Technical Contents

Engineering Guide: 3D Printed Services

Engineering Insight: The Role of Precision in 3D Printed Services

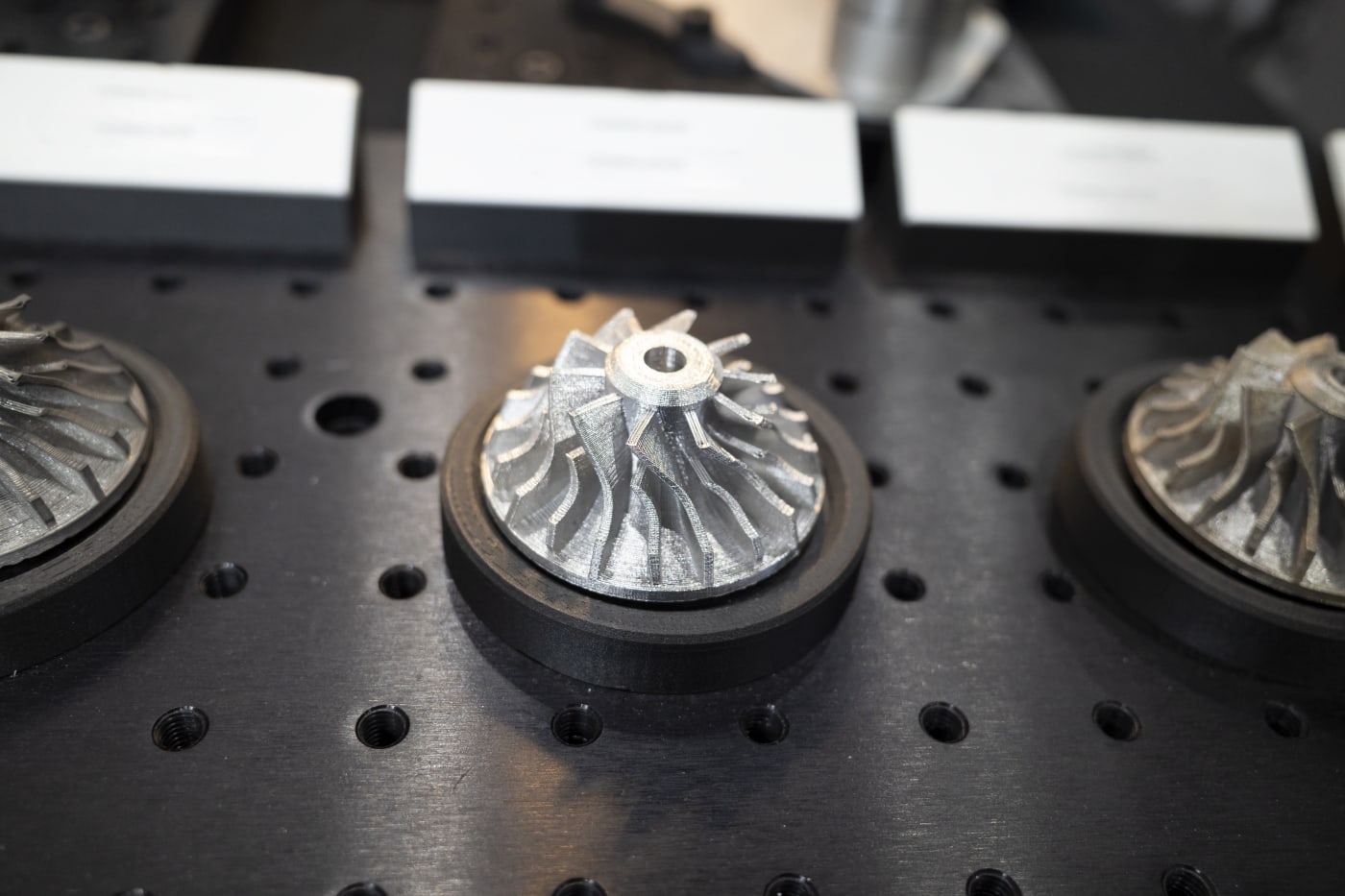

In the realm of custom metal manufacturing, 3D printed services have evolved from rapid prototyping tools into full-scale production solutions—especially in high-stakes industries such as aerospace, defense, and elite sports engineering. At Wuxi Lead Precision Machinery, we recognize that the true value of additive manufacturing lies not just in geometric freedom or reduced lead times, but in the ability to achieve micron-level precision consistently across complex, mission-critical components.

