 µm | 0.8 – 3.2 µm |

| Minimum Wall Thickness | 0.5 mm | 0.4 mm | 0.5 mm |

| Max Build Volume (CNC) | 1200 × 800 × 600 mm | 250 × 250 × 300 mm | 250 × 250 × 300 mm |

By combining advanced 3D printing design with 5-axis CNC capabilities and rigorous CMM inspection, Wuxi Lead Precision Machinery ensures that every component exceeds functional and regulatory expectations. Our technical infrastructure supports rapid iteration, full documentation, and scalable production — making us a trusted partner in high-end metal manufacturing.

Material & Finish Options

Strategic Material Selection for High-Performance Metal Additive Manufacturing

Material choice is the cornerstone of successful metal additive manufacturing, directly influencing part performance, durability, and cost-effectiveness. At Wuxi Lead Precision Machinery, we guide clients through the critical evaluation of Aluminum, Steel, and Titanium alloys based on rigorous application demands. Selecting the optimal material requires balancing mechanical properties, environmental resistance, weight constraints, and post-processing requirements. Our certified production lines ensure each alloy is processed to meet stringent aerospace, medical, and industrial standards, maximizing the inherent benefits of metal 3D printing for complex geometries.

Aluminum alloys, particularly aerospace-grade 7075 and 6061, offer an exceptional strength-to-weight ratio and excellent thermal conductivity. These materials are ideal for lightweight structural components in aerospace and automotive applications where weight reduction is paramount. Aluminum demonstrates good machinability post-print and responds effectively to surface treatments. Its lower density significantly reduces part mass compared to steel or titanium, though ultimate strength and high-temperature performance are correspondingly lower. Aluminum parts often require thermal stress relief and precision machining to achieve final tolerances.

High-strength steels, including 17-4 PH stainless and Maraging Steel 300, deliver superior hardness, wear resistance, and structural integrity. These alloys are the preferred choice for tooling, high-stress mechanical components, and applications demanding exceptional fatigue strength or corrosion resistance in harsh environments. Steel provides the highest density among common AM metals, contributing to part mass but enabling robust performance under extreme loads. Achieving optimal mechanical properties typically necessitates specific heat treatments like aging or solution annealing after printing.

Titanium alloys, predominantly Ti-6Al-4V (Grade 5), provide an unparalleled combination of high strength, low density, and outstanding biocompatibility and corrosion resistance. This makes titanium indispensable for critical aerospace components, medical implants, and marine applications exposed to aggressive chemicals or saltwater. While titanium offers the best strength-to-weight ratio of the three, its processing requires stringent inert atmosphere control during printing and often extensive post-build stress relief. The material’s biocompatibility is a key driver for certified medical device manufacturing.

The following table summarizes critical properties for common additively manufactured alloys:

| Material | Typical Alloy | Yield Strength (MPa) | Density (g/cm³) | Key Advantages | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg, 7075 | 200 – 500 | 2.68 – 2.81 | Lightweight, thermal conductivity | Aerospace brackets, heat sinks |

| Stainless Steel | 17-4 PH, 316L | 450 – 1300 | 7.8 – 8.0 | High strength, corrosion resistance | Tooling, hydraulic parts, valves |

| Titanium | Ti-6Al-4V | 800 – 1100 | 4.43 | Strength/weight, biocompatibility | Aircraft components, medical implants |

Anodizing is a vital electrochemical finish primarily applied to aluminum parts. This process significantly enhances surface hardness, wear resistance, and corrosion protection while allowing for precise color coding. Type II (sulfuric acid) anodizing is standard for general durability, while Type III (hardcoat) anodizing delivers maximum abrasion resistance for high-wear applications. Anodizing thickness and sealing processes are meticulously controlled to meet specific client specifications and environmental exposure requirements. It is essential to note that anodizing is specific to aluminum; steel and titanium require alternative surface engineering solutions like passivation, polishing, or specialized coatings.

Partner with Wuxi Lead Precision Machinery to navigate the complexities of material science and finishing for your next metal AM project. Our engineering team provides data-driven recommendations to ensure your design translates into a high-performance, production-ready component.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our 3D printing design service is engineered to deliver precision, repeatability, and zero-defect outcomes across every stage of production. Rooted in advanced metal additive manufacturing technologies, our process follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is optimized for dimensional accuracy, material integrity, and functional performance, ensuring that final components meet the exacting standards of aerospace, medical, and high-performance industrial applications.

The process begins with collaborative design engineering. Our team works closely with clients to translate conceptual models into manufacturable, high-precision 3D designs. Using topology optimization and finite element analysis (FEA), we refine geometries for structural efficiency, weight reduction, and thermal stability. Design for Additive Manufacturing (DfAM) principles are applied to eliminate unnecessary material, reduce assembly complexity, and enhance performance under load. All designs undergo rigorous simulation and thermal stress modeling to predict behavior during printing and in-service conditions.

