Technical Contents

Engineering Guide: 3D Printed Stainless Steel

Engineering Insight: 3D Printed Stainless Steel – Where Precision Defines Performance

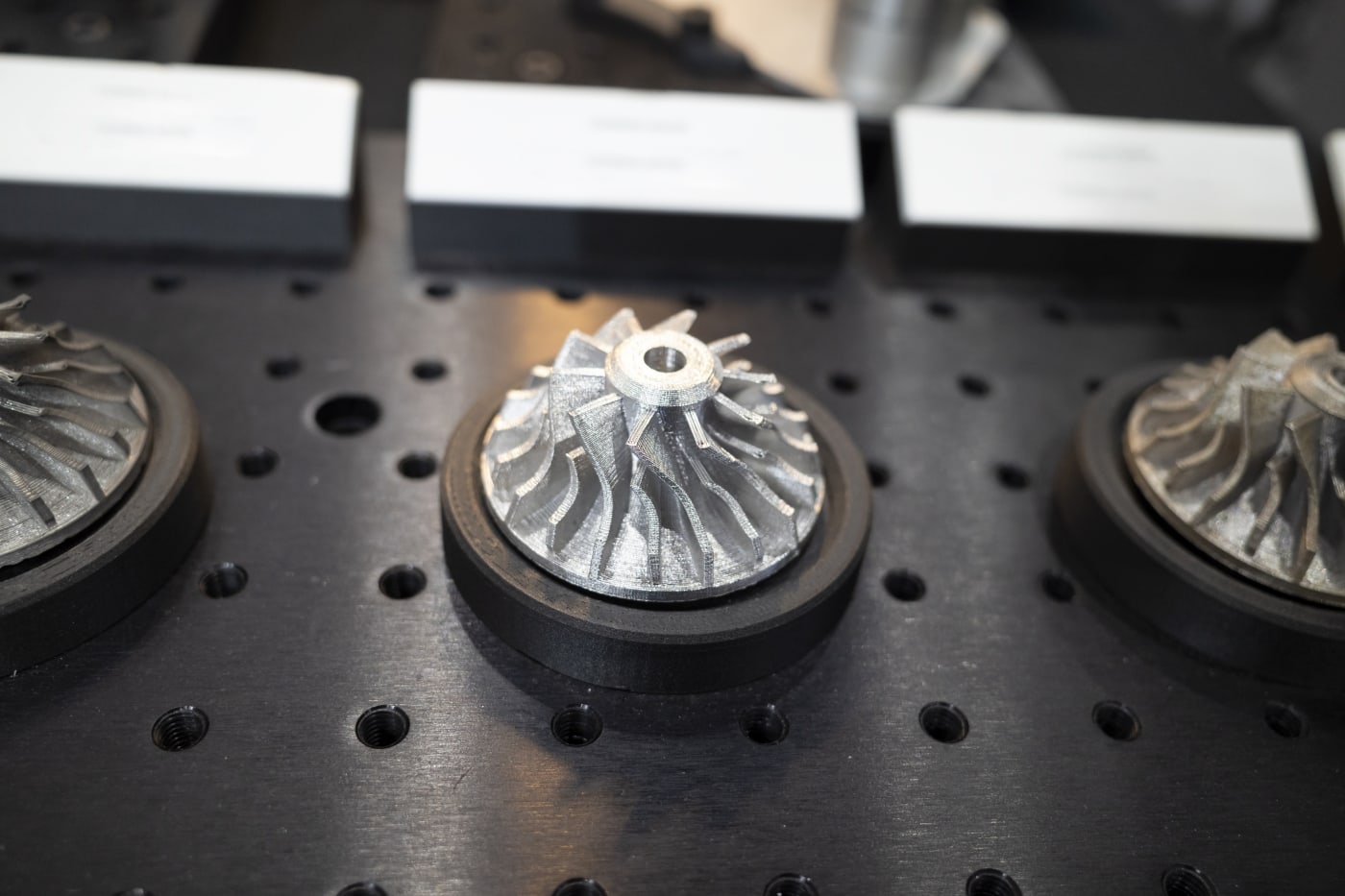

In the realm of advanced manufacturing, 3D printed stainless steel represents a transformative leap in design freedom, material efficiency, and structural complexity. However, the true value of this technology lies not just in its ability to produce intricate geometries, but in the precision with which those components are realized. At Wuxi Lead Precision Machinery, we understand that in high-stakes industries such as aerospace, defense, and precision instrumentation, tolerances are not merely specifications—they are non-negotiable requirements that define reliability, safety, and performance.

