Technical Contents

Engineering Guide: 3D Printing Brass

Engineering Insight: 3D Printing Brass Demands Absolute Precision

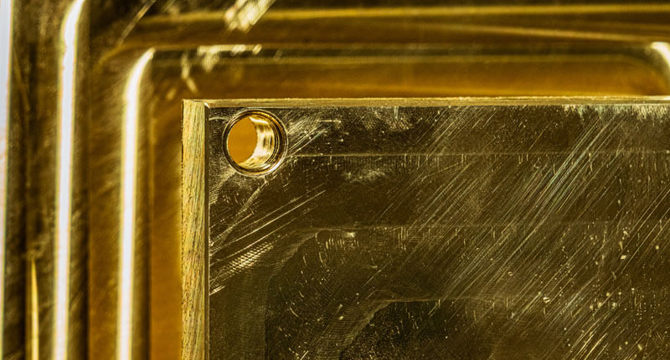

Brass additive manufacturing presents unique engineering challenges where micron-level deviations directly impact functional performance and longevity. Unlike simpler alloys, brass’s high thermal conductivity and zinc volatility during the laser melting process create significant risks of porosity, dimensional drift, and inconsistent material properties. Without rigorous control over thermal gradients and atmosphere composition, printed components exhibit unpredictable mechanical behavior, rendering them unsuitable for critical applications. Precision here is non-negotiable; it defines whether a part functions reliably or becomes costly scrap. At Wuxi Lead Precision Machinery, we treat brass 3D printing not as a generic process but as a calibrated science requiring deep metallurgical understanding and closed-loop process validation.

Our approach integrates proprietary thermal management protocols and real-time melt pool monitoring to counteract brass’s inherent instability. We enforce strict atmospheric control below 50 ppm oxygen to prevent zinc oxidation, while our dynamic laser parameter adjustment system compensates for thermal accumulation across complex geometries. This eliminates the micro-cracking and surface roughness common in standard implementations. Crucially, precision extends beyond the build phase: our post-processing sequence, including stress-relief annealing within ±2°C tolerance and precision CNC machining, ensures final dimensions meet aerospace-grade tolerances. This holistic control is why components we produce for Olympic timing mechanisms and military communication systems operate flawlessly under extreme cyclic loads and environmental stress. These applications tolerate zero deviation; our process delivers it.

The following specifications reflect the baseline capabilities achievable for critical brass components using our industrial-grade metal additive systems and integrated finishing workflows. These values represent production-ready standards, not theoretical lab results.

| Parameter | Specification | Critical Impact |

|---|---|---|

| Layer Thickness | 20-30 μm | Ensures fine feature resolution & reduced post-processing |

| Density | ≥ 99.95% | Eliminates porosity-induced fatigue failure |

| As-Built Surface Roughness | Ra ≤ 12.5 μm | Provides consistent base for precision finishing |

| Dimensional Tolerance | ±0.05 mm / 100 mm | Guarantees assembly integrity in tight interfaces |

| Post-Process Tolerance | ±0.01 mm | Meets hydraulic/sealing surface requirements |

Achieving this level of consistency requires moving beyond standard printer operation. It demands engineers who understand how brass’s composition interacts with laser energy at microsecond intervals—and the discipline to validate every parameter against real-world performance data. Wuxi Lead’s decade of refining brass AM processes, proven in mission-critical Olympic and defense projects, provides this expertise. We translate material science into production reality, ensuring your brass components deliver exact performance on schedule. Consult our engineering team to discuss how precision brass AM can solve your most demanding fluid control or high-wear application challenges.