Precision in 3D printing is not an optional enhancement—it is a foundational requirement. Unlike traditional subtractive methods, metal additive manufacturing builds parts layer by layer, often using laser or electron beam melting technologies. This process demands exact control over thermal dynamics, powder distribution, and laser calibration. Even minor deviations in layer thickness, melt pool stability, or support structure design can result in internal porosity, residual stress, or dimensional inaccuracies that compromise structural integrity.

At Lead Precision, our engineering team applies decades of experience in precision machining to the additive domain. This cross-disciplinary expertise allows us to optimize print parameters, post-processing workflows, and metrology protocols for each unique application. Our work on components for Olympic-level athletic equipment and military-grade subsystems underscores our commitment to performance under extreme conditions. In these applications, tolerances are not merely tight—they are non-negotiable.

We utilize industrial-grade metal 3D printing platforms capable of producing parts with exceptional repeatability and surface consistency. All builds undergo rigorous in-process monitoring and post-build inspection using coordinate measuring machines (CMM), optical scanning, and metallurgical analysis. This ensures that every component meets or exceeds the dimensional, mechanical, and material specifications required by our clients.

Our facility supports a range of high-performance alloys, including titanium Ti6Al4V, Inconel 718, stainless steel 316L, and aluminum AlSi10Mg. Each material is processed under controlled environments to prevent contamination and ensure homogeneity. Post-processing techniques such as hot isostatic pressing (HIP), stress relieving, and precision CNC finishing are integrated as needed to deliver fully functional, end-use parts.

The convergence of additive manufacturing and precision engineering defines the next generation of industrial innovation. At Wuxi Lead Precision Machinery, we are not just adopting 3D printing—we are advancing it with the rigor of traditional craftsmanship, enhanced by modern technology.

| Parameter | Capability |

|---|---|

| Layer Thickness | 20–60 μm |

| Build Volume | Up to 250 x 250 x 325 mm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processed Surface Finish | Ra <1.6 μm (with polishing/machining) |

| Supported Materials | Ti6Al4V, Inconel 718, SS 316L, AlSi10Mg |

| In-Process Monitoring | Real-time melt pool and layer imaging |

| Certification Standards | ISO 9001, ISO 13485 (medical option) |

This disciplined approach ensures that our 3D printed services meet the highest standards of reliability, repeatability, and precision—qualities demanded by the world’s most advanced engineering challenges.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing Excellence