Stainless steel, known for its corrosion resistance, mechanical strength, and thermal stability, becomes even more powerful when combined with additive manufacturing. Yet, the layer-by-layer deposition process introduces challenges in dimensional accuracy, surface integrity, and internal consistency. Without rigorous process control, even the most sophisticated 3D printing systems can produce parts with microstructural defects, residual stresses, or deviations that compromise functionality. This is where precision engineering separates industrial-grade output from experimental prototypes.

At Lead Precision, our approach integrates closed-loop monitoring, post-processing calibration, and in-house metrology to ensure every 3D printed stainless steel component meets exacting standards. Our facility employs laser powder bed fusion (LPBF) systems calibrated to maintain layer thicknesses within ±10 microns, supported by environmental controls that eliminate thermal distortion during build cycles. Each part undergoes rigorous inspection via coordinate measuring machines (CMM) and micro-CT scanning, validating internal density and geometric fidelity down to the micron level.

Our expertise is not theoretical. We have delivered mission-critical components for Olympic-grade athletic equipment, where marginal gains are measured in milliseconds, and for military-grade systems requiring compliance with MIL-STD specifications. These applications demand more than adherence to drawings—they require a culture of precision that permeates every stage of production, from material sourcing to final certification.

The following table outlines key performance specifications achievable with our 3D printed stainless steel processes:

| Parameter | Typical Value | Standard Compliance |

|---|---|---|

| Material | 316L, 17-4 PH, 304L | ASTM A479, AMS 5643 |

| Layer Thickness | 20–40 μm | ISO/ASTM 52900 |

| Dimensional Accuracy | ±0.05 mm per 100 mm | ISO 2768-m |

| Surface Roughness (as-built) | Ra 8–12 μm | ISO 4287 |

| Post-Processed Surface Finish | Ra 1.6–3.2 μm (machined/polished) | Custom to drawing |

| Density | >99.9% | ASTM B925 |

| Heat Treatment Options | H900, H1150, Solution Anneal | AMS 2759/2, MIL-H-5008 |

| Maximum Build Volume | 250 x 250 x 325 mm | Machine-dependent |

Precision in 3D printed stainless steel is not an outcome—it is an engineered result. At Wuxi Lead Precision Machinery, we combine advanced technology with decades of metallurgical insight to deliver components that perform under extreme conditions. When failure is not an option, the margin of error must be zero. That is the standard we uphold.