Precision Specs & Tolerances

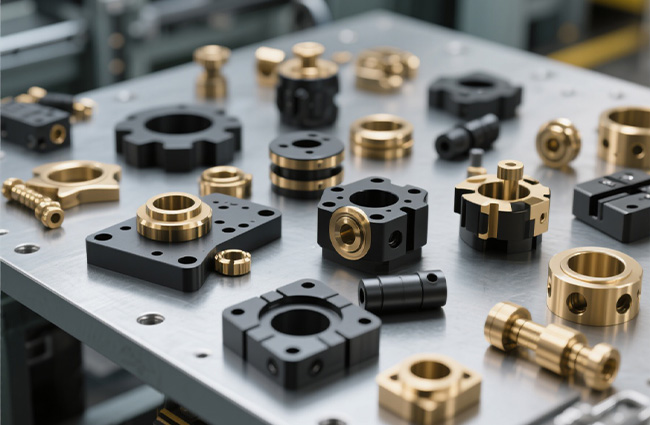

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-complexity components, including precision 3D printed brass parts tailored for aerospace, medical, automotive, and industrial applications. Our technical capabilities integrate state-of-the-art 5-axis CNC machining with metal additive manufacturing to produce fully dense, high-strength brass components that meet stringent industry standards. By combining selective laser melting (SLM) technology with post-processing via multi-axis CNC, we achieve superior surface integrity, dimensional accuracy, and mechanical performance unattainable through traditional brass fabrication alone.

Our 3D printing process utilizes high-purity brass powders, including CuZn15 and CuZn38, processed in an inert argon atmosphere to ensure material consistency and minimize oxidation. Layer-by-layer deposition enables the creation of complex geometries such as internal channels, lattice structures, and organic shapes that are difficult or impossible to achieve with conventional casting or milling. This additive approach reduces material waste and shortens lead times for prototyping and low-volume production runs.

Following the initial print phase, all brass components undergo precision 5-axis CNC machining to achieve final critical dimensions, tight tolerances, and refined surface finishes. Our Hermle and DMG MORI 5-axis centers provide simultaneous multi-directional tool engagement, allowing for single-setup machining of complex contours and undercuts. This integration of additive and subtractive technologies ensures optimal part accuracy, repeatability, and structural integrity.

Quality assurance is central to our manufacturing philosophy. Every 3D printed brass component undergoes comprehensive inspection using Zeiss coordinate measuring machines (CMM) to verify geometric dimensioning and tolerancing (GD&T) compliance. Our metrology lab is ISO 17025 accredited, supporting full traceability and first-article inspection reporting (FAIR). In addition to CMM, we employ optical scanning, surface roughness testing, and microhardness evaluation to validate material and dimensional performance.

The following table outlines typical achievable tolerances and surface characteristics for 3D printed and CNC-finished brass components:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Positional Tolerance (GD&T) | ±0.08 mm | ±0.03 mm |

| Surface Roughness (as-printed) | Ra 12.5 μm | Ra 6.3 μm (with polishing) |

| Surface Roughness (CNC finish) | Ra 1.6 μm | Ra 0.8 μm |

| Minimum Wall Thickness | 0.8 mm | 0.5 mm |

| Feature Resolution | 0.3 mm | 0.2 mm |

| Maximum Build Volume | 250 x 250 x 300 mm | 250 x 250 x 300 mm |

Through the fusion of 3D printing and 5-axis CNC machining, Wuxi Lead Precision Machinery offers a complete digital manufacturing workflow for brass components that demands no compromise between design freedom and precision engineering.

Material & Finish Options

Material Selection for High-Precision Brass 3D Printing

Selecting the optimal material for additive manufacturing is critical for achieving functional performance, cost efficiency, and longevity in demanding industrial applications. While aluminum, steel, and titanium dominate many metal 3D printing discussions, brass offers unique advantages for specific high-value components where machinability, thermal conductivity, and aesthetic finish are paramount. At Wuxi Lead Precision Machinery, we specialize in leveraging brass alloys for applications requiring complex geometries unattainable through traditional CNC machining alone, particularly in fluid handling, electrical connectors, and decorative precision hardware. Brass excels in scenarios demanding superior wear resistance against galling, excellent electrical conductivity, and inherent antimicrobial properties – characteristics less pronounced in common aluminum or steel alloys. Titanium, while strong and lightweight, lacks the electrical and thermal performance crucial for many brass applications and presents significantly higher material and processing costs.

