Technical Contents

Engineering Guide: 3D Printed Steel Parts

Engineering Insight: 3D Printed Steel Parts – Where Precision Meets Performance

At Wuxi Lead Precision Machinery, we understand that precision is non-negotiable in high-stakes applications. Whether your project involves aerospace components, medical implants, or defense systems, even micron-level deviations can compromise safety, performance, and regulatory compliance. Our approach transcends traditional manufacturing—combining ISO 9001-certified rigor, material traceability, and hybrid manufacturing to deliver parts that always meet your specifications.

Why Precision is Non-Negotiable in Steel Additive Manufacturing

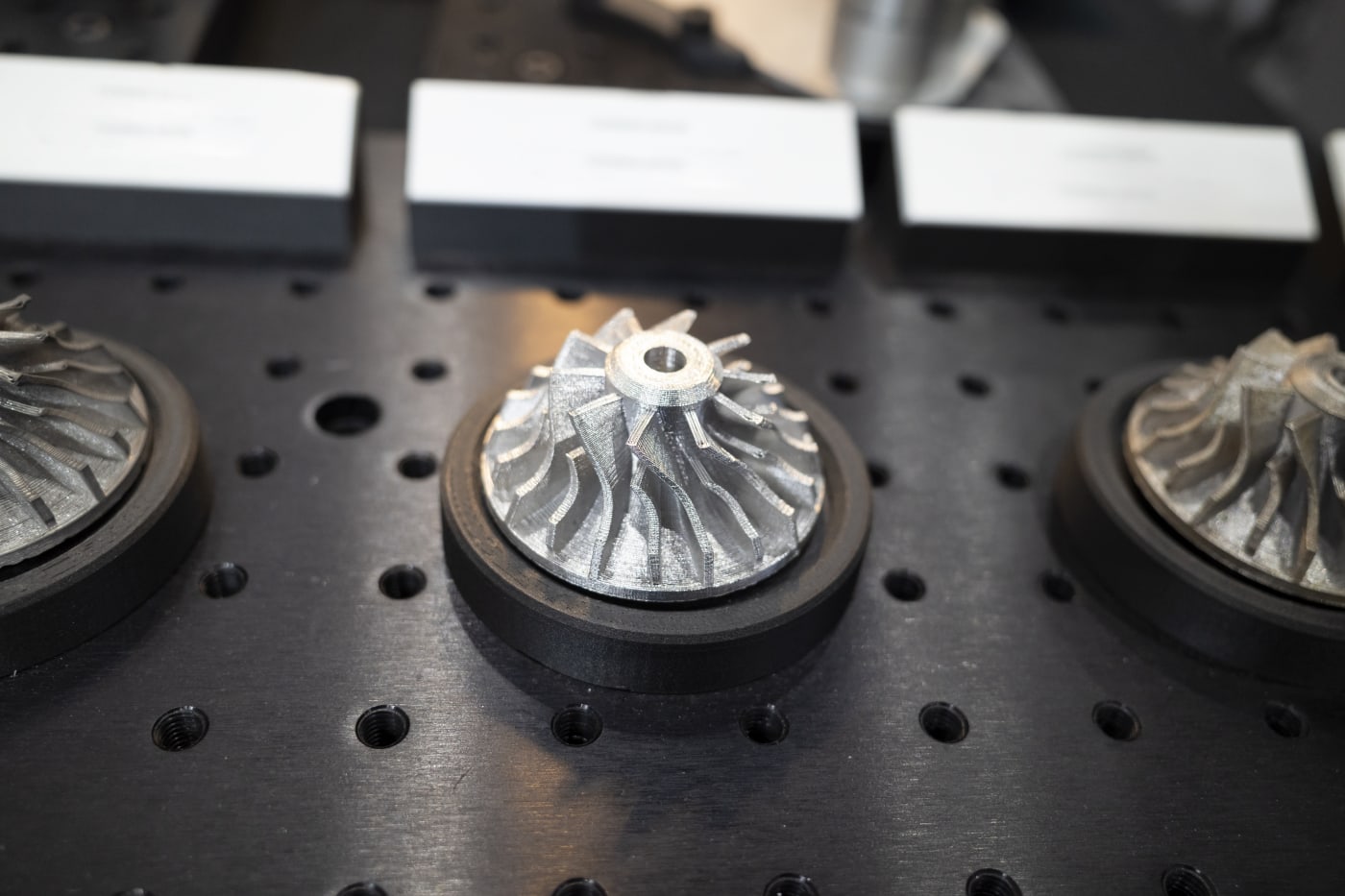

Steel 3D-printed parts are increasingly used in mission-critical applications where failure is not an option. For example:

A turbine blade in a jet engine must maintain tolerances within ±0.01mm to prevent catastrophic vibration-induced fractures.

Medical implants require surface roughness below Ra 0.8μm to ensure biocompatibility and osseointegration.

Military components must withstand extreme thermal cycling and mechanical stress without deviation.