Prototyping follows design finalization, serving as both a functional validation and process qualification step. Utilizing laser powder bed fusion (LPBF) technology with materials such as titanium Ti6Al4V, Inconel 718, and aluminum AlSi10Mg, we produce initial units under full production parameters. Each prototype is subjected to comprehensive metrology, including coordinate measuring machine (CMM) inspection, micro-CT scanning, and non-destructive testing (NDT). Surface roughness, porosity levels, and mechanical properties are verified against ASTM and ISO standards. Feedback from prototyping is integrated into final design adjustments, ensuring process stability before scale-up.

Mass production is executed on a scalable LPBF platform with automated powder handling, in-process monitoring, and real-time melt pool analysis. Our production cells operate under ISO 13485 and ISO 9001-certified conditions, with environmental controls to maintain consistent build quality. Each layer is monitored via high-speed imaging and thermal sensors, enabling immediate detection of anomalies. Post-processing includes stress relief annealing, support removal via CNC milling, and optional surface treatments such as HIP (Hot Isostatic Pressing), shot peening, or polishing to achieve required surface finishes.

Throughout the entire workflow, traceability is maintained via digital twin technology and batch-specific documentation. Every component is tracked from raw material certification through final inspection, supporting full compliance with regulatory requirements.

The following table outlines key technical specifications of our metal 3D printing process:

| Parameter | Specification |

|---|---|

| Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-built) | Ra 10–15 µm; down to Ra 0.8 µm post-polishing |

| Materials | Ti6Al4V, Inconel 718, AlSi10Mg, SS 316L, Maraging Steel |

| Post-Processing Options | HIP, CNC Machining, Heat Treatment, Polishing |

| Quality Standards | ISO 9001, ISO 13485, ASTM F857, ISO/ASTM 52921 |

By integrating precision engineering, closed-loop process control, and full-lifecycle validation, Wuxi Lead ensures zero-defect delivery across all production volumes. Our 3D printing design service is not just about manufacturing parts—it’s about guaranteeing performance, reliability, and compliance in every component we produce.

Why Choose Wuxi Lead Precision

Elevate Your Metal Manufacturing Outcomes Through Strategic Partnership

When precision metal components fail to meet exacting aerospace, medical, or industrial standards, the consequences extend beyond cost overruns—they jeopardize timelines, safety, and reputation. At Wuxi Lead Precision Machinery, we resolve this by integrating advanced 3D printing design expertise with 20+ years of certified CNC mastery. Our engineers collaborate from initial concept through final inspection, transforming complex geometries into mission-critical parts with zero compromise on integrity. We don’t just manufacture; we de-risk your supply chain through process ownership you can audit.

Our proprietary workflow begins with material-optimized 3D design validation, ensuring additive structures withstand post-processing stresses. Unlike generic service bureaus, we directly control every phase: laser melting, precision CNC milling, heat treatment, and 5-axis finishing. This vertical integration guarantees tolerances unattainable via fragmented outsourcing. Below are core capabilities enabling your success:

| Capability | Specification | Application Impact |

|---|---|---|

| Material Compatibility | Ti-6Al-4V, Inconel 718, 316L SS | Aerospace turbine durability |

| Dimensional Accuracy | ±0.025 mm after finishing | Medical implant biocompatibility |

| Surface Finish | Ra 0.4 µm (as-built) to Ra 0.1 µm | Hydraulic component sealing |

| Post-Processing Capacity | 5-axis milling, HIP, stress relief | Eliminates field failures |

| Quality Certification | ISO 9001:2015, NADCAP accredited | Meets Tier-1 automotive audits |

Partnering with Lead Precision means accessing China’s most rigorous metal manufacturing ecosystem without export logistics friction. Our Jiangsu facility operates under Western quality protocols, with real-time English-language reporting and dedicated project managers who speak your engineering language. We validate designs against your failure modes—not theoretical benchmarks—using in-house metrology labs featuring Zeiss CMMs and X-ray CT scanning.

The true differentiator lies in our closed-loop feedback between design and production. When your 3D-printed bracket requires micro-machined threads or critical datum surfaces, our CNC engineers co-develop the build strategy upfront. This prevents the 30% scrap rates common when additive and subtractive processes operate in silos. You gain one accountable partner for the entire value stream—from CAD file to certified part shipment.

Submit your most challenging metal component requirements to [email protected]. Include target volumes, material specifications, and geometric pain points. Within 24 business hours, our applications team will provide a feasibility assessment with actionable recommendations—not a generic quotation. For urgent projects, reference “URGENT-CTA” in your subject line to trigger expedited engineering review. Lead Precision delivers precision you measure in microns and trust in mission hours. Contact [email protected] to initiate your technical consultation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.