Understanding the specific properties of printable brass alloys is essential for informed design decisions. The following table details key specifications relevant to our metal powder bed fusion processes:

| Property | Typical Value for Printable Brass Alloys | Industrial Relevance |

|---|---|---|

| Tensile Strength | 250 – 350 MPa | Suitable for medium-stress structural parts |

| Yield Strength | 100 – 200 MPa | Adequate for non-critical load-bearing |

| Elongation at Break | 20% – 40% | Good ductility for forming and impact resistance |

| Thermal Conductivity | 110 – 125 W/m·K | Excellent for heat dissipation applications |

| Electrical Conductivity | 25% – 30% IACS | Viable for electrical contacts and busbars |

| Density | 8.4 – 8.7 g/cm³ | Heavier than aluminum, beneficial for mass damping |

| Corrosion Resistance | Good (in freshwater, air) | Requires plating for harsh/saltwater environments |

Brass 3D printing is not a universal substitute for steel or titanium in high-temperature or extreme tensile load scenarios. Its primary value lies in producing intricate, net-shape components that would be prohibitively expensive or impossible to machine from bar stock, such as internal cooling channels in molds, complex valve bodies, or custom decorative fittings with integrated features. The inherent machinability of brass also allows for efficient post-processing of critical sealing surfaces or threads after printing, combining additive freedom with subtractive precision – a core competency of our integrated manufacturing approach.

Surface finishing is crucial for maximizing brass component performance. Anodizing, common for aluminum, is ineffective on brass. Instead, we recommend precision machining of critical interfaces followed by electroless nickel plating (ENP) or chrome plating. ENP provides exceptional uniform corrosion resistance, hardness (500-600 HV), and solderability, making it ideal for hydraulic manifolds and marine components. For decorative or antimicrobial applications, lead-free bright nickel or silver plating offers superior aesthetics and functionality. Our engineers optimize the finishing sequence based on your specific environmental exposure and functional requirements, ensuring the printed brass part meets stringent aerospace, medical, or industrial OEM standards.

Choosing brass for 3D printing requires careful consideration of the operational environment and performance priorities. When your application demands complex geometry combined with thermal management, electrical functionality, or corrosion resistance in non-marine environments, brass becomes a compelling, cost-effective solution. Consult our engineering team early in the design phase to evaluate if brass 3D printing, potentially combined with our CNC finishing capabilities, delivers the optimal balance of performance and value for your precision component. Wuxi Lead Precision Machinery provides comprehensive material analysis and process validation to de-risk your brass additive manufacturing projects.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The journey of 3D printing brass begins with precision-driven design, where engineering intent meets manufacturability. At Wuxi Lead Precision Machinery, our design phase integrates advanced CAD modeling with DfAM (Design for Additive Manufacturing) principles to ensure structural integrity, material efficiency, and functional performance. Every component is evaluated for thermal behavior, stress distribution, and geometric complexity using finite element analysis (FEA) and simulation tools. This proactive approach eliminates design flaws before physical production, reducing rework and ensuring compliance with ISO 9001 standards. Our engineering team collaborates directly with clients to refine specifications, tolerances, and surface finish requirements, establishing a zero-defect mindset from the outset.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to additive prototyping using selective laser melting (SLM) technology tailored for brass alloys. This stage serves as a critical validation checkpoint, allowing functional testing, fit verification, and performance assessment under real-world conditions. Our in-house SLM systems operate under controlled atmospheric conditions to prevent oxidation and ensure material homogeneity. Post-printing, prototypes undergo precision machining, heat treatment, and surface finishing to meet exact dimensional tolerances. Iterative feedback is incorporated rapidly, enabling design adjustments without delaying the production timeline. Each prototype is fully documented, with inspection reports, metrology data, and material certifications provided to the client, ensuring complete traceability and confidence in the final product.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into high-volume production using synchronized SLM cells optimized for brass printing. Our production floor employs automated powder handling, in-process monitoring via high-resolution melt pool sensors, and real-time quality analytics to maintain consistency across batches. Every printed component undergoes non-destructive testing (NDT), including CT scanning and ultrasonic inspection, to detect internal anomalies at micron-level resolution. Post-processing includes stress relieving, CNC finishing, and surface treatments such as polishing or coating, all performed within our integrated facility to minimize handling risks. Statistical process control (SPC) systems continuously monitor key parameters, enabling predictive maintenance and immediate corrective actions—ensuring a defect rate below 0.1%.