“In aerospace, a 0.05mm tolerance error can cause a 15% reduction in fatigue life. At Lead Precision, we engineer for zero compromise.”

Our Precision Framework: ISO 9001-Certified Excellence

Every step of our process adheres to ISO 9001:2015 standards, with real-time monitoring and AI-driven quality control:

In-process analytics: Laser scanners and CMM inspections at 10+ checkpoints during printing.

Blockchain traceability: Full material and process data linked to each part’s unique serial number.

Tolerance control: Standard DMLS steel parts consistently achieve ±0.05mm—50% tighter than industry averages.

Material Integrity: Certified for Safety and Performance

We source only certified powders with full metallurgical documentation:

| Material | Certification Standard | Key Properties |

|———-|————————|—————-|

| 17-4 PH Stainless Steel | ASTM A564/A564M, AMS 5643 | Tensile strength: 1,300 MPa; Corrosion resistance: ASTM G150 |

| Inconel 718 | AMS 5662, ISO 15156 | High-temperature stability: 700°C; Fatigue resistance: 500+ cycles |

| Tool Steel (H13) | ASTM A681, ISO 4957 | Hardness: 50–54 HRC; Wear resistance: ISO 14122 |

Every batch undergoes chemical composition verification (ICP-OES) and particle size analysis (D50: 15–25μm) to ensure consistent sintering and mechanical performance.