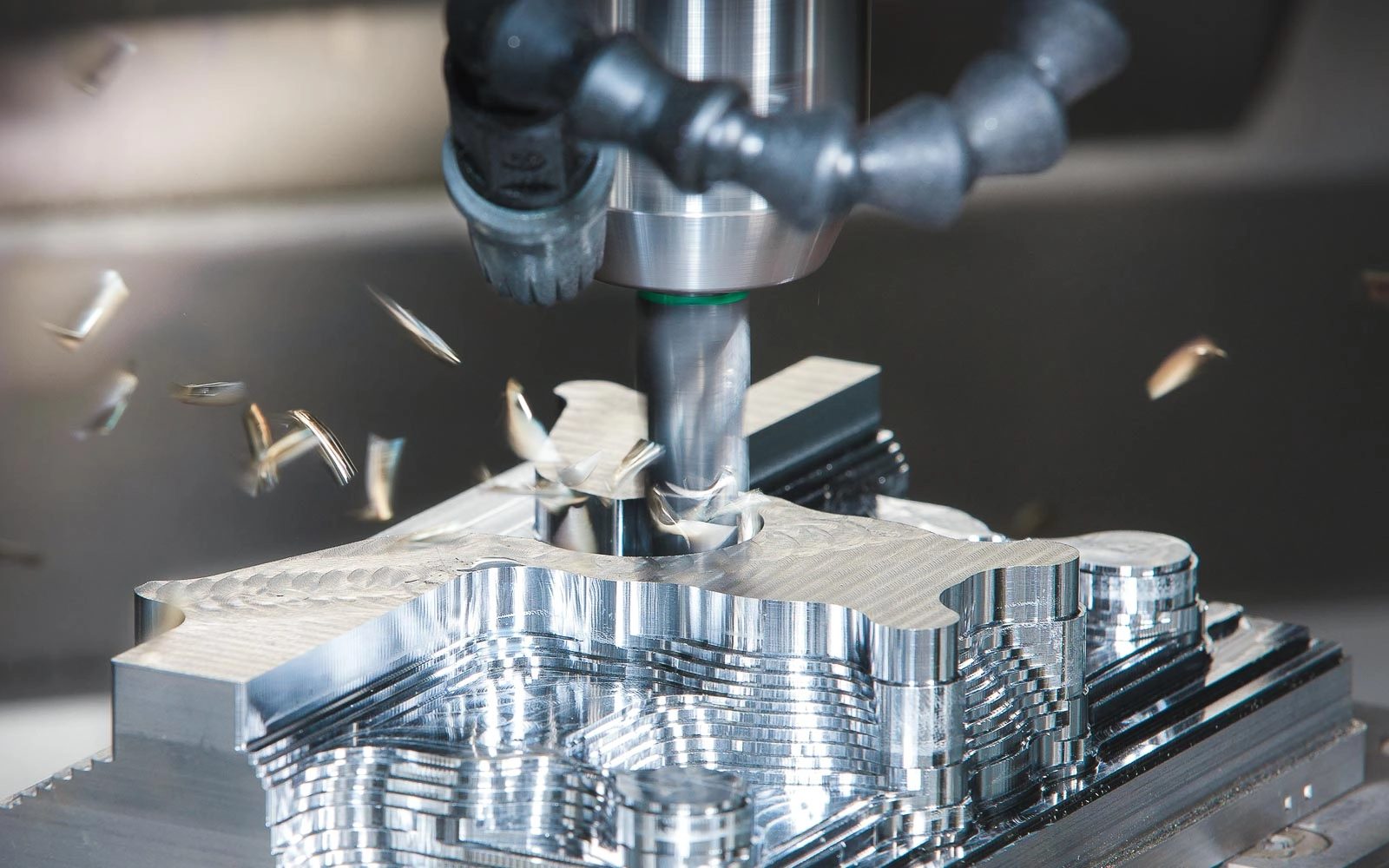

Wuxi Lead Precision Machinery specializes in high-integrity custom metal manufacturing for demanding industrial applications. While additive manufacturing serves specific prototyping and complex geometry niches, our core expertise and strategic investment focus on advanced subtractive processes, particularly multi-axis CNC machining. We recognize that mission-critical components in aerospace, medical, energy, and defense sectors require the material integrity, surface finish, and dimensional stability that precision CNC machining delivers, often surpassing the capabilities of current metal 3D printing for final production parts. Our facility is engineered to transform complex engineering designs into certified, high-performance metal components meeting the most stringent global standards.

Our technical foundation is built upon a modern fleet of 5-axis CNC machining centers, including DMG MORI and Hermle platforms. These systems enable the precise, single-setup machining of intricate geometries, deep cavities, and compound contours that would be impossible or prohibitively expensive with 3- or 4-axis methods. This capability significantly reduces part handling, minimizes cumulative error, improves feature-to-feature relationships, and accelerates throughput for complex components. We machine a comprehensive range of engineering metals, including titanium alloys (Ti-6Al-4V), Inconel 718 and 625, stainless steels (316L, 17-4PH), aluminum alloys (7075, 6061), and specialty materials like beryllium copper and tool steels. Each machine is maintained to OEM specifications and operated by certified technicians with deep process knowledge, ensuring optimal cutting strategies, tool life management, and thermal stability for micron-level consistency.

Rigorous quality control is non-negotiable. Every critical dimension and geometric feature undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs), primarily Zeiss CONTURA systems. Our CMM inspection protocols, compliant with ISO 9001 and AS9100 standards, provide full traceability and comprehensive dimensional reports. This metrology backbone validates conformance to engineering drawings and ensures that every component shipped meets the exacting tolerance requirements specified by our clients. Statistical Process Control (SPC) methodologies are integrated into high-volume production runs to maintain process capability and preempt potential deviations.