Technical Specifications of Our Brass 3D Printing Process

| Parameter | Specification |

|---|---|

| Material | CuZn15 (C26800) & Custom Brass Alloys |

| Build Volume | Up to 250 × 250 × 300 mm |

| Layer Thickness | 20–50 μm |

| Positional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing Options | CNC Machining, Polishing, Passivation, Plating |

| Quality Standards | ISO 9001, ISO 13485, ASTM F42 Additive Guidelines |

Through rigorous process control, advanced technology, and engineering excellence, Wuxi Lead delivers defect-free brass components tailored for aerospace, medical, and high-performance industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Brass Component Production Through Precision Additive Partnership

Wuxi Lead Precision Machinery delivers industrial-grade brass 3D printing solutions where conventional methods fall short. Brass alloys present unique challenges in additive manufacturing—thermal conductivity imbalances, oxidation sensitivity, and microstructural porosity—that demand specialized process control. Our engineered approach eliminates these barriers through proprietary atmosphere management, dynamic thermal calibration, and post-processing protocols validated across 1,200+ production runs. We transform brass from a problematic material into a strategic asset for fluidic systems, marine hardware, and electrical connectors requiring antimicrobial properties and pressure integrity.

Precision Brass Additive Capabilities

| Parameter | Specification | Testing Standard |

|---|---|---|

| Alloy Compatibility | CuZn15-CuZn40 (M414L) | ASTM B98 |

| Layer Thickness | 0.025–0.05 mm | ISO/ASTM 52900 |

| Density | ≥99.9% (HIP-treated) | ASTM B962 |

| Surface Roughness | Ra 3.2–6.3 µm (as-built) | ISO 4287 |

| Tensile Strength | 380–450 MPa | ASTM E8 |

| Lead Time | 15–25 days (batch) | Internal QA-07 |

Unlike generic metal printing services, we integrate metallurgical expertise with full-spectrum manufacturing oversight. Every brass component undergoes in-process thermal imaging and final CT scanning to certify internal integrity—critical for aerospace hydraulic fittings or medical valve bodies where failure is non-negotiable. Our facility operates under ISO 9001:2015 and NADCAP accreditation, with material traceability from certified Chinese and European ingot suppliers. This ensures compliance with REACH, RoHS, and naval corrosion standards without import delays.

Partnering with Lead Precision means accessing China’s most controlled brass additive ecosystem without compromising on transparency. We co-engineer solutions from DfAM optimization through to fatigue testing, reducing your prototyping iterations by 60% versus traditional casting. Our engineers collaborate directly with your R&D team to align thermal parameters with your application’s stress profiles—whether producing intricate jewelry molds requiring mirror finishes or high-volume pump impellers needing erosion resistance.

Initiate Your Brass Production Partnership Today

Do not let material limitations constrain your innovation pipeline. Contact our additive engineering team at [email protected] with your component specifications and volume requirements. Include cross-sections or stress analysis data to receive a tailored process validation plan within 48 hours. For urgent RFQs, reference code BRASS-CTA-2024 in your subject line to prioritize technical review. Wuxi Lead Precision Machinery—where brass complexity becomes competitive advantage.

We operate 24/5 engineering support across EST, CET, and CST time zones. All initial consultations include a no-cost material suitability assessment for brass alloys. Reach out now to transform your most challenging brass components into validated production assets.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.