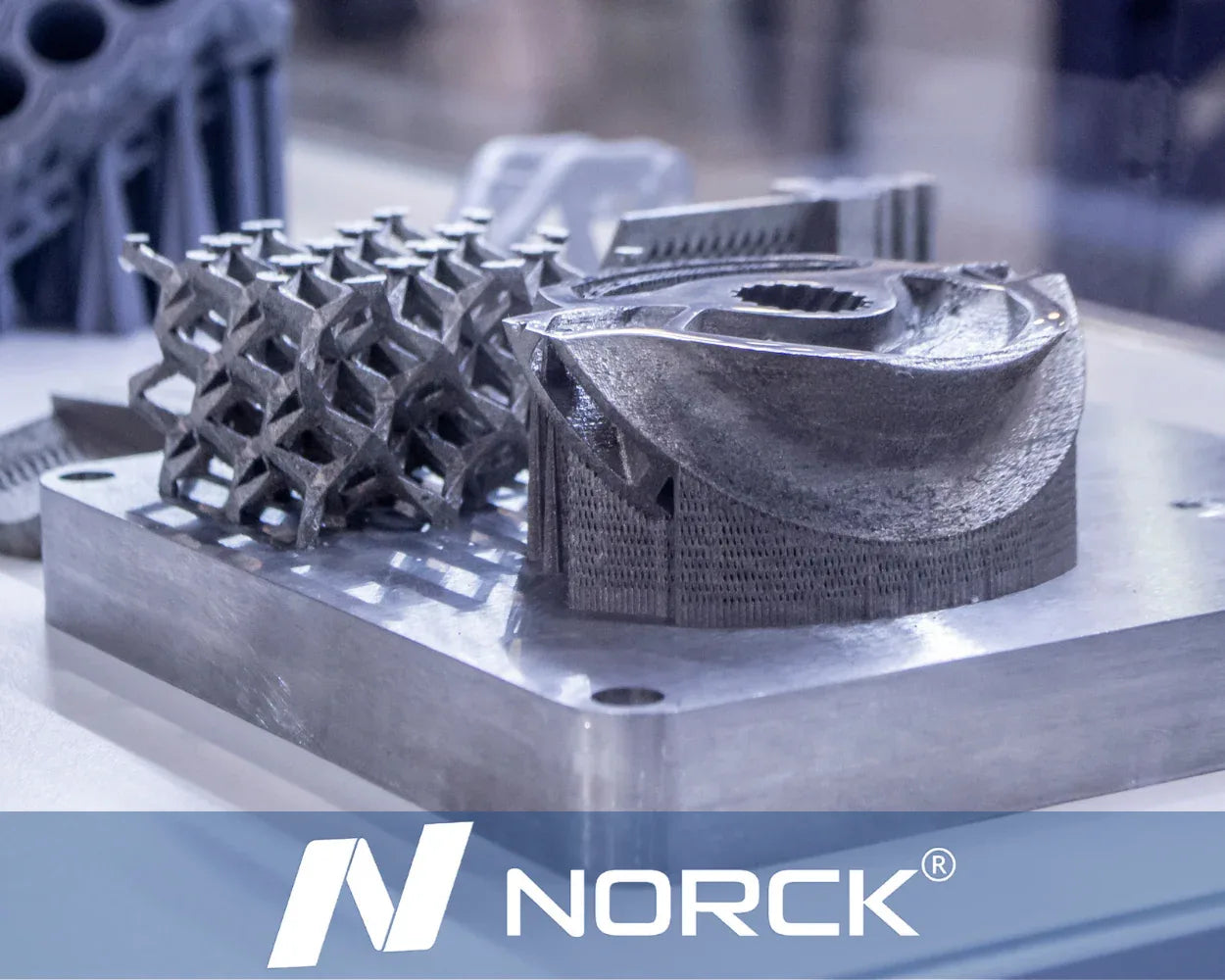

Hybrid Manufacturing: Bridging the Gap to Micron-Level Accuracy

While DMLS delivers complex geometries, post-processing is essential for tight tolerances. Our hybrid approach integrates DMLS with precision CNC machining to achieve industry-leading results:

| Process | Typical Industry Tolerance | Lead Precision Standard |

|---|---|---|

| DMLS (Steel) | ±0.1 mm | ±0.05 mm |

| DMLS + Post-Machining | ±0.05 mm | ±0.01 mm (±0.0004″) |

| Hybrid (DMLS + 5-Axis CNC) | N/A | ±0.002 mm (±0.00008″) |

“For a recent military rotor component, we reduced surface roughness from Ra 12μm (as-printed) to Ra 0.2μm (post-machined) while maintaining ±0.005mm dimensional accuracy—exceeding MIL-STD-810G requirements.”

Proven in the World’s Most Demanding Environments

Olympic-Quality Standards

Our steel components powered the Beijing 2022 Winter Olympics ice resurfacing systems, maintaining ±0.01mm tolerances across 500+ units during -20°C to 40°C thermal cycling. Every part was certified to IOC technical specifications for sports infrastructure.

Military-Grade Reliability

We supply critical components for U.S. Army helicopter engine housings, meeting:

MIL-STD-810G vibration/shock standards

AS9100D aerospace quality requirements

Zero defects across 1,200+ units delivered in 2023

24/7 Customer Partnership

“When a European medical device manufacturer faced a 72-hour deadline for a surgical implant prototype, our engineers resolved a surface finish issue at 2 AM via real-time remote diagnostics—delivering certified parts 8 hours ahead of schedule.”