Precision Specs & Tolerances

Technical Capabilities for 3D Printed Stainless Steel Components

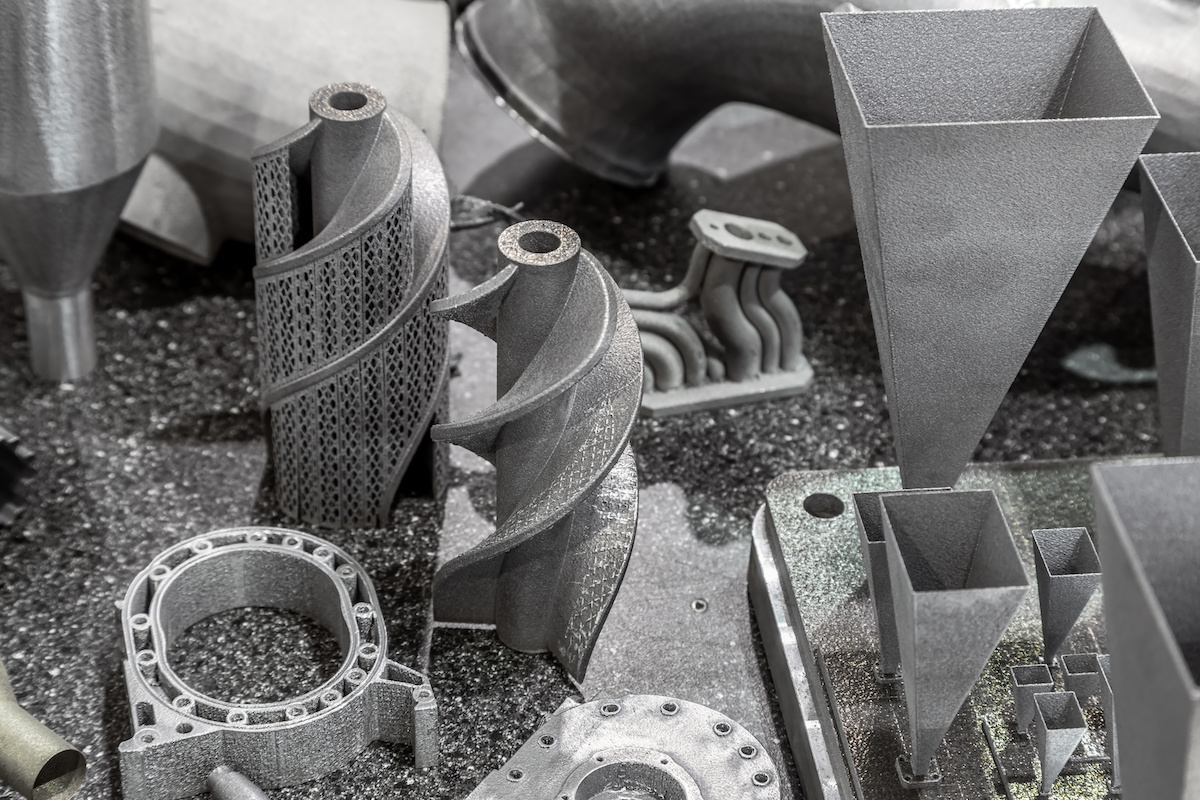

Wuxi Lead Precision Machinery integrates advanced metal additive manufacturing with precision subtractive capabilities to deliver mission-critical stainless steel components. Our end-to-end process begins with high-density laser powder bed fusion systems optimized for 316L, 17-4PH, and 15-5PH stainless steel alloys. These systems produce near-net-shape parts with exceptional material integrity, capturing complex geometries unattainable through conventional methods. However, true high-end performance requires seamless transition to precision finishing. This is where our core strength lies: we immediately pair additive production with in-house 5-axis CNC machining centers. This integrated workflow ensures critical features—such as sealing surfaces, bearing journals, and precision interfaces—achieve the exacting tolerances demanded by aerospace, medical, and energy sectors.

Post-processing is not an afterthought but a rigorously controlled phase. All additively manufactured stainless steel parts undergo stress relief and, where required, Hot Isostatic Pressing (HIP) to eliminate internal porosity and enhance fatigue resistance. Our 5-axis CNC platforms then perform precision milling, turning, and grinding operations in a single setup. This minimizes cumulative error and preserves geometric accuracy across multi-faceted components. Surface treatments—including electropolishing, passivation, and micro-machining—are applied under controlled cleanroom conditions to meet biocompatibility or ultra-high-vacuum standards.

Quality assurance is enforced at every stage through calibrated metrology. Dimensional verification utilizes Zeiss CONTURA CMM systems with 2.5 + L/300 µm accuracy, scanning complex contours via tactile and optical probes. Material properties are validated through in-house tensile testing, microstructure analysis, and porosity checks per ASTM F3301 and ISO/ASTM 52900 standards. The table below details achievable tolerances for critical features after final machining:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM / High-Precision Micrometer |

| Geometric (Flatness) | 0.02 mm | 0.005 mm | CMM / Optical Flat |

| Geometric (Concentricity) | Ø0.03 mm | Ø0.01 mm | CMM / V-Block Indicator |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

This disciplined convergence of additive manufacturing, precision machining, and metrology defines our technical capability. We transform 3D printed stainless steel from a prototyping solution into a certified production process for components where failure is not an option. Every part shipped carries full traceability documentation, including build parameters, heat treatment records, and first-article inspection reports. Partner with Wuxi Lead when your application demands stainless steel components that merge intricate design freedom with uncompromised dimensional integrity.

Material & Finish Options

When selecting materials for high-performance 3D printed components, engineering teams must balance strength, weight, corrosion resistance, and thermal properties. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced additive technologies, enabling precise fabrication in aluminum, stainless steel, and titanium. Each material offers distinct advantages depending on application requirements in aerospace, medical, automotive, and industrial equipment sectors.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components where thermal conductivity and low density are critical. This material is ideal for heat exchangers, drone frames, and automotive housings. Its excellent strength-to-weight ratio and good fatigue resistance make it suitable for dynamic loading environments. However, aluminum has lower hardness and wear resistance compared to steel, requiring surface enhancement when exposed to abrasive conditions.