The following table details our standard achievable geometric tolerances across common materials and feature types, reflecting our commitment to precision:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Material Applicability |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm | All Engineering Metals |

| Positional (Holes) | ±0.015 mm | ±0.005 mm | All Engineering Metals |

| Geometric (Flatness) | 0.015 mm | 0.003 mm | All Engineering Metals |

| Geometric (Roundness) | 0.010 mm | 0.002 mm | Shafts, Bores (All Metals) |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm | Critical Sealing/Flow Paths |

Wuxi Lead Precision Machinery provides the precision metal manufacturing backbone for applications where performance, reliability, and certification are paramount. Our integrated 5-axis CNC machining and CMM inspection capabilities deliver the dimensional accuracy, material integrity, and documented quality assurance that advanced industrial sectors require, complementing additive manufacturing workflows where final-part performance demands exceed AM’s current production limitations. Partner with us for components where precision is not optional.

Material & Finish Options

Material Selection for High-Performance 3D Printed Metal Components

Selecting the appropriate material is critical in achieving optimal performance, durability, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we specialize in advanced 3D printing technologies such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), enabling the production of complex, high-precision parts using premium-grade metals. Our expertise in aluminum, steel, and titanium alloys ensures clients receive components tailored to exact mechanical, thermal, and environmental requirements.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural applications requiring excellent strength-to-density ratios and good thermal conductivity. This material is ideal for aerospace, automotive, and heat exchanger components where weight reduction without compromising performance is essential. Its corrosion resistance and weldability further enhance its versatility in demanding environments.

Stainless steel variants, such as 316L and 17-4 PH, offer superior mechanical strength, corrosion resistance, and temperature stability. 316L is especially suited for marine, chemical processing, and medical applications due to its excellent resistance to chloride-induced pitting. In contrast, 17-4 PH provides high yield strength and can be precipitation hardened, making it a preferred choice for tooling, aerospace fittings, and high-stress industrial components.

Titanium, specifically Ti6Al4V (Grade 5), stands out for its exceptional strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosive environments. This alloy is extensively used in aerospace, defense, and medical implant industries where long-term reliability under stress is non-negotiable. Its ability to maintain integrity in both cryogenic and elevated temperatures makes it one of the most versatile materials in additive manufacturing.

Surface finishing plays a pivotal role in enhancing both functional performance and aesthetic quality. Anodizing is a commonly specified post-processing technique, particularly for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. Type II and Type III (hard coat) anodizing are available depending on application demands, with the latter offering superior hardness and thickness for high-abrasion environments.

The following table outlines key mechanical and physical properties of the primary materials we offer:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 280–320 | 2.67 | 8–12 | Aerospace, automotive, heat sinks |

| 316L Steel | 550–600 | 290–320 | 8.00 | 35–45 | Medical, marine, chemical |

| 17-4 PH Steel | 1000–1200 | 850–1000 | 7.75 | 10–15 | Tooling, aerospace, defense |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | 8–12 | Medical implants, jet engines |

At Wuxi Lead Precision Machinery, we support end-to-end material consultation, ensuring each 3D printed component meets rigorous industrial standards. Our engineering team collaborates closely with clients to align material and finish selection with operational demands, regulatory compliance, and lifecycle performance.

Manufacturing Process & QC

Production Process: From Design to Zero Defects Mass Production

At Wuxi Lead Precision Machinery, our integrated production process for custom metal 3D printed services is engineered for uncompromising quality and repeatability, delivering true zero defects from initial concept to high-volume output. This disciplined workflow eliminates costly errors inherent in fragmented approaches, ensuring your components meet the most stringent aerospace, medical, and industrial specifications without compromise.

The process begins with rigorous Design Phase collaboration. Our engineering team partners with your designers to optimize geometry specifically for metal additive manufacturing (DfAM). We conduct comprehensive simulation-driven analysis, including thermal stress prediction and support structure optimization, using validated software tools. This critical step identifies potential build failures or distortions before metal deposition starts, significantly reducing iteration cycles and ensuring the digital model is inherently manufacturable to zero-defect standards. Material selection is precisely matched to your functional requirements and environmental conditions.