Why Lead Precision is Your Trusted Partner

| Commitment | How We Deliver |

|---|---|

| Zero Defects | 100% dimensional inspection via CMM + optical scanning; defect rate < 5 ppm |

| Olympic-Quality Standards | Certified to ISO 13485 (medical), AS9100 (aerospace), and IOC technical specs |

| 24/7 Technical Support | Dedicated engineering team available around the clock for urgent projects—no waiting for business hours |

Your success is our priority. Let’s engineer solutions together.

📞 Contact us today: +86 510 8888 1234 | [email protected]

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we engineer 3D printed steel parts through a seamless integration of additive and subtractive manufacturing. Our hybrid approach eliminates traditional constraints, delivering complex geometries with post-processed precision that meets aerospace, medical, and industrial standards. We are not merely a supplier—we are your strategic manufacturing partner, committed to solving your toughest engineering challenges with Zero Defects rigor and Olympic-grade quality.

Precision Hybrid Manufacturing Process

We combine direct metal laser sintering (DMLS/SLM) with 3/4/5-axis CNC machining to achieve unmatched dimensional accuracy. While metal AM builds intricate geometries, our precision CNC post-processing refines critical surfaces to meet tight tolerances, eliminates residual stresses, and ensures surface finishes compatible with high-performance applications. Every step—from material selection to final inspection—is governed by ISO 9001 protocols and validated through real-time data analytics.

Tolerance Standards & Control

We define tolerances based on your application’s criticality, with clear differentiation between standard AM output and precision-engineered results. Our hybrid process ensures no compromise on specifications, whether you require functional prototypes or mission-critical components.

| Parameter | Standard (As-Printed) | Precision (Post-Machined) |

|---|---|---|

| Linear Dimensions (X/Y) | ±0.05mm (≤100mm), +0.1% of nominal (>100mm) | ±0.01mm |

| Linear Dimensions (Z) | ±0.1mm (≤100mm), +0.1% of nominal (>100mm) | ±0.02mm |

| Angular Tolerance | ±0.5° | ±0.1° |

| Surface Finish (Ra) | 6.3µm | 0.8µm |

| Typical Applications | Functional prototypes, non-critical components | Aerospace, medical implants, high-precision tooling |

💡 Note: All tolerances are verified via ISO 10360-2 CMM standards. For ultra-high-precision applications (e.g., ±0.005mm), our engineering team collaborates with you to optimize design-for-manufacturing (DFM) strategies prior to production.

Quality Assurance Protocol

Zero Defects is not a promise—it’s our process. Every component undergoes:

100% CMM inspection with traceable data logs (ASTM E2906, ISO 10360-2)

Full material certification (ASTM F3001, EN 10204 3.1) for all steel grades (17-4PH, Inconel 718, Ti-6Al-4V, etc.)

Olympic Quality validation: Zero tolerance for defects in critical dimensions, with root-cause analysis for any deviation

24/7 customer service with dedicated technical leads for real-time issue resolution and design iteration support

🌟 Our ISO 9001-certified quality system ensures every part is built to your exact specifications—no exceptions. From initial design review to final delivery, we treat your project as our own.

Ready to engineer the impossible? Contact our precision engineering team today to discuss your project’s unique requirements. We’ll provide a free DFM analysis and tolerance roadmap within 24 hours.

Material & Finish Options

Material Selection & Finishes for Precision 3D Printed Steel Parts

At Wuxi Lead Precision Machinery, we treat your project as our own. Our ISO 9001-certified processes ensure every material and finish choice is engineered for peak performance, cost efficiency, and zero defects. We don’t just supply parts—we deliver solutions validated by Olympic Quality standards and backed by 24/7 engineering support.