Stainless steel, especially 316L and 17-4 PH grades, delivers superior corrosion resistance and mechanical strength. 316L is widely used in marine and chemical processing environments due to its molybdenum-enhanced resistance to pitting and crevice corrosion. 17-4 PH stainless steel offers high yield strength and can be precipitation-hardened post-printing, making it ideal for tooling, valves, and high-stress mechanical parts. Both grades maintain integrity under extreme temperatures and are fully dense when processed via selective laser melting (SLM).

Titanium alloys, such as Ti6Al4V (Grade 5), provide an exceptional strength-to-density ratio and outstanding biocompatibility. These properties make titanium the material of choice for aerospace components, medical implants, and high-performance racing parts. It exhibits excellent performance in high-temperature environments and resists oxidation and corrosion in aggressive media. While more costly and challenging to process, titanium’s long-term durability often justifies its use in mission-critical applications.

Surface finishing plays a vital role in enhancing functionality and longevity. While anodizing is commonly associated with aluminum, it is not applicable to stainless steel or titanium in the traditional sense. For aluminum parts, Type II and Type III (hard coat) anodizing improve wear resistance, corrosion protection, and aesthetic consistency. Stainless steel components benefit from electropolishing or passivation to remove surface contaminants and enhance the natural chromium oxide layer. Titanium may undergo acid etching or thermal oxidation for improved surface adhesion or biocompatibility.

Below is a comparative overview of key mechanical properties for commonly used 3D printed metals:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 8–12 | 2.67 | Heat exchangers, lightweight enclosures |

| 316L Stainless Steel | 550–650 | 350–450 | 30–45 | 8.00 | Marine components, chemical valves |

| 17-4 PH Stainless Steel | 1000–1300 | 850–1000 | 10–15 | 7.80 | Tooling, high-stress fittings |

| Ti6Al4V | 900–950 | 800–850 | 10–12 | 4.43 | Aerospace, medical implants |

Material selection directly impacts performance, cost, and service life. At Wuxi Lead Precision Machinery, we support clients in matching material and finish to functional demands, ensuring optimal results in every custom build.

Manufacturing Process & QC

Precision Stainless Steel Additive Manufacturing: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our 3D printed stainless steel process transcends rapid prototyping to deliver mission-critical, serial production components meeting the most stringent aerospace, medical, and energy sector requirements. We implement a rigorously controlled workflow ensuring absolute dimensional accuracy and material integrity from initial concept through high-volume manufacturing, with Zero Defects as the non-negotiable outcome.

The process begins with advanced Design for Additive Manufacturing (DfAM). Our engineering team collaborates closely with clients, leveraging generative design and topology optimization software to maximize part performance while minimizing weight and material usage. Crucially, we integrate metallurgical simulation specific to stainless steel alloys (316L, 17-4PH, 15-5PH) to predict and mitigate thermal stresses, distortion, and porosity during printing. This phase includes comprehensive support structure optimization and build orientation analysis, validated through finite element analysis (FEA), preventing 80% of potential defects before the first layer is deposited. Material selection is guided by our in-house metallurgy lab, ensuring compatibility with end-use environmental demands.

Prototyping is not merely a form check but a full process validation step. Using our certified EOS M 290 and M 400 systems operating under strict inert gas environments, we produce functional prototypes with near-net-shape accuracy. Each prototype undergoes rigorous non-destructive testing (NDT) including high-resolution CT scanning and microstructure analysis to verify internal soundness, density (>99.95%), and mechanical properties against ASTM F3055 standards. This stage validates the digital twin of the production process, confirming thermal profiles, support strategies, and post-processing parameters. Client feedback is incorporated iteratively, with design refinements implemented digitally before committing to mass production tooling.

Mass production leverages our fully automated, ISO 13485 and AS9100 certified production cells. Key to achieving Zero Defects is our closed-loop quality management system. Real-time in-process monitoring tracks melt pool dynamics, layer adherence, and atmospheric conditions, automatically adjusting laser parameters to maintain consistency. Every build undergoes 100% dimensional inspection via coordinate measuring machines (CMM) and optical scanning against the master CAD model. Critical components receive additional NDT. Post-processing—including precision stress relief, HIP (Hot Isostatic Pressing) for critical applications, CNC machining for tight-tolerance features, and surface finishing—is performed under controlled conditions with full traceability from powder lot to final part. Statistical process control (SPC) data is continuously analyzed to drive proactive improvements.