Prototyping transitions seamlessly into Validation Phase. Utilizing our certified EOS and SLM Solutions platforms, we produce functional prototypes in your specified alloy—typically Ti-6Al-4V, Inconel 718, or AlSi10Mg. Every prototype undergoes full metrology: CT scanning verifies internal integrity and dimensional accuracy against the original CAD model, while mechanical testing confirms material properties meet ASTM or ISO standards. This phase is not merely about form and fit; it is a critical validation of the entire process chain under actual production parameters, providing data to lock the final manufacturing recipe.

Mass Production Execution leverages the validated parameters from prototyping, scaled within our climate-controlled production cells. Key to achieving zero defects is our embedded quality system. Each build undergoes in-situ melt pool monitoring and layer-wise thermal imaging. Post-processing, including precision HIP, stress relieving, and CNC machining, follows strictly controlled procedures with real-time SPC tracking. Final inspection employs multi-sensor CMMs and automated optical systems against the original tolerance map. Full material traceability and process documentation are provided with every shipment, meeting AS9100 and ISO 13485 requirements.

The following table outlines critical process specifications ensuring zero-defect outcomes:

| Parameter | Specification | Zero Defects Integration |

|---|---|---|

| Material Standards | AMS, ASTM, ISO certified alloys | Pre-build material certification & lot traceability |

| Dimensional Tolerance | ±0.02 mm to ±0.05 mm (as-built) | In-process metrology with automated SPC alerts |

| Surface Roughness (As-Built) | Ra 8-15 µm | Layer monitoring & adaptive parameter control |

| Internal Defect Level | Zero porosity >50µm (per ASTM E1921) | Real-time melt pool analytics & CT validation |

| Lead Time (Prototype) | 7-10 business days | Concurrent DfAM analysis & build preparation |

| Lead Time (Production) | Scalable from 50 to 10,000+ units | Dedicated cells with synchronized post-processing |

This closed-loop methodology, combining advanced hardware, proprietary software analytics, and deep metallurgical expertise, transforms additive potential into reliable, defect-free manufacturing. Wuxi Lead delivers not just parts, but engineered certainty for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, performance, and partnership. As a leading manufacturer in China specializing in high-accuracy custom metal components, we combine advanced 3D printing technology with decades of engineering expertise to serve global industries including aerospace, medical devices, energy, and high-performance automotive. When you choose to partner with us, you gain more than a supplier; you align with a team committed to innovation, quality, and on-time delivery.

Our state-of-the-art metal additive manufacturing systems are engineered to meet the most demanding specifications. From complex geometries to lightweight lattice structures, we produce components that traditional machining cannot achieve—while maintaining tight tolerances and superior material integrity. Every part undergoes rigorous inspection using coordinate measuring machines (CMM), metallurgical analysis, and non-destructive testing to ensure compliance with ISO 9001 and AS9100 standards.

We understand that your projects require more than just production capability—they demand technical collaboration. Our engineering team works closely with your design and R&D departments from concept to completion, offering design for additive manufacturing (DfAM) support, material selection guidance, and rapid prototyping iterations. Whether you need a single prototype or full-scale batch production, our scalable infrastructure ensures flexibility without compromising precision.

Our facility in Wuxi, China, is equipped with a full suite of post-processing capabilities, including heat treatment, hot isostatic pressing (HIP), CNC machining, and surface finishing. This vertical integration allows us to control every stage of production, reduce lead times, and maintain consistent quality across all deliverables.

Why partner with Lead Precision? Because we measure success not by volume, but by value. Our clients return because we consistently exceed expectations in technical performance, responsiveness, and reliability. We are not a one-size-fits-all provider—we tailor our processes to your unique requirements, ensuring optimal outcomes for even the most challenging applications.

If you are ready to elevate your manufacturing capabilities with a trusted partner in metal 3D printing, contact us today. Let our team at Wuxi Lead Precision Machinery bring your most advanced designs to life with precision you can rely on.

Contact us at [email protected] to start your next project.

| Specification | Capability |

|---|---|

| Build Envelope (Max) | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Materials | Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Tool Steel (Maraging Steel), Cobalt-Chrome |

| Tolerance | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Post-Processing Options | HIP, Heat Treatment, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001:2015, AS9100D, Full Material Traceability (Mill Cert 3.1), First Article Inspection (FAI) Reports |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.