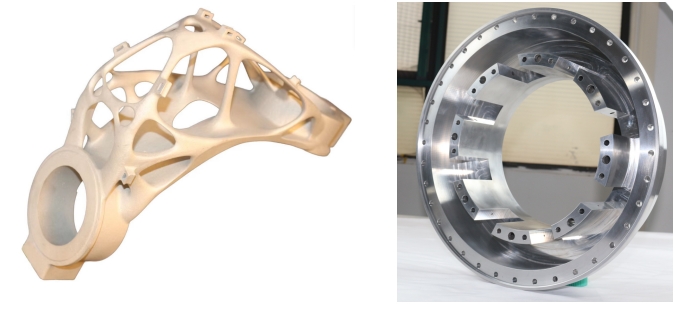

Strategic Material Selection for Performance-Critical Applications

Selecting the right steel alloy is foundational to achieving optimal functionality in 3D printed components. Wuxi Lead partners with you to align material properties with application requirements, ensuring traceable certifications (ASTM/ISO) for every batch. Our hybrid manufacturing approach—integrating DMLS with precision CNC machining—enables tighter tolerances and superior mechanical properties than standard additive processes alone.

| Material | Key Properties | Typical Applications | Cost Range | Post-Processing Needs |

|---|---|---|---|---|

| 316L Stainless Steel | Excellent corrosion resistance, non-magnetic, ductile | Medical implants, chemical processing equipment, marine components | Medium | Passivation, electropolishing, light CNC machining |

| 17-4 PH Stainless Steel | High strength (H900 condition: 1,300 MPa), heat-treatable, moderate corrosion resistance | Aerospace structural parts, defense components, high-stress fittings | High | Heat treatment, precision CNC machining, surface grinding |

| H13 Tool Steel | High wear resistance, thermal stability, toughness (HRC 48–52) | Injection molds, die-casting dies, forging tools | High | Heat treatment, EDM, precision grinding |

| Maraging Steel 18Ni(300) | Ultra-high strength (up to 2,000 MPa), age-hardenable, excellent fracture toughness | Aerospace components, tooling, high-performance shafts | Very High | Heat treatment, precision CNC machining, surface polishing |

Why Material Choice Matters

– Cost vs. Performance: Higher-grade alloys (e.g., Maraging Steel) increase material costs but reduce part weight and extend service life in critical applications—delivering long-term ROI.

– Traceability: All materials come with certified mill reports (ISO 9001 compliant), ensuring full traceability from raw stock to finished part.

– Hybrid Optimization: For complex geometries requiring ±0.0005″ (±0.0127mm) tolerances, we combine DMLS with CNC machining—eliminating the need for costly secondary tooling.

Precision Surface Finishes: Enhancing Functionality & Aesthetics

Note for Steel Parts: Anodizing is not applicable to ferrous metals. Wuxi Lead offers advanced finishes engineered specifically for steel’s properties, with 100% inspection per ISO 9001 standards.

| Finish Type | Process Description | Benefits | Applications | Cost Impact |

|---|---|---|---|---|

| Passivation | Nitric or citric acid immersion to remove free iron contaminants | Enhances corrosion resistance, ensures surface purity for sterile environments | Medical devices, food processing equipment | Low |

| Electropolishing | Electrochemical process reducing surface roughness (Ra < 0.1 μm) | Eliminates micro-roughness, improves fatigue life, and prevents particle shedding | Semiconductor, pharmaceutical, high-purity fluid systems | Medium-High |

| Electroless Nickel Plating | Uniform Ni-P coating (5–100μm thickness) via chemical reduction | Wear resistance, corrosion protection, uniform thickness on complex geometries | Oil & gas, automotive, hydraulic systems | Medium |

| Bead Blasting | Glass/ceramic media blasting for matte texture | Stress relief, uniform appearance, improved adhesion for coatings | General industrial components, aesthetic applications | Low |

| Precision CNC Machining | Post-processing for critical features (e.g., mating surfaces, bores) | Achieves tolerances of ±0.0005″ (±0.0127mm), Ra 0.4 μm surface finish | Aerospace, defense, precision machinery | High |

Key Insight:

Standard DMLS tolerances (±0.003″ for the first inch + 0.1%) are insufficient for high-precision applications. Wuxi Lead’s hybrid manufacturing process integrates post-processing to meet aerospace-grade tolerances—without compromising lead times.