Our commitment to Zero Defects is embedded in every stage, eliminating scrap costs and ensuring your stainless steel components perform flawlessly in demanding applications.

Wuxi Lead Precision Stainless Steel AM Production Specifications

| Parameter | Specification Detail | Quality Control Method |

|---|---|---|

| Alloys | 316L, 17-4PH, 15-5PH (ASTM F75, F138 compliant) | Certified Mill Test Reports, ICP-OES |

| Build Volume | Up to Ø 250 x 325 mm (M 290), Ø 400 x 400 mm (M 400) | Laser Calibration, Build Plate Verification |

| Layer Thickness | 20 – 60 µm (optimized per part geometry) | In-Process Layer Monitoring |

| Typical Density | > 99.95% | Archimedes, Microscopy, CT Scan |

| As-Built Accuracy | ± 0.05 mm per 100 mm | CMM, Optical Scanning |

| Surface Roughness | Ra 8 – 15 µm (as-built), Ra 0.8 – 1.6 µm (machined) | Profilometry |

| Critical NDT | CT Scan (5µm resolution), Dye Penetrant, Ultrasonic | Full Build Inspection per ASME BPVC Sec V |

| Traceability | Full Powder Lot to Final Part (QR Code System) | Digital Manufacturing Execution System |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced 3D Printed Stainless Steel Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing solutions that meet the rigorous demands of aerospace, medical, automotive, and industrial sectors. Our expertise in 3D printed stainless steel enables us to produce complex, high-strength components with exceptional repeatability and surface finish. When you partner with Lead Precision, you are not just sourcing parts—you are gaining a strategic manufacturing ally with deep technical insight and a commitment to excellence.

Our state-of-the-art metal additive manufacturing systems are optimized for stainless steel alloys including 316L, 17-4 PH, and 304, ensuring mechanical properties that meet or exceed industry standards. We combine laser powder bed fusion (LPBF) technology with stringent quality controls, in-house metallurgical analysis, and post-processing capabilities such as heat treatment, HIP (Hot Isostatic Pressing), and precision CNC finishing. This integrated approach guarantees parts that are not only dimensionally accurate but also functionally reliable under extreme conditions.

We understand that every project is unique. That’s why our engineering team works closely with clients from initial design consultation through final production. Whether you require low-volume prototypes, bridge tooling, or full-scale serial production, we offer scalable solutions tailored to your timeline, performance requirements, and budget. Our ISO 9001-certified facility in Wuxi, China, is equipped to handle international logistics with seamless documentation, real-time project tracking, and full traceability for every component produced.

Partnering with Lead Precision means access to a manufacturing partner who combines cutting-edge technology with decades of precision engineering experience. We are committed to innovation, quality, and responsiveness—ensuring your designs transition smoothly from concept to certified, mission-critical parts.

Explore the full potential of 3D printed stainless steel with a team that prioritizes performance, precision, and partnership.

Technical Specifications – 3D Printed Stainless Steel (Typical Values)

| Parameter | 316L Stainless Steel | 17-4 PH Stainless Steel | 304 Stainless Steel |

|---|---|---|---|

| Tensile Strength | ≥550 MPa | ≥1000 MPa | ≥580 MPa |

| Yield Strength (0.2%) | ≥200 MPa | ≥850 MPa | ≥250 MPa |

| Elongation at Break | ≥40% | ≥12% | ≥45% |

| Density | ≥99.5% of theoretical | ≥99.5% of theoretical | ≥99.5% of theoretical |

| Surface Roughness (as-built) | Ra 10–15 µm | Ra 10–15 µm | Ra 10–15 µm |

| Layer Thickness | 20–40 µm | 20–40 µm | 20–40 µm |

| Build Envelope | Up to 250 x 250 x 300 mm | Up to 250 x 250 x 300 mm | Up to 250 x 250 x 300 mm |

| Common Applications | Marine, chemical processing, medical implants | Aerospace, tooling, defense | Food processing, industrial components |

Contact us today at [email protected] to discuss your next project. Let Wuxi Lead Precision Machinery become your trusted partner in advanced metal additive manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.