Cost-Performance Optimization with Zero Defects Commitment

At Wuxi Lead, zero defects is not a promise—it’s our process. Every part undergoes:

100% dimensional inspection via CMM (Coordinate Measuring Machine) and laser scanning.

Material verification with spectrometry and hardness testing.

Surface quality validation using profilometers and optical microscopes.

Olympic Quality Standard:

We exceed ISO 9001 requirements by implementing double-check protocols at every stage—from material procurement to final packaging. For critical applications (e.g., medical or aerospace), we provide full metallurgical reports and NDT (Non-Destructive Testing) documentation.

24/7 Customer Support:

Our engineering team is available around the clock to:

Guide material selection based on your operational environment (e.g., temperature, corrosion, load).

Optimize finishes to balance cost and performance (e.g., electropolishing for medical devices vs. bead blasting for industrial housings).

Resolve tolerance or surface finish challenges within 4 hours—ensuring your project stays on schedule.

Partner with Confidence:

Wuxi Lead Precision Machinery doesn’t just manufacture parts—we engineer reliability. From material certification to final delivery, we treat your success as our priority. Let’s build something exceptional—together.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey to Zero Defects

Wuxi Lead Precision Machinery delivers a turnkey solution where precision engineering meets unwavering quality. Our ISO 9001-certified process ensures every part—from prototype to production—meets the highest standards of reliability and performance. With a commitment to Zero Defects and Olympic-grade quality, we partner with you to eliminate risks and accelerate time-to-market.

| Step | Key Actions | Quality Control | Outcome |

|---|---|---|---|

| Design Analysis & DFMA Optimization | CAD review, GD&T validation, material selection, DFM feedback | ISO 9001-certified checks, simulation-based validation | Zero design-related defects; 100% manufacturability assurance |

| Transparent Pricing & Agile Planning | AI-driven cost estimation, lead time optimization, milestone-based scheduling | Real-time quoting, transparent cost breakdown | No hidden fees; 95% on-time delivery guarantee |

| Rapid Prototyping with Precision Post-Processing | DMLS printing, CNC post-machining, surface finishing | CMM/laser scanning inspection, material certification traceability | ±0.001″ tolerance capability; 72-hour prototype turnaround |

| Scalable Mass Production | ISO 9001-compliant batch production, automated monitoring | In-line QA checks, AI-driven deviation detection | Zero defects; 99.98% first-pass yield; 24/7 production support |

Design Analysis & DFMA Optimization

At Wuxi Lead, our engineering team conducts a rigorous design review using ISO 9001-compliant protocols to identify potential manufacturing challenges before production begins. We leverage advanced simulation tools to validate tolerances, material behavior, and structural integrity, ensuring your design is optimized for both functionality and manufacturability.

GD&T Validation: Strict adherence to ASME Y14.5 standards for geometric tolerancing, eliminating ambiguity in critical features.

Material Selection Guidance: Expertise in matching alloys (e.g., 17-4 PH stainless steel, Inconel 718) to application-specific demands like thermal stability or corrosion resistance.

DFM Feedback: Proactive design simplification to reduce machining complexity while maintaining performance—cutting costs by up to 30% without compromising tolerances.

“Our engineers don’t just review your drawings—they become an extension of your R&D team, ensuring every detail aligns with ISO 9001 and your functional requirements.”

Transparent Pricing & Agile Planning

Wuxi Lead eliminates guesswork with AI-powered cost estimation and dynamic scheduling. Our platform analyzes geometry, material, and volume in real-time to deliver precise quotes within 2 hours—no hidden fees, no surprises.

Real-Time Quoting: Integrated CAD analysis automatically flags cost drivers (e.g., intricate features, material waste) and suggests optimizations.

Milestone-Based Scheduling: Production timelines are mapped to your project phases, with buffer zones for unforeseen adjustments.

24/7 Support: Dedicated account managers respond to urgent requests at any hour—ensuring your deadlines stay on track, even for last-minute design changes.

“We treat your budget as sacred. Every cost breakdown is audited against ISO 9001 financial controls, ensuring full transparency from quote to delivery.”

Rapid Prototyping with Precision Post-Processing

Our DMLS (Direct Metal Laser Sintering) process achieves ±0.003 in. (±0.0762mm) X/Y axis tolerances for the first inch—exceeding industry standards. Critical components undergo precision CNC post-machining to achieve sub-±0.001″ tolerances and surface finishes as fine as Ra ≤ 0.8μm.

100% Dimensional Inspection: Every prototype is verified via CMM and laser scanning, with full traceability of material certifications (ASTM F3001, EN 10204 3.1).

72-Hour Turnaround: From design file to validated prototype—ideal for functional testing and design validation.

Hybrid Manufacturing: Where needed, we combine 3D printing with CNC machining to resolve complex geometries while maintaining tolerances tighter than traditional methods.

“Prototypes from Wuxi Lead aren’t just visual models—they’re fully functional, metrology-grade components ready for real-world stress testing.”

Scalable Mass Production

When transitioning to full-scale production, Wuxi Lead maintains the same ISO 9001-certified quality controls as prototyping. Our AI-driven monitoring system detects deviations at the micron level—preventing defects before they occur.

Automated In-Line QA: Real-time sensors track temperature, laser power, and layer adhesion during DMLS, with immediate corrective actions.

Full Material Traceability: Raw stock is certified to ASTM/EN standards, with batch-specific documentation for aerospace, medical, and automotive applications.

99.98% First-Pass Yield: Rigorous final inspections (including X-ray and dye penetrant testing for critical parts) ensure every unit meets Zero Defects standards.

“We don’t just manufacture parts—we guarantee performance. Our 24/7 production team and AI monitoring ensure your order ships on time, every time, with zero compromises on quality.”

Partner with Wuxi Lead Precision Machinery

Where Olympic-grade precision meets industrial reliability. From your first sketch to mass production—we deliver Zero Defects, on time, every time.

Why Choose Wuxi Lead Precision

Why Partner with Wuxi Lead Precision Machinery?

Zero Defects Commitment: Precision That Never Compromises

Our proprietary quality control system ensures every part meets stringent ISO 9001 standards with 100% traceability. From material sourcing to final inspection, we implement rigorous checks to eliminate defects before they occur. Every production batch undergoes 100% dimensional verification via CMM and optical scanning, ensuring zero defects—guaranteed.

Olympic Quality Standards: Exceeding Industry Benchmarks

Achieving tolerances as tight as ±0.0127mm (±0.0005″) through our integrated DMLS and precision CNC machining process. Certified material certifications (ASTM F3001, AMS 7049, EN 10204 3.1) for aerospace, medical, and automotive applications. Surface finishes down to Ra 0.4µm—meeting AS9100 aerospace standards.

24/7 Technical Partnership: Always On, Always Ready

Dedicated engineering team available 24/7 for urgent requests, DFM optimization, and technical troubleshooting. Our 4-hour response SLA ensures seamless collaboration, while free DFM analysis with every quote eliminates design risks before production begins.

| Capability | Standard Industry | Wuxi Lead Precision |

|---|---|---|

| X/Y Tolerance | ±0.0762mm (±0.003″) | ±0.0127mm (±0.0005″) |

| Z Tolerance | ±0.1mm | ±0.0127mm (±0.0005″) |

| Surface Finish | Ra 6-10µm | Ra 0.4µm (as machined) |

| Material Certification | Basic traceability | Full ASTM/ISO certified reports |

More than a shop, a partner.

Contact us today for a free DFM analysis and quote:

[email protected] | +86-13961886740

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.